How To Package Powder: The Complete FAQ Guide In 2025

You can never ignore package powder in the manufacturing sector. Innumerable products are only prepared from powders. Whether it is pharmaceuticals, nutraceuticals, or non-health-related fields, the packaged powder plays an unparalleled role in their product's success.

Picture Courtesy: Euronews

The massive trick is none other than a packaged powder that transforms the substance into the right product. Remember, you should critically evaluate how to package powder when planning for filling or packaging powders. Do follow the article ‘How to Package Powder: The Complete FAQ Guide In 2024’ to get essential information and possible packaging powder for your industry.

1.What is package powder?

Package Powder: Picture Courtesy: Mtpak

As a matter of fact, the powder is a dry and loose substance that exists in either a free-flowing or non-free-flowing state. However, for various applications, you cannot use them in an existent shape.

Therefore, it is packed in different package materials for your convenience and its protection which makes it readily available for market and further applications. In the past few years, there has been a high rise in the demand for package powder due to unlimited benefits.

Nevertheless, a suitable and excellent package powder can either make your good profile or break it. Thus, various different and secure package powder materials have come into the market to improve your brand side by side offering high quality and promising safety against dust expulsion.

2.How package powder can be profitable?

Package powder

The package powder serves an integral role in your quality product and profit. There are certain reasons why a packaged powder can be involved in boosting your business.

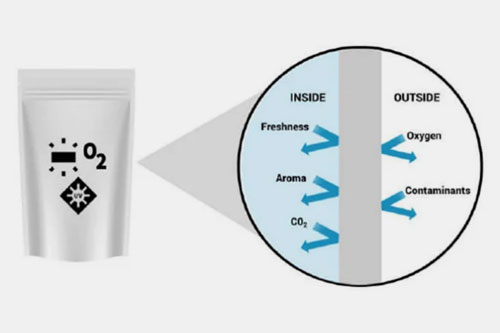

| Preservation of Freshness and Quality

|

This is considered one of the elemental entities as a package powder has the ability to preserve the quality of your powders. What makes your good quality product is its freshness and intact packaging that facilitates an airtight environment inside. Therefore, it ultimately protects the powder against unwanted factors that affect the freshness. so, it ultimately preserves high-quality standards and maintains the loyalty of your brand and customer satisfaction. |

| Extending Shelf Life

|

Package powder is just like creating a barrier against environmental factors that helps in keeping a high shelf life as it safe powders from unwanted hazards. For that, there are certain techniques that are used for package powders such as Modified Atmosphere Packaging (MAP) or vacuum packaging help in prolonging shelf life by reducing the chances of progression of microbes. |

| Convenient Handling and Transportation

|

The package powder is helpful in market handling and transportation worldwide in a super-efficient way. You can simply store them in a minimized space allowing flexible transportation without any chances of spillage or leakage, so, it is helpful in enhancing the overall marketing and shopping experiences for many suppliers. |

| Branding and Marketing

|

Good packaging is always serving as the best tool for enhancing your market value. You can add beautiful colors, graphics beautiful aesthetics, that can attract the customers when they see the packaging on the market shelves., furthermore, it allows a convenient mode to get your message or communication printed on the packaging with catchy designs with relevant product information, for example, the date of manufacturing, expiry, etc that assists too customer and builds a good impression. |

| Tamper evident packaging

|

The package powder ensures the customer that whatever they are taking is absolutely original and directly packed by the manufacturer. The strong sealing and tamper evident stamp guarantee the product delivered to you without any impeding. |

3.How to package powder?

The Steps For Package Powder

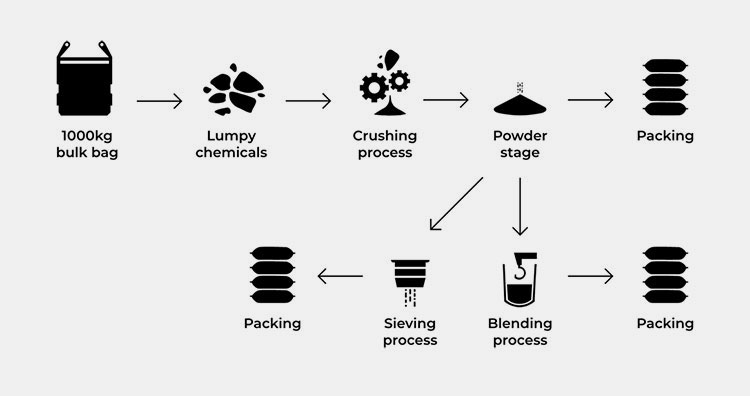

| Bulk Bag Package Powder

|

Bulk or tote bags are packed with powder by using a large powder filling machine, which is mainly worked by net-weighing filler to dispense a correct and large portion of powders into the bags |

Bulk package powder- Picture courtesy: National bulk equipment |

| Crushing

|

For manufacturing purposes, the crushing machine is used to reduce the particle size to the finest sizes. for this, a pulverizer, or grinder machine is used |

Pulverizer |

| Blending

|

To mix powders with active substances or improve flowability glidants or lubricants are used. For this, various types of blenders can be used such as V-blender, ribbon mixer, paddle mixer, etc. |

Blender |

| Sifting

|

To get consistency, the sifter machine is used to separate irregular particles and make powder with uniform sizes. The screening can be done by the vibratory mechanism which collects powder substance depending on different grading. |

Sifter |

| Package Powder

|

Whether in pouches, bags, cans, or containers, the final package powder is done to attain the final packaging ensuring the product is suitable for long-term storage and shipment. |

powder pack |

4.What are the different materials for Package powder?

Productive package powder demands versatility. The design of the material safety for the powder. Let’s discuss some of the established practices regarding the material for package powder.

Jars/cans/container

Jars/Cans/Container Package Powder

A hollow container, spherical cans, and jars are good choices for package powder. These containers must be hooked with a lightweight portable cap. These jars are composed of hard-wearing matter planned to store and supply powder products conveniently and secure them against external physical factors.

Sachet

Sachet

Another suitable material used for package powder is a sachet. It is a side hermetic pack that is made of either plastic or aluminum and is used for packaging powder. It offers a handy way to store your product that you can carry anywhere very easily.

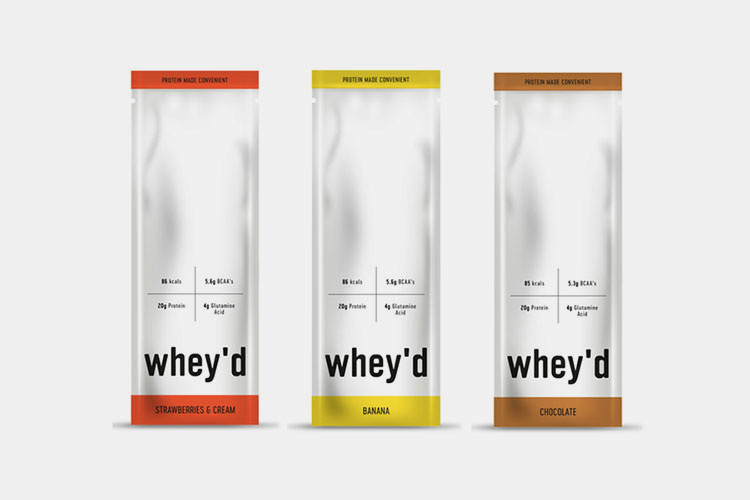

Premade Pouches

Pre-Made Pouches

Today, for package powder you have better options in the form of premade pouches. They have extra storage space and are convenient to position in your cabinet and shelves that’s why it is way more popular as package powder material.

Stick Packs

Stick Packs

You can go for the stick pack as it is the ideal solution with lots of customized options. The primary perks of using a stick pack for package powder are its suitability with substances, single-serving options, and sustainability.

Pillow Packs

Pillow Pack

Pillow packs are a hassle-free and accessible alternative to package powder. This is mainly used for small portions of package powder and you will get assured freshness with its seal on both ends i.e. top and bottom.

Bulk Package Powder Materials (Tote Bags)

Bulk package powder materials are becoming popular for their additional seals around the sides and bottom of package powder for retail and long-distance trading. Tote bags are excellent packaging solutions for powder substances.

5.What machines are used for package powder?

Let’s be very honest, when talking about package powder, you will be having with so many options and highly competitive modes, that the wow factor is only to get the right machine or right way that absolutely meets your demand and can package powder under your budget. Therefore, we have conducted the list of methods to package powder right just below:

Manual Package Powder

Manual package powder

This is a traditional way to package powders that is also known as a manual package powder. Let’s see its structure which is equipped with a handle and screw in some cases. Of course, when you push the handle or unscrew the knob, it will draw some quantity of powders into the package.

Here, the amount of package powders depends on the intensity of the pushing handle. How simple is that! This method is highly reliable, and the machine used for this purpose is so simple in certain ways. For example, it is economical, suitable for small businesses, and does not require high power consumption. Many home-based, research and small pharmacies utilized this method for packaging powder in limited quantities.

Mechanical Package Powder

Certain machines are further sub-classify into the following:

| Based on Package Technique

|

Based On the Type of Package Material

|

Based On Package Powder Machine Design

|

Based On Package Powder Automation |

| Auger Filler

Net Weight Filler Vibratory Filler Volume Filler Vacuum Filler |

Automatic Can Package Powder Machine

Premade Pouche Package Powder Machine Carton Package Powder Machine Film Form and Sealing Machine Stick Package Powder Machine Sachet Package powder machine Pillow Package powder machine |

Inline Package Powder Machine

Rotary Package Powder Machine

|

Fully Automatic Package Powder Machine

Semi-automatic package powder machine |

Based On the Package Technique

When you’re subjected to package powder, there are two basic techniques that every piece of equipment follows.

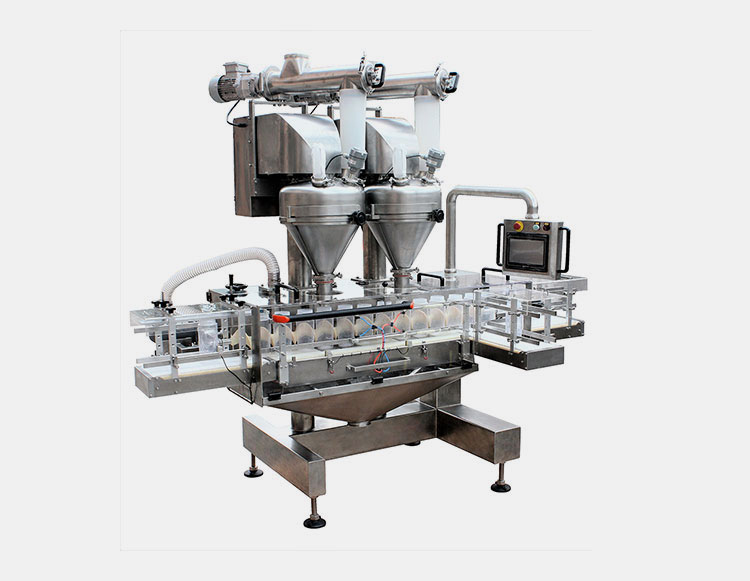

Auger Filler

Auger filler- Picture Courtesy: Pexicome Group

This is the most commonly used technique for the various packaging materials. The powder can be packed into the different packaging materials by using rotating auger screws equipped with auger filler cone that helps in the transportation of material from the reservoir hopper toward the container, or bag.

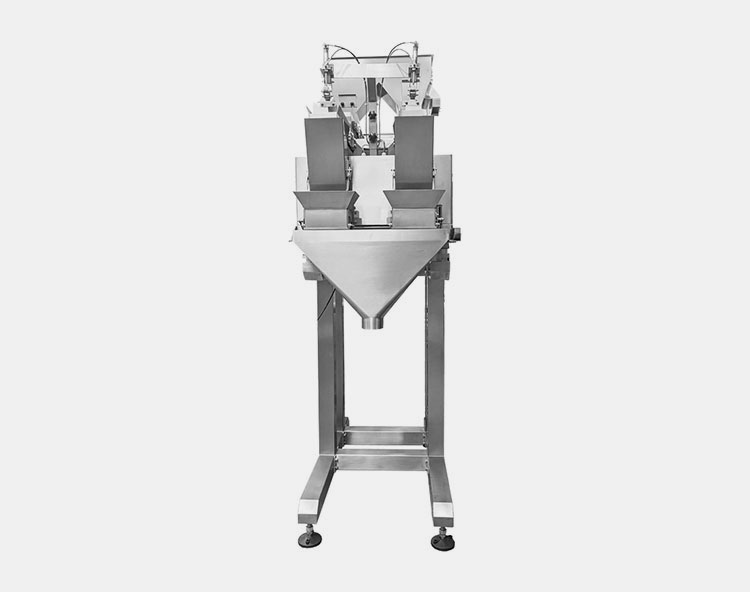

Net Weight Filler

Net Weight Filler

By its name, you can guess that it is used for filling high operation batches for the accurate package powder. The precise weight of the powder is measured by the machine prior to dispensing into the packaging materials.

Vibratory Filler

Vibratory filler- Picture Courtesy: All-Fill

It utilizes vibratory force to package powder into the materials. The purpose of vibration is to attain uniform and constant flow with an even distribution of particles and minimize the risk of aggregation. Several materials such as spices, or substances prone to clump are mainly subjected to vibratory filler.

Volume Filler

Volume filler- picture Courtesy: Lenis

This is the common type of filler that takes a specific volume of package powder where accuracy is the foremost requirement. This is capable of filling materials with broad shapes and sizes.

Vacuum Filler

Vacuum Package Powder- Picture Courtesy: GEA

A package powder machine works by creating a vacuum for the suction of powder, Therefore reducing the chances of dust formation and ensuring precise powder filling.

Based On the Type of Package Material

The package powder can be made in various materials; therefore, the following different machines are subjected to fill them. For example:

Automatic Can Package Powder Machine

Can Package Powder Machine- Picture Courtesy: Threepac

It completely utilizes automatic processing for the package powder process. The machine has the capability to treat various packaging materials, such as cans, jars, and bottles.

The machine is involved with feeding, filling, and capping.

This machine is mainly applied in nutraceuticals, pharmaceuticals, and food companies for the packaging of various products like powdered milk, health supplements, spices, etc.

Premade Pouch Package Powder Machine

Premade Pouch Package Powder Machine- Picture Courtesy: Honorpack

This is an automatic solution for the filling of various varieties of pre-made pouches with a consistent throughput. This machine is an ideal solution for large industries as it allows a high-speed package of powder with various customized options, such as fast changeover, excellent automation, various shapes and sizes of pre-made pouches, and compact floor space.

Film Form and Sealing Machine

Allpack FFS Series

These also known as FFS machines prevalent in package powder, and are mainly available in two basic types; a horizontal form, fill, sealing machine, and a vertical form film sealing machine. Each machine selection can be chosen by the customer depending on their requirement and the type of packaging they want.

If we compare VFFS to HFFS, a vertical machine is more recognized than a horizontal one due to certain reasons for example, it is very cost-effective, designed in a compact structure, and can be utilized from small to medium to large industries.

Stick Package Powder Machine

Allpack Stick Package Powder Machine

This machine is capable of packaging powder in a single-serving stick pack. This is known as a stick pack as its form of package resembles the stick. Modern consumers mostly prefer using single-serving products by selecting them due to offering accurate and travel-friendly packaging with improved aesthetics.

Sachet Package Powder Machine

Allpack Horizontal Sachet Package Powder Machine

For making of small sachet for package powder, the compact solution of a sachet machine is presented in the market that provides you with making and filling of sachet in flexible automation. This machine is designed with benefits to customers as it is quite economical and performs excellent tasks for a broad variety of powders such as free and non-flowing powders.

Pillow Package Powder Machine

Pillow package powder machine- Picture Courtesy: SED Pharma

This machine is suitable for packaging powder in pouches that are formed in the shape of pillow. The top, side, back, and bottom sealing and filling of powder can be done by the machine to dispense small and precise quantities of powder into each single pack.

Based On Package Powder Machine Design

Based on package powder machine designs, it is categorized into two basic types:

Inline Package Powder Machine

Inline Package Powder Machine

The inline is a very simple and reliable machine and used for many years. This is an easy-to-use machine with few drawbacks as it acquires a large floorspace, therefore customers with limited space are not suggested to purchase this machine.

Rotary Package Powder Machine

Rotary Package Powder Machine

As compared to an inline package powder machine, it is way much faster option with various properties. This is mainly designed with a carousel with empty pockets for adjusting feeding material. With the help of circular motion, empty package materials come to the filling section, the sensors detect, fill the powder, and leave the section.

Based on Package Powder Automation

Based on automation the package powder machines are two types.

Fully Automatic Package Powder Machine

Automatic Package Powder Machine

This is a modern package powder machine with extensive automation. In larger production lines, the machine can integrate with other units to bring the entire processing automatically day and night.

Semi-Automatic Package Powder Machine

Semi-Automatic Package Powder Machine- Picture Courtesy: Sino Pharmaceuticals

This machine is considered a better option for packaging powder than a manual or handheld procedure. It gives moderate package powder throughput therefore preferred in medium production sizes units.

6.Where do you apply package powder in industries?

Package powder is an integral process required in the various manufacturing and packaging industries worldwide. For example:

Food Industry

Food Industry

This is the fast-growing and highly demanding manufacturing sector linked to package powder. In this industry, safety and hygiene are fundamentally important to keep your product intact and potent for a long duration and acceptable to consumers. The package powder technique is required for the various steps till final marketing. For example, spices, sugar, grains, flour, tea, coffee, condiments, etc.

Pharmaceutical/ Medicinal Industry

Pharmaceutical Industry

The pharmaceutical industry is concerned with healthcare items, and for that precise and accurate package powder is needed for the formulation and packaging of solid dosage forms, and the preparation of liquid dosage forms such as syrups, suspensions, and topical preparations. None of any formulation is possible without package powder. For example: tablets, capsules, pellets, pills, antibiotics (topical, oral, injectables, etc).

Chemical Industry

Bleach Powder

In this industry package powder is essential for the safety of the user as well as the environment. For example, in the chemical industry, mainly package powder is concerned with organic and inorganic substances, neutralizing salts, bleaching agents, alkaline materials, and acidic and related compounds that are commonly available in dried free-flowing and non-free-flowing form.

Nutraceutical Industry

Nutraceutical Powders

This industry offers you three different types of power products. First, it provides health supplements, second, it provides functional food substances such as milk protein, and formula milk, thirdly, it offers you herbal or plant-based products. Many of them are available in powder form which necessitates package powder. that is why this machine is high in demand when it comes to packing nutraceutical goods.

Cosmetic Industry

Cosmetic industry- Picture Courtesy: Health

A fast-paced and dynamic sector associated with various skin-related and personal hygiene products in the powder formulation. It includes skin cleaners, concealing powder, loose powder, compact powders, and various foundations, hair care-related regimes that are mainly formulated in powder. That is why, the package powder technique is required for the filling formulation and marketing for the mentioned cosmetics items.

Agriculture Industry

Agriculture Industry- Picture Courtesy: Al Ardh

This industry plays a broader role in the boosting economy and high demand for package powder types of machinery for dealing with agricultural products such as grains, seeds, plant supplements, raw as well as finished products, etc. requiring package powder's accurate and dust-free packaging.

7.Does Package Powder Need Desiccant?

Oxygen absorber packets: Picture Courtesy: OxySorb

Desiccant is a moisture-absorbent agent that is particularly responsible for keeping powders dry. In many cases, it is recommended air-tight powder packing to avoid rapid degradation of potent ingredients and clumping. Therefore, desiccant is used in the packaging industry to avoid all these situations and to retain the chemical makeup of package powder.

But it depends on the conditions of the packaged powder. Like if your product is packaged in a large bulk container then it is very susceptible to absorbing unwanted moisture content. Therefore, the desiccant is used for package to maintain the quality of powder.

8.How long is a packaged powder safe?

Shelf life of package powder

Shelf life determines the time period starting from the production of the product till the time when the item no longer has that goodness in terms of quality.

So in the case of product safety, the pivotal role is played by its packaging. The protection system of a product i.e. package powder serves as a junction between the outside environment and the packaged item.

The major parameters influencing the shelf life of package powder include; temperature, moisture conditions, light, etc. Normally, package powder is safe for one to two years but it may vary from powder to powder substance.

Package powder for food and healthcare items is mainly done under strict conditions that to avoid oxidation. Therefore, N2 or vacuum is used to displace oxygen inside packaging with vacuum or N2 (inert and harmless) that lengthen shelf life and the package powder stays fresh for a longer period.

9.What are the challenging problems and solutions with package powder?

The package powder is a critical process that is dealt with in a careful manner. However, there are some common problems that you may face. We have mentioned them with possible solutions.

| Problem | Cause |

| Dust Formation | During packaging powder, there are greater risk for dust generation that is harmful to you as it may be directly inhaled and cause respiratory problems. Secondly, dust formation may lead to product wastage as particle blows off in the air. |

| Solution

Anti Dust Package Powder Filler- Picture Courtesy: Professional Pouch To solve this problem, you should opt for the machine that features an anti-dust unit that collects dust via positive pressure and collects in a collector. This will ultimately subside this problem; moreover, the package powder area must be well-ventilated ensuring a hygienic workspace. |

|

| Problem | Cause |

| Poor flow of package powder | Powders with poor flow commonly demonstrate weak flow with more cohesiveness. This may result in inaccuracies with poor quality filling. |

| Solution

Improving flowability An auger filler with a rotating agitator must be used for efficient package powders. Moreover, a vibratory hopper improves the flow rate by consistent vibration. Also, check |

|

| Problem | Cause |

| Powder Aggregation | powder clogging is another common problem that interrupts the flowability and quality. |

| Solution

Preventing Powder Clogging It is recommended to clean the equipment used for packaging powder to improve easy flow and minimize the chances of powder clogging. Using a sifter before packaging is a good option to ensure improved flow in packaging of powder. |

|

10.What are things to be considered for package powder?

Nevertheless, you may face some challenges while commencing the process of packaging powder. The slightest miscalculations may cause damage. Therefore, you must take the below factors into account for package powder.

Knowing the Powder’s Nature

Nature of Powder

Powder is available in two forms. It is either free-flowing or non-free-flowing powder. You must have the insights of powder form because it will definitely influence the preciseness, proficiency, and quality. For instance, you can identify its type by applying pressure. You will get the powder compacted in case of non-free-flowing powder. And if its shape didn’t get manipulated by pressure, it is a free-flowing powder.

| Powder Nature | Machine Requirement |

| Free-flowing powder | Auger, net weight, vibratory, etc. |

| Non-free-flowing powder | Auger Agitation, Vacuum Fillers, Compression Fillers. |

Are you Dealing with Free-Flowing Powder?

As its name indicates, this type of powder is found in free form. It flows freely without getting cohere. During the dispensation process, the particles move around freely without being stuck to other particles. Examples of free-flowing powder include sugar and salt.

Are you dealing with Non-Free-Flowing Powder?

Particles can stick to other particles if the powder type is non-free-flowing. Particles do not move freely. The cohesive attributes of milk powder make it a non-free-flowing type of powder.

Bulk Density

Knowing Bulk Density

Bulk density is an important factor that helps in selecting the optimum size of pouch or other packaging material. The industrialist can upgrade the package powder as long as they consider this significant factor.

For that you need this formula, (ρ) = M / V

ρ = denoted as bulk density (g/cm3)

M = denoted as the mass of the powder (g or kg)

V = denoted as a volume of the powder (cm³ or m³)

It also minimizes resource waste and assures consistency. For example; you need small-sized pouches to fit high-bulk-density powder in it. Such as brown sugar or sand can be effortlessly compacted. But some products like roasted coffee don’t fit in small pouches as it does not get compressed. Hence large pouches will be consistent with low-density powders.

Style of Material/Container

Style of Material/Container

As we have discussed diverse forms of materials are advantageously utilized for package powder, including jars, cans, pouches, stick packs, or pillow packs. By considering the correct style of material for package powder, you will reduce the potential risk of product damage. You ought to pick the required material based on powder usage. Such a powder sachet will be convenient for package powder that is valid for single usage. Similarly, you can opt for bulk package powder materials (tote bags) for mass products.

Conclusion

In summary, the role of package powder is inarguable in the packaging industry. There are unlimited options for package powder are emerge with deal with consumers' demands and meet challenges. Allpack understands its critical role in today’s market. That’s why- we have a broad series of package powder machines that are ideal for your business and requirements. If you have any queries or want to look at our extensive equipment. Please contact us now!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide