Jam Filling Machine: The Complete Buying Guide In 2025

Jam filling machines are an essential part of many food production processes. They are a convenient and cost-effective way to fill great-tasting jams, jellies, preserves, marmalades, and other desserts in your business. So, whether you’re making jams, jellies, sauces, or any other type of food that needs to be filled with a jam-like consistency, the suitable machine can make all the difference when it comes to making sure quality is maintained and productivity remains high.

With so much variety on the market, however, understanding which one will best fit your needs can become a daunting task as you try to work out exactly what features and specifications will best suit your requirement. With all this in mind, this guide is designed to help make choosing a jam filling machine easier for you in 2025 – from exploring different types available to examples of industry-leading models from top manufacturers, allowing you to confidently make an informed decision so that your business can reap the maximum reward.

1. What Is A Jam Filling Machine?

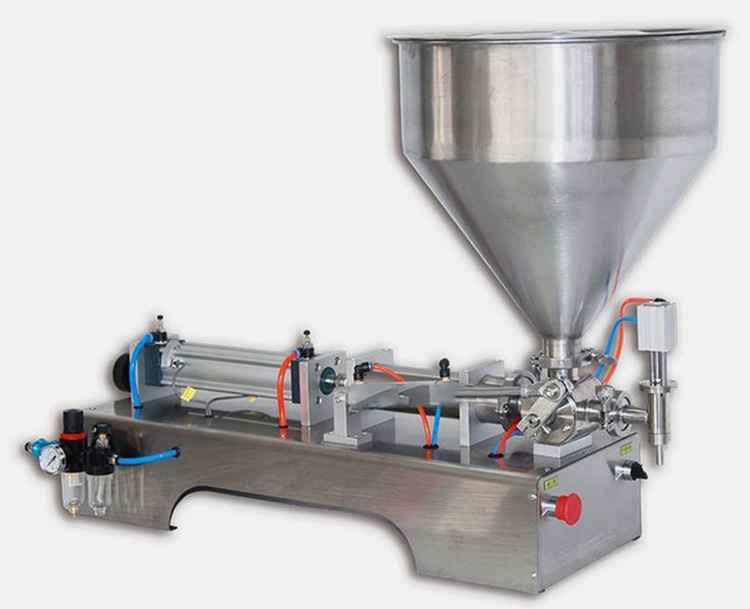

A jam filling machine is equipment used to fill jars and other containers with viscous fluids, such as jelly or preserves. It is an automated device that dispenses the product into each container quickly and accurately. This can be done either by weight, volume, or both. It is often used in production lines as part of a more extensive food packaging system.

The machine’s construction consists of a series of pumps, rollers, tanks, and valves to move the product from its storage container into each jar. It usually also has several nozzles that can be adjusted depending on the size of the jar and the amount of jam desired per fill. A jam filling machine is designed to be fast and efficient, increasing production speeds for businesses.

Furthermore, these machines are versatile in terms of the types of jams they can fill. They can handle a wide range of viscosities, from thick to thin jams and preserves, as well as different flavors and colors. Jam filling machines are also designed so that they can be adjusted easily, allowing for quick changes in the type of product and size of the jar.

2. What Are The Components Of A Jam Filling Machine?

A jam filling machine consists of several components that work together to accurately and efficiently fill containers with jams and jellies. The features include Hopper, weighing system, depositor, filling nozzle, control panel, and conveyor system.

- Hopper

The hopper is the first component of a jam filling machine. It holds and feeds the product into the other parts of the machine. The hopper size is customized to fit different products, and some models can be adjusted as needed.

- Depositor

The depositor is responsible for accurately, efficiently, and quickly transferring jam from the hopper into the containers. This component typically consists of a set of mechanical arms that move up and down to scoop the jam into the containers.

- Filling Nozzle

The filling nozzle is the part of the machine responsible for controlling the flow of products into containers. This component can be adjusted to allow more or less product to flow and change the shape and size of the deposit.

- Control Panel

The control panel operates the jam filling machine and usually includes an easy-to-use touchscreen system. It allows for easy adjustments of the other components and access to maintenance records and production logs.

3. How Does A Jam Filling Machine Work?

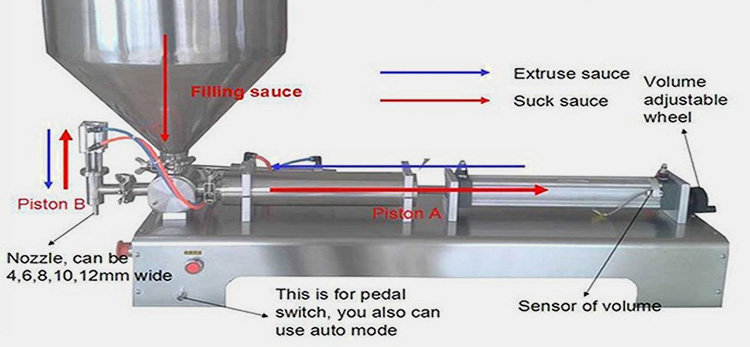

A jam filling machine is a type of automated system used to fill containers with jam or other viscous liquid products. It typically consists of an in-feed conveyor, product hopper, pump, filling nozzle, level control units, and an outfeed conveyor. The in-feed conveyor brings the empty containers to the hopper, which holds the jam. The pump transfers the jam from the hopper to a filling nozzle connected to a nozzle holder.

The nozzle moves along a programmed path and deposits an accurate product dose into each container as it passes under the nozzle. The level control unit detects when each container is full, sending a signal back to the nozzle holder and stopping the flow of the product. The out-feed conveyor then carries the filled containers away for further processing.

Jam filling machines are commonly used in food production and packaging, providing highly accurate and consistent results. They can be adapted to fit various container sizes, shapes, and types, making them a versatile and cost-effective choice for many businesses. Additionally, jam filling machines are easy to operate, with minimal maintenance to keep them running efficiently.

By using a jam filling machine, businesses can cut costs and improve the accuracy of their production processes, ensuring that each container contains the correct amount of product every time. This increases efficiency and can help boost profits while still producing a high-quality product.

4. What Are The Applications Of A Jam Filling Machine?

There are many uses for a jam filling machine in different industries.

- Food Industry

Jam filling machines quickly and accurately fill jars and containers with jams, jellies, sauces, syrups, and other products. The use of a machine eliminates the need for manual labor, saving time and money. Jam filling machines can also be used to fill pre-made pies and pastries with jam, allowing bakeries to fill a variety of baked goods quickly.

- Cosmetics Industry

Another application for jam filling machines is in the cosmetics industry. These machines are used to dispense creams, lotions, and other types of beauty products into containers with precision and accuracy.

- Pharmaceutical Industry

In the pharmaceutical industry, these machines can be used to fill capsules, pills, and tablets into bottles at high speed. They help ensure that the product maintains quality standards and is able to fill many products quickly and accurately.

- Chemical Industry

The chemical industry also relies on jam filling machines. They can be used to fill containers with chemicals, pesticides, and other industrial products quickly and accurately. This helps to ensure that the product remains of high quality as it is filled in a controlled environment.

In summary, jam filling machines have many uses in different industries ranging from food production to pharmaceuticals. These machines help to save time and money by eliminating the need for manual labor, as well as providing accuracy and quality control in filling products. They can be used to fill a variety of products, from jams and sauces to creams, lotions, and chemicals, with precision and accuracy.

5. What Are The Advantages Of A Jam Filling Machine?

- Speed

A jam filling machine is designed to quickly fill jars and containers with various products, including jams, jellies, sauces, dressings, and condiments. It can increase productivity by several times compared to manual or semi-automatic processes. This makes it ideal for companies that need to produce large quantities of products in a short amount of time.

- Versatility

Jam filling machines can be adjusted to accommodate different-sized containers and a variety of products. This makes them suitable for food production facilities that need to fill several types of products in different sizes and shapes.

- Reliability

They are designed to work accurately and consistently, ensuring that containers are filled with the specified amount of product. This helps to improve product quality and reduce waste, saving costs for companies.

- Hygiene

A jam filling machine is designed with a high level of hygiene in mind. It is constructed using stainless steel and other food-grade materials, which makes it easy to clean and maintain. This helps to ensure that products are filled in a clean, safe, and hygienic manner.

- Safety

A jam filling machine eliminates the need to use manual labor, which can be dangerous and prone to mistakes. By using a machine, you reduce the risk of spills, reducing the possibility of accidents in the workplace. Furthermore, the machine itself is designed to be ergonomic and user-friendly.

- Cost-Effective

A jam filling machine is an affordable piece of equipment that can be used to increase the production capacity of a food processing facility. The initial investment is usually recovered quickly in terms of increased productivity and cost savings.

- Easy Operation

A jam filling machine is designed to be easy to use, even for operators with limited technical knowledge. Most machines come with user-friendly interfaces that make it easy to set up and adjust settings according to the requirements of the product. This helps operators to get familiar with the operation of the machine quickly.

6. What Are The Different Types Of Jam Filling Machine?

Jam filling machines come in different sizes and designs depending on the application and production speeds required. It includes:

- Semi-Automatic Jam Filling Machine

This type of jam filling machine is manually operated and requires a worker to place the containers underneath the filler. The operator then adjusts the speed based on how much product needs to be filled and, when done, turns off the machine. The advantage of this filling machine is its low cost and small footprint.

- Automatic Jam Filling Machine

This type of jam filling machine is completely automatic, offering a high level of efficiency and accuracy. The containers are placed onto the conveyor belt, where they are transported under the filler, which dispenses the product according to pre-set settings. The speed can also be adjusted to meet the needs of the production line.

- Volumetric Jam Filling Machine

The jam filling machine is designed to dispense predetermined amounts of product into containers accurately. The product is weighed and checked for accuracy before being sent down the conveyor belt, filled with the correct amount of jam. This type of machine is ideal for businesses that require a high level of precision and accuracy.

- Rotary Auger Jam Filling Machine

Rotary auger fillers are another type of jam filling machine. These machines use an auger-shaped spindle to fill jars with liquid or semi-liquid products such as jams, jellies, and preserves. The product is dispensed through a series of nozzles that rotate the jar under the dispensing heads. This is a great option for automated filling with high accuracy and repeatability.

- Piston Jam Filling Machine

More specialized jam filling machines include piston fillers, which use a motor-driven plunger system to dispense product into jars, and cappers, which seal the jar lid onto the container. Piston fillers can handle thicker products such as peanut butter or nut butter, while cappers can be used to quickly and securely seal the lid onto the jar. It is an ideal choice for businesses that need to fill large amounts of products quickly and accurately.

7. What Are The Different Types Of Packaging Materials That Can Be Used With A Jam Filling Machine?

There are several options available when it comes to packaging materials for a jam filling machine. These include:

- Heat-sealable aluminum foil pouches

These are ideal for packaging jams as they can be sealed easily and securely. They are also lightweight and flexible, making them easy to transport. Additionally, foil pouches offer excellent protection from moisture, oxygen, light, and grease.

- Plastic containers

Plastic containers are a great choice for packaging jams because they provide complete protection and can also be sealed airtight. They come in a variety of shapes and sizes, so there is something to suit every product. Additionally, plastic containers are lightweight and easy to store.

- Glass jars

Jars made from glass are a timeless classic when it comes to packaging jams. They are a great choice for giving products a high-end look or for recyclability purposes.

- Metal cans

These are excellent for products requiring extra oxygen, light, and moisture protection. Metal cans can also be sealed airtight with lids or caps to ensure product freshness and quality. Additionally, they offer excellent recyclability.

Overall, many different types of packaging materials can be used with a jam filling machine. Depending on your product, budget, and desired look and feel, you can choose the most suitable option for your needs.

8. How Is A Jam Filling Machine Different From Standard Filling Machines?

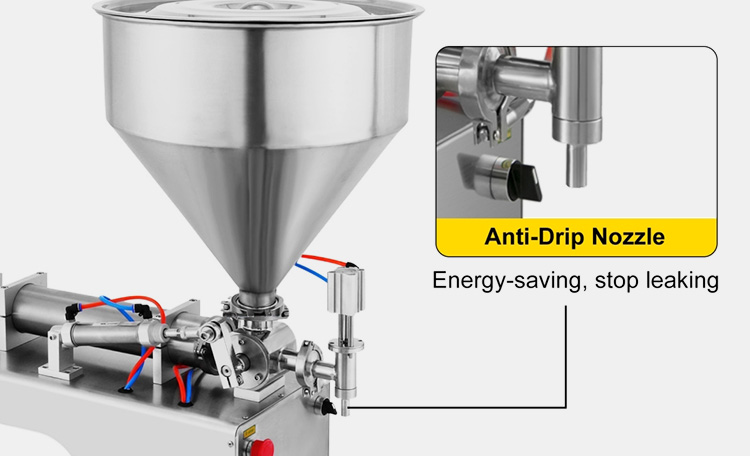

A jam filling machine is a type of filling machine specifically designed to accurately and efficiently fill containers with sticky or viscous products such as jams, jellies, preserves, and sauces. These machines are unique in that they use special features and technologies to prevent product leakage while also providing a higher level of accuracy when compared to traditional filling machines.

Jam filling machines differ from standard liquid food-filling machines in the way they handle thicker or semi-solid products. They utilize positive displacement pumps, which are designed to gently push rather than pull products. This ensures that the thick jam is not damaged or deformed in any way during the filling process.

Another difference between jam filling machines and standard liquid food-filling machines is how they handle pressure fluctuations. Jam is often highly aerated, meaning that its viscosity can change quickly. Traditional filling machines are not designed to address these drastic changes in pressure. In contrast, a jam filling machine is designed with sophisticated sensors that detect and adjust to changes in viscosity, ensuring that the product remains consistent throughout the entire process.

Finally, unlike standard liquid food-filling machines, jam filling machines utilize non-contact filling heads, eliminating the possibility of contamination or cross-contamination. This is incredibly important for products such as jams and jellies, whose textures and flavors can be altered by contact with foreign materials during production.

9. Are There Any Tips For Ensuring Maximum Efficiency With A Jam Filling Machine?

There are several important tips to keep in mind when using a jam filling machine for maximum efficiency.

- Check the Jam

Before you start the jam filling process, it’s important to check that the jam is of the right consistency. A too-thick or thin jam can cause fill accuracy problems and affect final product quality. You should also check that there are no lumps or foreign objects in a jam.

- Clean the Machine

It’s important to regularly clean the machine and remove any product residue, dust, dirt, or other build-up that can affect the filling process’s accuracy. It helps to keep the parts of the machine lubricated, as this will reduce wear and tear.

- Check Nozzle Settings

The nozzles on jam filling machines should be regularly checked for accuracy. This ensures that the product is filled consistently and accurately into containers. It’s important to check that the right amount of jam is being filled into each container, as this will help to reduce wastage and ensure consistency.

- Check the Speed Settings

The filling speed of a jam filling machine needs to be calibrated for maximum efficiency. Too fast a speed can increase the risk of product spillage, while too slow a speed can cause delays in production. It’s important to check that the correct settings are in place to ensure that the filling process runs smoothly.

- Monitor Temperature

The temperature of the jam can affect its consistency and also have an effect on filling accuracy. It’s important to monitor and regulate the jam’s temperature before entering the machine for optimal performance.

- Keep the Jam Flowing

To ensure maximum efficiency with a jam filling machine, it’s important to keep the jam moving in order to avoid any problems with air locks or blockages in the pipes. It’s also important to keep a close eye on the pumps and hoses used for filling as these can become worn over time and need to be replaced if necessary. Following these tips can help you maximize the efficiency of your jam filling machine.

10. What Problems Are Associated With Using A Jam Filling Machine And Their Possible Solution?

While jam filling machines have made the process of packaging jams and other similar food products much more efficient, there are still some issues that users may need help with along the way.

- Clogging

Jam filling machines can easily get clogged if they’re not cleaned regularly or if large chunks of solid material are in a jam. This can cause jams and other products to be unevenly distributed, leading to consistency in product quality.

Solution: Cleaning the machine regularly is essential for preventing clogs. It’s also important to make sure that there are no large chunks of solid material in the jam before filling it into containers.

- Jam spillage

Jam spillage is one of the most common problems associated with using a jam filling machine. This usually happens when too much product is put into the machine, or the nozzle isn’t correctly adjusted. Jam can also spill out of poorly-sealed containers due to improper sealing techniques.

Solution: To prevent jam spillage, users should ensure that the tube is correctly adjusted and that the containers are sealed properly. They should also be careful not to overfill the machine and use precise measurements when adding products.

- Leaks

Leaky seals can cause jams and other food products to leak out of containers. If not addressed, this can lead to product wastage and contamination.

Solution: To prevent leaks, users should ensure that the seals are adequately tightened before operating the machine. Additionally, they should regularly inspect the seals for any signs of wear or tear.

- Inaccurate fills

Jam filling machines can sometimes produce inaccurate fills due to incorrect settings or poor calibration. This could lead to consistency in product quality and satisfied customers.

Solution: To ensure accurate filling, users should regularly check and adjust the settings on the machine as needed. They should also calibrate the machine regularly to ensure that the fills are accurate.

11. What Are The Maintenance Procedures Of A Jam Filling Machine?

A jam filling machine is an essential piece of equipment. Therefore, you need to ensure that the machine is well maintained to ensure that it operates efficiently and safely. Here are some maintenance procedures for a jam filling machine:

- Cleaning

Cleaning is an essential part of maintaining a jam filling machine. Regular cleaning of the machine prevents the build-up of dirt and bacteria that can cause malfunction and contamination. Cleaning should include washing all parts with hot soapy water, rinsing thoroughly with clean water, and air drying entirely before reassembly.

- Lubrication

Lubrication is an essential maintenance procedure that must be performed regularly on a jam filling machine. Without proper lubrication, the machine may experience excessive wear and tear, or parts may not move properly. All moving parts of the jam filling machine should be lubricated with a light-duty oil such as 3-in-1 oil or a food-grade lubricant to ensure optimal performance. It is important to note that the machine should be turned off and unplugged before performing any maintenance procedure, including lubrication.

- Adjustments

Jam filling machines require regular adjustments to ensure that the product is being filled accurately and consistently. This may include adjusting the speed of the nozzles, the flow rate of the product, or the timing of the machine’s operations.

- Inspection

Inspection is an important part of the maintenance procedure for a jam filling machine. This includes a visual inspection of the machine’s components and testing and monitoring its performance. All parts should be checked during the inspection to ensure they are working correctly. The operator should check for any worn or defective parts that need replacing. Additionally, all connections and hoses should be examined for wear and tear, and any oil or grease leaks should be identified.

- Calibration

Calibration is an important part of the maintenance procedures for a jam filling machine. This procedure ensures that the machine fills and dispenses products accurately, consistently, and within safety parameters. Calibration involves adjusting the settings on the jam filling machine to ensure it operates correctly. For example, calibration may involve adjusting fill rates, piping pressures, motor speeds, or nozzle depths.

Conclusion:

A jam filling machine can make all the difference in producing quality goods and meeting your production demands. As you can see, there are many details to consider when looking for a good jam filling machine in 2025. That’s why you should contact Allpack – they have the experience and expertise to get you the right machine for your business. Don’t waste any time – contact them today to get started on finding the ideal jam filling machine for your business’s success.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide