Instant Noodle Seasoning Packaging Machine: The Complete Buying Guide In 2025

Although, the journey of noodles from its birthplace, China, to the rest of world took centuries, the process became inverse with technology when cultural diffusion was no longer dependent upon animal transport. Now, you can enjoy the bowl of instant noodles anywhere sitting in this world. But have you ever wondered why this wheat-based product tastes so tantalizing? Of course, due to the addition of delectable seasoning!

That's why we have come up with this informative buying guide about an Instant Noodle Seasoning Packaging Machine to help you preserve your instant noodle seasoning in better way. Not only that, but how the machine function, where can it be used, and what packaging formats it supports. These all will be explained. So, stay tuned and keep reading!

1.What Is The History Of Instant Noodle Seasoning?

Cuisine development during Chinese song dynasty- Picture Courtesy: wikimedia.com

The history of noodles from millet-based staple to the modern seasoned instant noodles has been a protracted one. By originating around 4000 years ago in China, noodles were transformed until a Japanese businessman Momofuku Ando, the very first person, made instant noodles in Japan to fight severe hunger during WWII.

From that moment, instant noodles manufacturers initiated the struggle for enhancing the taste, flavor, and enticement of instant noodles. The most desired substances they found were pepper, sodium, chilli, and onion powder. These components, when combined with other thickening agents like corn flour, were termed as instant noodle seasoning.

bestofbs.com

It's an interesting fact to know that instant noodle seasoning not only increase the delish of noodles but also hold beneficial nutritional value for human health. That's why, the idea became so popular and now in countries like Vietnam you will find instant noodles packs with 2 and 3 sachets each encasing different seasonings.

2.Define Instant Noodle Seasoning Packaging Machine?

Allpack- APK-130 Horizontal 4 side seal small salt powder granule sachet machine

Instant noodle seasoning packaging machine is a professional, flexible, and advanced machine tailored to pack all kinds of instant noodle seasonings in small to large bags and containers. The machine is highly secure, that it fully assures the hygiene and precision of both the product as well as packages.

With automatic system, it can produce large number of seasoning packages in less time. Moreover, the machine is capable of processing instant noodle seasonings in all its forms encompassing powder, granules, and liquid form. Hence, it can be used in areas beyond food.

3.What Is The Importance Of An Instant Noodle Seasoning Packaging Machine?

One of the major problems encountered by instant noodle manufacturers is how to secure the seasonings without which the noodle will be of no use. That's where the importance of an instant noodle seasoning packaging machine is realized. So, be ready to know further benefits:

Enhanced Protection

Safe instant noodle & seasoning packaging- Picture Courtesy: Behance

Instant noodle seasoning packaging machine is made up of durable stainless steel which is fully hygienic to process all kinds of seasonings without any harm. In addition to this, the process of packing seasonings into packages is carried out in extremely safe environment to keep them intact against environmental elements.

Reduce Waste

Teared up ketchup sachet presentation idea- Picture Courtesy: mociun.com

The automatic detection and weighing system of instant noodle seasoning packaging machine are contributing in large part to the reduction of material as well as packaging film waste. Therefore, the finished product you will get will be a precise one with no inconsistencies in volume and design.

Boost Production

Large number of seasoning bottles- Picture Courtesy: godairyfree.org

An instant noodle seasoning packaging machine come up with sophisticated technology where it can be integrated with other machines. Similarly, it has improved packaging speed to meet the utmost production targets.

Cost-effective

When talking about an instant noodle seasoning packaging, every entrepreneur wants to reduce the packaging cost. However, this goal can now be perfectly achieved by using an instant noodle seasoning packaging machine which has low maintenance cost, require limited labours, and most importantly reduce material and packaging waste. These all factors account for its reliability.

Brand Promotion

Woman displaying instant noodle seasoning sachet & bottle- Picture Courtesy: cleanmondaymeals.com

An instant noodle seasoning packaging machine provide you the chance to make eclectic design packages with perfect sealings. This in turn generate the sense of satisfaction in consumers who prefer to buy your quality products. So, the way to popularity of your brand become open.

4.What Type Of Instant Noodle Seasonings Can Be Packed By An Instant Noodle Seasoning Packaging Machine?

There are multiple forms of instant noodle seasonings being made and packed across the globe. These types can be categorized into three most common ones such as:

Powder Instant Noodle Seasoning

Powdered seasoning- Picture Courtesy: glebekitchen.com

Powder instant noodle seasoning is the popular one that is made from the mixture of different dried spices such as onion powder, pepper, salt, sugar, and garlic powder etc.

Liquid Instant Noodle Seasoning

Instant noodle soup sauce seasoning- Picture Courtesy: usa.lkk.com

Instant noodle seasoning is also available in liquid form. For instance, many instant noodle manufacturers use to deliver liquid instant noodle seasonings such a as soy sauce, sweet sugar sauce, and chilli sauce etc.

Granulated Instant Noodle Seasoning

Granulated seasoning mix- Picture Courtesy: nospoonnecessary.com

Another common form of instant noodle seasoning is granulated in nature. Such type of instant noodle seasoning consists of chopped vegetables and chicken which are first cooked and then dried for packing in bags and containers.

5.Enlist The Numerous Packaging Styles For An Instant Noodle Seasoning Packaging Machine?

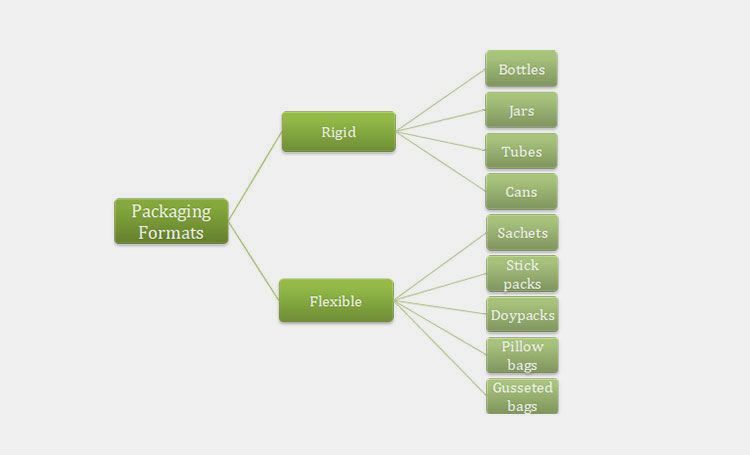

It is for sure that you have been to a retail market for grocery where multiple noodle packs are laying on the shelves with at least one to three instant noodle seasoning sachets. Now, the question is are these instant noodle packs the only single packaging format available? Of course not! There are multiple packaging styles which are used for the instant noodle seasoning packaging. These are as follows:

Bottles

Seasoning powder bottles- Picture Courtesy: packagingoftheworld.com

Bottles are the popular packaging containers used for instant noodle seasoning of powder and liquid nature. They are recloseable with a lid and often made from plastic or glass.

Jars

Seasoning in glass jar- Picture Courtesy: happyfoodstube.com

Jars can be described as large size rigid containers made from strong glass which provide both the safety and visual appeal to your instant noodle seasonings.

Tubes

Various seasoning tubes- Picture Courtesy: foodbev.com

Tubes are cylindrical type rigid containers with reclose able lids. They are made from aluminum, plastic, or biodegradable laminated hard paper. They are among the commonly used packaging formats which can be filled and packed by using an instant noodle seasoning packaging machine.

Cans

Seasoning in can- Picture Courtesy: mrsbalbirsingh.com

Cans are metal based durable containers often utilized for packing instant noodle seasoning. They are highly protected against moisture and sunlight. Therefore, most of the reputable brands you will find packing their instant noodle seasoning in cans.

Sachets

Instant noodle seasoning sachet- Picture Courtesy: thecountrycook.net

Sachet is the most commonly used packaging format for holding single serving instant noodle seasoning. It is suitable for both powder and liquid seasoning. Moreover, the shape and sealing of sachets vary from square to shaped sachet with 3 or 4 side seal respectively.

Standup Pouches

Liquid seasonings in doypacks- Picture Courtesy: thedieline.com

Standup pouch also known as doypack, is another type of packaging format which can be processed by using an instant noodle seasoning packaging machine. These pouches are highly convenient to use with option of using spouts for liquid seasoning. They can hold greater amount of material.

Stick Packs

Seasoning stick pack- Picture Courtesy: lonolife.com

Stick packs are small sized tubular shaped sachets which are best suitable to carry both liquid and powder instant noodle seasoning for single use. So, you can create beautiful stick packs by using this machine.

Pillow Bags

Seasoning pillow bag- Picture Courtesy: designerpeople.com

Pillow bag is another type of packaging format that is produced by an instant noodle seasoning packaging machine to pack powdery seasonings. It resembles pillow and, therefore, give your material additional safety against breakage and distortion.

Gussets Bags

Chili powder in gusseted bag & bottle- Picture Courtesy: Behance

Gusseted bags are large size bags with greater volume to hold bulk of instant noodle seasonings. This space is produced by the inclusion of a gusset in bottom or in longitudinal sides.

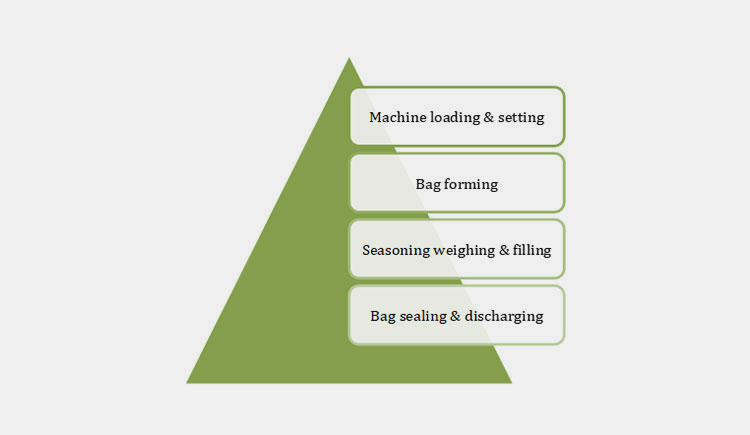

6.What Are The Working Principles Of An Instant Noodle Seasoning Packaging Machine?

There are few working principles on which an instant noodle seasoning packaging machine works. However, it is important to note that each type of instant noodle seasoning packaging machine follows a distinct way for seasoning packaging. Similarly, in this question, we have explained the working process of a form fill and seal instant noodle seasoning packaging machine:

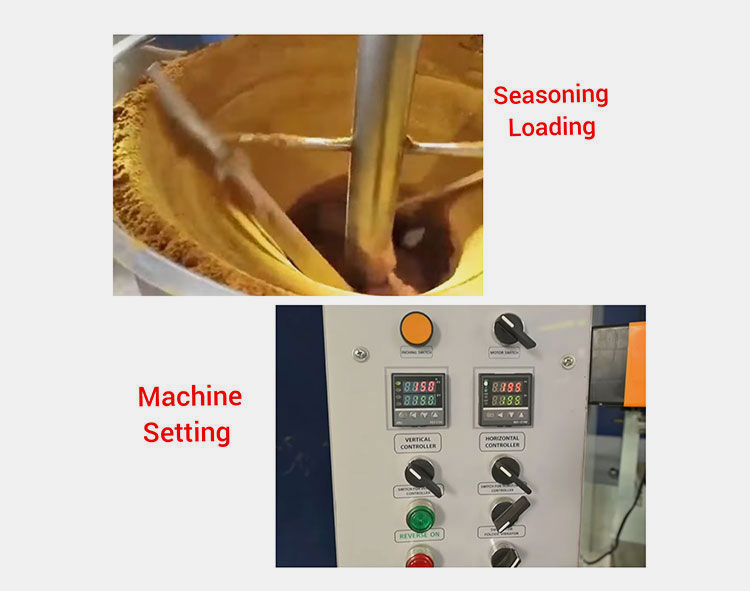

Machine Loading & Setting

Seasoning loading & machine setting- Picture Courtesy: Sama Engineering

The very first step will require an operator to load the sufficient volume of instant noodle seasoning in the hopper of machine. Along with that, supply the machine with a film roll for making bags. At the same time, operator will adjust the setting of machine to run the machine such as the amount of seasoning to be filled in each bag, the temperature of sealing bars, and coding data etc.

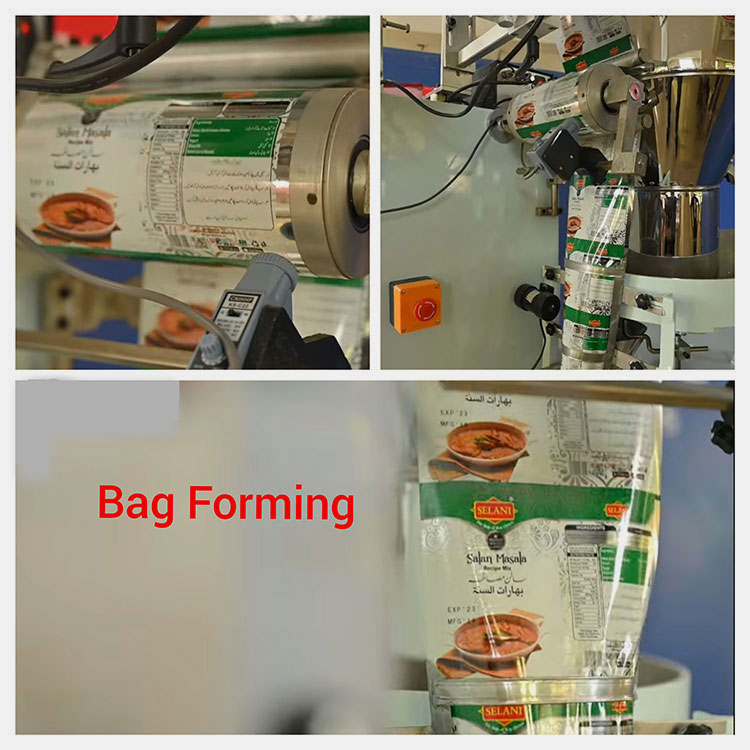

Bag Forming

Bag forming- Picture Courtesy: Sams Engineering

Moving forward, the machine will be switched on which in turn will energize the film holder to adopt continuous movement for film unwinding. As the film reaches to bag forming unit, it will be turned into one-fold by sealing bottom and longitudinal sides.

Seasoning Weighing & Filling

Seasoning weighing & seasoning filling- Picture Courtesy: Sama Engineering

In this phase, the instant noodle seasoning will be weighed using different techniques depending upon the type of machine you are using like auger filler, volumetric cup filler, or multi head weigher. Once weighed, a precise dosage of seasoning will be dispensed into bag.

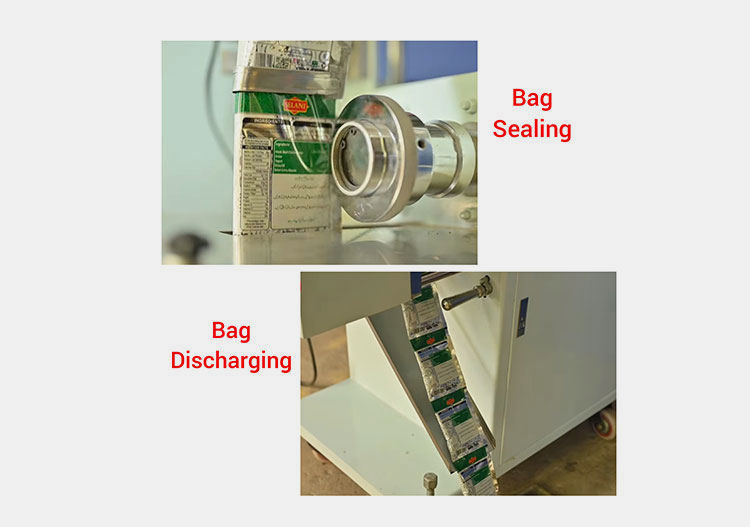

Bag Sealing & Discharging

Bag sealing & discharging- Picture Courtesy: Sama Engineering

Upon seasoning filling into bag, the bag will be tightly sealed from top by using heated sealing bars. Simultaneously, depending upon the operator setting, either the finished bags will be separated apart through cutting or they will be discharged from the machine with perforation only.

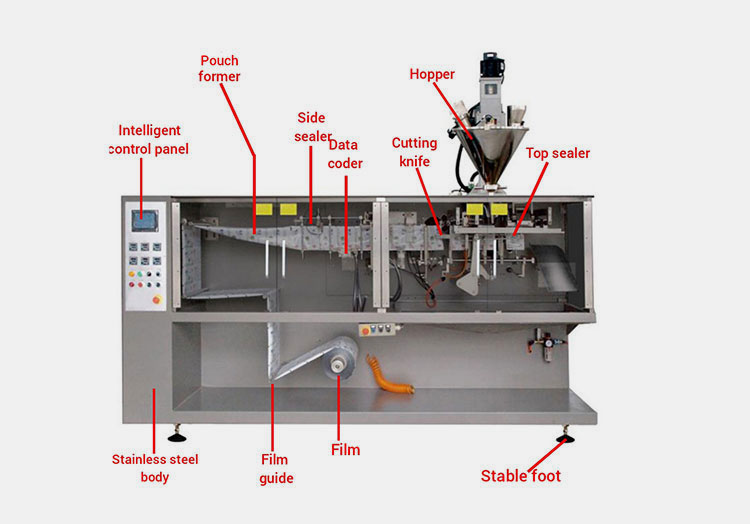

7.Describe The Components Of An Instant Noodle Seasoning Packaging Machine?

An instant noodle seasoning packaging machine consists of the following components:

Allpack- APK-130 Horizontal 4 side seal small salt powder granule sachet machine

Intelligent Control Panel

It refers to the control system of machine which is often located at the top front of machine. It holds over it multiple knobs along with a touch screen display where user set commands regarding the instant noodle seasoning such as the volume for each pack, film unwinding speed, and sealing temperature etc.

Film Guide

Film guide is a tool used to guide the direction and position of film. Therefore, you will find number of film guide rollers for making the unwinding of film a possible task.

Pouch Former

Film former is another critical component of an instant noodle seasoning packaging machine which is used to turn the flat layer of film into one-fold for bag forming.

Side Sealer

Side sealer is a vertical or longitudinal seal located right after the bag former. Its function is to seal the folded film from sides.

Data Coder

Data coder is another important part whose role is to print data on bags regarding instant noodle seasoning such as batch no, manufacturing date, and expiration date etc.

Cutting Knife

Cutting knife is also called a blade which is used to split the finished bags from continuous film.

Hopper

Hopper is a large size stainless steel pot often having a conical or funnel type shape. Its function is to hold the bulk of seasoning before operation and supplying the machine with seasonings for smooth functioning.

Top Sealer

It is a horizontal sealer which seal the filled bag from top, so, that the bag can be discharged from machine and ready for merchandising.

Stable Foot

Four feet are attached to the body of machine which helps in its even placement on the surface.

Film

Film is a thin layer often of plastic, aluminum, or laminated paper. It is inevitable part of an instant noodle seasoning packaging machine as it provides the machine with packaging material.

Stainless Steel Body

The main frame and overall body of an instant noodle seasoning packaging machine is made up of 304 stainless steel which is fully resistant to corrosion and come with antibacterial surface.

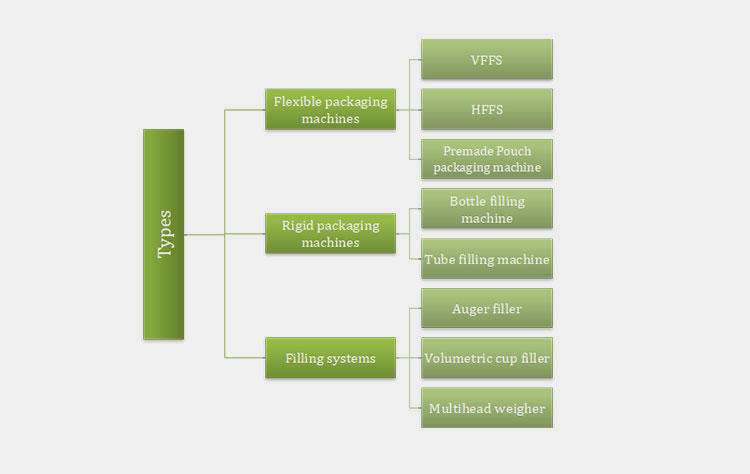

8.What Is The Classification For An Instant Noodle Seasoning Packaging Machine?

As the instant noodle seasonings come in different nature and forms, so is the case with types of machines used for it. These machines help you to get desired output while matching to the specific needs of your materials. Hence, to understand these machines look into the below explanation:

A.Flexible Packaging Machines

VFFS Instant Noodle Seasoning Packaging Machine

Spice VFFS Vertical Full Automatic powder packaging machine- Picture Courtesy: coretamp.com

Vertical form fill and seal instant noodle seasoning packaging machine is fully automatic in technology. It is best suitable to pack all kinds of free-flowing and adhesive seasonings. It has a vertical structure and integrates metering, bagging, weighing, filling, sealing, and cutting.

Working Process

It draws the packaging film from upside located film roll towards downward. During this process, it forms bag, load it with accurately weighed amount of seasoning, close its opening, print data, and then discharge it from machine after its cutting from the film.

HFFS Instant Noodle Seasoning Packaging Machine

Allpack- APK-130 Horizontal 4 side seal small salt powder granule sachet machine

Horizontal form fill and seal instant noodle seasoning packaging machine is high performance machine due to its resilience, productivity and quick changeover. The machine is available in simplex as well as duplex form. In addition, the former give you double production rate than the later. The machine is characterized by its horizontal body with extreme flexibility to pack 3 side, 4 side, twin sachet, and gusseted bottom pouches.

Working Process

The machine performs its function by unwinding the film from roll and pass it from linear horizontal station for packaging. The unwinded film is then guided by the guide rollers and bag former. Simultaneously, the film is turned into a single fold and sealed from vertical sides. After formation, bag is filled with single serving instant noodle seasoning and then sealed from top before its discharging.

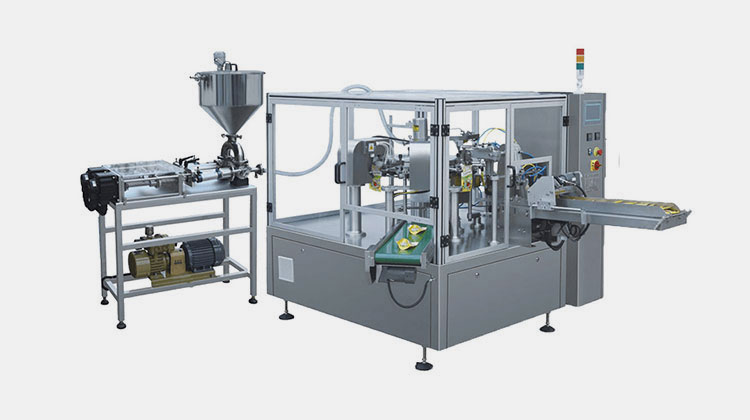

Premade Pouch Instant Noodle Seasoning Packaging Machine

Allpack- APKRL200-Y Rotary Liquid Premade Pouch Filling Machine

This machine by Allpack is highly advanced in technology and fulfill the demand of packing premade pouches with instant noodle seasoning. It can give you exceptional production output because of high automation and additional time that may be wasted on forming bags.

Working Process

It works automatically with no manual interruption. Starting from picking empty bags from magazine, the machine passes them through sequential stations of rotary channel naming seasoning weighing, filling, sealing, coding, and finally discharging.

B.Rigid Packaging Machines

Bottle Filling Instant Noodle Seasoning Packaging Machine

Spices powder automatic bottle filling machine

This type of instant noodle seasoning packaging machine is employed for packing instant noodle seasoning in various types of bottles, jars, and cans. The machine can be integrated with other machines such as bottle unscrambler, capping machine, and labeling machine etc.

Working Process

The machine first accurately weigh the seasoning. Afterwards, when bottles are fed on conveyor belt and they reach under filling head, the machine will begin dispensing weighed volume of seasoning into bottles one by one. Similarly, the filled bottles will be discharged from the machine through conveyor belt.

Tube Filling & Sealing Instant Noodle Seasoning Packaging Machine

Allpack- NF-60 automatic tube filling machine

Tube filling and sealing machine is another type of instant noodle seasoning packaging machine peculiarly brought into the field to pack liquid seasoning for convenient packaging. The machine is available in different automation level as well as with varying specifications.

Working Process

It starts functioning by moving empty tubes from tube magazine towards their fixation in a tube holder. Proceeding further, the weighed volume of instant noodle seasoning is introduced into these tubes, and they are moved for sealing, and embossing. At last, these tubes are ejected out if machine one by one.

C.Filling Systems

Auger Filler- Instant Noodle Seasoning Packaging Machine

Auger Filler- Picture Courtesy: foodmc.co.uk

Auger filler is one of the most popular types of filler used for packing instant noodle seasoning. It consists of an auger, a scrapper, stainless steel hopper, and a motor. This filler is ideally suitable for adhesive instant noodle seasoning powders.

Working Process

When operated, the auger aur a side scrapper adopts a continuous rotary movement in order to keep the powder in good flow condition and avoid accumulation.

Volumetric Cup Filler- Instant Noodle Seasoning Packaging Machine

Volumetric Cup Filler- Picture Courtesy: packaging-labeling.com

Volumetric Cup filler for instant noodle seasoning packaging machine is popularly used for seasoning. It has an integrated system of cups in which fixed amount of instant noodle seasoning is loaded without requiring additional tools. It is suitable for free-flowing and granulated instant noodle seasonings.

Working Process

It works by dispensing the instant noodle seasoning from hopper into the cups placed on a rotary tray. When cup get filled, the rotary turret move leaving the empty cup under filling nozzle. Similarly, the filled cup when reach to filling nozzle drop the dosage downward in bag or container.

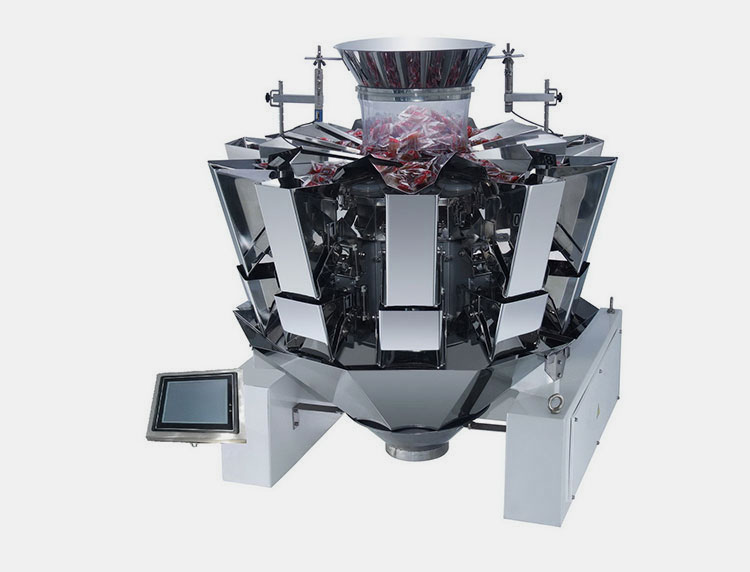

Multihead Filler- For Instant Noodle Seasoning Packaging Machine

Allpack- Weighing Machine/ multi head weigher

As the name indicates, this type of instant noodle seasoning packaging machine is particularly used for excessive volume of seasoning. It can be integrated with form fill and seal machine, premade pouch packaging machine, and bottle packing machine. Multihead filler is suitable for free-flowing powder and granulated seasonings.

Working Process

It follows simple working procedure where large volume of seasoning is first loaded into the hopper. Once powered on, the machine will start vibration leading the loaded seasoning to move forward. Similarly, the constant vibration will keep pushing the seasoning until it reaches the filling compartment. At last, precise dosage of seasoning will be discharged into the awaiting containers.

9.Highlight The Uses Of An Instant Noodle Seasoning Packaging Machine?

Instant noodle seasoning packaging machine has a broad spectrum in terms of applications. Ergo, you can employ it far beyond from mere noodle seasoning packaging. Let's know some of these areas!

Food Industry

Chicken legs with various condiments- Picture Courtesy: stocksy.com

In food industry instant noodle seasoning packaging machine automates packaging of seasoning for instant noodles, snacks, and condiments, ensuring consistency and convenience. Along with that, products like coffee, milk powder, coco powder, and beverages can also be packed by this machine.

Cosmetic Industry

Various liquid cosmetic bottles- Picture Courtesy: packagingoftheworld.com

An instant noodle seasoning packaging machine has also good demand in cosmetic industry for the packaging of powders, granules, and liquids such a as shampoo, lotion, hand washing gel, and hair dye etc.

Pharmaceutical Industry

Pharmaceutical powder with medicines- Picture Courtesy: coretamp.com

The machine provides precise dosing and hygienic containment for single-dose medications, supplements, and herbal products. Moreover, an instant noodle seasoning packaging machine is ideal for clinical trials and retail packaging.

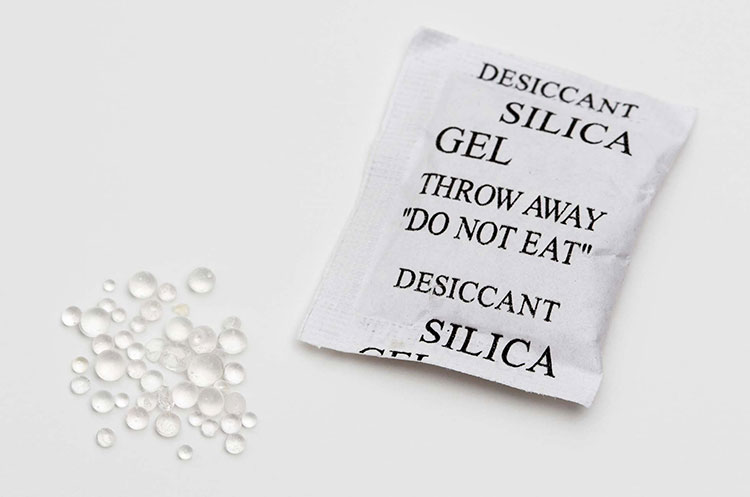

Chemical Industry

Silica gel bags- Picture Courtesy: startsat60.com

The use of an instant noodle seasoning packaging machine can also be found in chemical industry where it packages chemicals and sample-sized products for easy use and distribution. The common examples include glue, silica gel, cleaning agents, and pesticides etc.

Agriculture Industry

Multiple food grains- Picture Courtesy: ussharks.com

Agriculture industry is among other applications of an instant noodle seasoning packaging machine where thousands of grains and seeds are processed everyday.

10.Is there Any Leak Test For An Instant Noodle Seasoning Packaging Machine?

Mere packing your instant noodle seasonings in enclosed bags and containers does not validate their tight sealing. So, how can you confirm that your finished packages are free from leaks? Obviously through a leak test! This test provides you best notable means that must be practiced for satisfying customers and to remain strict to quality control. It has been described below:

Pack-Vac Leak Detector- Picture Courtesy: foodprocessing.com.au

Vacuum Leak Test

Among other leak tests, vacuum leak test is the suitable one which aims at identifying the possible leaks of an instant noodle seasoning package through the principle of vacuum.

- First, the finished package is placed in a water filled chamber, afterwards, air is evacuated from the chamber.

- Secondly, pressure is generated inside this chamber to detect leak.

- During this stage, if bubbles start generating from package, then there is the presence of leak.

- On the other hand, if the package remains same even after enough pressure, then the package is fully protected against leakage.

11.What Quality Standards Should An Instant Noodle Seasoning Packaging Machine Meet With?

As an instant noodle seasoning packaging machine is manufactured to deal with sensitive materials like food, it is significant that it must adhere certain quality standards. Similarly, it will ensure that the machine is safe for objects. Below are few necessary quality standards:

Quality Standards icon- Picture Courtesy: estartupindia.com

- GMP: The machine must comply the standards and regulations circulated by Good Manufacturing Practices which is an international quality standard organization.

- FDA: An instant noodle seasoning packaging machine should also adhere to the principles and policies established by an American agency of Food and Drug Administration.

- ISO: International Organization for Standardization is another organization that has presence all around the world in different countries. Therefore, make sure your machine is meeting with all these standards.

12.How To Counter The Spontaneous Problems Caused By An Instant Noodle Seasoning Packaging Machine?

It is certain, that while operating an instant noodle seasoning packaging machine it may show a sudden disruption due to technical error. However, this minor issue may trigger you. So, this question has been composed to make you relax and enable you to be the troubleshooter of your own machine. Let's explore how!

| i. Weak, partial, or no sealing | ||

Highlighted sealing of instant noodle seasoning sachet- Picture Courtesy: thecountrycook.net |

Cause:

Broken or disconnected sealing bar wire Too low temperature Loose sealing jaws Dirty sealing jaws |

Solution:

Replace the wire with new suitable one or connect it to power properly Increase the temperature of sealing bars to suitable level Tight the sealing jaws Clean the sealing jaws |

| ii. Blocking of filling nozzles while dosing | ||

Displaying blockage of filling nozzle- Picture Courtesy: ciasrl.it |

Cause:

Incompatible filling system for seasoning Collection of debris in filling nozzle Low time duration for package filling |

Solution:

Use the type of filling system as per the requirement of particular seasoning (check question no 8 for understanding) Clean the filling nozzle Increase the time duration for filling each package |

| iii. Package leaking | ||

Leaked tomato ketchup sachet |

Cause:

Package is not sealed properly Wrong cutting during package splitting |

Solution:

Check the sealing temperature, sealing jaws, and fill time duration Adjust the distance between sealing and cutting station |

| iv. Bottles falling during conveying | ||

Marked bottle separators- Picture Courtesy: JDA Progress |

Cause:

The size of bottles is too smaller than the width of conveyor Bottle separator is not functioning properly |

Solution:

Readjust the width of conveyor in accordance with the size of bottles Check if the bottle separator is disconnected |

| v.Overfilling of bottles during operation | ||

Control Panel for setting machine- Picture Courtes: Sama Engineering |

Cause:

The setting of machine is incorrect |

Solution:

Set the amount of seasoning to be filled in each pack by using control panel |

| vi. Instant noodle seasoning dispersion during filling | ||

Highlighting the gap between filling head and bottle mouth- Picture Courtesy: All-Fill Inc |

Cause

Gap between the bottle head and filling head Too small bottles |

Solution

Adjust the filling head to that of bottle Use bottles as per the specifications of machine |

13.What Tips Should Be Followed For Getting The Best Instant Noodle Seasoning Packaging Machine?

When selecting an instant noodle seasoning packaging machine, several factors need consideration, including:

Adaptability

Instant noodle seasoning powder & liquid- Picture Courtesy: buzzfeed.com

No doubt, every manufacturer desire to have a machine that can be used for many objects, so, they will not be bothered to bear further investment. In such case, you need to look for an instant noodle seasoning packaging machine that can accommodate various packet sizes, packaging materials, and types of seasoning to adapt to changing production needs.

Cost

Calculating cost- Picture Courtesy: superprof.co.in

Evaluate both the initial purchase cost and long-term operational expenses such as maintenance cost, energy consumption, and potential downtime of an instant noodle seasoning packaging machine.

Specifications

Technical specifications icon- Picture Courtesy: internetdevels.com

Make sure to consider the specific features offered by an instant noodle seasoning packaging machine which you are intending to purchas. For example, automation levels, packaging speed, filling accuracy, sealing quality, and compatibility with different packaging materials etc.

Quality

Another crucial tip is to check the machine's build quality, durability, and reliability to ensure consistent performance and longevity. Most importantly, the construction material which is in direct contact with material must be complying international and local quality standards.

Conclusion

It's time to wrap up this detailed buying guide on an Instant Noodle Seasoning Packaging Machine. Was it helpful? We hope you have enjoyed this review and have found your perplexities regarding the machine solved now. So, what's your next step? Well, it must be an instant one as this machine can be lucrative for your business. You can earn a good reputation among the uncountable lovers of noodles by supplying them with perfectly packed instant noodle seasoning. So, no need to make further delay and contact us now to get what others are wishing for!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide