How To Press Your Own Pills?

The unending growth of technology has opened the doors of inventions for humans to progress in their lives. Similarly, we often confront people with rising tendencies towards entrepreneurship and business field instead of rushing towards restricted jobs. In this way, the most suitable area which they find worthy is pressing tablets in diverse sectors such as pharmaceutical, nutraceucal, food, veterinary, cosmetics and many others.

Are you too among one of them, planning to initiate your own business of pressing pills? Or want to press your own pills in home for various purposes? But are in state of ambivalence? If so! No need to worry. As, we have come up with an amazing blog post for you which will be surely enough to answer your complex queries started from How to press your own pills and getting ended up with choosing the best compatible tool for achieving it. Just take the start and get all what you need!

1.What Is Meant By Pressing Pills?

Pill press machine- Picture Courtesy: unbiogrund.com

Whether it is the healthcare, beauty care, daily cleaning, or agricultural protection need for pills is realized everywhere. Similarly, the demand for pills is directly augmenting. Reasons are numerous, taking from its precise structure to easy swallowing, dissolution, and bother free handling. And we know that all types of pills are made up of powder. But how powder can be turned into such an organized and uniform state without being liquified? The answer is definitely by pressing!

Pressing is the most popular and easy way commonly employed for making pills. It involves the punching of powdery formulation with much exertion which ultimately result in the creation of precise pills. The size, shape, and weight of pills may vary according to changing die and ingredients taken. However, these pills can last longer by keeping them away from humidity, temperature, and light etc.

2.What Ingredients & Tools Will You Need To Press Your Own Pills?

Everything we have in our daily life is the composition of several components or ingredients which have been processed with the help of certain tools. Likewise, pressing your own pills will indeed require certain ingredients and equipment. Therefore, we have explained for your ease the list of essentials you will need for pill formulation. Have a look towards them for better understanding!

Ingredients

Active Ingredients

Active ingredients used in pills refers to the components which have a therapeutic effect on the body. For instance, active ingredients are actually those substances which enable a pill to have beneficial health effects which it claims. Its common example include paracetamol, an ingredient added to pills used for pain relief and atorvastatin, found in cholesterol-lowering pills.

Inactive Ingredients

Inactive ingredients, on the other hand, are put in the pills formulation for the purpose of their structural integrity, manifestation, flavor and absorption frequency. Therefore, they do not have any effect on patients' health, however, some people may not be able to take them because of allergic issues, which is an exception. Some common inactive ingredients involve:

| No | Inactive Ingredients | Pictures |

| 1 | Binders

Pill binders, also known as binding agents, are substances added into pills formulation in order to delay pill disintegration. It is vital in helping medication to maintain its integrity and promote gentle dissolution. Most used binders include cellulose, starch, and gelatin |

Tablet excipients binder -Picture Courtesy: pharmaexcipients.com |

| 2 | Disintegrants

While binders slow down dissolution process, disintegrants have inverse effects on pills by increasing the disintegration. Hence, they are added to pills for break-up when contacting aqueous fluids. |

Effervescent tablet fizzing in water -Picture Courtesy: wellbeingnutrition.com |

| 3 | Flavors

Fruit flavors are also added into pills especially those used for chewing like buccal and sublingual pills to release pleasant taste. |

Various fruit flavored effervescent tablets tubes -Picture Courtesy: amazinggrass.com |

| 4 | Fillers

Mostly, the amount of drug is so small that it cannot be handled conveniently. Therefore, fillers are added for easy handling. |

Granules- Picture Courtesy: ipharmachine.com |

| 5 | Gildants

Glidants are anticaking agents added into pills to reduce caking during making. |

Silica powder- Picture Courtesy: sydoniskin.com |

| 6 | Sweetening Agents

Sucrose is the most popular sweetening agent used in pills to impart palatable taste to often unpleasant substances. |

Glucose powder- Picture Courtesy: indiamart.com |

Tools

Here tools mean all those equipment which you will need during making your own pills. These are described below:

| No | Tools | Pictures |

| 1 | Miller

Miller is primarily used for reducing the size of material taken for pills manufacturing such as granules, food items, or herbal substances. It chops down the whole objects into uniform powder for convenient pills formulation. |

Milling and size reduction cone mill -Picture Courtesy: chitramechtech.com |

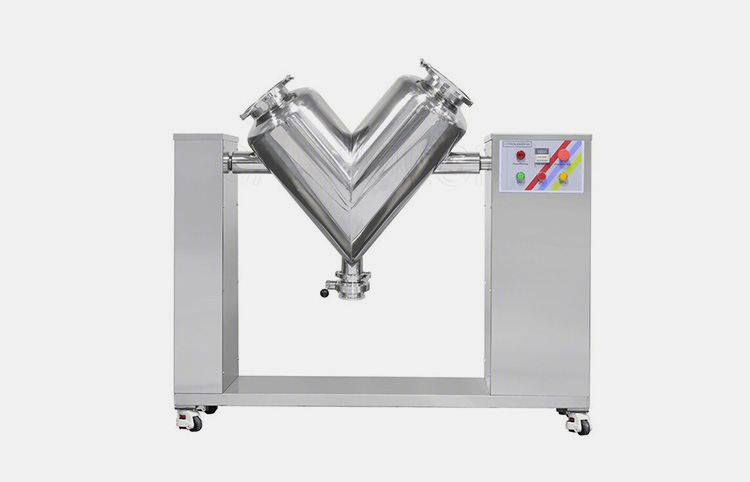

| 2 | Mixer

As the title illustrates, the task of mixer is to mix the various ingredients including both active and inactive. Therefore, no particle is left unmixed. |

Automatic V Cone Blender Machine- Picture Courtesy: fclassmachines.com |

| 3 | Granulator

Granulator is an important machine used in pharmaceutical pills processing. Its function is to form uniform and free flowing granules from powder, so, that they can be easily compressed for making pills. |

FL Series Fluidized Granulating Drier- Allpack |

| 4 | Weighing Scale

Weighing scale is a device designed to determine the weight of powders, granules, and other materials when laid over it. Thus, it can be used for weighing pills formulation prepared to avoid irregularities. |

Weighing scale- Picture Courtesy: indiamart.com |

| 5 | Pill Press

Undeniably, the most crucial tool you will ever require for making your own pills is pill press. This equipment composed of several components to transform your dry powders or granules into hard stable pills. Hence, if you want to make pills manually at home, you can use a handheld or manual pill press. On the other hand, for industrial use, you can use fully automatic or semi-automatic pill press. |

Tablet press machine -Picture Courtesy: bestshoptheday.com |

| 6 | Coating Machine

Coating machine is optional but, in some cases, essential machine to use for coating the bitter taste, maintaining structural integrity, and appeal of pills. |

Tablet coating machine- Picture Courtesy: ipharmachine.com |

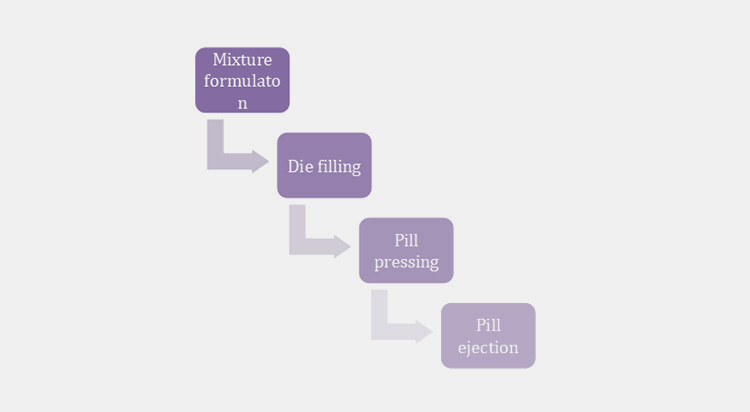

3.How To Press Your Own Pills Manually At Home?

You might be planning to press your own pills at home, and that's a great idea! Pressing your own pills at home is a piece of cake for several reasons. This way is more affordable than purchasing expensive vitamins and supplements. Also, you get fresh and quality ingredients processed in your own home. Let's know the step-by-step process for pressing your own pills at home:

Mixture Formulation

Various herbal powders- Picture Courtesy: healthnews.com

First, you need to make pills formula by mixing various active ingredients and excipients. Put them collectively in a bowl and mix with the help of a spoon.

Die Filling

Pill mixture filling into press die cavity- Picture Courtesy: LFA Machines

Once, the pill mixture gets ready, you can take fixed amount of pill mixture and simply put it into die hole of the pill press through spoon. Now, close the pill press by fitting a punvh over die cavity.

Pill Pressing

Pill pressing- Picture Courtesy: LFA Machines

This is the most crucial step, where you need to exert pressure on pill press punch which will resultantly form solid, uniform, and clear pill.

Pill Ejection

Pill ejection- Picture Courtesy: LFA Machines

In the last step, you have to open the pill press and eject pill you have made by your own.

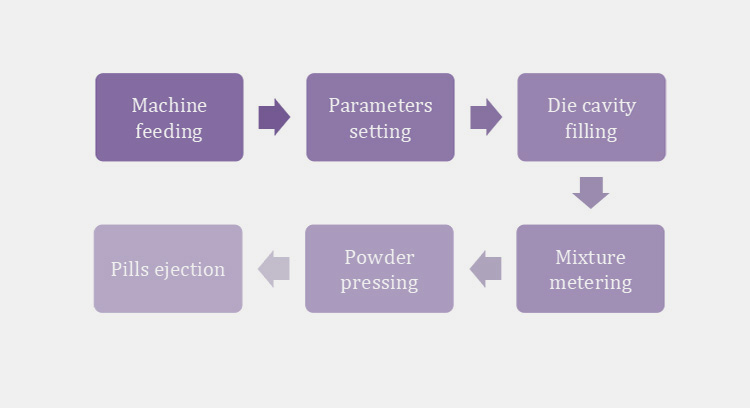

4.How To Press Your Own Pills Through Machine On Industrial Level?

Making your own pills via machine is somehow different from that of manual pressing of pills. Here, you need to focus on the steps explained below:

Machine Feeding

For starting pill making process via machine, you need to feed its hopper with enough pill formula which may be in powder or granules form.

Parameters Setting

Now, you can power on the machine for setting basic parameters such as amount to be taken for making each pill, the compression force to be applied, and dwell time of the machine etc., with the help of control panel.

Die Cavity Filling

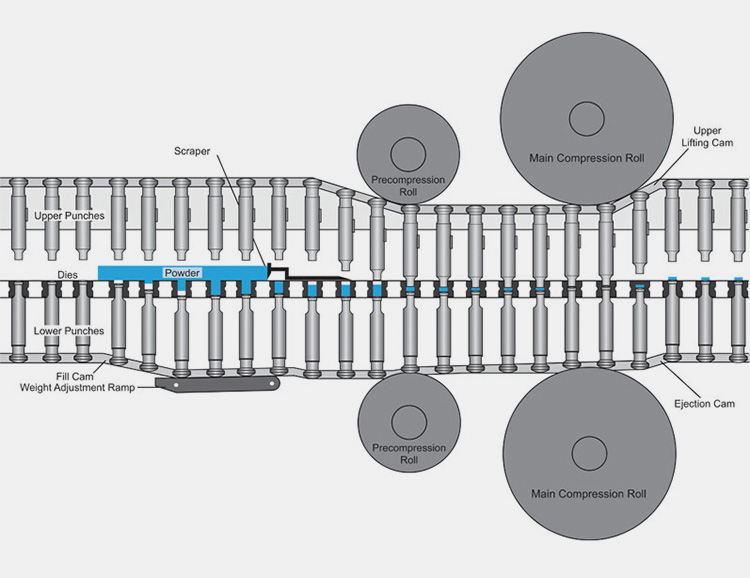

Working process of pill press machine- Picture Courtesy: prestigeinspirefoundation.in

Once, the machine's setting gets done just press the start button to make machine work. From here, machine will begin to blend pill mixture inside hopper and then deliver it to die cavity.

Mixture Metering

At this point, the question of how much pill mixture should be taken for making each pill is determined by a metering cam integrated inside the machine. It will only allow the desirable volume of formulation to enter die cavity and expel out excess powders or granules from cavity through.

Powder Pressing

Ultimately, you will observe the machine pressing powder laying in dia cavity through much force applied by lower and upper punches, resulting in the formation of precise, hard, and uniform pills.

Pills Ejection

Pills discharging in tablet press from Korsch- Picture Courtesy: korsch.com

This last step of pills ejection encompasses the discharging of formed pills from die cavity. For this purpose, the upper punches raise above, and lower punches push the pills out of die cavities towards discharge chute, and thus collected in a container.

5.Explain The Different Methods Used For Manufacturing Pills?

Generally, there are three methods adopted for making pills. They can be better understood by looking into underlying details:

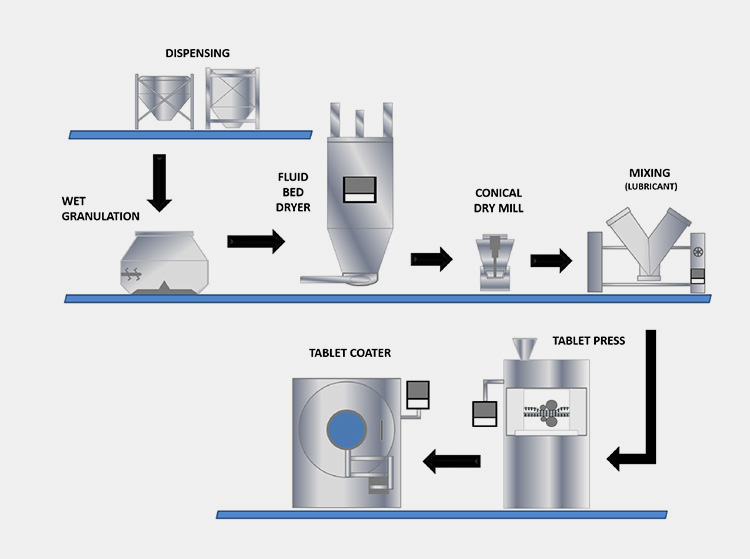

Wet Granulation

Wet granulation method is most used way for making pills. It is a suitable technique for the size enlargement of pill mixture, from powders to granules. Therefore, it is suitable for therapeutic agents which are chemically stable and do not affect by wet granulation.

Wet granulation of pills- Picture Courtesy: freemantech.co.uk

Process:

- It involves mixing binders into active ingredients through water to form binder solution.

- Mix binder solution with other excipients such as disintegrants and glidants to form a dough.

- Process the dough through sieve to make granules.

- Dry the wet granules at 60° temperature.

- Weigh granules for each pill and compress them to form pills.

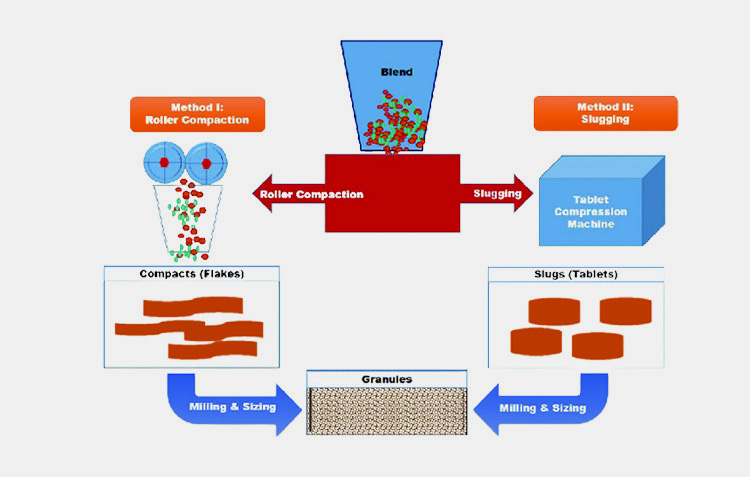

Dry Granulation

Dry granulation method of making pills is opposite to wet granulation technique. It involves compacting powders into large slugs and breaking them down to form granules. Hence, this method is best for agents sensitive to moisture and elevated temperature and reduce the chances of quality degradation.

Dry granulation process- Picture Courtesy: ipharmachine.com

Process:

- It encompasses milling the solid materials into powders.

- Mixing active ingredients and excipients together.

- Turning mixed ingredients into slugs or compacts.

- Sieve the slugs to turn into dry granules.

- Compress dry granules into pills.

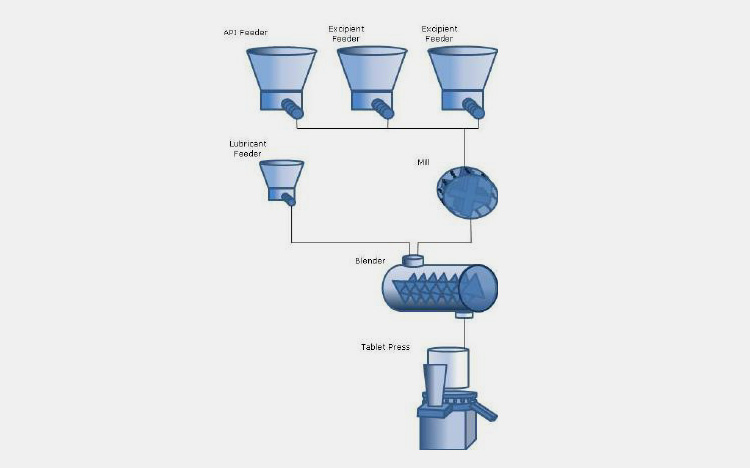

Direct Compression

Unlike wet granulation and dry granulation, direct compression method does not modify the physical properties of ingredients rather compressed them into pills. It is extremely cost-effective way for pill pressing, therefore, widely employed for generic drugs.

Diagram of a direct compression continuous process- Picture Courtesy: researchgate.net

Process:

- Mill the whole therapeutic and excipients to make free flowing powder.

- Mix both active and inactive ingredients homogeneously.

- Press the homogeneous pill mixture to make hard pills.

6.What Sizes and Shapes of Pills You Can Press?

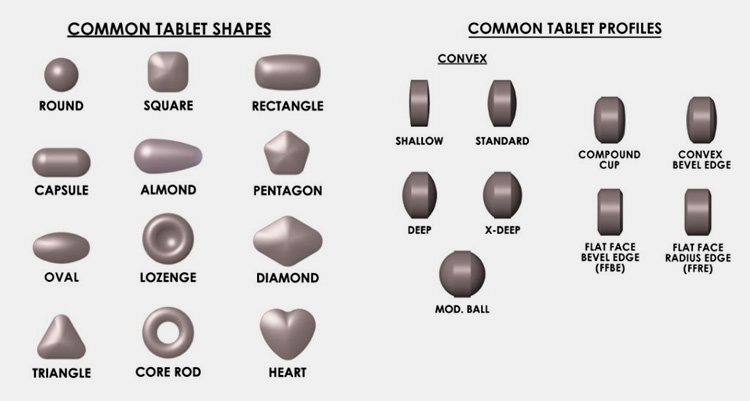

Common shapes & profiles of tablets- Picture Courtesy: ftloscience.com

There are large numbers of shapes and sizes available for pills. So, you can use them when designing your own pills.

Shapes

The common shapes used for pills include round, square, oval, capsule, and many others as shown in the picture above. Shapes are sometimes, adopted to resemble the pill purpose. For example, heart and lozenge pills may be used for heart and immunity health respectively. Apart from this, study shows that flat shaped and oval pills are more esophagus tolerant and support easy swallowing than triangle and round, which must be used in low dosage only.

Sizes

While, shapes relate to the appearance of pills, size is concerned with dosage. There are variety of pill sizes available for pharmaceutical tablets. However, most pills size range from 1mm to 2mm. Sizes of pills can be determined according to the age of patient like children, adults, and older people.

7.How To Troubleshoot The Common Problems Occur During Pill Pressing?

While pressing your own pills, you might struggle with common pills defects. But we don't want you to bother for it. Therefore, understanding in tackling these issues in advance will be indeed helpful for you.

| No | Problems | Causes | Troubleshooting | Pictures |

| 1 | Binding of pills inside die cavity | It may happen due to excessive moisture, less lubricants, or punch is not suitable | Enhance the granules drying time, put adequate amount of binder, and replace punch if incompatible |

Binding of pill in die cavity- Picture Courtesy: biogrund.com |

| 2 | Pills sticking after getting pressed | This problem occurs in wet granulation method where inadequate drying of granules results in the sticking of pills | Keep it in mind, that wet granulation method of pill manufacturing requires the wet granules to be dried under 60° temperature |

manufacturingchemist.com |

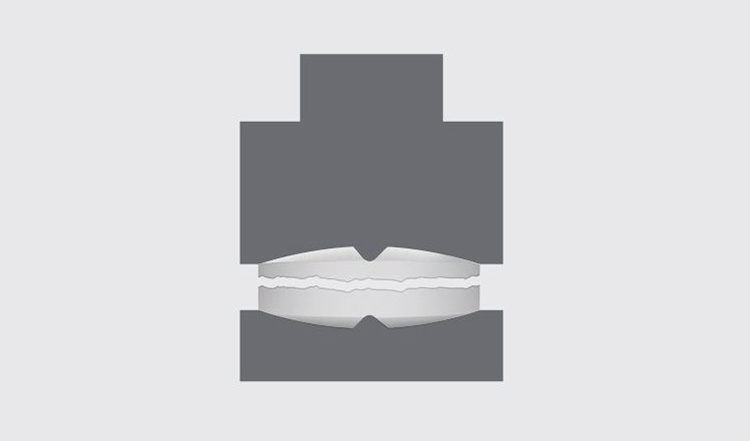

| 3 | Pills get break while pressing | The most common cause is more or less dwell time | You need to reduce the dwell time if pill is hard but broken and increase the dwell timing if pill is broken due to ingredients disintegration |

Broken pills display- Picture Courtesy: Shutterstock |

| 4 | Excessive breakableness of pills | There are many reasons for it such as low dwell time, entrapped air in cavity, and high abrasion | It can be solved by increasing compression time, so, that air will get enough time to escape. Also, use cohesive binders to avoid abrasion |

Friable pills with tester- Picture Courtesy: biogrund.com |

| 5 | Mottling of tablets | Inappropriate blending of colorants and insufficient drying of mixture cause uneven distribution of pigmentation | It can be avoided by applying uniform blending and giving your particulates enough time to get dry |

Mottle tablets- Picture Courtesy: ipharmachine.com |

8.Factors Affecting The Quality Of Pills During Pressing?

Whenever, you intend to press your own pills, keep in mind that there are many factors which may obstruct your way to gain quality pills. What are these? We have discussed them below. Make sure to fully get all of them:

Weight

Weight of pills is the most crucial factor to look for when making pills. While pill press removes the access ingredients from die cavity, it does not weigh the formulation. Hence, you must be careful to weigh the mixture in advance when pressing pills manually, and adjust the hopper, feed, and flow of ingredients to make consistent pills.

Pressure

Pressing handheld tablet press- Picture Courtesy: sotsu.co.jp

Application of required pressure to press pills is another significant aspect to look for. As it determines the hardness of pills; the greater the pressure the higher will be hardness or vise versa.

Pressing Tools Condition

Irregular mold die for tablet press machine- Picture Courtesy: bestshoptheday.com

Punching tools and die cavity are the key stimulants to form your pills. Similarly, damaged and dirty tools will affect your pills' quality negativity. Therefore, it is necessary to keep them clean and tidy.

Ingredients

Dual color granules- Picture Courtesy: ipharmachine.com

Which type of ingredients you are going to use in your pills will absolutely have a long-lasting impact not only on the users who take them but also on your business. In essence, using non-allergen, non-addictive, and quality ingredients will make your pills enchanting for consumers.

Conclusion

To sum up, we are sure that you have finally got the answer to how to press your own pills! It is imperative to have clear understanding of the components, tools, and methods for pressing pills before rushing upon starting it without any knowledge. Which will, otherwise, lead you to face conundrums. Now when you are fully equipped with essential knowledge of pressing your own pills, what's your next step? Do you want to make start from home or small industrial start up? For your eagerness in either of case, we are always here to assist you and provide you the best pill press having one year of warranty. Feel free to contact us!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide