Ice Pop Packaging: The Complete FAQ Guide In 2025

The invention of ice pop was an accident but now it is a favorite treat of people in summer. A lick of this sugary and fruit ice pop is like a cool breeze on sunny days. But how quality and taste of ice pop is preserved?

The answer is with ice pop packaging. This packaging upholds the taste, smell and texture of the ice pop. The ice pop packaging has a prime value for its protective characteristics and product identification. A vibrant and color popping ice pop packaging tempts consumers and boosts impulse buying.

Do you want to understand various essential aspects of ice pop packaging then buckle up for a mindboggling journey.

1.What is Ice Pop?

Ice Pop

An ice pop is a kind of frozen dessert that every so often comes with a stick protruding from its central part. These sticks provide support for handling ice pop. It is created by freezing sugary fruity liquids and fruit juices. Commercially, ice pops are formulated from sugars, corn syrup, fruit essence, flavoring agents, and color dyes.

It was first invented by a young 11-year-old kid named Frank Epperson in 1905. He patented his creation in 1924 by giving it the name Popsicle®.

2.What is Ice Pop Packaging?

Ice Pop Packaging

Ice pop or ice popsicle packaging is defined, as a protective material that completely wraps the frozen treats. Ice pop packaging is vital in the distribution, storage, and sales of ice pop.

It goes beyond just wrapping ice pop and includes every design aspect like creating and testing packaging. Ice pop packaging is a flexible and semi-rigid hollow covering-like container for transporting ice pop

Ice pop packaging is an exciting and striking container that comes in every shape, format and design style to engage customers.

3.Why Choose Ice Pop Packaging?

Ice pop packaging is a robust and sturdy all-rounder that is essential in extending the retail shelf of the ice pop and acts as a barrier to reduce its damage and spoilage. Here is a list of reasons why buyers and sellers prefer ice pop in packaging.

Extreme Protection

Extreme Protection with Ice Pop Packaging- Picture Courtesy: Dieline

The first and foremost important reason for ice pop packaging is its protection. It protects ice pop against all odds of temperature changes, moisture, dryness, etc. It is made with durable material that protects ice pop from mechanical stress during rough handling and bumpy ride. With ice pop packaging, there is no risk of spill and mess.

Maintaining Freshness

Maintaining Freshness with Ice Pop Packaging- Picture Courtesy: Sirane Group

Yes, with ice pop packaging brands can serve their products intact to the customers. Enclosure of ice pop inside the packaging keeps it free from dust, debris, and microbial contamination. Thus, ice pop lovers can enjoy the yummy delicious flavour and fruity fragrance of ice pop.

Attraction and Impulse Buying

Attraction and Impulse Buying with Ice Pop Packaging- Picture Courtesy: Pinterest

Vibrant and stylish ice pop packaging goes a long way in captivating buyers than simple ice pop sticks. With bold and eye-catching ice pop packaging, products stand out in the display freezer and this striking packaging certainly increases the sale chance.

Branding and Marketing

Branding and Marketing with Ice Pop Packaging- Picture Courtesy: Packaging of the World

Ice pop packaging can serve as a brand model that advertises the ice pop to users. Consistent use of colors, font and coherent placement of logos on ice pop packaging aids in retaining brand information in consumers' minds, leading to the creation of a loyal customer base and constant repurchase.

Utility and Portability

Utility and Portability with Ice Pop Packaging- Picture Courtesy: inyourarea.co.uk

Both buyers and sellers benefit from the convenience and utility of the ice pop packaging. It comes with handles, sticks, and zippers that aid in storing, carrying, and handling the ice pop. It comes in a single-pack that is advantageous to hard-pressed individuals as it is eaten while on the move.

4.What are Popular Ice Pop Packaging Types?

To captivate kids and young-at-heart adults, manufacturers have launched a variety of ice pop packaging styles. These packaging types are discussed in detail below:

Single Serve Ice Pop Packaging

It includes numerous ice pop packaging formats like:

Pillow Pouch

Pillow Pouch Ice Pop Packaging- Picture Courtesy: Trend Hunter

It is a flexible pouch ice pop packaging manufactured from lightweight plastics. It has a standard top, bottom, and middle seal that creates a pillow-like appearance. It has more labeling and marketing area than other ice pop packaging.

Paper Tube

Paper Tube Ice Pop Packaging- Picture Courtesy: Frozen Food Europe

It is a cylindrical tubular structure and holds single-serving of ice pop. It is typically formed from compostable paper that offers more sustainability. These paper tubes offer a sophisticated look for attracting high-end customers.

Push-Up Pop

Push-up IcePop Packaging- Picture Courtesy: Delish

This ice pop packaging is a rod-shaped tube that has a plunger. This mechanism forces ice pop to pop up to enjoy it. Its outer wrap is manufactured using plastics and may be transparent. Push-up ice pop packaging is favored by novelty brands.

Plastic Sleeve

Plastic Sleeve Ice Pop Packaging- Picture Courtesy: Foodal

It is a long cylindrical tube and less costly than other ice pop packaging, making it a favored choice for cost-conscious consumers. It is manufactured from clear plastic that allows ice pop lovers to easily view the inner ice pop content.

Triangular Ice Pop Packaging

Triangular Ice Pop Packaging- Picture Courtesy: Bargo Wholesale

As the name indicates, this packaging is a triangular ergonomic design that offers a unique look to ice pop packaging in contrast with classy rectangular or pillow-shaped packaging. This distinct look mesmerizes customers by standing out on retail shelves.

Cardboard Box

Cardboard Box Ice Pop Packaging- Picture Courtesy: Red Dot Award

It is an oblong case or box for storing the ice pop product. It has an optimum printing area that allows brands to showcase their brand logos and values.

Cardboard Sleeve

Cardboard Sleeve Ice Pop Packaging- Picture Courtesy: Dieline

It is a rectangular wrap made from cardboard or paperboard. The function of individual cardboard sleeves is hygiene and cleanliness of ice pops. These cardboard sleeves are less pricey than plastic semi-rigid containers.

Cup

Cup Ice Pop Packaging- Picture Courtesy: Bulla Dairy Food

This is round packaging with a flat base, packing a one-time serving of the ice pop. It is equipped with lids or overcaps that assist in resealing the ice pop packaging.

Multi-Serve Ice Pop Packaging

Ice Pop Carton

Multi-Serve Ice Cardboard Carton- Picture Courtesy: Unilever

It is a four-sided cardboard or paperboard container having separate compartments for placing individual ice pops. This often comes in a family pack and has 4-5 ice pop stick packaging.

Tub

Tub Ice Pop Packaging- Picture Courtesy: Dieline

These are large quadrilateral, square, or round-shaped containers, storing multiple servings of the ice pop packaging. It is easily reclosed and covered using a Snap-On lid.

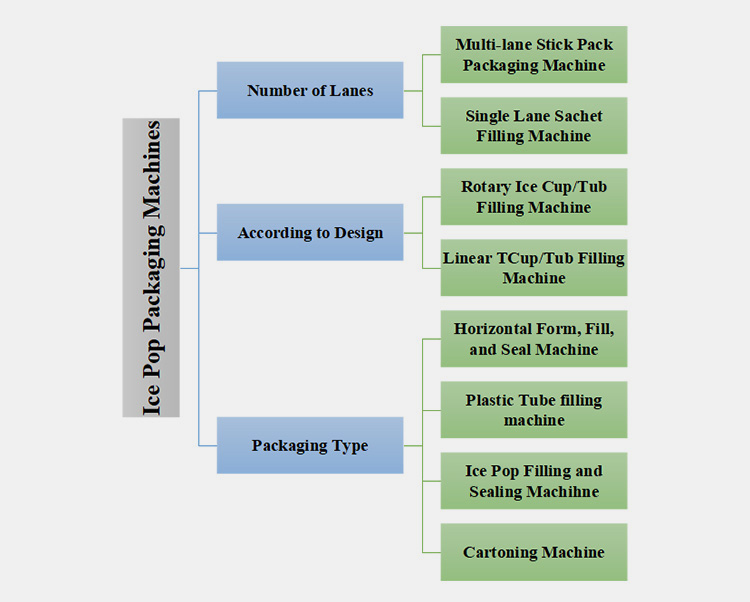

5.What are Basic Ice Pop Packaging Machines?

Ice pop has diverse packaging styles and to cater to such an assortment of ice pop packaging styles, different kinds of ice pop packaging machines are seen in the production plants. The detail of these machines is discussed below:

Classification According Number of Lanes

Multi-lane Stick Pack Packaging Machine

Allpack Multi-Lane Stick Pack Packaging Machine

This machine creates a stylish product appearance and, therefore is routinely seen in packaging plants. Due to its numerous lanes, it has a higher production capacity and efficiency than a single-lane sachet packaging machine. The packaging film is cut into numerous strips during ice pop packaging with this machine. The number of these cut strips depends upon the number of lanes. These strips travel to their respective lanes for forming, ice pop filling, and sealing.

Single Lane Sachet Filling Machine

Single-Lane Sachet Packaging Machine

This machine creates one ice pop packaging at a time and therefore, it is typically best suited for small and medium enterprises. It has one set of hoppers, a forming station, and horizontal sealers. The stick-like packaging is created by folding and sealing two edges of packaging film at the forming station. After ice pop filling, the packaging is heat-sealed by horizontal sealing jaws.

According to Design

Rotary Cup/Tub Filling Machine

Rotary Cup/Tub Filling Machine- Picture Courtesy: BE Machinery

This system is perfect for production with small spaces, as it has a compact configuration. Optimum efficiency and seamless operation are only possible with the rotary cup or tub-filling machine. In this machine, the cup after loading into the turntable pocket travels to the cleaning, filling, lidding, and capping area in sequence.

Linear Cup/Tub Filling Machine

Linear Cup/Tub Filling Machine- Picture Courtesy: bzmachinery.net

This machine is conveniently added to existing productions to increase output capacity. It has a clean and modular configuration and features large conveyors for the transportation of ice pop cups or tubes. These containers move to the filling area, where efficient filling equipment and nozzle dispense the exact quantity of ice pop. Upon loading, they move to the down-the-line lidding station.

According to the Packaging Type

Horizontal Form, Fill, and Seal Machine

Horizontal Form, Fill, and Seal Machine

The packaging operation occurs in the horizontal direction in this machine, hence the name, horizontal form, fill, and seal machine (HFFS). It creates an attractive flexible pillow-like ice pop pouch packaging.

The film goes in a horizontal direction after unwinding in this machine and is transformed into a pouch with the help of forming collar and vertical sealers. After that, ice pop is loaded into the pouch and finally top ends are sealed using horizontal sealers.

Plastic Tube filling machine

Plastic Tube filling machine

It is a robust and sturdy unit made with stainless steel, offering clean packaging operation. It features a rotary turntable design in which multiple plastic tubes are processed at the same time. The rotary turntable boosts its productivity.

Its operation is completely automated during which the tube feeding device loads one plastic tube inside a tube holder during one turn of the carousel. This tube is then moved to the filling and sealing station during the subsequent turn of turntable.

Ice Pop Filling and Sealing Machine

Ice Pop Filling and Sealing Machine

It is popular because it forms eye-pleasing packaging. Although it has a higher footprint, even then, it is favored among manufacturers, because of its fast speed and efficient packaging. The empty plastic tubes like packs are loaded on the grippers by the operators and are moved to the filling station, where filling nozzles fill the ice pop liquid in these tubes. Afterward, the heated sealer fuses the opening of the filled ice pop tube.

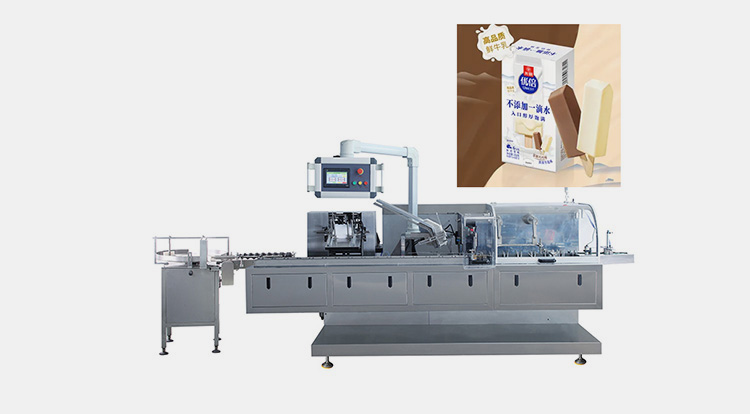

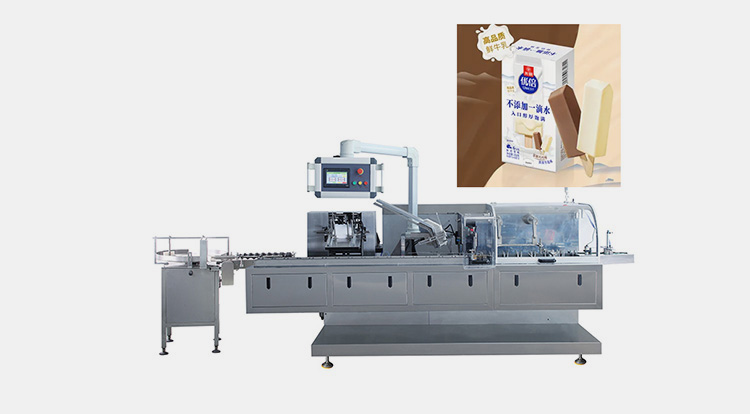

Cartoning Machine

Allpack cartoning machine

In various countries, cartoning machine is the popular choice for ice pop packaging where flat shape cards are loaded into the machine. The formation of cartons are carried out by machine itself as it is composed of important features that allows orientation and folding of card edges to form a carton. The ice pop is loaded upon formation of carton automatically. The equipment is specified with a series of sensors and safety devices allowing a safe and effective run.

6.Do Ice Pop Packaging Dimensions Differ Depending upon Ice Pop Type?

Yes, based on ice pop type, there are different dimensions of ice pop packaging. The shape and size of Ice Pop influence its packaging dimensions. Some ice pop packaging and their dimensions are penned below:

| Classical Stick

It comes in a classical pillow or sachet packaging. It has a stick attached to its lower end. This ice pop packaging is 5-6 inches in length and has a classical rectangular shape. |

Classical Ice Pop Stick- Picture Courtesy: Dieline |

| Push-Up Ice Pop

Cylindrical paper wraps hold push-up ice pop and it is longer than classical pop-up stick packaging. It is 6-8 inches long. |

Push-Pop Ice Pop- Picture Courtesy: Yahoo |

| Character Ice Pop

This type of ice pop comes in character shapes, for instance, cartoons, fruits or animals to entice the consumers. Its packaging dimensions vary with the design of ice pop. |

Character Ice Pop - Picture Courtesy: Thrillist |

| Freezer Bar

This ice pop type is contained in rectangular-shaped packaging and is 3-4 inches in thickness. It is packaged in individual cardboard packaging. |

Freeze Bar Ice Pop - Picture Courtesy: Packaging of the World |

| Freezies Ice Pops

These are tubular ice pop packaging in plastic wraps and are 4-6 inches long. |

Classical Ice Pop Stick- Picture Courtesy: Packaging of the World |

7.Is Ice Pop Packaging Sustainable?

Sustainable Ice Pop Packaging- Picture Courtesy: Trend Hunter

With more and more businesses, opting for sustainability, consequently, green and eco-friendly packaging has become a new norm in ice pop packaging. Earthy design and recyclable inks are widely used in the ice pop packaging.

Moreover, the ice pop brands of today use sustainable and recyclable materials that have zero environmental impact. Brown unprocessed paper, seaweed materials and sugarcane films in ice pop packaging are naturally sourced from plants and algae, hence, these materials are easily decomposed by microbes.

In addition to packaging materials, brands are striving to decrease fuel consumption by using renewable energy sources while creating and filling ice pop packaging. This is one step further in eco-friendly and sustainable efforts.

8.Is Ice Pop Packaging Tamper-Proof?

Tamper-proof Ice Pop Packaging – Picture Courtesy: Packaging of the World

In short answer yes, ice pop packaging is tamper-proof. Basic ice pop packaging like ice pop sticks and paper tubes tamper-evident seals that will tear upon tampering. Furthermore, on cardboard sleeve type of ice pop packaging, small holes and punctures are observed upon tampering.

Re-closable ice pop packaging like pop-up ice pop includes locking mechanism lids that avert unauthorized packaging access. Some types of ice pop have color-changing logos and tamper-proof tear strips that get damaged if the ice pop container is tampered with.

Some ice pop brands wrap their ice pop packaging in tamper-proof shrink wraps for extreme anti-tampering.

9.What are the Essential Parameters for Designing Ice Pop Packaging?

As ice pop packaging serves as a brand ambassador, it is necessary to carefully plan and execute its design otherwise your money and effort will be wasted. We are giving some essential tips for designing ice pop packaging.

Size and Shape of Ice Pop

Size and Shape of Ice Pop Packaging- Picture Courtesy: Packaging of the World

Design ice pop packaging by keeping in mind the contour of your ice pop product. If ice pop packaging is smaller it will not fit your product and leads to redesigning while too large ice pop packaging will result in a waste of packaging material and money.

Packaging Material Choice

Packaging Material of Ice Pop Packaging- Picture Courtesy: Trend Hunter

Your potential packaging material must be food-grade, robust, and tough. Secondly, it must be leakage-proof, otherwise ice pop will leak from it. The packaging material must offer optimum protection and avert ice pop melting.

Stackability and Movability

Stackability of Ice Pop Packaging- Picture Courtesy: Packaging of the World

Make sure that your designed ice pop packaging is easily stacked and adjusted in small spaces to provide convenience in transportation. Moreover, it must offer portability, because portable ice pop packaging is preferred by children and adults alike.

Ease of Accessibility and Resealing

Ice Pop Packaging- Picture Courtesy: Behance

Ice pop packaging should include tear-open notches and other features so that it is easily opened by consumers. Moreover, it should be designed with resealable tapes and add on, for re-closing after use. These elements add value to ice pop packaging.

10.What Regulatory Compliance Standards of Ice Pop Packaging?

As with other food packaging, ice pop packaging must comply with different regulatory standards to ascertain the safety of human health and the environment. These regulatory compliance standards are discussed below:

FDA

FDA- Picture Courtesy: BioWorld

This packaging certificate is used all across the globe, especially, in the United States. It guarantees that ice pop packaging is completely safe for food wrapping. It also ascertains that ice pop packaging does not release harmful substances that may spoil ice pop ingredients.

ISO

ISO

This ice pop packaging certification establishes that the packaging is designed to fulfill consumer needs and it includes information for safe handling and storage of ice pop. The ice pop packaging must be child-resistant and must have re-closable options to comply with ISO standards.

BRCGS

BRCGS- Picture Courtesy: LRQA

It stands for Brand Reputation Compliance Global Standards. It is a global benchmark, recognized in many countries to certify packaging and food safety. To acquire BRCGS certification brand must conduct a risk assessment and establish that its ice pop packaging is manufactured using hygienic protocols.

HACCP

HACCP- Picture Courtesy: Impakter

It stands for Hazard Analysis and Critical Control Points. The HACCP certification states that raw materials of ice pop packaging do not pose a safety risk to human wellbeing. It also certifies that the packaging manufacturing process is implemented to manage possible hazards.

11.What are Storage Tips for Ice Pop Packaging?

Storage of Ice Pop Packaging- Picture Courtesy: Packaging of the World

Do you have ice pop in your hands and are wondering how to keep it from melting? Here are some storage tips.

Ice pop in packaging melts easily, therefore, it requires proper care and storage to keep it from dissolving. It is best to store the ice pop packaging in its original packaging and if not possible, then it is best to place in it an airtight container to prevent its contamination.

Also, store ice pop packaging in the freezer at a temperature of -20° to -30°C, because otherwise it will melt and you will not get to enjoy your ice pop.

If ice pop packaging is stored properly at a steady temperature, it will be good for 6-8 months without losing its deliciousness.

12.What are the Future Prospects of Ice Pop Packaging?

Future Prospects of Ice Pop Packaging- Picture Courtesy: Tetra Pak

Increasingly hot climates the boosted the sale of ice pop in recent years. It has been predicted that the ice pop market will witness a growth CAGR of 5.5% in the years 2022 to 2030. This surge in the ice pop arena will drive the expansion of the ice pop packaging market.

Innovation in packaging is essential for its sale and ice pop packaging is no exception to the rule. In the future, ice pop packaging will be enclosed in sustainable and biodegradable materials, for instance, paper or seaweed. Moreover, it will be made with eatable coatings that will be enjoyed with ice pops.

Active packaging sensors will be included in ice pop packaging to notify users and handlers about the temperature of ice pop. This will increase retailing and transportation time. Moreover, futuristic ice pop packaging will include trackers that allow manufacturers to track the journey of ice pop.

Conclusion

A summer treat- ice pop is incomplete without its packaging. Bold, vibrant, stunning, and, stylish ice pop packaging not only increases the worth of ice pop products but also provides a great unboxing experience to consumers. Branding, protection, marketability, product communication, stackability, and, portability are some feathers in the cap of Ice Pop packaging. Investment in the ice pop packaging business brings huge profits, as ice pop packaging is a booming market. So, are you looking for exciting ideas for designing your ice pop packaging or are you in search of an ice pop packaging machine, Plus, if you have any question related to Ice Pop Packaging; then you stop because you are at the perfect spot. We, Allpack offer the best machines & Free Expert Guidance to you. Contact Us Now.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours