ISO For Pharma: The Complete FAQ Guide In 2025

Whether you are running a pharmaceutical industry for a long period of time or new in the field, skipping to know about ISO For Pharma is no exception! Since, the concerned area is supposed to carry out precise, hygienic, and safe processing, compliance to quality standards like ISO become inevitable. Similarly, most of the manufacturers find it hard to get all the necessary information about ISO For Pharma.

Thus, we are here to address your concerns. After reading this in-depth FAQ guide, you will be able to comprehend what basically ISO For Pharma means. Not only this, but how can you get the certification for your company, what are its benefits, which areas it covers and much other aspects. So, no need to fret, just stay calm and dive deep into this review!

1.What Is Meant By ISO For Pharma?

ISO for pharma illustration- Picture Courtesy: pharmaoffer.com

ISO, International Organization for Standardization, is a global body that establishes rules and regulations for certifying goods and products. These principles provide a strong check to produce safe and quality products. With presence in over 160 countries, ISO is recognized worldwide and today it is considered inevitable for pharma companies.

In this way, ISO for pharma is a particular area of ISO standards that only deals with pharmaceutical industry. It represents compulsory recommendations for the quality control of pharmaceutical equipment, manufacturing methods, research and development, and associated aspects to ensure safety and hygiene. Hence, a reputable company must always meet these requirements through compliance.

2.What Are The Benefits Of ISO For Pharma?

ISO for pharma carry substantial benefits due to its comprehensive principles that cover every aspect related to public health, drugs, and related equipment. So, in below explanation you will know how positive effects the compliance to ISO for pharma can have on your business at large:

Ensure Safety

The prime objective of ISO for pharma is to ensure safety. Now, it is associated with patients safety as well as the environmental safety because the regulations advocate for using quality material in the construction of pharmaceutical equipment which ultimately reduce the chances of contamination. Similarly, it obliges manufacturers to follow environmental sustainability requirements.

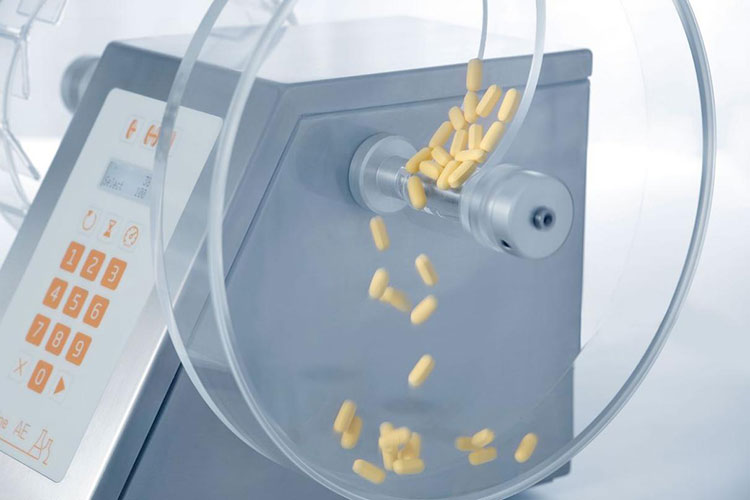

Enhance Efficiency

Precise tablet friability testing- Picture Courtesy: pharmaceutical-networking.com

Running a pharma industry is not a game rather you need to be very serious and attentive at the same time. Thus, ISO for pharma streamline successful practices which are really helpful in reducing time waste. Consequently, by adopting these processes you become able to uplift your production at the very initial stage and skip experiencing any failure.

Improve Quality Control

Quality control icon- Picture Courtesy: devteam.space

Compromise on quality control of pharmaceutical products is nonnegotiable. That's why, ISO for pharma provide basis for each step from initial research to thorough testing and final development of materials. Provision of such tiny instructions can ultimately result in the production of top quality goods which can better add value to patients lives.

Build Global Credibility

Complying to international standards like ISO is now a prerequisite for international trade, reputation, and recognition. Similar is the case with ISO for pharma which helps you uplift the value of your goods and build Global credibility in the competitive market.

Customer Satisfaction

Patient picking capsule

The ultimate goal of every entrepreneur is to have higher demand for produced goods. That becomes pretty easy when you have certification of ISO for pharma as it helps in satisfying customers which is all what you need.

3.Why ISO For Pharma Is Important In Pharmaceutical Industry?

Medicines spilling from bottle- Picture Courtesy: thalassaemia.org

ISO for pharma is considered a compulsory standard in pharmaceutical field because it is the most comprehensive quality standard that deals with every aspect of pharmaceutical manufacturing. Be it drugs production, testing, distribution or the designing of sophisticated machines, ISO for pharma touches every area.

Similarly, it deals with quality management systems, environmental management, and risk assessment etc. This dynamic approach has raised its significance and now pharma companies are bound to follow these regulations. It is crucial for illustrating the company's adherence to safety, quality, and efficacy of products and at the same time signify their excellence.

4.What Are The ISO Requirements For Pharmaceutical Industry?

Generally, ISO requirements for pharmaceutical industry aims at enhancing the quality control stages for the improvement of patient health safety and efficiency of manufacturing. In this way, few such requirements of ISO on part of pharmaceutical industry are as follows:

Capsule testing in pharmaceutical laboratory- Picture Courtesy: emmainternational.com

Quality Management

One of the primary requirement of ISO for pharmaceutical industry is quality management. It represents the regulations that directly deals with the quality of machines and drugs which are to be produced. Thus, it sets forth the construction material for equipment and material for drug manufacturing and packaging.

Testing

Testing is another significant requirement of the ISO which must be carried out in pharmaceutical industry. It is because laboratory testing validates the authenticity, effectiveness, and shelf life of drugs. In addition, transparency testing, tablet friability testing, and dissolution testing are some of the examples in this respect.

Production Methods

ISO also provide a framework and methods which are supposed to be practiced in pharma sector as obligatory measures. This is of paramount importance as it helps the industries to adopt new techniques for production with increase in technology.

Environmental Safety

ISO also guides pharmaceutical industry on using environmental friendly means to reduce waste and minimizing ecological impact. Ultimately, it leads to environmental sustainability.

5.What Do You Do To Apply For ISO Certification For The Pharmaceutical Industry?

ISO application process illustration- Picture Courtesy: isoindia.org

In order to apply for ISO certification for the pharmaceutical industry, you need to start with multi-step process that simply include your understanding of the relevant standard. Once you have finalized the intended standard, it is time to adopt these regulations practically in your business.

Now, select a recognized and credible ISO body and file an application that must include all the necessary aspects which you need such as liability issues, access rights, and confidentiality. Thus, your application is ready to be sent to the concerned body for reviewing and accrediting you with an ISO certificate.

6.Enlist The Major Standards Of ISO For Pharma?

There are several major standards of ISO which are applicable to pharmaceutical sector. These are as follows:

ISO 9001 Standard

ISO 9001 Certification- Picture Courtesy: registrationarena.com

ISO 9001:2015 is considered the most eminent standard of ISO which deals with the quality management systems of any industry. Thus, it is important for pharma in a way that the concerned companies must adhere the quality, safety, and efficiency requirements as well as processes for producing goods. So, that customer expectations can be better fulfilled by supplying quality material.

ISO 14001 Standard

ISO 14001 standard is yet another significant standard that represents concerns for environment. In this way, a pharma company is bound to conduct its practices while respecting the manufacturing compatibility with environmental laws. Similarly, it helps in reducing the negative impact of pharmaceutical companies on surroundings.

ISO 45001 Standard

ISO 45001 Certification- Picture Courtesy: registrationarena.com

It represents occupational health and safety management system which is directly linked to the workforce in pharmaceutical industry. Thus it helps in ensuring the safety life of workers to make sure they perform their functions without any risk.

ISO 50001 Standard

ISO 50001 Certification- Picture Courtesy: registrationarena.com

ISO 50001 standard is another significant standard that is associated with energy management systems demonstrating the practical way for improving use of energy in pharmaceutical companies. With the help of this certification, manufacturers can carbon footprint and wastage is reduced which paves way for cost-effectiveness and efficiency.

ISO 27701 Standard

ISO 27701 is a standard for privacy information management system. It provides a framework for safeguarding the privacy and data of organization. Being a globally valued sector, pharmaceutical company should follow its principles for the procedures and handling of personal data.

ISO 22000 Standard

ISO 22000 Certification- Picture Courtesy: registrationarena.com

This standard is for food safety and management systems. As pharma industry produces edible drugs and other supplements in form of syrups and medicated milk powder and protein powder etc., complying to this standard helps in enhancing its worth. Moreover, customers also have trust in ISO 22000 certified products as they certify the safety of products.

ISO 17025 Standard

It is crucial for drug development and and quality control which are the key factors in pharmaceutical industry. Thus, it focuses on the general requirements for competence of laboratory testing and calibration system.

7.How Do You Do To Become ISO Certificated For The pharmaceutical Industry?

The process for obtaining an ISO certificate for pharma is pretty easy. You just need to follow few steps and making sure requirements of each step are fulfilled properly. These include:

- Firstly, you need to determine the type of standard which you want and properly understand all the requirements under it.

- Secondly, you need to implement the regulations, that comes under the desired ISO certificate, in your industry.

- Thirdly, you are supposed to document the principles which you have applied in your business. For this, you may hire a legal consultant.

- Fourthly, the internal audit team will assess the compliance to regulations in your field.

- Fifthly, In case of any gaps in adherence to the ISO standard principles, you need provide a strategy in application for how would you fill the gap.

- Finally, an external audit team will review your application and after analyzing the current compliance to regulations and future plans for following, you will be awarded the ISO certificate.

8.How Long Is A Certificate Of ISO For Pharma Valid For?

Validity icon- Picture Courtesy: Shutterstock

This question carry great significance for the reason that many pharmaceutical manufacturers often think that they just need ISO for pharma certificate once in a lifetime. However, that's not the case. In fact, it is obligatory for pharmaceutical companies to keep updating their methods, processes, and training staff with respect to changes in demand for safety.

Therefore, the ideal time period for the validity of ISO for pharma certificate is 3 years. After the completion of three years, you need to renew the certification by booking a recertification assessment. In addition to it, a surveillance is conducted annually to check the application of standard in company.

9.What Is The Future Of ISO For Pharma?

Human finger pressing future start button- Picture Courtesy: emmersonwills.com

ISO for pharma is playing vital role in promoting safe and sound processing of drugs from their production till distribution across the globe. This element has now made it quite easy to approach the market in countries where national regulations are not stringent.

In this way, the future of ISO for pharma seems to be more powerful and increasing especially in areas like digitization and data security as the technology is rapidly growing in healthcare industry. Thus, ISO standards like 27001 are getting fame and much expectations are associated with these standards for granting the safety to pharmaceutical companies.

10.What Are The Challenges While Maintaining ISO For Pharma?

Challenge crossing icon- Picture Courtesy: Freepik

While maintaining ISO for pharma, the pharmaceutical manufacturers may face certain challenges during the process. These hurdles are often related to the upgradation of system such as staff training, improvement in existing production methods, and advancing the testing for quality control.

All these requirements need additional resources, time, and energies which ultimately become burden on companies especially those working on small scale. Thus, the most challenging task is the adaptation to changes in standards. However, despite these difficulties, the benefits of ISO for pharma certification are far more valuable.

Conclusion

To put in a nutshell, ISO For Pharma is an obligatory standard for all the pharmaceutical and drug manufacturing companies regardless of what their production level is. The reason is long terms advantages and most importantly public health safety which should be the first priority of every industry. Since, the standard is inevitable to comply, its classification must be understood thoroughly which are explained above. Besides this, it is also very important to keep updating the processes for improvement. So, if you found this article helpful and want to have further information about it, then we are here to help!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide