Box Sealer Machine: The Complete FAQ Guide In 2025

Are you looking for a quick and easy way to create tamper-proof seals on boxes? Look no further than the box sealer machine! This revolutionary packaging equipment allows you to quickly and securely close any type or size of box.

From lightweight Kraft paper boxes to heavy-duty plastic containers, the box sealer machine is designed to ensure that your product arrives at its final destination looking pristine and protected from tampering.

With its adjustable clamping pressure and simple operation, a box sealer machine is essential for any business needing reliable sealing solutions. Read on to learn more about how this innovative solution can make your job easier!

1.What Is A Box Sealer Machine?

A box sealer machine is a type of automated packaging equipment that seals the tops and bottoms of boxes with adhesive tape. By sealing box tops and bottoms with adhesive tape, box sealers provide a secure way of shipping products while preventing them from being opened or tampered with during transit.

These essential tools can be used in various industries, such as warehousing, logistics, retail shipping, food processing, and pharmaceuticals, for sealing boxes filled with products such as clothing, food items, drugs, and medical supplies.

Box sealer machines come in various sizes and can be customized to meet specific needs. Some models are designed to work with boxes of any size, while others require particular box dimensions. Box sealers can also be equipped with other features, such as labeling and coding systems, to streamline the packaging process further.

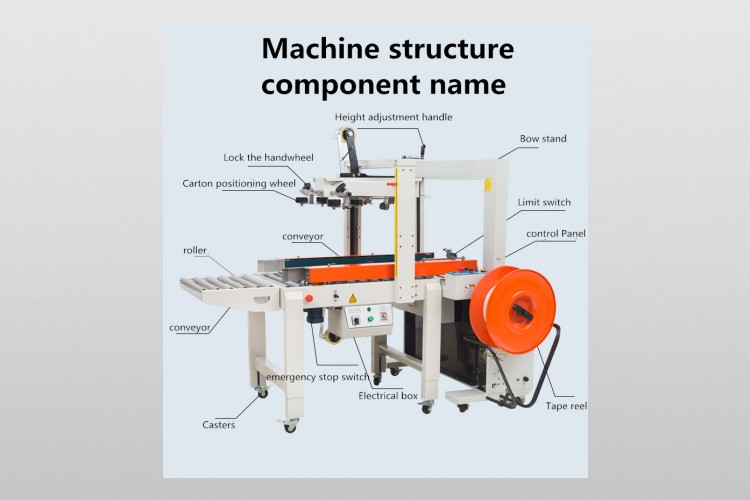

2.What Are The Components Of A Box Sealer Machine?

The components that make up a box sealer machine include:

- Conveyor system

This is the backbone of the box sealer machine, responsible for moving the box along for sealing. It usually consists of two rollers, a motor, and a drive system.

- Sealing head

This is the box sealer’s ‘working arm,’ which applies adhesive tape or glue to the box. This part contains an adjustable height and angle setting for sealing different box sizes and a pressure roller for box opening and closing.

- Pressure roller

This is the box sealer’s ‘closing arm,’ which presses down on the box to ensure a tight and secure seal. The pressure roller is adjustable for different box sizes and materials.

- Tape or glue dispensing system

This component applies the adhesive to box seals. It includes a motor, drive system, pulley, and box feeder for the tape or glue.

- Control panel

This is the box sealer’s ‘brain,’ which controls the entire machine functions, including box feeding, box sealing speed, and pressure roller settings. The control panel also contains a box size sensor and box counter for easy box tracking.

3.What Are The Advantages Of A Box Sealer Machine?

Box sealer machines offer a range of benefits that make them the ideal choice for businesses looking to streamline their production processes. They include:

- Increased Efficiency and Speed

Box sealer machines are designed to increase efficiency, speed production times, and reduce material and labor costs. By creating an automated process, boxes can be sealed quickly with minimal effort or waste of materials.

- Cost-Efficiency

Box sealers are highly cost effective and designed to reduce labor and material costs. Companies can save on labor costs and materials by eliminating manual sealing.

- Improved Safety

Box sealers offer improved safety standards in comparison to manual sealing processes. They provide a much safer working environment, eliminating the risk of accidents or injuries due to an automated process.

- Consistent Quality

Box sealers are designed to ensure a consistent quality of the product. By providing an automated process, boxes are sealed securely and quickly with minimal effort or wastage of materials. This ensures the highest level of product quality and consistency.

- Variety of Accessories

Box sealers come with various accessories, such as adjustable height and sealing temperatures. This allows companies to customize the box sealer machine to meet their specific needs and applications.

- Easy Maintenance

Box sealers come with easy-to-maintain components that reduce downtime, increase productivity, and save money on labor costs. By providing an automated process, boxes are sealed quickly and securely with minimal wastage of materials.

4.What Are The Applications Of A Box Sealer Machine?

Box sealer machines are widely used in various industries and applications to provide an efficient and secure way of sealing cartons and boxes. Such industries include:

- Food and Beverage Packaging

Box sealer machines are commonly used for packaging food products for retail. They help to maintain the freshness of food items by securely sealing them inside boxes or containers.

- Pharmaceutical Industry

For pharmaceutical companies, box sealers are essential for securely packaging drug products that must be shipped to customers.

- Cosmetic Industry

Box sealers are ideal for sealing cosmetic products into box containers and protecting them from damage during shipping.

4.What Are The Working Principle Of A Box Sealer Machine?

A box sealer machine works by using two strips of adhesive tape on each side of the box to form an airtight and watertight seal. The process starts when the operator feeds the box into the machine and is passed through a series of rollers and heated plates.

The heat activates the adhesive on the tape, which then bonds together to form an airtight seal. Once sealed, the box can be securely stored or shipped without fear of contents spilling out.

5.What Are The Different Types Of Box Sealer Machines Available On The Market?

A) Manual box sealer machines

These machines require manual operation to seal the cartons. They use a hand crank handle or foot pedal to activate pressure onto the adhesive tape to securely close the box flaps.

Components

Manual box sealer machines typically consist of a base frame, an adhesive roller and belt system, adjustable side guides, tensioning arm, manual top drive wheel, manual bottom drive wheel, safety guard or cover plate, and power supply.

The base frame supports the other components of the machine and ensures its stability during use. The adhesive roller and belt system applies adhesive to the sealed box and is typically adjustable.

The adjustable side guides ensure that the box is appropriately aligned and sealed before it moves onto the manual top drive wheel for sealing. The manual top drive wheel applies pressure and tension to seal boxes, while the manual bottom drive wheel helps to hold them in place as they move through the machine.

Lastly, manual box sealer machines may also include a safety guard or cover plate to protect the user and ensure that all safety regulations are adhered to. In addition to these components, manual box sealer machines require an external power supply.

Working Principle

Manual box sealer machines use pressure and heat to create a strong bond between the box flaps. The manual machine simultaneously seals one side, requiring manual operation.

To begin sealing, the operator places the box in the manual machine’s jaws and adjusts them so that they will securely hold the upper and lower flaps of the box. The manual machine then uses heated plates on either side of the box to heat up and create a bond between the two flaps.

Once the heat has been applied, pressure is also involved to ensure a firm seal is achieved. This manual process can be repeated as many times as necessary, depending on the size and shape of the box. As soon as the manual box sealer machine has successfully sealed the box, it can be removed and used for transport or storage.

Applications

Manual box sealer machines are versatile equipment for various packaging and sealing tasks. Typical applications include carton closing, shrink wrapping, banding, case packing, and palletizing. Manual box sealers provide fast and consistent closure on just about any size of corrugated boxes made from various materials, including cardboard, plastic, and paper.

B) Fully-Automatic box sealer machines

These are fully automated and require minimal human intervention for operation. They automatically detect the box size, adjust the machine settings accordingly and apply adhesive tape to close the box flaps securely.

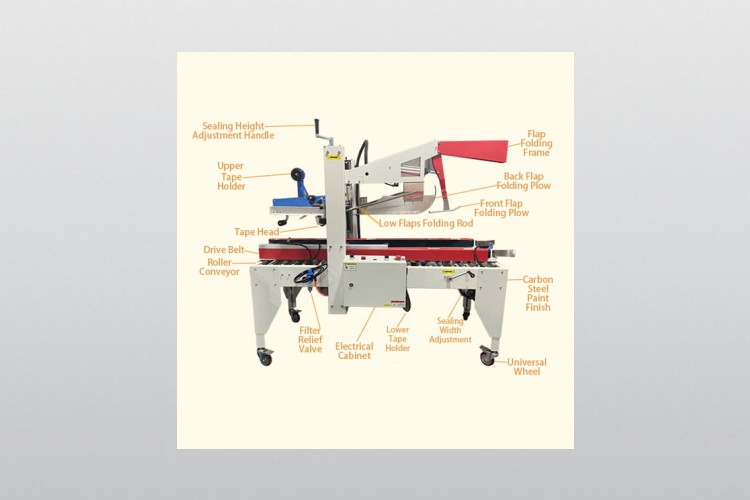

Components

Automatic box sealer machines comprise several components that complete the sealing process.

These components include a box transport system, conveyor belt, automatic tape dispenser, automatic flap closers, automatic hot glue guns, automatic lid openers, automatic top covers, automatic bottom covers, and automatic corner closers.

The box transport system is responsible for moving the boxes from one station to another during sealing. The conveyor belt ensures that all boxes are transported at a consistent speed. The automatic tape dispenser attaches adhesive tape to the boxes and seals them in place.

Automatic flap closers close the flaps of each box securely. The automatic hot glue guns apply an adhesive to secure any overlaps, while automatic lid openers and top/bottom covers open and close the lids on boxes that have been sealed. Finally, automatic corner closers seal the corners of a box shut.

Working Principle

These machines use a combination of taping, gluing, or hot-melt adhesive to ensure the box is securely sealed. The automatic sealing process begins with the operator placing an empty box on the infeed conveyor belt.

Once in position, the automatic box sealer machine will automatically measure and adjust the box’s height, width, and depth to ensure a secure fit. It then applies a combination of adhesive, tape, or hot-melt glue to close the box’s top flaps.

Applications

Automatic box sealer machines are used in a variety of industries and applications. In the food industry, automatic box sealers are used for packaging processed food items for distribution.

In the pharmaceutical industry, automatic box sealers can package drugs, tablets, and capsules into individual containers. Automatic box sealers also have many industrial applications, such as packaging and sealing items like electronics, automotive parts, and other large-volume materials.

C.) Semi-automatic box sealer machines

These automated machines require human intervention, such as loading and unloading boxes, tape change, and changing box size change.

Components

Semi-automatic box sealer machines typically consist of:

- An adjustable conveyor belt.

- A control panel.

- An electric motor.

- A set of guide rails for guiding boxes along the conveyor.

- A sealing head to apply pressure and heat to close the box flaps.

- A semi-automatic sealing tape dispenser.

Also, the semi-automatic box sealer machine includes a film holder, which allows users to apply a layer of film over the top of the boxes before they are sealed. All semi-automatic box sealer machines feature adjustable speed and sealing pressure settings, as well as a timer that allows users to adjust the duration of the sealing process for each box.

Working Principles

Semi-automatic box sealer machines are machines that use heat and pressure to seal cardboard boxes. This machine uses a heating element to heat two strips of plastic tape, which are applied across the box’s top and bottom. Pressure is then applied to ensure a secure seal. Once the seals have been used, the box is ready for packaging.

Applications

Semi-automatic box sealer machines can be used in a variety of industries, including food processing, pharmaceuticals, electronics, and more. These machines can be used in the food industry to package food items such as cereals, pasta, and snacks for retail stores. Furthermore, semi-automatic box sealers are also useful in healthcare facilities, where semi-automatic boxes can be used to quickly and securely package items for sterilization.

6.What Is The Difference Between Automatic And Semi-Automatic Box Sealer Machine?

a) Automatic box sealer machine

b) Semi-automatic box sealer machine

The major difference between an automatic box sealer machine and a semi-automatic box sealer machine is the level of automation. An automatic box sealer machine is fully automated, meaning all processes are completely automated with minimal human intervention.

This includes box transport, product placement, taping, and case sealing operations. The process typically requires no manual labor or resetting of box sizes, making it a more efficient option for high-volume production lines.

A semi-automatic box sealer machine offers some degree of automation but still requires manual intervention to operate it properly. Typically, this includes manually loading boxes onto the conveyor and manually placing products into the box prior to box sealing operation.

Additionally, these machines will require manual adjustment for box sizes. While semi-automatic box sealers are more affordable and may be ideal for smaller production lines, they require more manual labor and can be less efficient than automatic box sealer machines.

7.What Products Can Be Sealed Using A Box Sealer Machine?

Box sealer machines are used to close and seal box flaps for a variety of products, such as:

- Food products

Box sealer machines quickly and securely package food items such as snacks, frozen foods, and dry goods.

- Medicine

Box sealers are used to create airtight containers for medicines in order to keep them fresh and safe during storage and transport.

- Cosmetics

Box sealers can package cosmetics such as makeup, lotions, and skincare products.

- Household goods

Box sealers can be used to package various household items, such as small appliances, tools, and electronics, for safety during transport and storage.

8.What Materials Can A Box Sealer Machine Handle?

A box sealer machine can handle a variety of materials, including:

- Cardboard

Box sealers use heated blades to quickly and efficiently close and seal cardboard boxes, providing consistent box closures that won’t come undone in transit or storage.

- Corrugated plastic

This material is often used for packaging products such as food, electronics, and cosmetics due to its strong design and waterproof properties. A box sealer allows for quick and easy box closure on these items.

- Polyethylene bags

These are usually formed with film rolls that provide an airtight closure when sealed by a box sealing machine, making them ideal for delicate shipping items like pharmaceuticals.

- Bubble wrap

Bubble wrap is often used as a cushioning material in box sealers, providing extra protection for items during shipping.

9.Are There Any Customization Options Available For Box Sealers Machines?

Yes, box sealer machines can be customized to fit your packaging needs.

Box sealer machines can be configured with different sealing speeds and even feature adjustable height settings for boxes of various sizes. Additionally, box sealers can be equipped with multiple accessories, such as box width sensors, corner cutters, and conveyor systems that ensure box seals are secure and uniform.

Also, many box sealers come with a wide variety of features that enable you to customize the machine to meet the specific requirements of your application. With customization options available, box sealers can be tailored to provide an ideal solution for various industries, including food service, beverage distribution centers, pharmaceuticals, manufacturing plants, and more.

10.What Are The Safety Measures Taken When Using A Box Sealer Machine?

- Wear Protective Gear

When using box sealer machines, wearing personal protective equipment such as eye protection, gloves, and long-sleeved clothing is essential. This protects workers from any potential hazards caused by the box sealer machine.

- Keep Clear of Moving Parts

Box sealer machines have moving parts that can be dangerous if workers are not careful. It is essential to stay clear of the box sealer machine while in motion and avoid getting close to any of its moving parts.

- Regular Maintenance

To ensure the box sealer machine is working correctly and safely, regular maintenance should be carried out on the box sealer machine. This includes checking for any wear and tear, cleaning all parts of the box sealer machine, and ensuring all safety features are in working order.

- Follow Instructions

All box sealer machines come with an operator’s manual that outlines the proper use and safety measures to be taken when using the box sealer machine. Reading and understanding these instructions is essential before using the box sealer machine.

- Use Appropriate Box Sizes.

It is essential to use boxes of an appropriate size for the box sealer machine you are using, as boxes that are too large or small can cause problems with the box sealing process.

11.What Are The Common Problems Associated With Using A Box Sealer Machine And Their Possible Solutions?

- Poor Sealing Quality

Another issue is that box sealer machines can encounter poor sealing quality due to incorrect settings on the device.

Solution

To ensure good box seals, it’s essential to check that the adjustable speed, temperature, and length of the box seal are set correctly. Additionally, it would help if you regularly inspected your box sealer for any wear or damage impacting the quality of box seals.

- Jamming

One of the most common problems with box sealer machines is that they can be prone to jamming. Jamming happens when a box or other material gets stuck in the machine and prevents it from functioning correctly.

Solution

This issue can often be solved by cleaning out debris around the box sealer and ensuring that materials are put into the machine properly.

- Difficulty in Adjusting Settings

It can sometimes be difficult to adjust settings on box sealers for different box sizes/shapes. Solutions

Selecting box sealer machines with adjustable settings to fit the box being sealed or using a box sealer that is designed with pre-set options for commonly used boxes.

- Limited Tape Capacity

Box sealers often have limited tape capacity, which forces users to refill them with tape frequently.

Solutions

Choosing box sealing machines that are designed for larger volumes of packaging and employing an automated system for restocking tapes when they run low in the box sealer machine’s storage bin.

- Overheating

Box sealer machines can be prone to overheating due to improper ventilation or incorrect usage.

Solutions

Ensuring that box sealer machines are well ventilated, using a box sealer with cooling capabilities, and keeping the box sealer machine away from direct sunlight.

12.Is There An Easy Way To Monitor And Troubleshoot The Box Sealer Machines?

Absolutely! With the right box sealer machine maintenance tools, you can quickly and easily track the performance of your box sealers. That way, you’ll be able to identify potential problems before they become costly repairs or replacements.

To do this, consider using a box sealer machine monitor system. This monitoring technology lets you see real-time data from your box sealer machines, such as temperature readings and humidity levels.

You can also set up alerts that let you know when a box sealer machine is malfunctioning or has an issue that needs attention. Additionally, some systems will provide a graphical analysis of your box sealing process so you can better understand how changes in temperature or other factors affect the quality of your product packaging.

14.What Are The Maintenance Procedures Of A Box Sealer Machine?

Maintenance of box sealer machines is critical to keeping them in working order and ensuring they remain safe and efficient. Therefore, the following maintenance procedures should be adhered to:

- Inspection

The essential step in maintenance is inspecting the box sealer machine before each use. Inspecting the box sealer includes visually examining the box sealing bar and tape heads and checking all moving parts for any signs of wear or damage.

- Cleaning

Cleaning is also an important part of box sealer maintenance. All surfaces should be wiped down with a cleaning solution after each use, and box sealers should be thoroughly cleaned at least once a month.

- Lubrication

It is also necessary to lubricate box sealer machines regularly, using a non-petroleum-based oil per the manufacturer’s instructions. This will help keep all moving parts in good working order and reduce wear and tear on the box sealer machine.

- Testing

Box sealer machines should be tested before each shift to ensure safety and efficiency. This includes checking all settings on the box sealer to ensure they are correct and trying the motion of parts and running cycles if necessary.

15.What Factors Should Be Considered Before Purchasing A Box Sealer Machine?

The following factors should be considered before investing in a box sealer machine.

- Speed

Depending on the number of boxes you need to process in a day, it is essential to choose the right type of box sealer machine that will meet your production needs.

- Operating cost

Consider the operating cost of box sealer machines, such as energy consumption and maintenance costs. High-end box sealers can be more expensive to run than their counterparts, so it is vital to consider the long-term costs before making your purchase.

- Durability

When investing in a box sealer machine, buying a device that is robust and built with quality materials is essential. The box sealer should withstand daily wear and tear and operate efficiently despite being used in harsh environments.

- Ease of use

Your box sealer should be easy to use and understand. Otherwise, it could cause frustration and slow down production. Look for box sealers with intuitive controls and a user-friendly design so that your team can quickly learn how to operate the box sealer machine.

- Box Size

Ensure the box sealer you purchase suits the box sizes you need to process daily. Box sealers come with different box size capabilities, so make sure you buy the box sealer that can meet your production requirements.

Conclusion

Box sealer machines are wonderful additions to any business that needs to send out products regularly. Not only do they save time, but they also ensure that your products arrive at their destination securely and without damage. If you’re interested in purchasing a box sealer machine for your business, we highly recommend contacting Allpack. We have a wide selection of machines to choose from, and our team is incredibly knowledgeable about each one. We’re confident that you’ll find the perfect machine for your needs and that you’ll be happy with your purchase.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours