Jar Labeling Machine: The Complete Buying Guide in 2025

Creatively labeled products in jars are instant hit among customers. Labeling and design are first thing that capture attention of customers. This is where jar labelling machine is of prime importance.

Jar labeling machine has a significant place in jar packaging line. Brands can simplify and boost their labeling performance through the use of this machine. Many challenges in labeling are resolved by adding a labeling machines in the production line. If you are planning to invest in this handy equipment, look no further, and read this informative guide to select the best jar labeling machine for your business.

Let’s take a closer look!

1.What Is A Jar Labeling Machine?

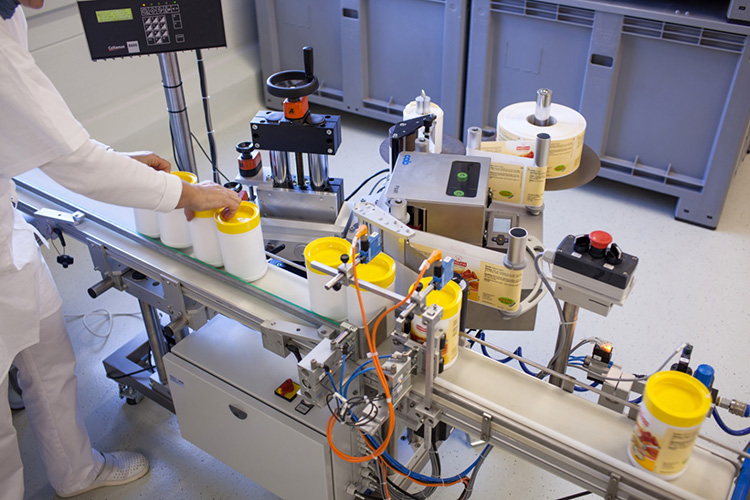

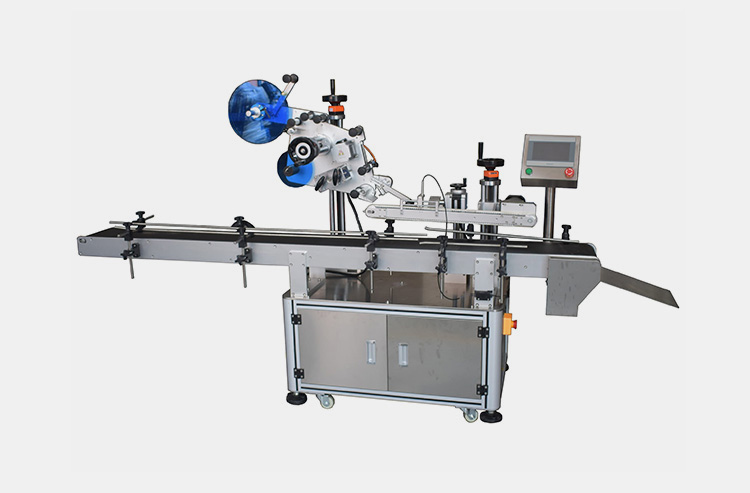

Jar Labeling Machine

A jar labeling machine is a versatile and adaptable piece of equipment employed in both small and multi-scale businesses for labeling products. This machine dispenses stickers or other addon tapes on different types of jars such as round, flat, or cylindrical.

Sometimes this device prints and then applies labels. There are all kinds of jar labeling machines in the market- both portable and large fully automated.

This machine is constructed for labeling in various orientations and positions such as labeling top, bottom, front, and back sides of jars as well as for wrap-around labeling of jars.

2.What are the Industrial Uses of Jar Labeling Machine?

Jar labeling machine has gained immense popularity over the recent years in several industries due to its flexibility and ease of labeling. This useful equipment has found its use in several industries such as:

Food Industry

Beautifully labeled food products with creative topography and graphics are usually the best bet to grab the eye of passersby. This is why a jar labeling machine is the first choice when it comes to designing food packaging. Honey, jam, ketchup, condiments, pastes, sauces, and many more yummy foodstuffs is labeled by this practical machine.

Cosmetic Industry

Labeling of cosmetic products is necessary in informing users about ingredients, warnings, and usage of cosmetic products. Therefore, jar labeling machine is preferred by many popular cosmetic brands due to its neat, attractive, and stunning labeling of various cosmetic products like foundations, creams, dyes, blushes, etc.

Personal Care Industry

Tough and eye-catching labels on personal care products in jars are all because of jar labeling machine. The use of this machine in the personal care industry creates orderly and immaculate products. These labels by jar labeling machine are typically deployed for the promotion of shampoos, body washes, sanitizers, soaps, gels, etc.

Pharmaceutical and Nutraceutical Industry

Precise information communication is strongly advised by drug regulatory authorities. Thus, pharmaceutical and nutraceutical industry use jar labeling machine to print and label facts and ingredients over the vitamin, cream, tablets, pills, and ointment jars.

Paint Industry

Appealing and colorful packaging of paint products such as oil-based paints, watercolors, acrylic, and polishes is because of jar labeling machine. This machine adheres to or prints eye-catching labels that often spark an artistic sense in customers.

Home Decoration Industry

Scented and vibrant candles have acquired a special place in home decoration. People often buy these candles due to their visually captivating jar packaging. The jar labeling machine enhances the appeal of candle jar packaging by elegantly labeling fragrant candles.

3.How Does Having A Jar Labeling Machine Bring Benefits To Your Business?

Production recognition is significantly determined by labeling. Jar labeling machine is efficient equipment that greatly eases your labeling needs. Adding this machine to your packaging plant leads to a great many advantages.

High Productivity

Picture Courtesy: avery

This is one of the biggest benefits of jar labeling machine. Manual labeling could be slow and tedious, consequently resulting in fewer labeling products. But jar labeling machine is automated with advanced controls and labeling systems leading to more labeled jars in a short time. Having this machine will boost the production efficiency of businesses.

Low Labor Assistance

Picture Courtesy: Capital Label Company

Yes, the use of jar labeling machine in your production requires minimal human assistance thus decreasing burden on workforce. A single operator is needed to adjust the settings of jar labeling machine in turn saves your labor wages.

Consistency and Precision

Picture Courtesy: Pharma Manager

Jar labeling machine is best known for its accurate and precise positioning of labels over products. Its consistency often reduces the chance of misalignment and crumbling of labels and this machine strongly bonds labels that last long and uphold a professional display of product.

Low Wastage

Moreover, with a jar labeling machine, you can save huge amounts of expensive label films. As this machine lowers human mistakes while labeling you can minimize label waste which in turn increases your industrial sustainability.

Product Tracking

With modern labeling technology, jar labeling machine also has a role in product tracking and tracing. Often fraudulent activities are committed during product shipment. However, with a jar labeling machine, you can place QR codes, bar codes, batch numbers, tracing numbers, holograms, etc., to decrease counterfeiting and tampering events.

4.What Is The Working Of The Jar Labeling Machine?

The working of a jar labeling machine generally depends upon design and label placement. A general working principle in different kinds of jar labeling machines is detailed below for your information.

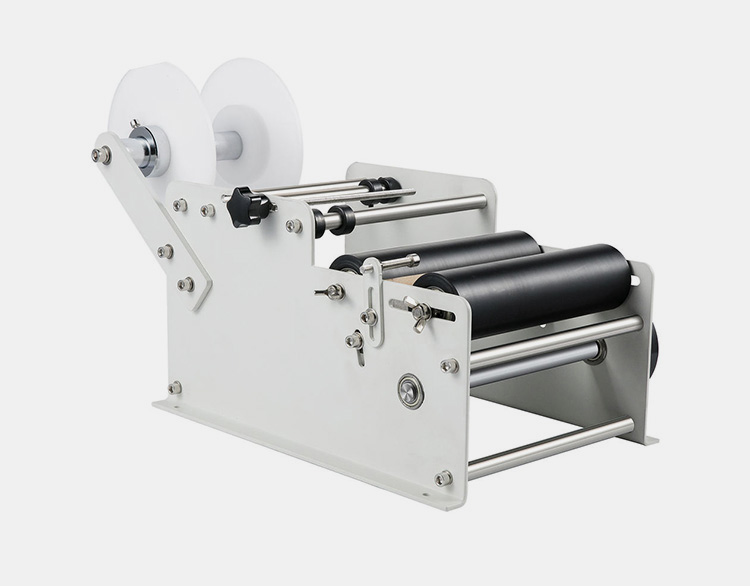

Label Roll Placement and Label Dispensing

Picture Courtesy: hanlar filling machine

At the start of labeling operation, first, the operator loads the large roll of labels, foils, or paper on the label unwinding disk. Next, the label film or foil is passed over rollers to keep it under tension. Photoelectric registration sensor detects the gap between labels and ensures correct label placement.

Jar Loading

Picture Courtesy: Market Industries

Next, the empty jars are placed one after the other on the conveyors either by the operator or by the bottle unscrambling machine. Jar labeling machine is equipped with different sensing systems that ensure proper space between moving jars.

Label Application and Smoothing

Picture Courtesy: Market Industries

This process depends upon the type of jar labeling machine. In some equipped first hot glue is applied on the labels that are then wrapped or glued to the jars. Some labels have adhesive and are applied by force over the jars. The labeling head is pressed against the surface of jars to stick labels. After label application, the next step is evening or smoothing of wrinkles with rollers or brushes. This process ensures high-quality labeling.

Jar Expulsion

Picture Courtesy: Packaging Strategies

After labeling, label quality is checked. If there are no deformities in labels such as wrinkles or misplacement then the label jars are removed and ejected from the labeling area and are moved down the line for further packaging or filling.

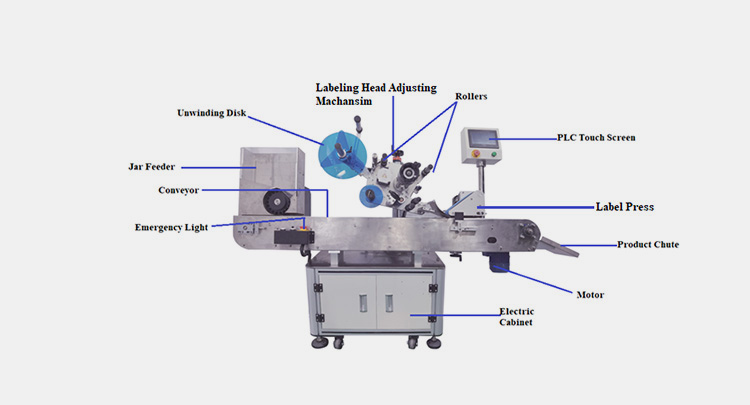

5.What Are the Basic Components Of Jar Labeling Machine?

Jar labeling machine consists of various mechanical components that have a specific role in jar labeling. Understanding functions of these parts can assist in troubleshooting the equipment. A list of important parts is composed for your knowledge.

| Jar Feeder | This part of jar labeling machine receives jars from hopper and systemically and steadily loads them in the right standing position on the conveyor. This part automates the labeling process. |

| Unwinding Disk | It is responsible for unwinding labels from the roll. It rotates for uncoiling of label film. This part also controls the tension in the film. |

| Labeling Head Adjusting Mechanism | It is a handheld wheel or level for adjusting the height or positioning of the labeling head. This ensures proper alignment of labeling press with the jar which in turn leads to correct label placement. |

| Rollers | These are the support rollers that hold film under proper tension and ensure there is no chance of error in label placement. |

| Label Press | This part sticks labels on the side or circumference of the jars. It applies the necessary force for the gluing of labels. It is also equipped with dispensing mechanism that cuts labels from films. |

| PLC Touch Screen | It is a computerized part that makes the programming of jar labeling machine easy. It is an intuitive touch screen with different options for adjusting labeling parameters. |

| Product Chute | Jars after label inspection go to the product chute from where they are removed from the machine. |

| Motor | It is an electrically powered part that mechanizes the movement of conveyors and labeling application systems. |

| Electric Cabinet | Various electric components like switches, relays, wires, and cables are enclosed in the fireproof cabinet. Electric connections to various parts are present in the electric cabinet. |

| Emergency Light | It is a safety feature present in jar labeling machine that indicates the fault in the system. It lights to notify users about problems with machines. |

| Conveyor | For consistent transport of jars across different units, conveyor systems are added to the equipment. Belts or chains ascertain the precise passage of jars and aid in the synchronicity of labeling process. |

6.What Kind Of Machine Are Integrated Into Jar Labeling Machine Production Line?

Jar labeling machine production line consists of a series of equipment integrated to automate and increase the efficiency of packaging products. These machines have their specific function in the synchronized packing of consumer goods in various industries.

Here is the list of some important machines that complete the packaging setup.

| Machine | Working Principle | Image |

| Jar Feeding and Unscrambling Machine

This machine is specially designed for increasing and systemizing the feeding and positioning of jars on the conveyors. It aligns the jars in an orderly manner on the conveyor platform. |

The jars are fed into the machine hopper in random order and the rotary disc and roller collect these jars and place them into holes. The jars are loaded on the machine conveyor in an upright manner from these holes. |

Picture Courtesy: vkpak |

| Counter and Filling Machine

In the pharmaceutical, nutraceutical, and confectionary industry counting and filling machine aids in counting and loading an exact number of pills and other snacks in jars. |

This machine has a high vision system and camera sensors that detect several products passing through filling systems. After counting the right amount fillers are employed in this machine for feeding products into jars either by vibration or by gravity. |

Picture Courtesy: C.E. King Limited |

| Desiccant Inserter

To prevent hygroscopic and sensitive products from absorbing moisture upon exposure to humid environment, desiccant inserter machine is used. It places absorbent materials in the jars. |

Absorbent packs are loaded on conveyors as belts. This machine is designed with cutting knife that cuts packets from the end of belts into small pouches and inserts them into jars, placed under the chute. |

Picture Courtesy: CVC Technologies |

| Capping Machine

For securing products and for preventing their spillage capping machine is employed in the jar labeling production line. This machine tightly applies caps on the mouth of jars to affirm their seal. |

First machine picks caps from the chute and puts them on the mouths of jars. Next spinning disc or capping heads in the equipment rotate and twist the caps to securely seal jars |

Picture Courtesy: C.E. King Limited |

| Induction Sealing Machine

To prevent tampering, induction sealing machine is often the part of packaging line. The function of this machine is to apply tamper-proof hermetic seals to the opening of jars.

|

With the help of high-temperature heating elements in an induction sealing machine, the foil or liner present on the inner side of caps is melted and glued on the opening of jars. |

Picture Courtesy: Taiwantrade |

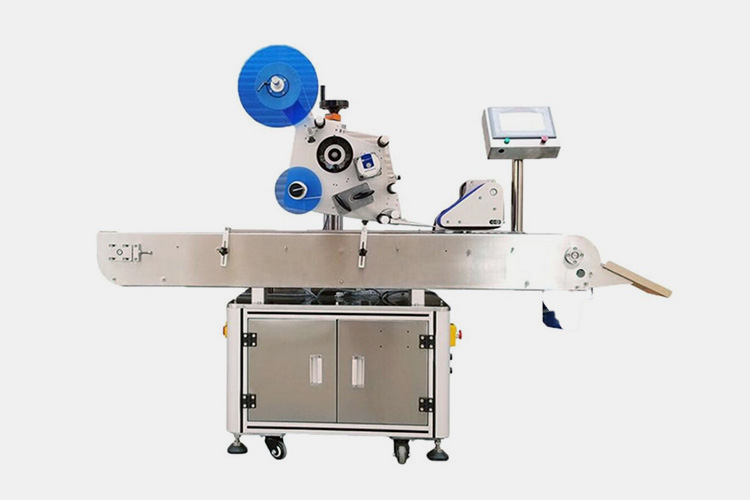

| Jar Labeling Machine

This is a robust and adaptable machine employed for brand awareness, product identification, and information communication purposes. |

Labeling heads, rollers, and unwinding disks offered with this machine apply and stick labels using hot or wet glue and pressure. |

Picture Courtesy: DirectIndustry |

7.In What Different Ways Jar Labeling Machine Is Classified?

The details of classification are penned below which you might find useful.

Depending Upon the Level of Automation

There are three types of jar labeling machine based on level of automation.

Manual Jar Labeling Machine

Manual Jar Labeling Machine

It is a simple portable desktop machine in which every labeling function is performed by the operator. Loading of jars, pressing of labels, and removal of jars from the machine is done manually. It has handheld wheels and rollers and is a cost-effective solution for small home-based industries.

Semi-automatic Jar Labeling Machine

Semi-automatic Jar Labeling Machine

This machine is the advanced form of manual jar labeling machine having output efficiency more than its manual counterpart. This machine has semi-automatic functionalities such as manual loading of jars while labeling process is autonomous. It is compact in design thus it does not have high space constraints.

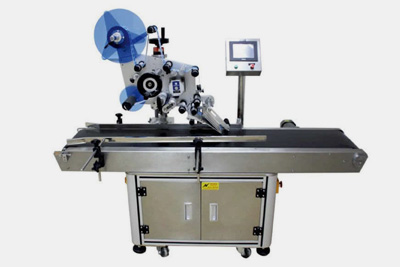

Automatic Jar Labeling Machine

Automatic Jar Labeling Machine

This machine is fully independent and with simple parameter adjustments on its HMI touch screen, this equipment is capable of carrying out labeling from scratch. Having this machine in production lowers the need for a large labor force. It is very effective in large-scale production where high-volume labeling is required.

Depending Upon the Orientation

Based on the orientation of the container, there are two types of jar labeling machine.

Horizontal Jar Labeling Machine

Horizontal Jar Labeling Machine

This machine labels jars while they are lying horizontally. This machine is ideal for processing jars with unstable bases. These containers cannot stand upright so labeling is done while lying on the side by a horizontal labeling machine.

Vertical Jar Labeling Machine

Vertical Jar Labeling Machine

This type of jar labeling machine labels the jars while they are standing upright on the moving conveyors. The labels are applied vertically by this equipment. It is very effective for labeling jars with stable bases such as cylindrical jars.

Depending Upon the Type of Adhesive

There are four types of jar labeling machines when classified based on adhesive type.

Wet-Glue Jar Labeling Machine

Wet-Glue Jar Labeling Machine- Picture Courtesy: NK Industries

This machine is popular for applying glue to labels at room temperature. The glue used by this machine is liquid before labeling thus there is no need for melting the glue. It is typically employed for labeling rigid glass or plastic containers.

Hot-Glue Jar Labeling Machine

Hot-Glue Jar Labeling Machine- Picture Courtesy: vkpak

This kind of jar labeling machine uses glue for labeling that is solid at room temperature. Heating bars are employed for melting this glue and then smearing it on the back of labels. This machine usually applies wrap-around labels and jars are rotated for applying labels.

Pressure-Sensitive Jar Labeling Machine

Pressure-Sensitive Jar Labeling Machine

This machine is also called a self-adhesive jar labeling machine since it uses pre-glued stickers for labeling purposes. It does not need any water or heat to stick the labels rather the labels are pressed on the jars using pressure. It is a cost-effective solution that minimizes utility bills.

Shrink Sleeve Jar Labeling Machine

Shrink Sleeve Jar Labeling Machine- Picture Courtesy: Paima Packaging Machinery

It applies ornate thermoplastic material over the surface of rigid jars before applying heat. After heating the material occupies the whole body of the jars. The labels also called sleeves, are not only used for labeling purposes but are also tamper-evident reasons.

Depending Upon Label Placement

Three kinds of jar labeling machines exist in the market based on their label placement.

Side Jar Labeling Machine

Side Jar Labeling Machine

It is also called a front and back labeling machine. It can label one or two sides of the jars. It can apply self-adhesive labels on the front and back panels of jars at high speeds. It improves the visual appeal of products by adhering to perfect labels over jars.

Wrap-Around Jar Labeling Machine

Wrap-Around Jar Labeling Machine

The labels in this type of machine are employed around the whole circumference by rotating the jars. The labels in this equipment are more easily employed than pick-and-place labels and have better visual appeal.

Corner Jar Labeling Machine

Corner Jar Labeling Machine- Picture Courtesy: Filling Machine

This machine is suitable for applying tamper-proof labels at the adjacent corners of jars, especially over the top. This machine is employed for reducing criminal activities and tampering with product jars.

Depending Upon Printing

There are two types of jar labeling machines based on printing ability.

Print & Glue Jar Labeling Machine

Print & Glue Jar Labeling Machine- Picture Courtesy: Quaderal Labeling Systems

This machine has a built-in printer such as a thermal transfer or inkjet printer for printing high-definition labels before applying them. This machine is best suited for customized and specific labeling according to brand image and also for printing barcodes, product expiry dates, etc.

Jar Labeling Machine Without Printer

Jar Labeling Machine Without Printer

This machine applies pre-printed labels over the jars. It is a simple machine comprising of less parts than its counterparts. Moreover, it has more speed and less processing time than a print and glue labeling machine.

Depending Upon Design

There are two kinds of jar labeling machines when classified based on design orientation.

Rotary Jar Labeling Machine

Rotary Jar Labeling Machine- Picture Courtesy: Quaderal Labeling Systems

This machine adopts a circular configuration. The jars are placed on the rotary wheel or turntable and different jars are labeled simultaneously in the rotary jar labeling machine. It has high labeling efficiency and is ideal for processing high-volume batches.

Inline Jar Labeling Machine

Inline Jar Labeling Machine

In this type of jar labeling machine, labeling functions occur sequentially due to its linear or Z-type configuration. The jars in this machine go one by one at different labeling stations. It can be easily accommodated in existing production plants.

8.What Are The Different Label Materials Used By Jar Labeling Machine?

With innovation in packaging, different types of label materials are used. Jar labeling machine is capable of handling diverse label materials.

| Material | Explanation | Picture |

| Polyester Film | It is a type of plastic (PET) film It is extremely tough, weather-resistant, and has flexibility and recyclability |  |

| Paper | It is one of the most cost-friendly options for labeling but is least long-lasting. It is coated with varnish, laminate, and other finishes to increase its weather-resistant ability. |  |

| Polypropylene | This material is tough and resistant to tearing. Moreover, it has little oil and water permeability. Thus are suitable for a wide range of environments. |  |

| PVC | It is ideal for shrink-labeling purposes and is flexible and versatile. PVC is waterproof and withstands rigorous environmental settings. |  |

| Metallic Foils | It is metallic foil paper known for its luster and sheen. It increases product display appeal with its premium look. |  |

| Holographic Foil | It is metallic foil with striking color shifts and patterns. This label material is often deployed for security, anti-counterfeiting, and brand-building purposes. |  |

| Thermal Transfer Label | This material is used for printing barcodes, ingredient tracing, and tracking numbers. |  |

9.What Type Of Jar Materials Are Labeled By Jar Labeling Machine?

Recently advancement in material technology has seen unique hybrid materials for jar manufacturing. Some common jar materials handled by jar labeling machine are:

Glass

Clear or colored glass is commonly used for storing different food products such as coffee, tea, chemicals, etc. The glass surface is smooth and pressure-sensitive labels are commonly employed for labeling glass jars.

Plastic

This type of jar is manufactured using PET, PP, HDPE, and BOPP plastics. Plastic jars are widely utilized in industries for packaging various consumer goods. However, plastic jars have varying labeling requirements.

Composite

This type of jar is formed by plastic and metallic parts. Strong adhesive materials are required for labeling these jars.

10.What Is Cleaning And Maintaining Tips For Jar Labeling Machine?

Some cleaning and maintaining tips for jar labeling machines that you might find useful.

| Cleaning |

| First power off the machine before starting.

Next remove label strips, fragments, and other debris from the labeling area. Gently wipe down the frame and stand with wet cloth. Remove any sticky material from label head and applicator with spray of alcohol or cleaning solution and soft brush. Clean sensors and conveyors with a minute amount of cleaning agent and lint-free cloth. Remove debris and dust from electric components via a soft brush. Reassemble the machine after cleaning. |

| Maintenance |

| On a daily basis, check the labeling components for damage or defect.

Adjust the alignment of rollers, unwinding disk, and labeling head daily. Daily check for tension in labeling holder and rewinder. Lubricate moving components in the jar labeling machine once a week. Check the alignment of drive belts, chains, and guide system of conveyors every week. Properly align them if needed. Recalibrate various sensors to ensure their correct work status weekly. Check the insulation and working order of electric parts monthly. |

11.How To Overcome Common Problems In Jar Labeling Machine?

Problems and issues routinely occur while operating any equipment and a jar labeling machine is no exception to the rule. However, lengthy downtimes can often cause slowing and delay in packaging. These problems are quite easily resolved by training workforce.

A few common problems are discussed below for your information.

| Cause | Solution | Image |

| Blockage or Jamming of Labels | ||

| Improper label film tension.

Faulty alignment of rollers. Dirty label applicators. |

Fix the tension in label film for smooth feed.

Properly orient and align rollers. Clean dirty and sticky label applicator beforehand. |

Picture Courtesy: Miles Label |

| Misplacement of Labels | ||

| Improper setting of label registration sensor causing poor label position detection.

Incorrect alignment of labeling head. Unsteady conveyor speed causes uneven transport of jars. |

Adjust and recalibrate the settings of sensor for proper placement.

Adjust height of labeling head. Adjust drive belts and other parts to ensure conveyor is moving at steady speed. |

Picture Courtesy: Keyence |

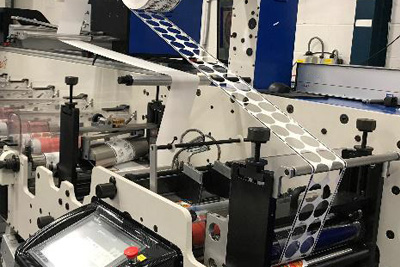

| Inconsistency in Label Feed | ||

| Faulty labeling speed settings

Fluctuations in voltage supply |

Calibrate the instrument and adjust the label unwinding speed on the HMI

Ensure stable supply of power |

Picture Courtesy: Focus Label |

| Label Detachment from Jar | ||

| Incompatibility of adhesive to jar surface.

Poor quality label material. High temperature while storage of labels. Uneven adhesive application. |

Use adhesives that are compatible with jar material.

Use high-quality labels. Adjust the temperature while storage of labels. Properly apply and spread adhesive. |

Picture Courtesy: M_use |

| Air Bubbles in Labels | ||

| Air molecules are trapped underneath the glue or other adhesive.

The surface of jar is rough and uneven Presence of dust particles while labeling |

Adjust machine setting for uniformly spreading labels.

Use jars of high quality. Thoroughly clean labeling heads and jars before label application. |

Picture Courtesy: CTM Labeling System |

12.What Points Should Be Considered When Purchasing A Jar Labeling Machine?

The purchase of jar labeling machine could be heavy on the wallet but in the longer run a well-match equipment can bring substantial revenue. So, it is best to select this machine with great caution. Here are a few important factors that should be taken into account before reaching a decision:

Credibility of Manufacturer

Before going out for purchase, methodically evaluate the credibility of the manufacturer selling jar labeling machine. Go through customer reviews and endorsements. Look for aftersales support. A good manufacturer has a list of positive reviews and well-satisfied customers.

Nature of Label

First determine the material, size, shape, and adhesive type of label. Different makes and models of jar labeling machines have different label processing capabilities. Hence, it is best to select a machine that is capable of processing your label types.

Jar Features

Secondly, determine the shape such as round or cylindrical, size, and material of the jar. Your selected jar labeling machine should be well aligned with your jar characteristics for an efficient labeling process.

Production Volume

If you are part of a small-scale business then opt low a speed jar labeling machine. This machine would be best suited to your needs without going overbroad on the price tag. But for mass-scale production, it is best to not compromise on the budget and go for a high processing capacity machine.

Conclusion

Jar labeling machine has gained quite a traction for their accurate and precise labeling. Having said equipment significantly augments your productions and brings higher profits. Hope this guide increased your understanding of a jar labeling machine. Want to buy this equipment then visit our website for further quotation and pricing. Happy Shopping!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide