How to Troubleshoot Common Problems of Capping Machines

Do you own or work in the packaging industry? What is the daily cap count you have to operate? Your answer must be “a lot”.

The capping machine is one such crucial element in various industrial packaging lines. The entire manufacturing timeline will be impacted if it malfunctions out of the blue. So, what should you do?

Understanding the major components of the capping machine and its operation is crucial in establishing a solid foundation for effectively troubleshooting your capping machine. With this information, you can identify the reason for its malfunction and eventually get your capper back on track.

This blog post will cover the common problems of capping machines, their underlying causes, and some of their possible troubleshooting techniques. Now let's get right to it!

1.Capping Machine

Capping Machine – Picture Courtesy: Weighpack

A capping machine is useful industrial equipment that applies caps on various containers, making them airtight and the products within them secure. This device plays a major role in packaging and is one of the most critical components of packaging lines across industries, such as pharmaceuticals, food, chemicals, cosmetics, and beverage.

The capping machine is a versatile equipment and its capability of handling multiple types of containers coheres its place as a fundamental part of packaging solutions.

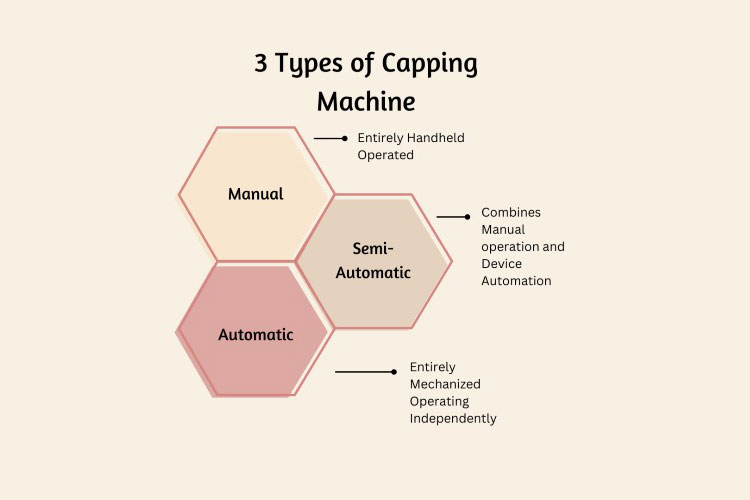

2.Different Types of Capping Machines

The capping machine is renowned for its speed and precision. You will observe various designs and versions on the market, specifically engineered for varying manufacturing demands. They are typically categorized into 3 classes according to the degree of automation.

Manual Capping Machine

Manual Capping Machine

The handheld capping device is a perfect tool for smaller tasks. It is a portable tool, providing you with meticulous check over the process. It is a reasonable device for newly constituted businesses. It has a limited production capacity, entirely relying on the operator’s skills and energy.

Semi-Automatic Capping Machine

Semi-Automatic Capping Machine

The semi-automatic capping machine involves manual functions and device automation. It is suitable for medium-sized industries. The manufacturing limit is approximately 20 to 30 containers per minute, offering a significant speed at an affordable price.

The manual tasks include placing a cap on the vessel head and the discharge of screwed vessels. The rest of the process is completed by the device through automated mechanisms.

Automatic Capping Machine

Automatic Capping Machine

The automatic capping machine is a smart device that can finish the complete process automatically and efficiently. It is a recommended device for large-scale activities. It can process about 200 containers per minute. The device has two capping mechanisms; spindle and chuck technique. The most commonly used technique is spindle capping.

3.How to Troubleshoot Common Problems of Capping Machines?

Now you know about different models of capping machines. They are sophisticated devices but like every industrial device, they also encounter certain problems due to continuous operation and extensive usage. To keep your workflow optimized and to rectify the issues, you must know about these problems and their possible reasons.

Here you will get to know about the common problems encountered in several models of capping machines and how to troubleshoot them. So, without any further delay, let’s get to the topic:

Manual Capping Machine Problems and Solutions

A user-friendly manual capping machine is made possible by its straightforward construction. Still, it may malfunction from time to time. So let's examine the potential problems with the device and their fixes.

| Detached Cap |  |

| Causes

Misalignment of cap with the vessel. An incorrect capping method is applied. |

Solutions

Reposition the bottle’s lid. Employ the appropriate capping method. |

| Improper Cap Fitting |  |

| Causes

The capper segment is impaired. The vessel is not aligned with the device or settings. |

Solutions

Consider replacement of damaged components. Make adjustments to accommodate the bottles. |

| Deformed Cap |  |

| Causes

The characteristics of cap is not synchronized with the capping head. A wrong way of capping is employed. An excessive amount of torque is applied. |

Solutions

Make adjustments to the capping head according to the cap’s features. Employ a correct capping method for respective lids. Balance the amount of torque applied. |

Semi-Automatic Capping Machine Problems and Solutions

A semi-automatic capping machine also faces some problems during its operation. Some of the commonly experienced issues and their troubleshooting tips are discussed:

| Faulty Motor |  |

| Causes

The motor is malfunctioned. The motor is moving slowly due to friction. Impaired wiring. Interruption in the power source. |

Solutions

Replace the impaired motor. Lubricate the motor to reduce friction. Resolve the issue of wiring. Ensure an uninterrupted power supply. |

| Malfunctioned Pneumatic Piston |  |

| Causes

Inadequate air pressure. Damaged timer or relay. Defective throttle or solenoid faucet. |

Solutions

Adjust the air pressure. Substitute the relay and timer. Repair or substitute the faucets. |

| Insufficient Fastening of Cap |  |

| Causes

The processing rate is too fast. The torque applied is insufficient. The lid is damaged or has a smooth interior. The size of capping head is not fitting. The cap is improperly settled. |

Solutions

Adjust the processing speed. Regulate the torque applied to the required level. Remove the damaged or faulty cap. Employ a right-sized capping head. Calibrate or align the cap fitting block. |

Automatic Capping Machine Problems and Solutions

Automatic capping machines are the most advanced and adaptable form of equipment. Although it usually does not break down, there may be some faults and you must know them to avoid costly spills.

| Knocking Over of Receptacles |  |

| Causes

The conveyor belt is damaged or inclined. The conveyor speed is too high. The gripping belt has too strong or weak clasp. |

Solutions

Adjust the conveyor belt to make it level. Replace the damaged conveyor belt. Regulate the conveyor speed and grip of the gripping belt. |

| Missing Cap |  |

| Causes

The cap feed and stock are over. There is an obstruction in the cap feeding route. The conveyor speed is not in order with the cap feeder/placer. |

Solutions

Ensure significant quantities of caps in the hopper. Check for any clogged cap or obstruction in the cap feeding. Clear the obstruction. Synchronize the conveyor speed with the feeder. |

| Overtightened Cap |  |

| Causes

The spindle discs are too congested. The torque adjusted is too high. |

Solutions

Ensure proper spacing between spindle discs. Regulate the torque applied via the operation panel. |

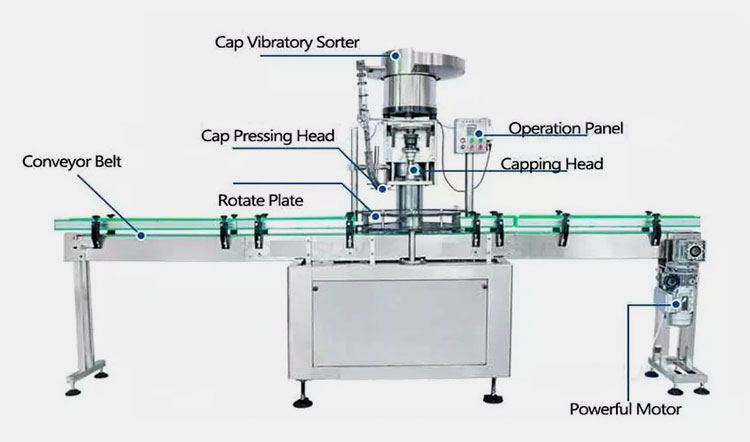

4.Key Components of a Capping Machine

Capping machines are advanced equipment composed of several mechanical and electrical components, each contributing uniquely to the overall processing. The key components included in a capping machine are:

Key Components of a Capping Machine

| Components | Description |

| Conveyor Belt | The conveyor belt is a platform that transits containers through different processing stages. It ensures streamlined workflow and uninterrupted movement of containers, keeping suitable space and time between them. It can be customized to adjust varying container sizes and processing speeds. |

| Rotate Plate | It is a rotating structure that holds and assembles the containers for capping. It is a useful component for high-speed processing. It houses multiple containers at a time, allowing the capping head to cap containers in succession with ease. The rotational speed can be adjusted to synchronize with the conveyor belt and capping head’s speed. |

| Capping Head | It is a critical component of the device, applying caps to the containers. It positions the cap on the containers and applies the necessary torque to ensure a secure closure. It can have multiple designs or adjustments to handle various caps. |

| Cap Pressing Head | It works in combination with the capping head. It applies descending pressure on the caps and ensures its firm attachment. |

| Cap Vibratory Sorter | It is responsible for organizing the caps before they are positioned onto the containers. It ensures a constant feed of organized caps to the capping segment. The sorter uses the vibratory mechanism to move and orient the caps. |

| Operation Panel | It is a touch screen with software installed. It allows the operators to monitor and regulate the whole process. It makes the device easier to use. |

| Powerful Motor | The motor connects the machine to the power supply necessary for smooth functioning. |

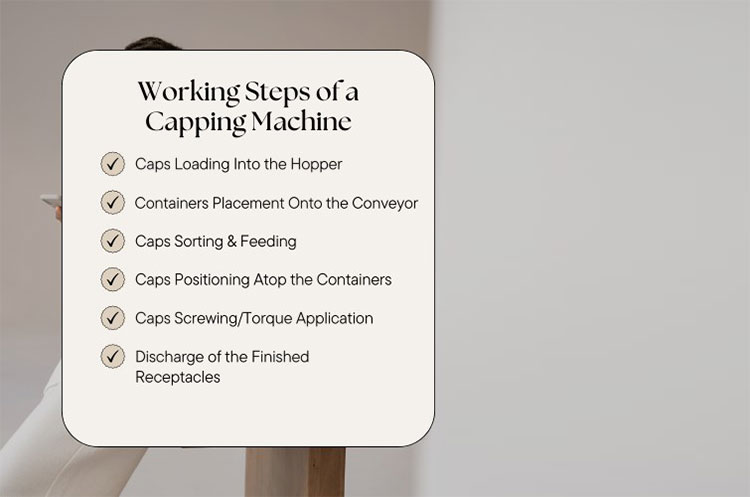

5.Working

The capping machine’s working is evidence of one of the wonders of technology and engineering. Let’s examine each phase of the capping procedure, paying particular attention to the screw capping step:

At the beginning of the process, the cap loader assembles and provides the caps to the device. Simultaneously, the containers ready to be sealed are also fed to the device via the conveyor belt.

As the bottle reaches the capping section, the cap that has been gathered already is positioned atop the bottle. It is a critical step in the process, maintaining a streamlined workflow and ensuring each bottle gets its perfect cap.

In the next phase, the bottle along with the cap is guided forward. This is where capping heads play their role. They descend and apply the appropriate amount of torque on the cap. The amount of torque is adjusted suitably to ensure a tightened cap without damaging the bottle or cap.

In the case of semi-automatic variants, the caps are placed on bottles manually following the application of torque by the capping heads.

After the secure capping of bottles, they are discharged along the way on the conveyor belt for further processing.

6.Importance and Benefits

Due to numerous incredible benefits, capping machines have gained importance across various industries. They provide extensive benefits to ensure the product’s integrity, quality, and safety. Some key benefits of the capping machine are discussed here:

Increased Efficiency and Productivity

Increased Efficiency and Productivity

Every manufacturer desires efficient and rapid production to meet the high production demands. And that’s what an automatic capping machine provides. The device automates the processing line, neglecting human involvement, ultimately leading to increased production output while maintaining efficiency and consistency.

Reliable and Uniform Capping

Reliable and Uniform Capping

Another compelling benefit a capping machine offers is its reliable and uniform capping. With proper adjustment of the parameters, each bottle will be sealed in the same fashion, resulting in product uniformity. Automation reduces the chances of capping errors and preserves the finished product’s quality throughout the process.

Improved Product Safety and Quality

Improved Product Safety and Quality

The effective sealing provided by the capping machine ensures the product remains safe and secure, avoiding leaks and spills during further processing, storage, and transportation. Moreover, the consistency in the process enhances the overall product’s quality hence improving customer satisfaction.

Cost Benefits

Cost Benefits

Investing in a capping machine offers long-term cost benefits. It automates the workflow and minimizes the need for labor. Additionally, it reduces the chances of human errors that could lead to spills and leakages and ultimately resource wastage.

Customization

Customization

The advanced versions of capping machines allow manufacturers to process various products, caps, and containers with the same equipment through easy changeovers and customization.

7.Applications

The significance of capping machines is broad. It is a popular device across various sectors. The major ones are discussed below:

Beverage Industry

Applications of Capping Machines in the Beverage Industry

The capping machine is employed in the beverage industry to secure bottles containing carbonated and non-carbonated drinks and juices. The efficient capping preserves the product’s integrity and freshness.

Food Industry

Applications of Capping Machines in the Food Industry – Picture Courtesy: Pasta Sauces

Several food products are effectively enclosed in various bottles using a capping machine. These products include viscous and non-viscous materials, such as ketchup, vinegar, sauces, oils, honey, and jams.

Pharmaceutical Industry

Applications of Capping Machines in the Pharmaceutical Industry

In the pharmaceutical industry, several bottle types are used for packaging multiple dosage forms, including tablets, capsules, syrups, suspensions, and elixirs. The capping machine is used for their efficient capping, protecting them from external environmental effects.

Personal Care Industry

Applications of Capping Machines in the Personal Care Industry

Certain personal care products are packaged in bottles or similar containers in the cosmetics industry. The capping machine allows the material to remain fresh for an extended time by providing efficient closures.

Chemical Industry

Applications of Capping Machines in the Chemical Industry

The bottles containing chemicals need to be effectively sealed and capped as the chemicals inside can be irritating and infectious. Chemicals that are capped using a capping machine include detergents, cleansers, dyes, paints, and other industrial chemicals.

Automotive Industry

Applications of Capping Machines in the Automotive Industry

In the automotive industry, automotive care products are bottled and efficiently capped using a capping machine. Items like windshield washer fluid, mobile oils, and battery acids come in bottles and cans and should be preserved in leak-proof capping.

8.Maintenance

Maintenance of Capping Machine

Apart from obtaining troubleshooting skills for your capping machine, regular maintenance of your device is also important. This will keep the device in optimal condition for a longer period and reduce the chances of errors.

Inadequate proper maintenance will make your device prone to frequent breakdowns. It will result in reduced production efficiency. Here you will perceive a few helpful pointers on your device’s maintenance:

Daily Maintenance

Wipe out the complete device to remove the dust and accumulated particles with water and soft cloth. A suitable detergent can also be used instead of water.

Oil the dynamic parts of the device. Use the lubricant suggested by your device manufacturer.

Examine every nut and screw and make them tight.

Weekly Maintenance

Thoroughly clean your device at least once a week. Disassemble the device and clean all the components. The focus should be more on areas that are hard to clean during daily upkeep.

Inspect the parts for any impairment or tear. Consider immediate replacement or repair.

Check for the electrical wiring. Repair it immediately as loose wiring can be hazardous.

Adjust the capping torque and other parameters appropriately to avoid inconsistency and damage.

Monthly Maintenance

Perform an extensive inspection every month to protect the device from breakdowns.

Document all the maintenance programs conducted, personnel names, dates, and problems identified and fixed.

Conclusion

The capping machine is a must-have component for every production line dealing with products to be packaged in bottles. It offers numerous benefits, including speed, precision, and efficiency. Although it is a sophisticated piece of equipment, it still encounter problems due to continuous working. Every entrepreneur desires of a device with a longer lifetime. If you want your device in top working condition, you must know about the problems encountered and how to fix them immediately plus performing regular maintenance. For more information on troubleshooting your capping machine, please contact Allpack, a leading industrial equipment manufacturer and service provider.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours