How to Seal Aluminium?

Aluminium is a wonderful metal used in the manufacturing of all kinds of products, from aeroplanes to architectural items, from flashlights to cameras and many more. To make it corrosion-resistant and wear-resistant, it is sealed. The sealing of aluminium also boosts its shine, appearance, and thickness and is essential in protecting this metal from all types of environmental agents.

Different sealing techniques, for instance, electrolysis, chemical sealant, and coatings are used for sealing aluminium.

Are you dealing in aluminium products and want to learn more about sealing methods for aluminium? Then carefully through this blog as it will answer all your questions about aluminium sealing.

1.Why to Seal Aluminium?

Aluminium is the most utilized metal and serves various functions in manufacturing applications. There are many reasons for sealing aluminium, for instance:

Prevention of Corrosion

Prevention of Corrosion

Aluminium tends to corrode in humid environments as moisture in the air promotes oxidation of aluminium. As a result of corrosion aluminium loses its effectivity and shine. That being the case, aluminium is sealed by different sealants and coatings to prevent its rusting. This sealed aluminium is highly corrosion-resistant and thus has long serviceable life.

Boosts Aluminium Durability

Seal Aluminum Durability

Unprocessed aluminium is prone to mechanical damage, for instance, scratching, bending, and wear and tear. But with sealing, a protective coating is added to aluminium that boosts its durability, consequently, it can easily be resistant to rough treatment and abrasion.

Enhanced Product Aesthetic

Enhanced Product Aesthetic

With sealing aluminium, its visual appeal is increased and it appears more lustrous and polished. This sealed aluminium will uphold its original colour and uniform finish for a longer time while unsealed aluminium will lose its shiny appearance and discolour over time.

High Chemical Resistance

High Chemical Resistance- Picture Courtesy: Packaging Gateway

Aluminium is often exposed to an environment where it faces harsh chemicals. These chemicals will react with aluminium leading to its degradation. But with sealing, aluminium can withstand harsh acids and alkalis. The protective sealant barrier on aluminium allows it to uphold its structural integrity in a degrading chemical environment.

Improved Cleaning

Improved Cleaning- Picture Courtesy: Maids By Trade

In addition to protection and resistance, the aluminium sealing also comes in handy while cleaning it. The sealing of aluminium causes uniform and polished surfaces that make it easier to clean aluminium products. Moreover, the sealed aluminium deters dust, oils, and other contaminants.

2.How to Seal Aluminium?

With technological innovation, different methods are invented to seal the aluminium for its weather resistance. Some of these methods are penned below for your understanding:

Anodizing

Anodizing- Picture Courtesy: anodized aluminum

It is one of the most important methods utilized for sealing aluminium. It is an electrolytic process that elevates the thickness of the oxide layer on the aluminium surface. The direct current is supplied to the electrolytic solution of aluminium oxide and sulphuric acid or chromic acid to seal aluminium.

This process is applied to seal aluminium for different uses, like forming aeroplanes and architectural parts.

Chromating

Chromating- Picture Courtesy: AeroSpace Metals

It is also named chemical conversion coating. It is the process in which the aluminium part is deposited inside the chemical bath usually containing chromate salt to achieve aluminium sealing of desired thickness.

It is mostly used for sealing aluminium nuts and screws.

Powder Coating

Powder Coating

As the name suggests, this process involves the application of dry powder on the surface of aluminium and then heat is applied for curing it. This method is typically employed for sealing aluminium for decorative purposes in the automotive and furniture industries.

Sealant and Lacquer Coating

Sealant and Lacquer Coating- Picture Courtesy: McCahill Painting Company

A delicate layer of sealant and lacquer is sprayed on the surface of aluminium to strengthen its durability and mechanical resistance. This sealant creates a barrier coat and prevents its oxidation and reactivity with other chemicals. The lacquer method of sealing aluminium is used in diverse industries, for instance, food, beverage, aerospace, etc.

Electropainting

Electropainting- Picture Courtesy: 3 Colours Painting

It is yet another method for sealing aluminium. In this process, a primer is used to improve the attraction of aluminium for paint sealant. Afterwards, paint is applied with the aid of an airbrush or spike brush to increase the durability of the seal. This method is widely used in the automotive industry.

3.Common Mistakes to Avoid While Aluminium Sealing

When sealing aluminium, it is advised to proceed with great caution as even a smaller mistake could result in sufficient sealing, ultimately causing corrosion and decreased protective aluminium barrier.

For your convenience, here are some basic mistakes to avoid during aluminium sealing:

Incorrect Selection of Sealent

Incorrect Selection of Sealent

The saying that one shoe does not fit all applies to aluminium sealants as well. Different alloys of aluminium have their specific sealant. Therefore, the wrong selection of sealant results in improper sealing, often leading to leakage and abrasion.

Incorrect Application of Sealant

Incorrect Application of Sealant- Picture Courtesy: The Gorilla Glue Company

It is a common mistake while sealing the aluminium. Non-uniform and uneven coverage of sealant produce microscopic fissures in the aluminium sealing that direct the corrosivity of aluminium. This incorrect application also results in ineffective barriers.

Hence, it is recommended to follow proper protocols while sealing. Use proper tools for instance brushes, spray nozzles, and rollers to ensure even application of sealant.

Poor Surface Preparation

Poor Surface Preparation- Picture Courtesy: Toppr

The surface of unprocessed aluminium habitually comes in lots of impurities and contaminants, for instance, oil, grease, dust, and other debris. These contaminants adhere to the surface of the aluminium and its poor cleaning before sealing, results in weak bonding and insufficient seal effectiveness.

To avoid such a disaster, first, prepare the aluminium surface and get rid of impurities by methodically cleaning and drying the aluminium surface.

Inadequate Drying or Curing Duration

Inadequate Drying or Curing Duration- Picture Courtesy: Linkedin

Sometimes, due to time constraints, users haste the drying and curing time and use or package aluminium without proper drying. This leads to poor bonding of sealant with aluminium which in turn leads to poor insulation and inadequate protection of aluminium.

To avoid such issues, sufficient time should be given for curing and drying, as advised by the manufacturer and aluminium should not be exposed to strain without complete drying.

4.Environmental Considerations of Sealing Aluminium

With increasing awareness about global warming, manufacturers and customers are equally concerned about the environmental impact of various sealing methods of aluminium. Various environmental considerations should be taken into account while choosing the sealing method.

Release of Volatile Compounds

Release of Volatile Compounds by Sealants

Sealants and other lacquers emit a high number of volatile compounds. These compounds contribute to air pollution. The anodizing sealing method is the most eco-friendly method, releasing lower quantities of volatile organic compounds, halogens, and heavy methods.

Fuel Consumption

Carbon Neutral Aluminium Sealing Methods- Picture Courtesy: Scrap and recycle news - RecycleInMe

Some sealing methods are energy-intensive and consume energy to heat chemicals as a result, carbon dioxide gas is released into the environment, increasing its carbon footprint. Spraying of sealant and lacquering do not use energy and, therefore are carbon neutral.

Water Contamination

Water Contamination- Picture Courtesy: MEL Science

In certain sealing methods of aluminium, chemicals run into the water bodies causing their contamination. For example, in the chromating method, chromium salts are released in water systems. Hence, consider potential water contamination when choosing the aluminium sealing method.

Remember to thoroughly research and compare sealing methods and also take into account the pros and cons of different sealing methods in terms of their eco-friendliness. Select a technique that is perfectly balanced between effectiveness and environment conservation.

5.Success Tips for Sealing Aluminium

Winning the battle of sealing aluminium goes beyond avoiding simple mistakes. It takes extreme planning and intense testing. Some success tips to master the feat of aluminium sealing are:

Prime Aluminium Surface

Prime Aluminium Surface

Uneven and rough surfaces of aluminium create a hindrance when sealing aluminium and lead to uneven sealings. Therefore, you must smooth the surface of aluminium using different approaches for cleaning, sanding, and, polishing. This will bring about a smooth finish and in turn, you will attain optimal sealing outcomes.

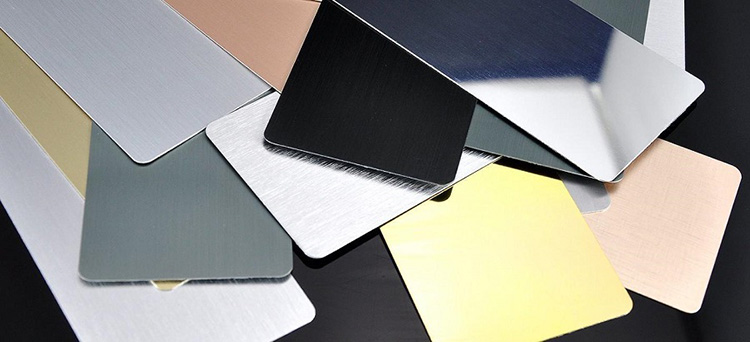

Learn About Various Aluminium Alloys

Aluminium Alloys

Different alloys of aluminium are present in the market, containing traces of various elements, such as copper, manganese, and copper. These alloys require specific types of sealants to form an effective seal.

Therefore, for successful sealing, it is important to learn about aluminium alloys and their characteristic sealants.

Prepare for Contraction and Expansion of Aluminium

Contraction and Expansion of Aluminium

Aluminium is a metal that contracts and expands at low and high temperatures, respectively. Use a seal that can withstand such changes, failure to do so, results in the bending, hardness, and cracking of sealants and loss of seal adhesivity.

Test Small Batch

Test Small Batch

Before diving all the way headfirst into aluminium sealing, first test the small batch. In this way, you develop your perfect recipe without wasting your resources. Perform sealant combability tests on small amounts of aluminium before going for full scale.

Safe Storage

Safe Storage of Sealed Alumininum- Picture Courtesy: Factory Fast

After the successful bonding of sealant with aluminium, the next step is its storage. It is a crucial step that many users overlook. Some chemicals, UV radiation, and oxygen are culprits that cause premature seal degradation and lower sealing properties.

For that reason, it is suggested to store sealed aluminium away from harsh and degrading chemicals. Furthermore, its ideal storage place is a cool, dark, and low-humid warehouse that is not exposed to direct sunlight.

Conclusion

Aluminium is the most sought-after metal in industries, hence to boost its protective characteristic, durability, chemical resistance, its physical appearance, aluminium is sealed. Different innovative techniques, such as anodizing, coating, chromating, and painting, exist in the market for sealing aluminium. Each of these methods has its advantages and limitations when their environmental impacts are studied. Also, users make common mistakes while sealing aluminium, for instance, inadequate curing, wrong sealant selection, and improper surface preparation. Hope this blog has addressed a puzzling question which is how to seal aluminium. If you have any question from ‘How to Seal Aluminium? You can contact our Allpack customer care.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide