Tea Packaging: The Complete FAQ Guide In 2025

Tea Packaging: The Complete FAQ Guide In 2025

Tea has become a popular afternoon drink all across the world. Tea lovers are found both in the eastern and western world. There is a myriad of different types of tea available in beautiful special packaging that is vital in protecting freshness, aroma, color, and flavors. Not only preserving tantalizing flavors, tea packaging also provides a luxurious unboxing experience to high-end customers.

Tea packaging is what sets you apart from your customers. If you are looking for an idea to customize your tea packaging then go through this informative blog to learn all that there is about tea packaging.

1.What is Meant By Tea Packaging?

Tea Packaging- Picture Courtesy: PRINT Magazine

For handling, shipping, distribution, and consumption, it is vital to package tea, otherwise, it would be messy and troublesome to handle and transport tea. Moreover, it would be costly to haul tea from one place to another. Moreover, without tea packaging, it would be impossible to market tea.

Therefore, tea is contained in a tough protective barrier material thus, making it easy to handle, ship, distribute and consume tea. Tea packaging also serves as a brand ambassador. It inspires and tempts consumers to buy tea products.

Diverse kinds of tea packaging for instance pouches, tea bags, tin, jars, and boxes are available in the market and are vital for retaining the freshness, communication, and performance of tea.

2.What Are the Benefits of Tea Packaging?

Tea packaging is a specialized wrapping that is an important part of the tea industry. Striking tea packaging not only catches the eye of customers but also impacts the quality and tea-drinking experience. A few of the vital benefits of tea packaging are listed below:

Impermeable Barrier

Tea Packaging- Picture Courtesy: Terra Luna Herbals

Numerous environmental agents degrade the nutritional quality and flavour of tea. Therefore, tea packaging serves as a tough and resistant barrier that is moisture and oxygen-proof. Moreover, high temperature also augments chemical reactions in the tea powders and tea leaves. Heat alters the color of tea. Tea packaging acts as an insulator and maintains the temperature of the inner product, consequently protecting it from higher temperatures.

Transportation

Transportation of Tea Packaging- Picture Courtesy: Philipp Zurmöhle

By containing tea inside the packaging, it is easier to measure the quantity of tea and carry it for retailing. Furthermore, it is easier to ship and haul tea over long distances as it does not leak and create a mess due to tough packaging. It also averts product wastage and tea remains intact throughout its journey from warehouse to kitchen shelves.

No Contamination

Tea Packaging- Picture Courtesy: Maxipos

Different biological pathogens like bacteria, fungi, insects, pests, and vermin feed on open tea due to which it gets rotten and moulded. However, tea packaging is a strong protection that prevents pathogens from passing the tea packaging and spoiling tea.

Advertising

Advertising with Tea Packaging- Picture Courtesy: esthdonghoadian

One of the biggest advantages of tea packaging is its marketability and brand promotion. Unique and artistic tea packaging portrays the brand's value and its social causes. In addition to this, conspicuous tea packaging has prominence on retail shelves attracting passersby and increasing buying impulse.

Communication

Communication with Tea Packaging- Picture Courtesy: Teavision

By employing eye-catching topography and fonts, the brand owners through tea packaging inform tea lovers about the benefits and usage of packed tea. Tea packaging has all the vital information about tea and its safety.

3.What Are Different Tea Packaging Styles?

Since tea is a widely popular drink of people all across the globe, allure tea-lovers there are numerous tea packaging styles. A complete detail of tea packaging styles is penned below:

Tubes

Tube Tea Packaging- Picture Courtesy: Dieline

It is a sturdy cylindrical or round-shaped container perfect for storing tea leaves. It is a type of high-end tea packaging and is usually employed to attract classy customers since it gives a premium look and feel.

Tin

Tin Tea Packaging- Picture Courtesy: Silo Creative

This is a durable and robust container and is made with metals. This packaging comes in round and rectangular shapes. It is closed with hard and unbreakable lids to provide it with impermeability. Tins are usually used for storing tea leaves.

Jars

Tea Jar Packaging- Picture Courtesy: Cups Above Tea

Tea jar packaging has a round, cylinder, or square shape with a wide opening. Tea jars are closed with caps, consequently protecting the inside tea. Mason jars are typically used for packaging tea as they present tea packaging with a luxurious look.

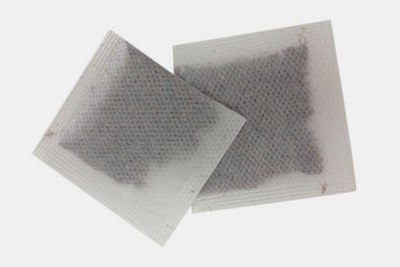

Tea Bags

Tea Bag Packaging

These are tea powders or leaves present in food-grade material usually employed for making instant tea. This packaging is put inside the hot water for acquiring a quick tea experience. This no-huss and no-fuss packaging is well-liked by everyone because of its simplicity and mess-free performance.

Pouch

These tea packaging styles are everywhere. tea pouches are customized with windows, tear-away notches, euro holes, zippers, ties, and many more to create a convenient unpackaging experience for tea lovers. Some common tea pouch packaging styles are:

| Standup Pouch

Picture Courtesy: World Brand Design Society |

As the name suggests, this pouch can stand upright due to its flat base. It is also called doypack and is popular among tea brands because of its low manufacturing cost and ease of brand promotion. |

| Gusset Tea Pouch

Gusset Tea Pouch- Picture Courtesy: Emsur |

These pouches typically have cylindrical shapes with round bases and hence cannot stand upright. But these pouches are popular as they hold more volume of tea since they can expand when filled and have extra space due to their gusset design. |

| Flat Bottom Tea Pouch

Flat-bottom Tea Pouch- Picture Courtesy: Biopacktech |

It is also called a block bottom pouch and has a square shape. It has a much flatter bottom, thus resembling a box when standing. It has a stable base and presents an attractive look on the display shelves. Due to its much wider base, it can hold large quantities of tea. |

| Quad-Seal Tea Pouch

Quad-seal Tea Pouch- Picture Courtesy: Ouma |

This pouch style has a distinct top seal which offers it a unique shape. Due to folding at the bottom, it does not have a stable configuration. However, tea brands routinely use this packaging because of its more weight-holding capacity. |

| Sachet Tea Packaging

Sachet Tea Packaging- Picture Courtesy: Pyramid Tea Bag |

Many tea lovers like sachet tea packaging because of its simple design and lightweight. It usually contains single-serving tea and is easily carried around in travel cases of on-the-go consumers. The sachet has seals on 3 or 4 sides. |

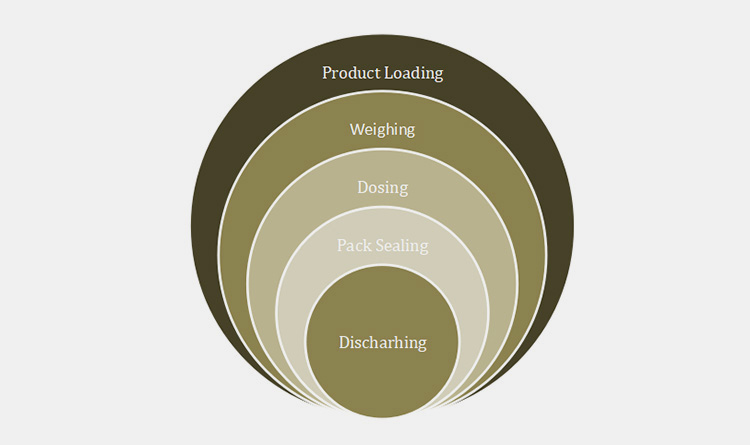

4.What Are Machines Routinely Employed For Tea Packaging?

As tea packaging belong to a wide spectrum such as jars or tins to accommodate such diversity, manufacturers have developed different tea packaging machine. These machines are discussed in detail below:

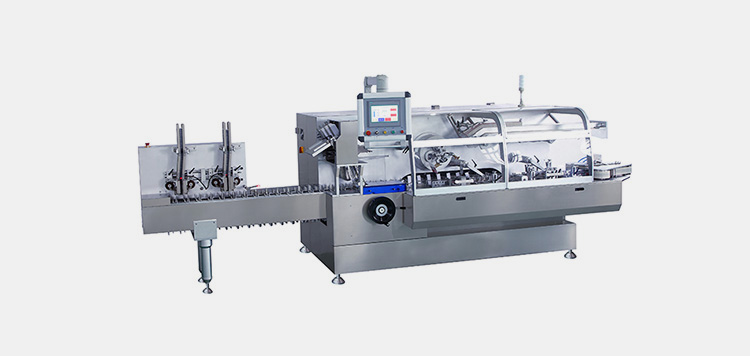

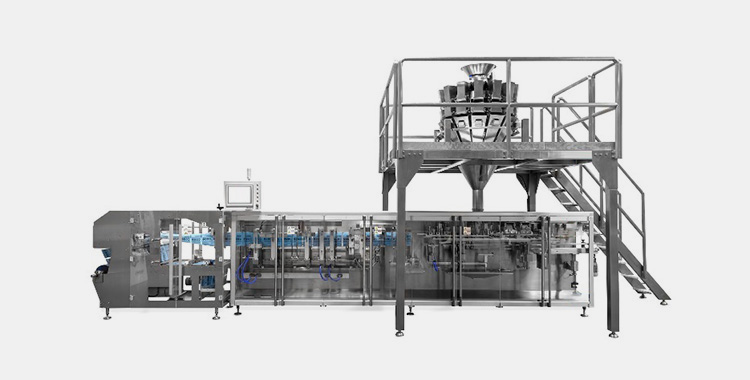

Tea Bag Packaging Machine

Tea Bag Packaging Machine

No tea packaging line is complete without the tea bag packaging machine. It is an automated solution for packaging tea in different tea bag styles and types whether pyramid or triangular. It can thread tea bags and attach paper labels. Moreover, it has advanced technology and can pack tea bags in an outer pouch.

Working Principle

Packaging film is placed on the film unwinder and it is transported to the forming station where the cutting knife and sealing jaws cut and seal the tea bag, respectively. After partial tea bag formation, tea is filled inside the tea bag through the filling head. In the next step, the bag is fully sealed and goes to another unit where the aluminum foil is cut, sealed and filled by a tea bag. Once filled, aluminum foil is heat-sealed for protection.

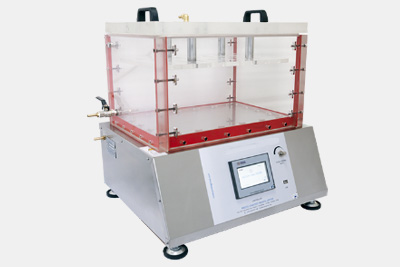

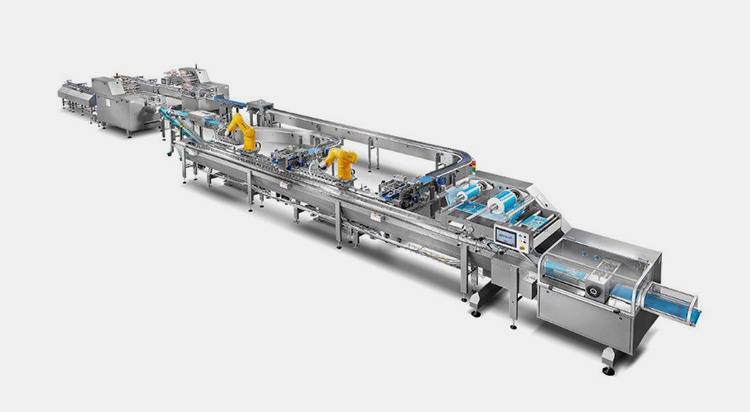

Vertical Form Fill and Seal Machine

Vertical Form Fill and Seal Tea Packaging Machine

It is one of the most common machines in food packaging lines. This machine transforms a packaging film roll into a stylish display-ready tea pouch. It is a most adaptable machine and with simple changeovers, it can process a variety of pouch packaging styles such as a pillow, standup, gussets, block bottom, and steelo pouch. Moreover, it can incorporate zippers and euro holes in the tea pouches.

Working Principle

First, a large load of tea is introduced inside the hopper present at the top. After that, the packaging film is placed on the film holder. On film unwinding, it moves over the rollers and the dancer’s arm. These mechanical components keep the film under appropriate tension and the film reaches a cone-like forming tube where it is folded and moulded into the pouch by the combined action of sealing elements and forming collar. After pouch formation, tea filling takes place via rotation of auger plates or gravity. In the end, heated bars hermetically seal the top end of the filled pouch.

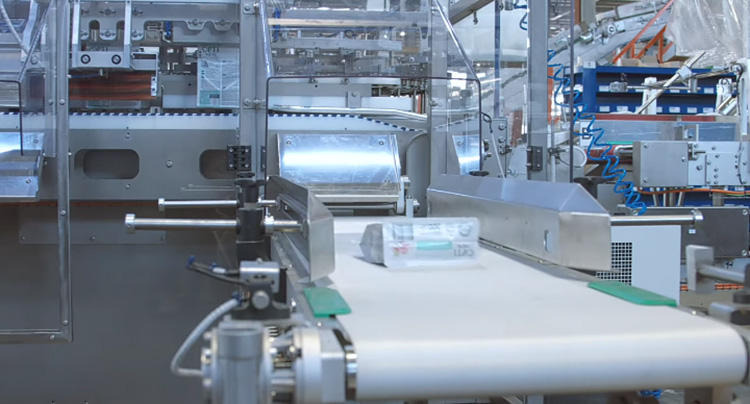

Tea Premade Pouch Packaging Machine

Tea Premade Pouch Packaging Machine- Picture Courtesy: HonorPack

It is a fast unit that has a rotary configuration and can fill multiple tea pouches. This machine uses already-formed pouches for tea packaging, consequently saving the time required for making tea pouches. Moreover, it can customize tea pouches with different add-on features such as tear-away seals, zippers, ties, etc.

Working Principle

First, a stack of premade tea pouches is loaded inside the pouch placement area from where the holder picks and moves them to the opening unit. The grippers open the squashed pouch and then in the inflating unit, compressed air is fed into a pouch for full inflation. Then, tea powders or leaves are introduced inside the inflated pouch via filling heads. After tea feeding, the sealing elements seal the filled pouch.

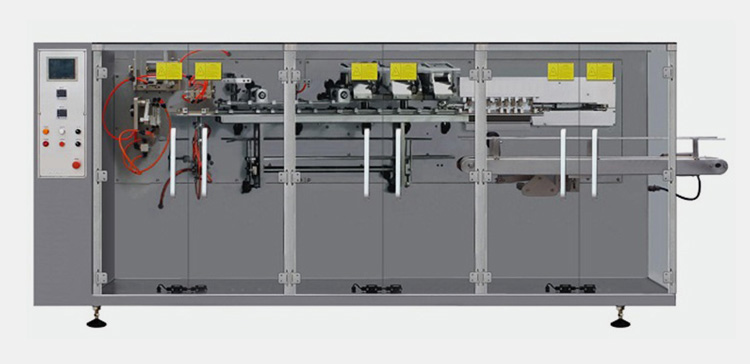

Tea Sachet Packaging Machine

Tea Sachet Packaging Machine

Due to the popularity of single-serve tea sachets, tea sachet packaging machine is routinely used by the tea packaging industry. It can process both plastic and aluminium foil and fabricate three or four side seal sachets. It is a compact machine with smaller space needs and thus is easily accommodated in plants with little space. Moreover, it uses less packaging film so is well-liked by tea brands.

Working Principle

Its working steps are straightforward and identical to the VFFS machine. Before batch processing, the large film roll is placed on the film roller and this film is unwound and passed over the roller. After it goes to the top where the forming tube is present. This tube assists in sachet formation. Once the sachet is formed, tea powders are filled from the filling units. Then sealing bars are employed for heat-sealing the top sides of the sachet.

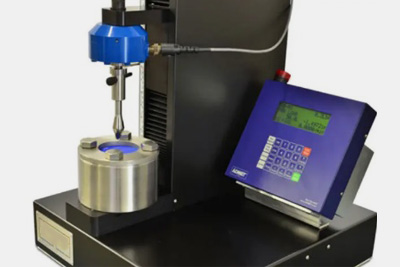

Tea Jar or Tin Filling Machine

Tea Jar or Tin Packaging Machine- Picture Courtesy: Powder Filling Machine

A tea jar or tin packaging machine is a robust and automated unit that is fitted with auger filling or net weigh filling devices that assist in the accurate dosing of tea powders and tea leaves in a jar or tin. This machine has advanced sensors that detect the presence of jars or tin on the conveyors and if there is no container, filling stops.

Working Principle

The operator first doses the hopper with a large volume of tea and then places tin or jars at a fixed distance on the conveyor. These containers move to the filling station by the movement of the conveyor. Once the container reaches the filling station, the tea is moved from the hopper to the filling devices and ultimately to the filling nozzles from where the tea is fed inside the container. Once filling is completed, the tea-filled container is moved to the next station where capping and sealing take place.

5.What Materials Are Used For Tea Packaging?

Advancement in material fabrication has led to a variety of materials for tea packaging. These materials are penned below:

| Filter Paper

Everywhere you see, tea bags are manufactured using filter paper. It is a very cost-effective option for tea packaging. It is designed in a myriad of ways and maintains the potency and flavour of tea. Moreover, it has small pores that allow the tea to breathe but prevent the entry of gases and moisture. |

Paper Tea Pouch- Picture Courtesy: Global Services |

| Nylon

It is one of the most frequently used materials that provide an excellent barrier against gases, water, odors, and temperature. Tea packaging machines can easily handle nylon material. This material will create a brand identity and maintain tea freshness. |

Nylon Tea Bag- Picture Courtesy: Magiktea |

| Silk

It is an exceptional material for packaging tea powders because of its breathability and it does not soak up heat which allows the tea bag to remain fresh. Moreover, it gives the tea bag a luxurious look and increases the visual appeal of tea packaging. |

Silk Tea Bag- Picture Courtesy: 99% Invisible |

| Aluminum

It is a ductile material mostly used for making pouches and tins. It offers excellent barrier properties against different agents such as UV light, gas, water, fats, and microbes. Moreover, it helps in retaining the freshness of tea by providing impermeability against aromas, chemicals, and taste. |

Aluminum Pouch- Picture Courtesy: Logos Packaging |

| Tinplate

It is a thin steel sheet coated with tin and is used in premium tea packaging. It is about 0.16-0.2 mm. It is a non-toxic material, consequently considered safe for tea packaging. |

Tin Tea Packaging |

| Plastics

Today, plastics are most widely popular for manufacturing flexible pouches as well as jars. It is the most readily available material and thus is regarded as the cost-saving option for tea packaging. Furthermore, plastics are resistant materials offering higher protection against elements. |

Plastic Tea Pouch- Picture Courtesy: Alveus Prenium Tea |

| Paper

Different forms of paper like kraft paper, cardboard, or paper board are employed for tea packaging. Tea boxes and pouches are manufactured using paper. However, paper is not effective in protecting tea against environmental agents. |

Paper Tea Pouch- Picture Courtesy: Packaging bag manufacturer |

6.What are Tea Packaging Requirements?

Tea Packaging Requirement- Picture Courtesy: Zenvista Packagings

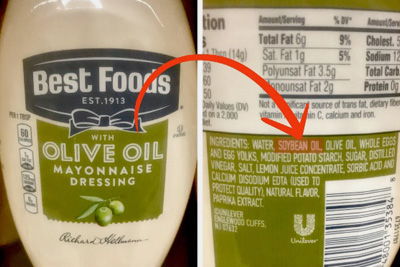

Food packaging guidelines are quite stringent; therefore, the tea industry must abide by different labelling regulations. Labelling requirements include ingredient list, nutritional value, calorie percentage and net weight of the tea. Some basic tea packaging requirements are detailed below:

Information Section

It is the most vital part of tea packaging labelling. It communicates to tea lovers about the brand name, advantages of products, ingredients, uses, total weight, nutritional value (number of calories, carbohydrates, fats, proteins), number of servings per tea packaging container, storage instructions, and best-before-date.

Moreover, it is required by law to list any of the 14 allergens present in tea. These allergens include soybean, gluten, peanuts, etc.

Brand Statement

In this section, brands mention tea names, types of tea, and tea leaf varieties. It is stated in tea packaging requirements that this section must be written in clear and readable typography that is easily read by consumers.

Certification

Different kinds of certifications such as Fairtrade, Rainforest Alliance, and UTZ, on tea packaging is a reflection of tea quality and also amplifies the chances of selling tea goods. In the United States, it is compulsory to display that tea is approved by the FDA. It is necessary to include different certifications as it will increase customer trust in the brand and ensure them that the brand will provide natural contamination-free tea.

7.How does Tea Retain Its Freshness?

Freshness in Tea Packaging- Picture Courtesy: lovelypackage.com

Many culprits can degrade the freshness and potency of the tea. Oxygen and moisture typically cause oxidation and mustiness in the tea. Similarly, tea is also affected by outside odors. Tea absorbs external smells and loses its aromatic flavour and fragrance. To maintain the freshness of tea, strong impermeable barrier packaging materials are used that assist in retaining the strength of tea.

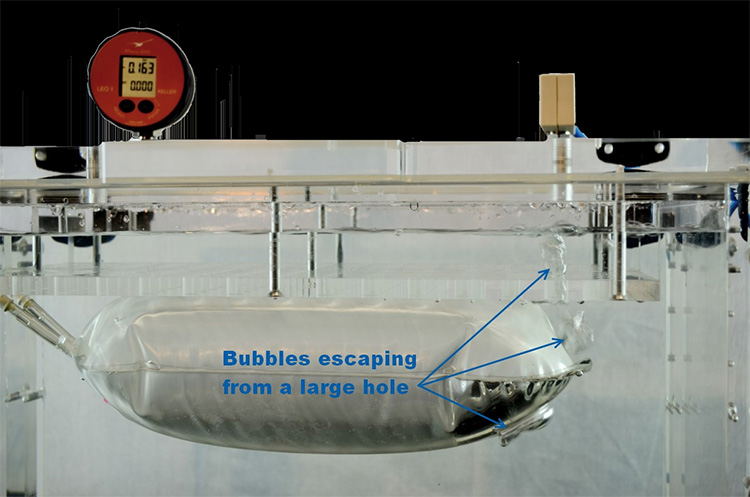

Moreover, before sealing tea packaging different techniques such as Modified Atmosphere Packaging, nitrogen flushing or vacuum packaging are employed. In MAP, the internal atmosphere in packaging is modified, which prevents the oxygen and moisture from destroying the crisp taste of tea. Besides this, in nitrogen flushing, inert nitrogen is introduced inside the tea packaging removing other harmful gases and water vapors from the packaging that may contribute to the degradation of aromatic richness of tea.

Also, vacuum packaging establishes a vacuum inside the container to remove air before sealing the tea packaging. It extends the shelf-life of the tea and stops the microbes from growing.

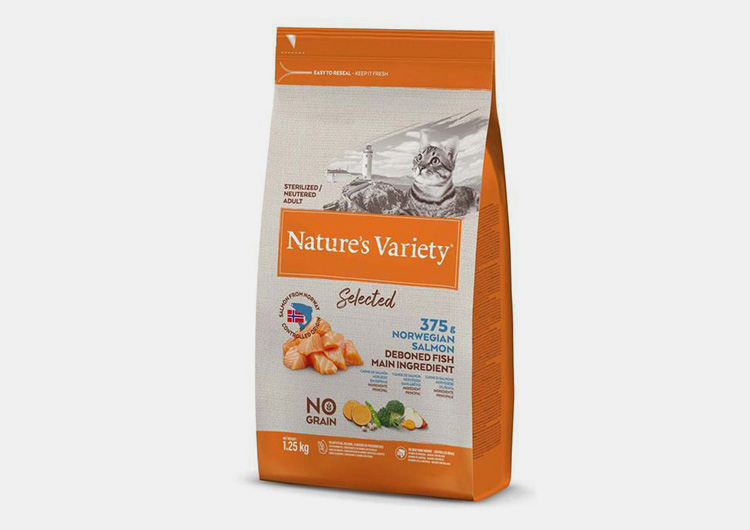

8.Is tea packaging sustainable?

Sustainability of Tea Packaging- Picture Courtesy: Muzli Search

Nowadays, customers demand sustainable packaging as they are aware of environmental problems and know that huge tons of packaging end up in landfills. Thus, brands are always striving to manufacture their packaging, especially food packaging with green materials. To help this cause, tea packaging also comes in sustainable packaging. Brands chose materials, such as aluminum and tinplate that are recycled easily.

Different types of materials such as non-woven fabrics, biodegradable mesh, and degradable PLA are used for creating tea bags and pouches. These materials are extremely sustainable and green since they can be degraded and decomposed easily by microbes. Moreover, brands are using compostable materials that do not harm the environment in any way.

9.What Is the Shelf Life of Packaged Tea?

Shelf-life of Tea Packaging- Picture Courtesy: Teafloor

Drinking tea is a luxurious experience for tea lovers. They sit on a lazy afternoon and enjoy a cup of tea without having to worry about it going off. This is because tea hardly ever gets spoiled as long as it is stored in a cold and dark place.

Opened tea in packaging is good for around 2-3 months and it is best to consume opened tea within 10 weeks. Generally, tea will last till its expiry date which is usually mentioned on the back of the tea packaging. Unopened tea bags or pouches are good for 2 years. Tea bags retain the pleasant fragrance of tea for about 24 months without tasting off. However, the best packaging for storing tea is tinplate. It is dark and its airtight sealing is good for preserving tea. It has a tough barrier that can protect tea from both direct UV light as well as ambient light.

Conclusion

Tea packaging is an up-to-the-minute commodity that increases the chances of buying. A powerful enormously original tea packaging is the thing that increases the eminence of tea brands on the display shelves and entices the customer. Tea packaging is essential in containing tea and persevering its potency. It’s the tea packaging that takes tea to places. Hopefully, by reading through this blog, you have learned all the important aspects of tea packaging. If you have further inquiries about tea packaging, you are more than welcome to contact our Allpack customer care.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tea Packaging: The Complete FAQ Guide In 2025 Read More »