Honey Stick Packing Machine: The Complete Buying Guide In 2025

Although everyone is familiar with the sweet, sticky substance that hangs out inside convenient squeezy supermarket bottles, what is inside all that golden sweetness? Honey is typically a sugar substitute, but it is more chemically complex and interesting than simple sugar. Most honey packaging loves to remind you, that bees make honey from nectar gathered from flowers however it is not simple sugar turned into golden syrup instead it's a complex evolutionary tool designed for the bee’s survival.

As businesses strive to meet rising consumer demand for high-quality honey, the honey stick packing machine emerges as an indispensable tool, ensuring competitive advantage and fostering growth in a dynamic market. Honey stick packing machine is a revolutionary way for honey to be packed and delivered to customers with optimum quality, hygiene, safety, and sustainability. So let's have a deeper understanding of the equipment!

1. What Is A Honey Stick Packing Machine?

Honey Stick Packing machine - Picture Courtesy: Cankey packaging machine

A specialized piece of machinery called a honey stick packing machine is used to fill and seal honey into handy single-serving stick packs automatically. These devices are designed specifically to accommodate the special qualities of honey, guaranteeing accurate filling and tight sealing to stop leaks and preserve product quality. Popular for their convenience and portability, honey stick packs are a great choice for single-use applications, promotional sampling, and on-the-go consumption.

2. What Are The Benefits Of Honey Stick Packing Machine?

When production is occurring on large scale then the machinery is expected to work efficiently and talking about honey stick packing machine, it is one of the most cost effective and efficiently working equipment. It provides several benefits to production line that helps in bulk production of honey sticks.

The significance of honey stick packing machine is described below:

High Flexibility:

Honey Stick packaging Machine- Picture Courtesy: Auto pack

Because of its great degree of versatility, the honey stick packing machine can handle a wide range of stick pack sizes and ensures to satisfy a wide range of market demands. This flexibility includes managing varied fill volumes and packaging materials, guaranteeing compatibility with a range of honey flavors and viscosity. The machine is perfect for manufacturers who need adaptability in their packing processes without sacrificing efficiency or product quality because of its programmable settings, which allow for quick changeovers and customization.

Fast Speed:

Stick packaging Machine- Picture Courtesy: qpharma

The high-speed operation of honey stick packing machines greatly increases production efficiency. Because of their precise control systems and sophisticated automation, these machines can generate hundreds of stick packs every minute. Their swift performance guarantees accurate and high-quality packaging of big amounts of honey in a timely manner.

Handling Is Easy:

Easy Handling- Picture Courtesy: Lascar Electronics

Honey stick packing machines have automated mechanisms that make maintenance and operation easier, as well as user-friendly interfaces for effortless handling. Usually, these devices include user-friendly control panels that let users adjust variables like speed, filling amount, and sealing temperature. For businesses looking to optimize their packaging operations, these automated procedures guarantee constant output with little manual intervention, and their modular design makes cleaning and maintenance easier.

Accuracy

Measuring accurate results - Picture Courtesy: Kaizenaire

There are less chances of error as honey stick packing machine are more time saving, reliable and highly efficient.

Maintenance

Machine Maintenance - Picture Courtesy: MES

Maintaining a stick packing machine is very easy and workers can easily replace parts and errors in case of a problem. So weekly, monthly and yearly maintenance schedule cab be set for better performance.

3. What Are The Applications Of Honey Stick Packing Machine?

Honey stick packing machine is a very efficient machinery that can produce honey sticks that are used in various day to day use products. It provides high quality honey to end consumer with ease of packaging and handling. Honey stick packaging machine is widely used in following industries:

Pharmaceutical Products

Honey cough syrup in stick packing - Picture Courtesy: Dribbble

Honey is used various pharmaceutical products because of its anti-allergic, anti-oxidant, anti-diabetic and antibacterial properties. Honey is considered very effective in sore throat and coughs so it is widely used in various cough syrups and elixirs. It is also used in medications such as eye ointments.

Food Products

Honey in cereals- Picture Courtesy: Ashraf Naturals

Food industry is a huge industry where honey is widely used in many products. Honey sticks are used in cereals as a substitute for sugar. They are also used in various beverages and snacks. They are used as flavouring agent in bakery products. Honey sticks can also be use a topping for desserts like ice creams, cakes, yogurt and fruit salads.

Beverages

Tea with honey as a sweetener - Picture Courtesy: Ashraf Naturals

Honey sticks are widely used in various beverages as a sweetener. It is most commonly used in teas, coffees, smoothies, cocktails and fresh juices. Its anti- diabetic properties maintains calories and reduces sugar intake making the drinks healthy and tasty.

Cosmetics

Skincare products containing honey in Stick packing - Picture Courtesy: Whizzcart

Honey is widely used in various skincare and cosmetic products since long time. Some of the common applications in cosmetic industry are

- Lip Balms

- Moisturizing lotions and creams

- Anti- Ageing products

- Hair care products

- Sunblocks

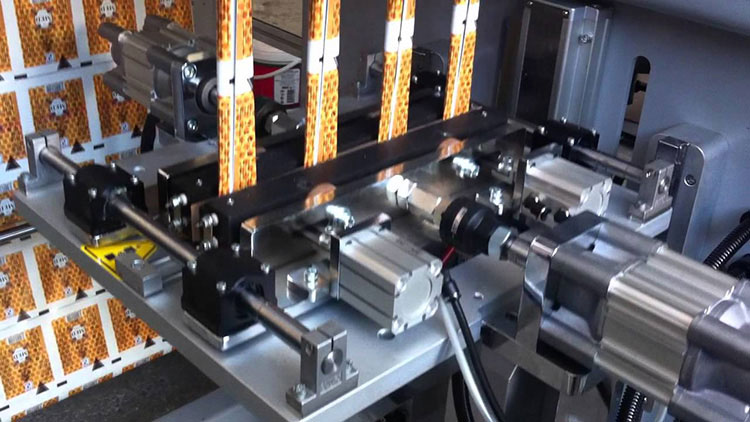

4.What Is The Principle On Which Honey Stick Packing Machine Operates?

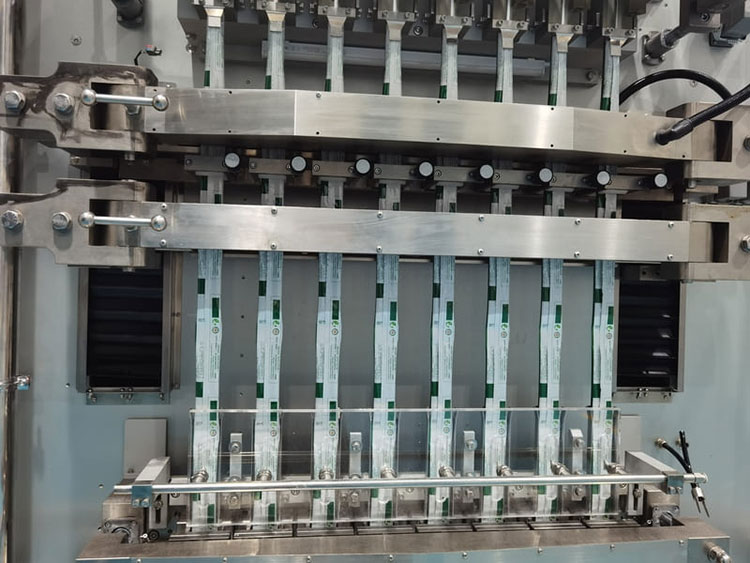

Multilane stick packing machine - Picture Courtesy: Coretamp

The filling and sealing of honey into stick-shaped packaging is automated by a honey stick packing machine.

- A roll of packing film is first unwound by the machine, after which it is shaped into tubular shapes. Appropriate amounts of honey are poured into these sticks by pumping it through nozzles.

- Then the unwinding of film occurs and as a result of rotation of unwinding disk and movement of cross sealing jaws that are located in front of the equipment. Then with a help of a printer the film is printed.

- Once the process of printing is completed then the next step starts where a consistent pressure is applied by nip rollers on the film. After passing from nip rollers the film is transported to cutting section called the slitter assembly. Now according to the lanes of honey stick machines the film is cut into various sections with help of a cutting knives.

- Now once the film is cut into various strips it goes to the next section where the film is transformed to form honey sticks with the sealing of two sides of stick pack.

- In the next step the vertical side and edges of the stick pack are sealed through vertical seal bar and horizontal seal bar.

- After the closing of sealing jaws honey is dispensed to the honey sticks from the hopper through volumetric valves.

- The machine then uses heat sealing to seal the sticks, resulting in the creation of individual sticks. After being sealed, the sticks are trimmed to the appropriate length and gathered for packaging. A programmable system that guarantees accuracy, efficiency, and consistency oversees the entire operation.

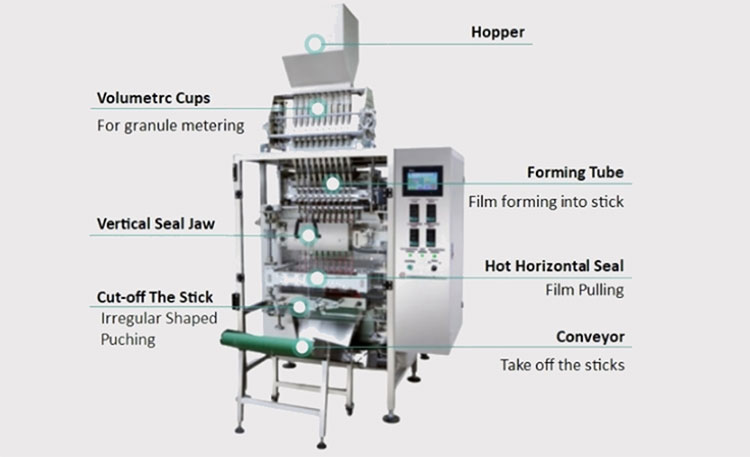

5.Describe The Components Of Honey Stick Packing Machine.

Components of honey stick packing machine - Picture Courtesy: Allpack

Various components are involved in honey stick packing machine. All these parts play their specific role.

Some basic parts are these:

Hopper:

Hopper - Picture Courtesy: Nicejugsmk.shop

Hopper is a stainless steel dome like structure that is used for dispensing honey to the packaging line. It acts as a reservoir for continues supply of honey. Sometimes it also contains stirrer or agitator where the consistency of honey has to be maintained. Its mechanism is synchronized with filling mechanism that ensures precise filling of tubes without leakage.

Forming Sticks

Forming tubes - Picture Courtesy: Allpack

When the unwinding of film role occurs with series of rollers then this film is moved to the forming section. Then this film passes through the collar and forms it into sticks. After this it is moved to heat sealing section where it is sealed to form a proper stick. Now this newly formed seal is ready for filling.

Vertical Seal Jaw:

Vertical seal - Picture Courtesy: Breedewegh

A heated sealing bar and an opposing anvil, or sealing surface, make up the vertical seal jaw. At this point, the edges of the film come together.

The inner surfaces of the film melt and fuse together as a result of pressure and heat applied by the heated sealing bar pressing the film's edges up against the anvil. The heat application's duration and temperature are carefully regulated to guarantee a robust seal without causing any harm to the film.

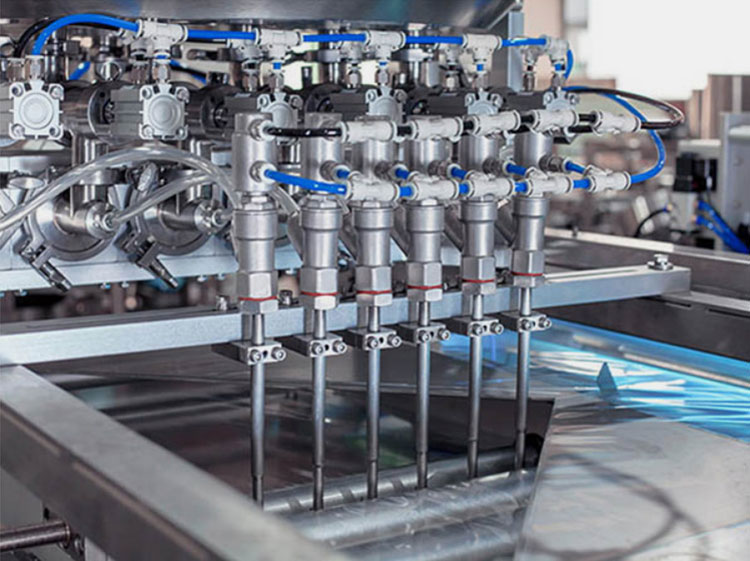

Hot Horizontal Seal

By closing around the tube, the heated horizontal tubes pressurize and heat the packaging film. The film's inner layers, which are usually covered in a heat-seal able substance, melt and fuse together as a result of the heat.

Strong bonding between the melted layers is ensured by the pressure, resulting in a robust seal. To guarantee consistent sealing without causing harm to the film or the honey within, this process is carefully regulated.

Conveyor System:

Conveyor System- Picture Courtesy: Vimeo

Conveyor system is a part where finished sticks are transported and collected. It is a very efficient automated system that separate all the sticks and then transport them to the desired section for finishing.

6.What Is The Classification Of Stick Packing Machine?

For the packaging of honey different machines are available in various configurations so that the brands on it can select any of those depending upon their requirements some important packaging machines are detailed below:

Single Stick Honey Packing Machine

Single stick honey packing machine - Picture Courtesy: Guidingpartnerships

Description: Its a small machine that fill single honey stick in single cycle. It is suitable for small scale production. It does not occupy lot of space. It is also easy to handle and operate.

Multi Lane Honey Stick Packing Machine

Multi lane honey stick packing machine - Picture Courtesy: Stanleymilton

Description: It consist of multiple lanes and is suitable for large scale production. It produces multiple sticks in a single cycle. They are very efficient and in a single round can produce hundreds of honey sticks within very less time.

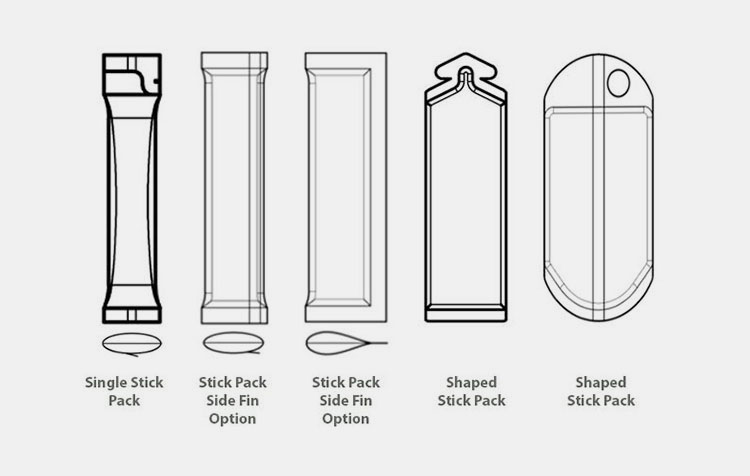

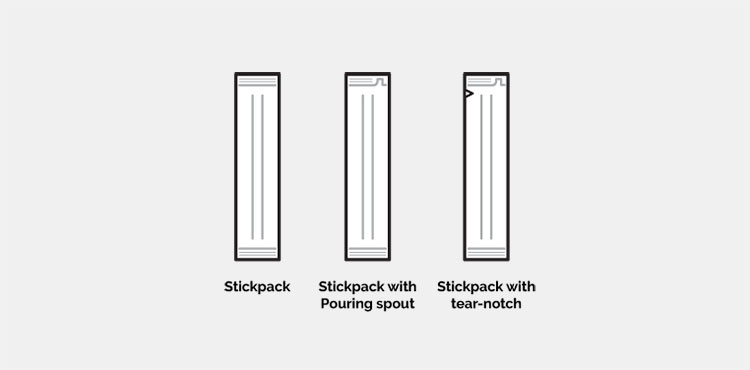

7.Is Honey Stick Packing Machine Able to Handle Different Shapes and Cutting Types?

Different shapes of stick packaging - Picture Courtesy: Markindo

Honey stick packaging machines can be used for different kinds of shapes and cutting styles. The answer is yes, the honey stick packaging machine can handle different shapes and cutting styles.

Cut type options:

Straight cut: this shape has the advantages of low cost and high efficiency, but it is not suitable for products with high ceiling requirements because of its relatively poor ceiling performance.

Serrated: the serrated shape of the stick packaging increases the sealing strength of the packaging and has a unique appearance.

Round: it is a kind of widely used stick packaging characterized using a round design in the ceiling part which not only has aesthetic appeal but also ensures the ceiling and safety of the product.

Different types of seal - Picture Courtesy: Honetop

Seal type options:

Diamond: the use of a diamond-shaped structure for sealing provides a unique appearance and appeal to the product.

Serrated: this design is widely used in the packaging industry as the shape has good elasticity and can better adapt to different shapes and sizes of products.

Micro diamond: this shape is like a diamond shape but has better sealing than a diamond shape.

8.What Are The Technical Features Of Honey Stick Packaging Machine?

- Stainless Steel body

- Presence of a stirrer in hopper

- Date coding

- Presence of photoelectric eye

- Multi language HMI

- Horizontal Sealing Bar

- Emergency Stop Button

- Cutter

- Forming Tubes

- Piston Pump

9.What Are The Problems Encountered By Honey Stick Packing Machine?

Overheating Of Machine :

Overheating of machinery caution - Picture Courtesy: Vecteezy

Blockage of filters or less ventilation leads to heating up of machine. So machines should be placed in ventilated areas and should not be overloaded. In the event that the equipment overheats, use an emergency shutdown process to safely shut it down, avoiding damage and other dangers.To keep an eye on the machine's temperature at all times, use thermal cameras and temperature sensors. To let operators know when the temperature goes above acceptable bounds, set up alerts.

Contamination Of Honey:

Contaminated honey - Picture Courtesy: Flow Forum

Sometimes unclean surface of machine or improper filtration contaminate honey. To avoid this regular cleaning of machinery is recommended. Make sure to thoroughly clean all machine parts that come into contact with honey, such as the conveyor belts, hoppers, and nozzles. Ensure that every employee complies with stringent hygiene guidelines, which include donning clean uniforms, hairnets, and gloves.

Honey’s Consistency:

Homogeneous consistency of honey - Picture Courtesy: Medical Dialogue

Stickiness can cause problem so more fluid consistency preferred. The consistency of honey should be right and stirrer should be there to keep it homogeneous. To preserve the honey's viscosity, make sure it is maintained at the ideal temperature. Warming honey to a flow-able consistency is ideal, but not hot enough to compromise its quality.

Untrained Machinery Operator:

Unskilled staff - Picture Courtesy: Multiskill Training

The workers and other staff should be well equipped to handle machinery. Untrained staff can lead to decreased production efficiency. Provide a user manual that is simple to read and includes step-by-step instructions, safety precautions, troubleshooting advice, and maintenance methods. Make sure it's always available.

Inconsistent Filling:

Consistent and homogeneous filling - Picture Courtesy: Jogossvieesa

Defect in calibration and nozzles can cause improper filling. So the defected parts should be replaced timely and calibrations should be done of the equipment for accurate filling. To prevent misalignment during the filling process, which might result in variable stick sizes and fill levels, make sure the packing sheet is correctly tensioned and aligned.

Honey Temperature:

Heated honey - Picture courtesy: Bilaal

Packaging hopper should be kept at 40-45 degrees. Keeping honey at right temperature prevents it from crystallizing and maintains its consistency. Before honey reaches the process, keep it in temperature-controlled tanks. These tanks are able to be adjusted to the ideal temperature required for a fluid flow. To maintain the temperature, use temperature sensors and thermostats.

10.How To Improve The Efficiency Of Honey Stick Packaging Machine?

Excessive industrial use of honey stick packing machine can sometimes hinder the efficiency of machinery reducing the output and creating various challenges for the production line. In order to reduce this risk there are various ways through which you can maintain the efficiency of honey stick packing machine :

| 1. | Maintaining Cleanliness |

Clean equipment - Picture Courtesy: Jochamp Regular cleaning of stick packing machine ensures an efficient dispensing of product. Use appropriate cleaning products for cleaning various parts of machinery |

| 2. | Regular Calibration |

Calibration tool - Picture Courtesy: Evolve Ltd For proper functioning of stick packing machine regular calibration is very important. It has to be ensured that the machine is calibrated accurately so that it can perform its function without any lag. |

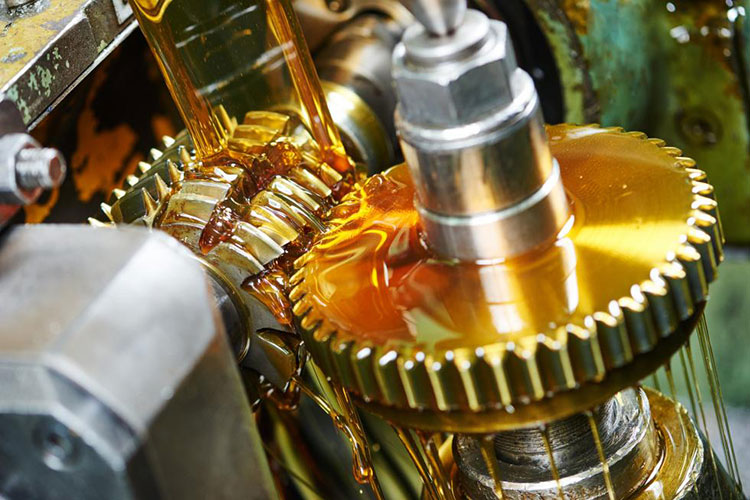

| 3. | Regular Lubrication |

Machine lubrication - Picture Courtesy: Electrical Apparatus Honey stick packing machine requires proper care of its part that can only be done through regular lubrication. Remove dust and debris from machine and grease machine parts properly. |

| 4. | Troubleshooting |

Troubleshooting machine - Picture Courtesy: Fluid Power Journal It is very important to troubleshoot the problem if honey stick packing machine is not working properly. Check all the settings of machine and contact a professional if you can not solve the problem. |

| 5. | Skilled Machinery Operator |

Skilled Operator - Picture Courtesy: Excelsior University The staff operating the machinery should be skilled enough and should have regular training. |

11.What are the main tips for selecting the best honey stick packing machine?

Several factors are involved while selecting the best stick packing machine. Certain parameters should be kept into consideration so that you take informed buying decision in 2024. Following factors should be considered:

Capacity and Output

Output determination by filling stick packs - Picture Courtesy: Trakya Makine

It is important to determine the production rate that how many units of honey sticks needs to be produced per hour per day. Choose a machine accordingly that can handle your desired production rate accordingly and efficiently.

Packaging Speed, Size and Shape

Different types of liquid stick packs - Picture Courtesy: Mail.orphirah.nl

Find that machine in which you can adjust different speeds according to your production requirements. The machine should be able to operate on a consistent packaging speed. It should be able to deal with different packaging and sizes.

Sealing Mechanism

Filling and sealing mechanism - Picture Courtesy: MSJ Packaging

While selecting a honey stick packing machine look for a machine with reliable and airtight sealing so that quality and freshness of honey sticks could be preserved. Pay close attention to the sealing mechanism of the machine as it can effect the integrity and quality of the honey sticks.

Cost and ROI

Cost and ROI - Picture Courtesy: Freepik

When buying the best honey stick packing machine certain factors like production efficiency, machine features and capability and expected return on investment helps in evaluating the cost of machinery.

CONCLUSION

The packaging process is revolutionized by the dynamic use of honey stick packing machines. Use honey stick packing machines to transform your packaging process! Attain unparalleled productivity, diversity, and quality assurance in the manufacturing of honey sticks. Make your packaging unique by using a variety of materials, sizes, and forms to accommodate any manufacturing situation. Uphold consistent standards and maximize productivity through advanced technology and precise engineering. Honey stick packing machine can help you increase output, cut labour expenses, and improve the calibre of your output. Using honey stick packing equipment helps boost your profitability and competitiveness in the honey market, regardless of the size of your operation. So wait no longer and upgrade your operations today!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide