Jelly Filling Machine: The Complete Buying Guide In 2025

Are you looking for jelly filling machine that best suits your production setup? Are you interested in buying a jelly filling machine? Do you want to get more information related to a jelly filling machine? This is the right place to help you in solving all your queries and select the best type of jelly filling machine for you. This guide gives you understand the process of a jelly filling machine and its types available globally. Please read the complete buying guide to get much possible knowledge from it.

1.What Is A Jelly Filling Machine?

Petroleum Jelly Filling Machine - Picture Courtesy: VKPAK Liquid Filling Machinery

A jelly filling machine is a precise and efficient way to fill and pack jelly into various sizes and shapes of packaging. The machine has an automated process that accommodates various types of jelly products. The product of quality is maintained in a uniform manner no matter what packaging design or shape is processed. It makes the jelly product look pleasant and fills each corner of it.

2.Which Industries Use Jelly Filling Machine In Their Process?

Jelly filling machine has various applications due to its highly precise operation. Some of the industries where jelly filling machines are used are

Food Industry

Food Industry Jelly Products - Picture Courtesy: One 4 Leather

Jelly filling machines are widely used in food industries to fill and package different types of jelly products. The product remains preserved and hygienic for a much longer period to meet customer demand. Similar products to jelly like jam are also accommodated within a single jelly filling machine.

Beverage Industry

Fruit Juice Jelly Drink- Picture Courtesy: Yantai Meifeng Plastic Products

In multiple conditions, jelly filling machines are present in beverage and dairy industry for filling of jelly made up of different types of fruits. These are filled in various types of cans, sachets and strips in a precise and accurate manner so that no spoilage can occur due to their viscosity.

Pharmaceutical Industry

Lubricating Jelly - Picture Courtesy: Wellona Pharma

Oral medicated jellies that are produced in pharmaceutical industry are filled and packed using highly efficient jelly filling machine. These formulated gels and jellies are administered through these machines and are consumed according to the prescribed dosage by physicians. These jellies can be either lubricating, medicated or the ones used during electrocardiography.

Bakery Industry

Bakery Jelly - Picture Courtesy: Puffcity Marketplace

Extensively jelly filling machines are used in bakery industry too as cakes, cookies and other bakery items require jelly as a byproduct to their process. Uniform products in shape and size are produced through these jelly filling machines.

3.What Are The Benefits Of A Jelly Filling Machine?

Benefits

Some of the benefits of a jelly filling machine are

Efficiency

Efficient Jelly Slice - Picture Courtesy: Taste

To increase the efficiency of jelly filling processes, jelly filling machines are significantly important and they maintain the uniformity within the process and fill each of the packaging in an efficient and precise manner. Both low and high volume of production can easily be produced through these machines keeping proper integration in each product.

Consistency

Flavor Jelly Filled - Picture Courtesy: SKAvend LTD Trading

One of the most important benefits of a jelly filling machine is that it has a consistent flow of jelly filling with maintaining the quality of product. Each product has same amount of jelly filled according to the parameter set into the machines. The taste and appearance of each product remains consistent throughout the production setup.

Reducing Product Wastage

Natural Fruit Jelly Without Leakage - Picture Courtesy: Candy Warehouse

Jelly filling machines are high versatile their function as it is controlled with high precision. The machine prevents both over and under filling of jelly product so that the limited material according to setting parameters can be optimized. In this way no material wastage occurs and also the spoilage is prevented within the system.

Multiple Shape Handling

Multi Fruit Shape Jelly Candy Ice Pop - Picture Courtesy: Shantou Yixin Food Co. Ltd.

The versatility of a jelly filling machine can be judged by this parameter also that different shapes and sizes of packaging materials can easily be handled in a single processing machine. High volume of production can be achieved with fast conveying system to meet the requirements.

Customization

Jelly filling machine do not limit their process to a single working but also different viscosities of jelly and other products are filled using these machines. Machines are flexible so that different dies according to filling shapes can easily be changed to customize the productivity.

4.What Is The Working Procedure Of A Jelly Filling Machine?

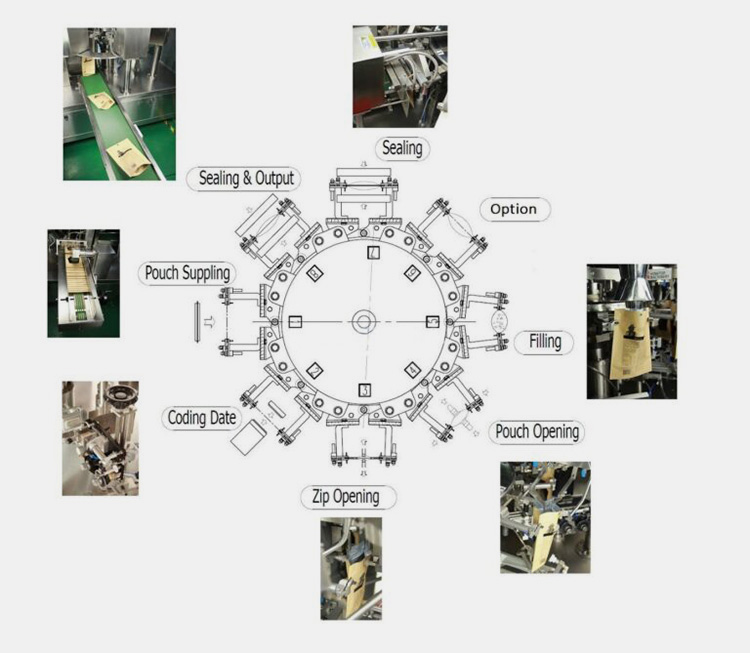

Working Of A Pouch Jelly Filling Sealing Machine

The working procedure of jelly filling machine follows series of steps that are organized in a systematic manner. These are

Feeding

Initially the hopper or container placed at the top of a jelly filling machine is filled with jelly that is to be filled in packaging materials. The packaging materials whether they are containers, sachets, strips or etc are placed onto the conveying system and loaded into the filling area.

Pouch Opening And Filling

The jelly material travels from the hopper to the filling nozzles via proper filling channels. Once the jelly material reached the filling nozzle it is stopped through shut valves. As the packaging material reaches the filling nozzle, the valves open automatically and the jelly material is dispensed into the packaging. Accurate amount of jelly is dispensed according to the set parameters.

Capping And Sealing

One after other the jelly is filled in a precise and consistent manner and then moved towards the sealing or capping method. Proper sealing is applied on each packaging and caps on containers or jars. This process is done so that no spoilage can occur during the transportation and material quality can live for a longer period.

5.What Are The Main Components In A Jelly Filling Machine?

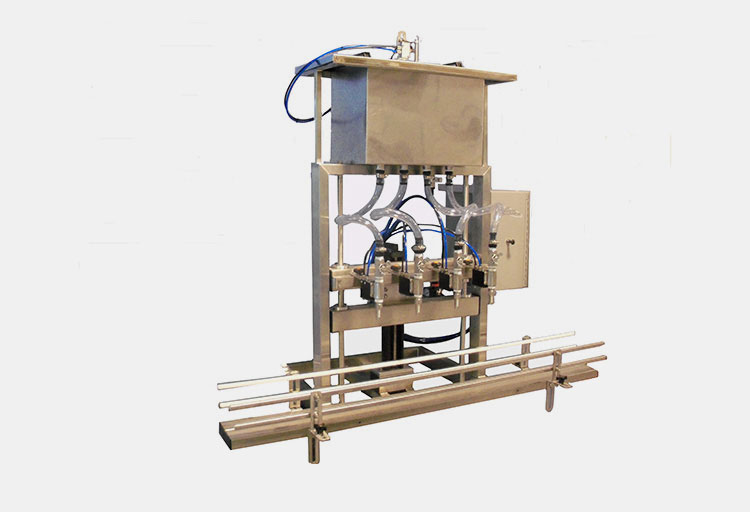

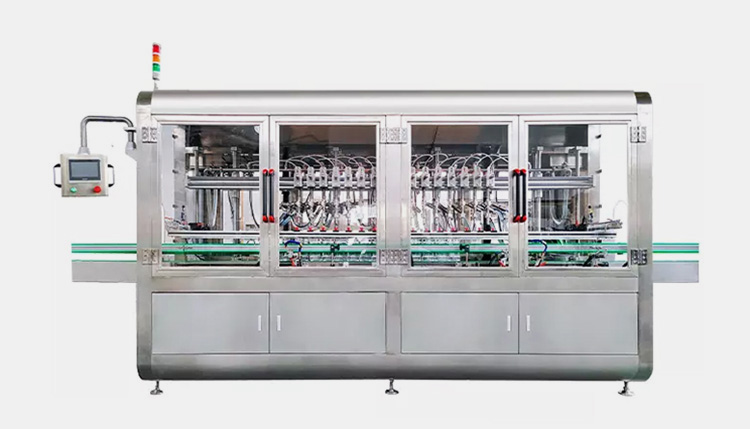

Stainless Steel Fully Automatic Viscous Jelly Filling Machine

The main components in a jelly filling machine are

Hopper

Hoppers are mostly present at the top of a jelly filling machine that contains the jelly material in it. Jelly is filled into these hoppers and then supplied to the filling nozzle by different mechanisms. They might differ in sizes but have the same functions.

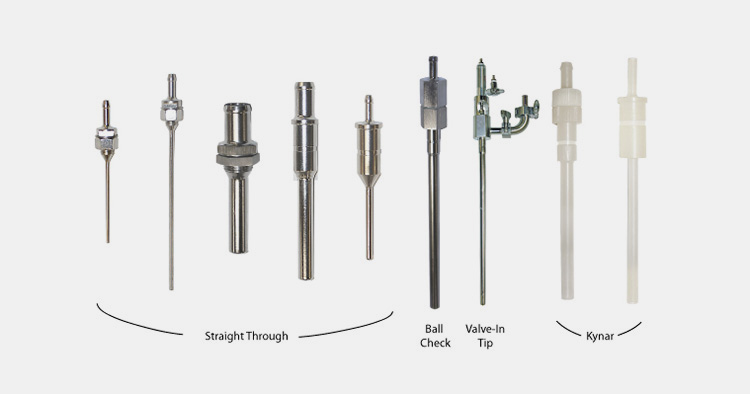

Filling Nozzle

Filling nozzle is present at the end of a filling line that is responsible to dispense the material into the packaging. Once the packaging reaches these filling nozzles, the material gets released from the system and enters into the packaging. An automatic shut off valve is connected with this filling nozzle that closes once the maximum limit is reached. Some jelly filling machines have more than one filling nozzle to perform speedy process.

Conveyor System

For proper movement of packaging material into the system, conveyors are used in automatic jelly filling machines. The packaging material is placed at the start of the loading size and then it precisely moves towards each step of the process. The speed of conveyor system can be controlled according to the productivity.

Film Rollers

For sachets, pouches and bags that are filled by a jelly filling machine, film rollers are associated with it that holds the packaging film roll on it. It supplies the film into the system in an efficient manner so that no breakage can occur.

Heating System

For different jelly product sizes and shapes, various types of heating are integrated in a jelly filling machine so that the top of the packaging material can be sealed properly. The temperature of this heating system is maintained according to the type and tolerance properties of a packaging material.

Operational Panel

This is the place from where the operator can closely monitor all the process going on in a jelly filling machine. The conveying speed, temperature, filling speed and other parameters are also set through this display interfaces.

6.What Types Of Jelly Filling Machines Are Available Globally?

Globally various types of jelly filling machines are used to fill jelly packaging. Some of them are

Piston Jelly Filling Machine

Advanced Piston Jelly Filling Machine

A piston filling machine has a combination of piston and cylinder that is used to draw the jelly out of the filling nozzle. The two and fro motion of piston is responsible for the movement of jelly. Machines are both manual and automatic that are used according to the filling accuracy required.

Working Principle

Firstly, jelly product is filled in the hopper or container of a piston jelly filling machine that is placed at the top of it.

On the same time the packaging materials is entered into the system either manually or through an automated conveying system.

Once the packaging material reaches the filling nozzle, the piston starts moving forward and backward with the help of attached cylinder.

This movement drags the material towards the filling nozzle and dispenses it in an accurate amount.

The jellies are continuously filled in a precise manner so that no spoilage occurs during its movement around the globe.

Gravity Jelly Filling Machine

Gravity Jelly Filling Machine

The other type of a jelly filling machine is a gravity jelly filling machine. The jelly material flows depending upon the method of gravity that allows free flowing of material. The system remains cost effective and also requires no pumping procedure.

Working Principle

Initially the jelly product is filled in the hopper or container of a gravity jelly filling machine that is placed at the top of it.

On the same time the packaging materials is entered into the system either manually or through an automated conveying system.

Once the packaging material reaches the filling nozzle, the jelly flows from the hopper towards the filling nozzle in a free flow manner with the help of gravitational force.

This material is blocked at the filling nozzle and is dispensed once the jelly packaging is identified beneath it.

The jellies are continuously filled in a precise manner in a gravity jelly filling machine so that no spoilage occurs once they are transported globally.

Rotary Jelly Filling Machine

Automatic Rotary Juice Jelly Yogurt Filling Machine - Picture Courtesy: Henan Chanda Machinery

A rotary jelly filling machine has a long rotating turret in it that is used to fill multiple jelly packaging in a short interval of time. The machine is mostly used in large scale industry whose productivity is too high.

Working Principle

The jelly product is initially filled in the hopper or container present at the top of a rotating jelly filling machine.

Meanwhile packaging materials are entered into the system either manually or through an automated conveying system.

As the rotating turret hold the filling package in large numbers the filling nozzles attached to it fill it according to the given parameters.

Once the material is filled into the packaging they are offloaded at the other side of the conveyor where the jelly packaging is received.

Continuous filling is done in a precise manner and then moved globally.

Overflow Jelly Filling Machine

Automatic Overflow Jelly Filling Machine - Picture Courtesy: VKPAK

To avoid material spoilage and overflow, this type of jelly filling machines is a best option to be used. The overflow jelly travels back to the filling system to prevent material wastage and to keep the system efficient.

Working Principle

In an overflow jelly filling machine, the hopper or container placed at the top is firstly filled with the jelly product.

Packaging materials on the other end is entered into the system either manually or through an automated conveying system.

Once the packaging material reaches the filling nozzle, the nozzle releases the jelly in an efficient manner.

The excess jelly product returns back through the overflow mechanism and collect for reuse to prevent wastage.

The jellies are continuously filled in a precise manner until the production requirement is achieved.

7.Which Containers Can Be Filled By The Jelly Filling Machine?

Some of the materials used for jelly filling procedures are

Pouches And Sachets

Jelly Pouch Type

Most of the pouches and sachets made up of plastic material like polyethylene, polypropylene, and polyester are used to fill and package different types of jelly products. Other than this aluminum foil is also used by which pouches are created to fill jelly in it. These often resist the entrance to atmospheric factors life humidity, moisture and etc.

Jars

Jelly Glass Canning Jar - Picture Courtesy: The Home Depot

Glass and plastic jars are the common packaging material used for filling of jelly products to keep them secure for a longer period and to maintain their purity. Polyethylene terephthalate is mostly used for making plastic jars.

Cans

Jelly Green Can

A jelly filling is mostly done in metal cans and have multiple layered thickness to provide strong shelter to the product. Jellies remain secure for a longer period in these metal cans and remain prevented from moisture and oxidation reactions.

Plastic Tray

Jelly Plastic Tray

For bulk packaging of jellies and in large scale industries, plastic trays made up of either polyvinyl chloride or polyethylene is used.

8.How Can The Maximum Efficiency Be Ensured In A Jelly Filling Machine?

Jelly Fruit Snack - Picture Courtesy: FUSTON

To ensure maximum efficiency from a jelly filling machine it is always required from the manufacturer to select the right type of machine for their process setup. Machines with low production volume and less automation level can be a waste of money for large scale industries. Other this factor, proper schedule maintenance of machine, proper rest to the machine after completing large batches and adjustment from experts can make it efficient.

9.How Different Sizes Of Jelly Cups Be Processed In A Single Jelly Filling Machine?

Colorful Fruit Shapes Jelly Candy - Picture Courtesy: Funnystar Food Co. Ltd.

The most significant benefit of a jelly filling machine is that it can easily accommodate various types of jelly cups of different sizes and shapes in a single machine due to

Quick Changeover

A jelly filling machine has a changeover mechanism that can set the whole system according to the size, shape and flow of packaging material. The rails, moulds, guides and others can be adjusted according to the transition in different sizes.

Adjustable Filling Nozzles

Liquid Filling Nozzles - Picture Courtesy: Filamatic

Jelly filling machine have an adjustable filling nozzle setting in it that can be set according to the opening size of different cups. Different diameter nozzles can be changed easily and makes it able to fill variety of cups.

Multi-Head Filling System

4 Heads Jelly Filling Sealing Machine

Mostly in jelly filling machines there is an option for multi head adjustments that makes it capable of filling more than one packaging at a same time. This can also increase the efficiency of the system.

Advanced Conveying System

The most significant feature remains the automated traveling of jelly packaging and it is responsible to bring it towards the filling nozzle. A single jelly filling machine can guide different conveying parameters by aligning it according to the size of cup. This can make the cup easily move within the system.

10.What Is The Difference Between A Jam Filling Machine And A Jelly Filling Machine?

Difference Between Jam Filling Machine And Jelly Filling Machine

Both of the machines are efficient in their filling procedures but have some differences. These are

Filling Composition

As the name indicates a jam filling machine has filling of crushed fruit jam as its filling ingredient and also involves its pulp while filling to give it an extra essence.

While jelly filling machine uses jellies made up of the syrup of juices of fresh fruits that then becomes solid in form while packaging.

Viscous Material

Jam Vs. Jelly What’s The Difference - Picture Courtesy: Harry & David

The viscosity of jam is usually high due to the solid particles and the machine is designed in a way to tackle this situation.

Varieties of viscosities are found in jelly products that can be released from nozzles of different adjustable sizes.

Nozzle Design

Due to the pulp and fruit particles, the filling nozzles of jam filling machines are designed in a way that large particles can also be dispensed from it.

Simple filling nozzles are used in jelly filling machines according to the size and texture of jelly product.

Filling Packaging Material

Both of the machines use similar type of filling packaging material. Either they are filled ii pouches, jars, sachets or metal cans. But jams are majorly packaged in glass jars due to their visibility and costumer attraction feature.

11.What Are The Auxiliary Machines Associated With A Jelly Filling Machine?

Along with the process of a jelly filling machine there are other auxiliary machines too that support the filling and packaging of jelly products in a precise and efficient manner. Some of the auxiliary machines are

Capping Machine

Cup Jelly Capping Machine - Picture Courtesy: Celine Trading

Cups that are filled with jelly products are further send for sealing where capping machine installs cap on their top and seals it in an efficient manner. The seal secures the jelly product and also prevents material spoilage.

Labeling Machine

Automatic Jelly Cup Labeling Machine

For proper mentioning of product and manufacturer related information. Labeling machines are present in a process line of jelly filling machine. These machines display all the brand related material so that the customer can easily be get awareness regarding the product and its ingredients.

Conclusion

A jelling filling machine is a highly reliable and efficient way of filling packaging materials of different sizes and shapes. To select the right type of jelly filling machine it is always necessary that the manufacturer should be completely aware of its all types and the productivity level each machine offers. All pack here provides you complete information regarding a jelly filling machine and its related information. If this buying guide still remains some queries in your mind then contact our customer representative that are available 24/7 for your guidance.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide