Honey Stick Machine: The Complete Buying Guide In 2025

Do you know honey is the only food made by insects that human beings eat? Raw honey packs lots of health benefits, thus there is a huge demand for honey. To captivate end-users, brands deploy different packaging styles- one being stick packs.

These honey stick packs are fabricated by an innovative and handy device called a honey stick machine. Numerous honey packaging employs this machine because of its streamlined honey packaging, cost-effectiveness, and compact design.

This blog is designed for users, who are keen on learning more about honey stick machines. Now relax and enjoy this informative post.

1.What is Meany By Honey Stick Machine?

Honey Stick Machine- Picture Courtesy: Allpack

This equipment as the name suggests, is utilized for wrapping honey inside plastic or other kinds of film materials. Honey stick machine is a significant component of the packaging line and is essential in providing protection and helping secure the honey for shipment and transportation.

It encloses the honey by covering it with plastic polymer film or aluminum foil. It creates a narrow tube like a straw that has a higher length-to-width ratio. These honey sticks usually are best for on-the-go lifestyles as they have a one-time serving of honey.

2.What Kinds of Advantages Does Honey Stick Machine Bring to Production?

A honey stick machine is popular among packaging sectors because of its extreme protection-bestowing properties and its cost-effectiveness. It is not only employed in product sealing but also creates a striking product display.

Some benefits of these machines are discussed below for your knowledge:

High Flexibility

High Flexibility- Picture Courtesy: Pouch Packing machine

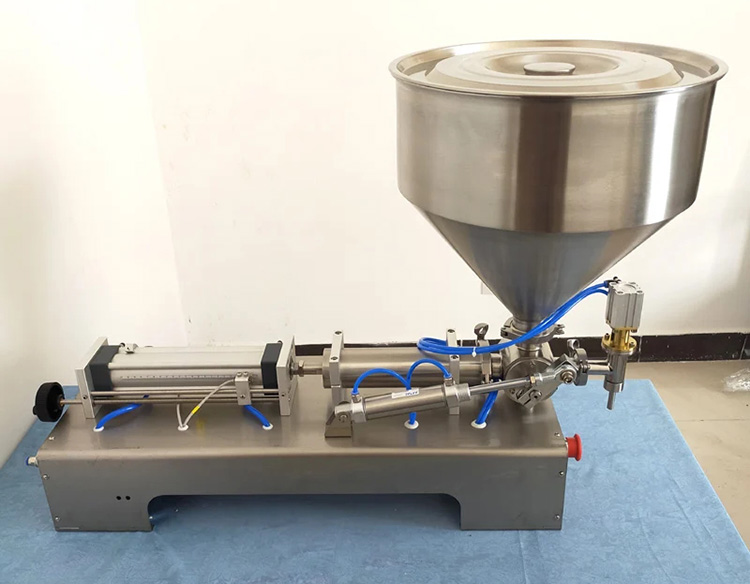

It is equipped with piston and other volumetric pumps that offer high flexibility and can accommodate all sundry products whether viscous or free-flow, pasty, and watery liquids. This is because pump fillers can process any type of liquid and with few adjustments, it can process solid and powdery items as well.

Meeting Changing Demand

Meeting Changing Demand- Picture Courtesy: Losan Pharma

In addition to flexibility, the honey stick machine can output numerous honey sticks, varying in length and design. Thus, this machine can fulfill not only present packaging needs but will process new future packaging needs as well. The machine is composed of accessible parts that allow for swift changeover and in turn, increase the versatility of equipment.

Fast Speed

Fast Speed- Picture Courtesy: Landpacking

This machine is equipped with high-tech controls that automate the honey packaging operation, lower output time, and aid in a quicker payback period, in contrast with manual filling. Fast speed and high efficiency allow brands to deliver more honey sticks to the market.

Easy Handling

Easy Handling- Picture Courtesy: Lascar Electronics

This machine provides better honey flow visibility and users can easily see packaging operation due to its modular construction, therefore, the operator easily monitor the progress of an operation. With HMI controls, they can easily program the honey stick packaging process.

Hygienic Design and Reduced Contamination

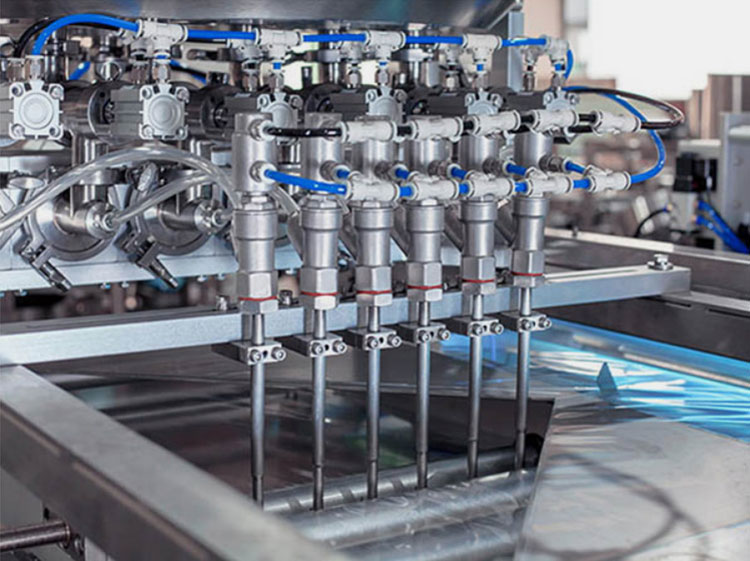

Hygienic Design- Picture Courtesy: jochamp

This machine is manufactured adhering to cGMP guidelines; hence it is high in demand in food and other industries due to its hygienic filling. With the aid of a swivel dosing system, the machine is quickly cleaned lowering cross-contamination.

3.In What Industrial Sectors Honey Stick Machine Utilized?

Honey stick machine is an essential component of various industrial units due to its affordable single-serve packaging that is favored among end-users. Its industrial applications are:

Food Industry

Use of Honey Stick Machine in Food Industry: Picture Courtesy: Dieline

This industry is one of the biggest consumers of the honey stick machine because it has high throughput while conserving floor space. In the food industry, this machine packs honey, salt, coffee, tea, peanut butter, sugar, dip, dressing, chili sauce, ketchup, and many more in the stick pack.

Dairy Industry

Use of Honey Stick Machine in Dairy Industry: Picture Courtesy: Dieline

In the dairy industry, the honey stick machine is renowned because of its better dosing precision and user-friendliness. This industry uses this machine for packaging butter, cheese, whipped cream, and ice cream.

Beverage Industry

Use of Honey Stick Machine in Beverage Industry: Picture Courtesy: Moon Juice

The demand for processed beverages and energy drinks is increasing in the modern world, hence the honey stick pack machine is increasingly employed in the beverage industry for packaging different energy drinks, juices, smoothies, and coffee drinks inside the stick pack.

Cosmetic Industry

Use of Honey Stick Machine in Cosmetic Industry: Picture Courtesy: Dieline

In the cosmetic industry, the honey stick machine is routinely employed because of its higher dose accuracy and lower packaging waste. Cosmetic brands use this machine for packaging makeup removers, shampoos, shaving gel, body wash, and sunscreens.

Nutraceutical Industry

Use of Honey Stick Machine in Nutraceutical Industry: Picture Courtesy: Blue Line Labels

This machine is a dedicated unit equipped with precise control for dosing nutraceutical supplements in single-serve stick packs that are easily carried out in bags and pockets. Honey stick machine dispenses sports supplements, probiotics, gut mix, workout formula, and energy shakes inside narrow stick packs.

Confectionary Industry

Use of Honey Stick Machine in Confectionery Industry: Picture Courtesy: Coconut Cloud

This machine uses minimal packaging film, resulting in lower operational costs, due to this it is a major part of the confectionary packaging. It is utilized for storing hot chocolate, liquid chewing gums, candies, gummies, etc.

4.What are the Basic Components of a Honey Stick Machine?

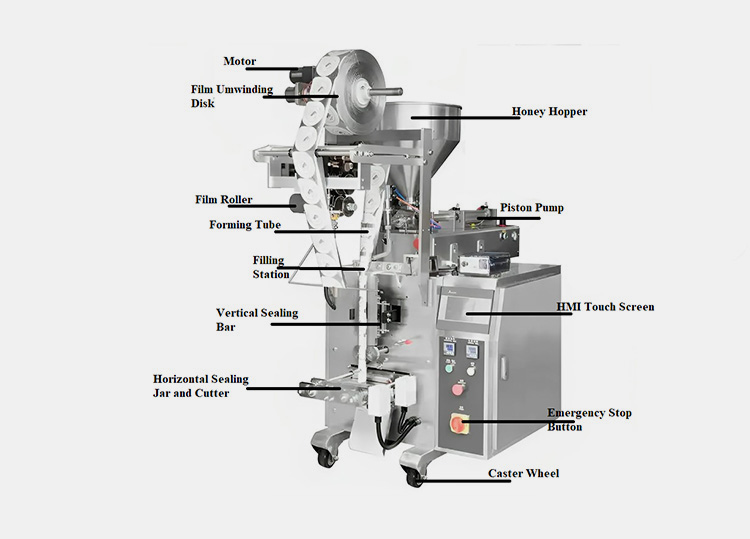

The honey stick machine is designed with different stick former, filler, and sealers. A detail of these parts is discussed below:

Parts of Honey Stick Machine

| Motor | It is powered by electricity and transforms it into mechanical energy for running various parts, for instance, sealing bars, unwinding disks, and film roller. It is also called the powerhouse of the equipment. |

| Unwinding Disk | This part rotates to unwind the packaging film. By its rotation, the film goes to the film roller. |

| Honey Hopper | The bulk quantity of the honey is fed into a conical-shaped hopper present at the upper side of the honey stick machine. This funnel-shaped device stores a bulk volume of honey for its uninterrupted flow to filler systems. |

| Film Roller | There are different types of rollers, for example, nip roller that keep the firm under constant tension and are essential in preventing the spillage of film. |

| Forming Tube | It is a conical-shaped device present in the middle part of the honey stick machine. this part has a human collar that folds and shapes the packaging film into a stick-like pack. |

| Filling Station | This part dispenses the honey product gradually in the stick pack. It is equipped with pumps and pistons that aid in filling precise amounts of honey into packaging. |

| Piston Pump | It is a cylindrical device that moves to and fro to draw the honey from a hopper into filling nozzles. |

| Vertical Sealing Bar | These parts heat and seal the two edges of the film sideways. High temperature and pressure are employed for melting and fusing the two sides. |

| Horizontal Sealing Bar | These heated bars are employed for sealing the top and bottom sides of the packaging film. These parts have a similar mode of action as that of the vertical sealing bar except for their direction of working. |

| Cutter | It is a sharp blade present in the middle of the horizontal sealing bar. It is used for separating the two stick packs from each other. |

| HMI Touch Screen | It is an automated and intuitive touch screen that provides ease of customizing the packaging operation of the honey stick machine. This control panel has different programming options that are reset with one click of a finger. |

| Emergency Stop Button | In case of an electric emergency or fire hazard, this button is pressed to immediately stop the machine without waiting for the normal machine to shut down which takes time. |

| Caster Wheel | These are the wheels that not only offer mobility but also support the honey stick machine. |

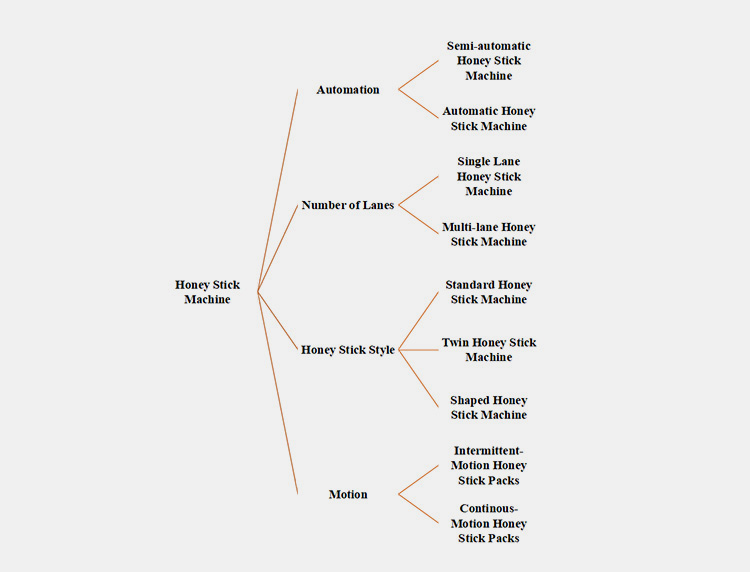

5.What Types of Honey Stick Machines Exist in the Market?

With innovation, manufacturers have produced different kinds of honey stick machines having different automation levels and design-build. The classification of honey stick machines is penned below:

Classification According to Automation

Semi-automatic Honey Stick Machine

Semi-automatic Honey Stick Machine

This type of honey stick machine adopts both automated and manual modes of operation. The operation starts with the manual loading of the film roll on the machine and ends with the manual removal of honey sticks from the machine.

The rest of the packaging from forming to filling stick packs is completely independent and carried out with the help of a machine PLC unit.

It has low productivity and is a significant component in small and medium-sized honey packaging lines.

Automatic Honey Stick Machine

Automatic Honey Stick Machine- Picture Courtesy: Autopack

This kind of honey stick machine is highly popular in massive productions due to its swift packaging and automation. It features multiple lanes and thus can output multiple honey sticks per minute.

The programming of the PLC unit is carried out by the user while the rest of the steps from loading to unloading is performed seamlessly by the machine. It is larger sized and requires more room for its setting.

Classification According to the Number of Lanes

Single Lane Honey Stick Machine

Single Lane Honey Stick Machine- Picture Courtesy: lenis machines inc.

This machine is designed with a single lane that forms and fills one honey stick in one cycle. Due to the presence of a single-lane, this machine is on the smaller end of the spectrum and thus is easily accommodated in productions with space constraints.

It has limited production capacity and is best for small-scale operations. With its quick change of parts, it can produce different-length honey stick packs.

Multi-lane Honey Stick Machine

Multi-lane Honey Stick Machine- Picture Courtesy: Allpack

It is designed with one or more lanes, consequently, outputting numerous honey sticks in one cycle. Some models of multi-lane honey stick pack machines have as many as 20 lanes with an output rate of 1600 honey sticks per minute.

These multiple lanes have synchronized forming, filling, and sealing of honey stick packs. It boosts the production rate of massive-sized packaging lines.

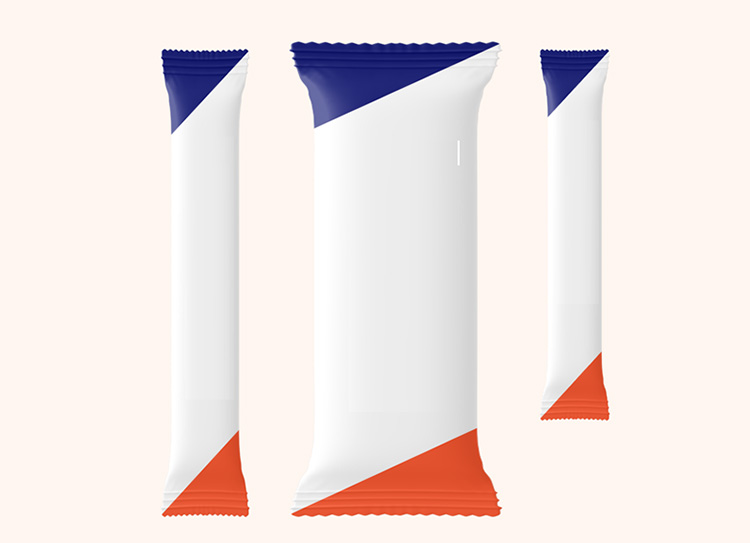

Classification According to Honey Stick Style

Standard Honey Stick Machine

Standard Honey Stick Machine- Picture Courtesy: openPR.com

As the name indicates, this type of honey stick machine creates normal honey sticks that have standard length, width, and design. This machine produces a 6-7 inch long stick pack with a width of ¼ inch.

Moreover, this type of honey stick machine is customized to create different styled seals, for instance, patterns, standard, embossed seals, etc.

Twin Honey Stick Machine

Twin Honey Stick Machine- Picture Courtesy: Aikpak

This machine consists of two product hoppers that fill honey and other products in two attached stick packs simultaneously. This machine forms a twin honey stick or fills complementary products with honey.

Filling two sticks at once increases the production efficiency of businesses, therefore, this machine is routinely found in bigger packaging lines.

Shaped Honey Stick Machine

Shaped Honey Stick Machine- Picture Courtesy: Aranow

For marketability and advertisement, a shaped honey stick machine is routinely employed in production. It goes beyond the standard straight honey sticks and creates unique honey sticks with styled seals to attract and captivate the end-users, especially children.

It is a playful approach to fabricating honey sticks consequently, bringing more profits for production, however, this machine requires higher investment than a standard honey stick machine.

Classification According to Motion

Intermittent-Motion Honey Stick Packs

Intermittent-Motion Honey Stick Packs- Picture Courtesy: IMA.it

It pauses between the cycles while honey sticks are being formed, filled, and sealed. It is also known as the stop-and-go machine. Therefore, the output capacity is slower than its continuous counterparts.

This process control offers high precision, versatility, and flexibility with easy changeover. Moreover, due to its compact configuration, it is more affordable than continuous-motion honey stick packs.

Continuous-Motion Honey Stick Packs

Continuous-Motion Honey Stick Packs- Picture Courtesy: jintian pack

It works constantly without stopping between the cycles. Its seamless and nonstop operation results in higher production efficiency and owing to this, the continuous-motion honey stick machine is highly sought-after in larger production.

It does not stop during filling, forming, and, sealing, hence can package numerous honey sticks in one go. However, this machine requires a higher initial investment.

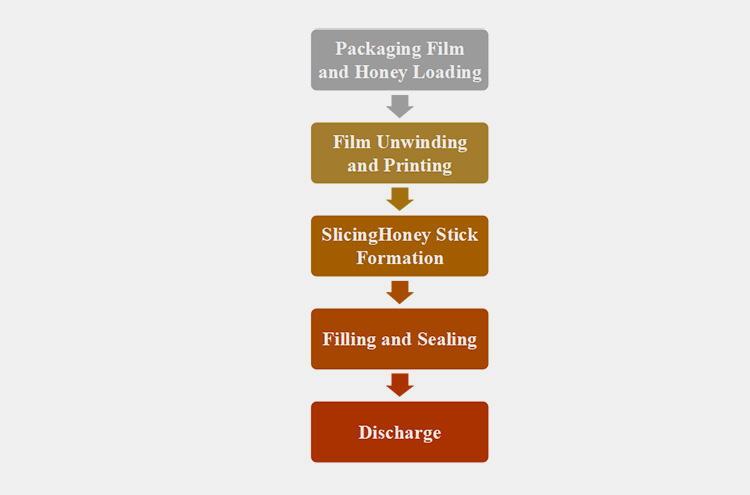

6.What is the Working Principle of the Honey Stick Machine?

To streamline the working of a honey stick machine, every component is designated a specific role and is then carried out by components flawlessly for synchronized forming, filling, and sealing operation. Here are the working steps of the honey stick machine:

Packaging Film and Honey Loading

Packaging Film Loading- Picture Courtesy: lintegra.pl

Before starting the machine for honey packaging, first, the bulk quantity of honey is fed inside the product hopper found at the upper side of the machine. Secondly, a large food-grade material film roll is placed on the film holder. The film is wounded around the core called roll stock.

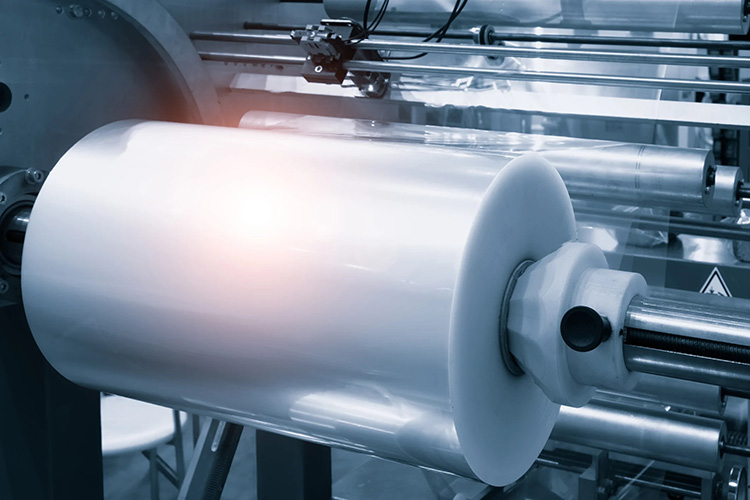

Film Unwinding and Printing

Film Unwinding - Picture Courtesy: DUO PLAST

At the start of the honey stick machine, the film began to unwind by the rotation of the unwinding disk and the motion of cross-sealing jaws present at the front side of the machine. After unwinding, the film is printed. This is the optional step carried out in some models of honey stick machines with the help of a printer or date-stamping device.

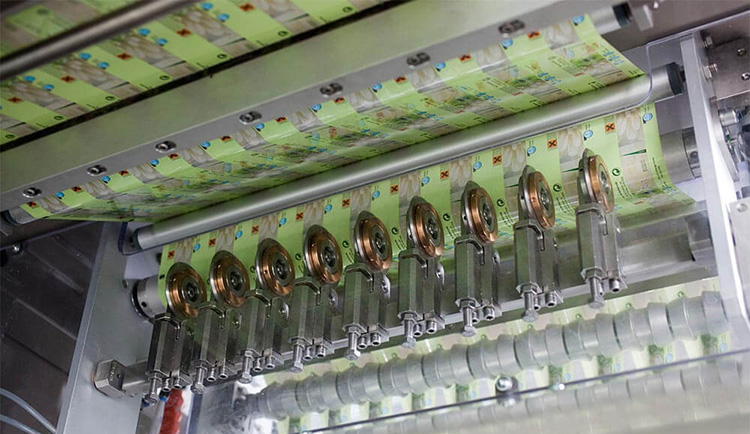

Slicing

Slicing of Film- Picture Courtesy: Viking Masek

After printing, the nip rollers take the packaging film and exert uniform pressure on the latter to keep it under uniform tension which aids in the proper movement of the dancer’s arm. From the nip roller, the film is transported to the cutting section also known as the slitter assembly.

Here the large film is cut into smaller pieces depending on the number of lanes in the honey stick machine. The cutting knives in this section shred the film while it is moving through the cutting section.

Honey Stick Formation

Formation of Honey Stickpack- Picture Courtesy: Jochamp

After the cutting step, the film strips are moved to the separate forming tube, one film strip for each lane. As the film is passed over the forming tube collar, it is doubled around the conical forming section.

Afterwards, the film is transformed into a stick pack as two sides of the film overlap and are sealed with each other.

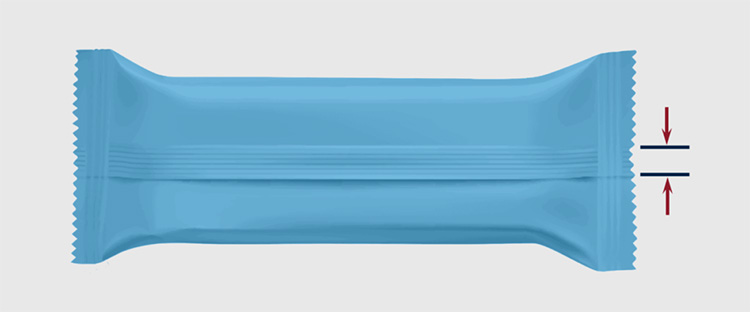

Filling and Sealing

Filling and Sealing- Picture Courtesy: MSJ Packaging

The vertical sealing bar seals the vertical side of the film while the horizontal sealing bar fuses the edges of the top end of one stick pack and the bottom edge of the other stick pack.

When sealing jaws are closed, the honey from the hopper flows into the volumetric or net-weigh filler and then is dispensed inside the stick packs via pumps or valves.

Discharge

Discharge of Honey Stick – Picture courtesy: Jochamp

Upon complete fill, cutting blades come forward and cut the top end of one stick pack and the bottom seal of the other stick pack, and the finished honey sticks fall in the outfeed chute.

7.What are the Different Types of Seals Created by Honey Stick Machine?

The honey stick machine is adjusted to create different types of seals. These seals are formed by various mechanisms. The detail of the seals is discussed below:

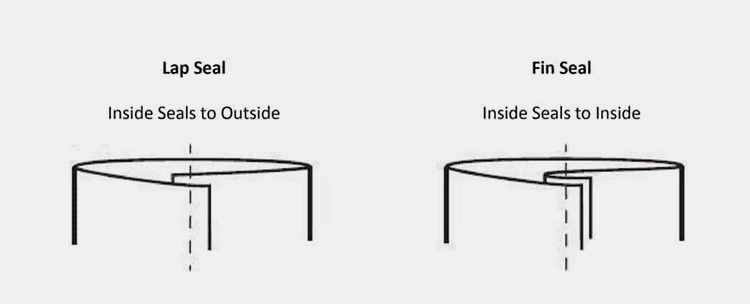

Types of Seals According to Working Mechanism

Fin Seal

Fin Seal-Picture Courtesy: Greener Corporation

It is also called a fold-over seal and is formed by joining the two interior sides of the seal and then the seal on the back is formed. It is also called T-seal.

Lap Seal

Lap Seal- Picture Courtesy: nVenia

Its other name is an overlapped seam. It is created by sealing the outer side of one film onto the inner side of another film. There are two types of lap seals- standard lap seal and reverse lap seal.

Types of Seals According to Sides

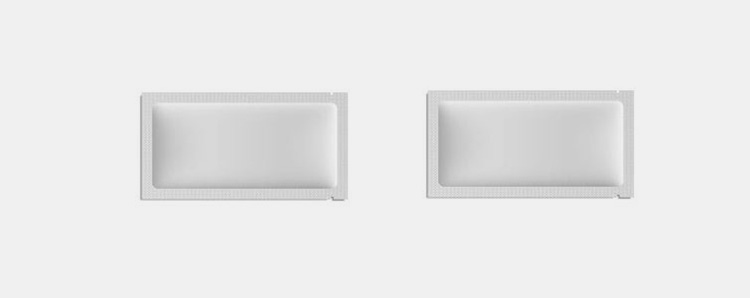

3-Side Seal

3-Side Seal-Picture Courtesy: Design Bundles

It is created by sealing three sides of a stick pack and keeping one side open. The front and back pieces of film are sealed at 3 edges and the bottom film is folded.

4-Side Seal

4-Side Seal- Picture Courtesy: Stream Peak

This type of seal is formed by sealing the edges of film at all four edges; front, back, left, and right side.

Types of Seal According to Pattern

Round Seal

Round Seal- Picture Courtesy: ePAC Flexible Packaging

Sometimes honey stick machine is customized to seal the edges of the stick pack with a curved circular seal instead of a regular rectangular seal. This seal is usually present at the top side of the stick pack and sometimes both the top and bottom of honey stick packs have round seals.

Contour Seal

Contour Seal- Picture Courtesy: Aranow

In addition to a round seal, the sealing jaws can be modified in a honey stick machine to make a complex design seal that goes beyond the normal rectangular seal. This type of seal is present in shaped stick packs.

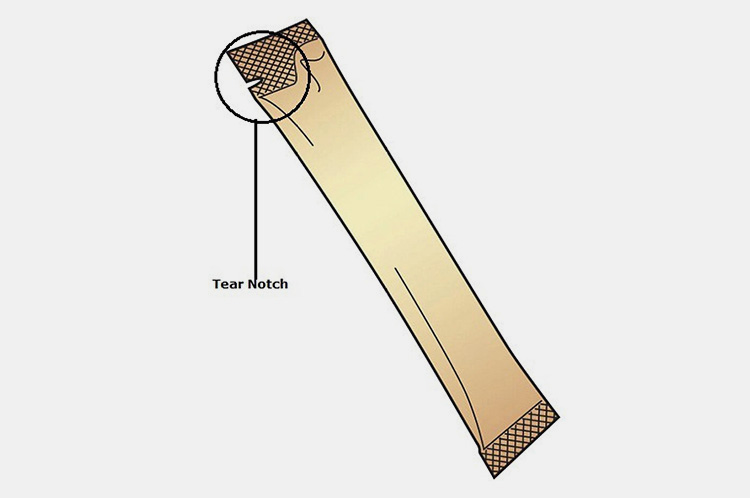

Tear-Notch Seal

Tear-Notch Seal-Picture Courtesy: Reform Packaging

This type of seal has perforations along its length or has a small pre-cut portion that allows users to easily tear the stick packs without requiring scissors.

8.How do Honey Stick and Honey Sachet Machines Differ From Each other?

These machines have similar functions of packing single-serve honey, however; there are some significant differences between honey stick and honey sachet machines such as:

| Honey Stick Machine | Honey Sachet Machine |

| This type of machine is utilized to generate stick packs that are tube-like with high length and lower width. | Honey sachet machines create flat-lay sachets having rectangular and square shapes. |

| This machine is ideal for processing free-flowing materials, for instance, grains, powders, and thinner liquids. | It is ideal for all kinds of materials including viscous creams and pastes. |

| This machine usually seals the stick packs at the top, bottom, and backside. | These machines seal the sachets at 3 or 4 edges. |

| The honey stick machine is less pricey than the honey sachet machine. | It has more advanced specifications; therefore, is more expensive. |

| It usually heats seal PET or LPDE films. | It uses different methods for sealing the sachet, such as heat, cold, and adhesive sealing. |

| It is usually employed in the food and beverage industry. | This machine is found in all and sundry industries, for instance, pharmaceutical food, household, personal care, etc. |

9.What is the Maintenance Schedule for the Honey Stick Machine?

Maintaining a honey stick machine is correlated with long and healthy operational time. So, below is the maintenance schedule of the honey stick machine:

Maintenance of Honey Stick Machine- Picture Courtesy: Spack Machine

| Daily Maintenance | First, wipe out and thoroughly clean the surfaces to remove the honey buildup or spillage.

Examine and wash the interior of filling systems and hoppers. Examine the electrical wiring and fix any loose connections. |

| Weekly Maintenance | Check and ensure the correct working order of safety switches, interlocks, and alarms.

Wash and clean the photoelectric registration sensor to ascertain the correct film mark. Check for loose nuts and screws and tighten them when required. Check belts for wear and tear in film belts and tighten them to maintain proper tension. |

| Monthly Maintenance | Inspect for defective seals and gaskets and replace them if needed.

Recalibrate machine fillers to ensure precise loading. Check the the working order of pneumatic components and repair them is leakage. |

| Quarterly Maintenance | Examine thoroughly the machine's electric system and replace faulty switches and wires.

Oil machine ball bearings and servo-drives. Examine the working performance of the heated sealer and temperature regulators. |

| Yearly Maintenance | Conduct a full and detailed examination of the machine including mechanical, electric, and computational parts.

Replace or repair old and defective parts. Perform yearly updates of honey stick machine software. |

10.Are there Any Safety Tips for Operating a Honey Stick Machine?

Safety Tips for Honey Stick Machine- Picture Courtesy: jochamp

Yes, operating a honey stick machine is like any other machine, requiring great care and caution to avoid operator injury and the hazard of fire and electricity. Some important safety tips for operating a honey stick machine are:

Safety always comes first, therefore, before operating a honey stick machine wear personal protective equipment, for instance, safety goggles, gloves, and overalls to protect yourself in case of chemical spillage.

Secondly, properly install and operate the honey stick machine as recommended by the machine manual. Ensure consistent temperature and pressure to prevent equipment malfunctioning and overheating of the machine.

Do not come in contact with the machine while it is running, as there is a risk of static charge that could cause an electric shock. Also, ensure proper grounding of the machine.

Use a safety guard in front of the machine to avoid accidental machine access as mobile parts and hot sealer could lead to burning and injury.

Additionally, always properly turn off the machine while maintaining and cleaning to prevent static shock.

11.What are the Principal Problems and their Troubleshooting in Honey Stick Machine?

Sometimes unanticipated problems arise in the honey stick machine that could lead to deferred downtimes and huge loss of money. However, you can easily troubleshoot these unexpected issues by following some tips such as:

| Cause | Solution | Image |

| Leakage in Stick Pack Seal | ||

| Poor and uneven sealing pressure

Improper temperature during stick pack sealing Damaged and old sealer bars |

Adjust the sealing pressure

Input correct temperature settings as per manufacturer recommendations Replace the old sealer bars |

Leakage in Stick Pack Seal- Picture Courtesy: CNC Products |

| Film Get Wrinkled and Torn During Operation | ||

| Poor film tension

Damaged and old film rollers Incompatible film thickness |

Adjust the film tension to avoid wrinkling and tearing

Change the film rollers Use the right film thickness |

Film Get Wrinkled and Torn During Operation-Picture Courtesy: TAPPI.org |

| Jamming or Blockage of Film | ||

| Out of order of sensors

Blockage in the film path Misalignment of rollers |

Clean the sensor if needed then replace it

Clear the blockage in the film path Realign the rollers |

Jamming or Blockage of Film- Picture Courtesy: Thomas.net |

| Overheating of Machine | ||

| Inadequate ventilation

Defective or worn-out motor Unclean or bunged air filters |

Fix the ventilation of the machine by installing a fan or by improving the compressed air system

Repair or replace the motor Thoroughly clean the air filter to get rid of debris. |

Overheating of Machine- Picture Courtesy: Makwell |

| Inconsistent Fill | ||

| Incorrect calibration of pump filler

Presence of air bubbles in honey Defective seals of nozzles and filling hose |

Recalibrate the pump filler

Remove air bubbles in honey by degassing Change the damaged seals |

Inconsistent Fill |

| Contamination in Filled Honey | ||

| Poor filtration of raw honey

Unclean machine surfaces |

Implement filtration systems to remove impurities from honey

Wipe and sanitize the exterior and interior of the machine |

Contamination in Filled Honey |

12.What are Major Consideration Points to Ponder Before Buying a Honey Stick Machine?

The old saying that time is money is important every day, especially in the manufacturing unit. Investing in an ideal honey stick pack results in faster processing and a higher return on investment.

Some prime things that should be taken into account before buying:

Consider Expected Output

Processing Capacity of Honey Stick Machine- Picture Courtesy: South Valley Packaging

Before buying, first, calculate how many batches will you process per shift. Also, determine the processing volume of each batch.

Both these estimates will give you an idea about the size, mixing cycle, and speed of your potential honey stick machine.

List Reliable Manufacturers

Listing Reputable Manufacturers

Afterwards, list suitable manufacturers that are dealing in your required honey stick packs. For this look up websites of different vendors, search for their customer reviews, and select those with huge listings of positive recommendations talking about high-quality timely services of vendors.

Size and Material Compatibility

Size and Material Compatibility- Picture Courtesy: Fodapack

Plan for potential sizes and packaging materials of honey stick packs. It is crucial because different models of honey stick machines have their specific processing stick pack sizes and packaging materials.

Compare Features of Different Equipment

Compare Features of Different Equipment- Picture Courtesy: mespack

When in the market, compare the specifications of different positive-looking honey stick machines. Look for their design, manufacturing materials, ease of machine accessibility, and convenient control panel that would boost your production after investment. After comparing, select the machine that ticks many boxes on your list.

Conclusion

Yummy honey is a favourite among grownups and kids, so to cater for its high demand, brands prefer to install a honey stick machine in their production plants. This machine packs a single serving of honey- suitable for an on-the-go lifestyle- in tubular-shaped stick packs. High production efficiency, affordability, accuracy, precision, and flexibility are some plus points among its long list of benefits. Different models of honey stick machines are available based on automation, motion, and packaging style. To know more about this machine, immediately contact our Allpack customer care. Happy Shopping!!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours