Multi-Lane 4 Side Sealing Powder Packaging Machine: The Complete Buying Guide In 2025

Multi-Lane 4 Side Sealing Powder Packaging Machine: The Complete Buying Guide In 2025

In a world where everyone is preoccupied with the work around them, convenience is the king. You will hardly find any person who prefer hardship over ease. So, whether is it food, medicine, or beauty care products, their precise volume is carried out by people in small handy sachets for instant use. Now, the question arises, how can it be made possible to supply materials like powders in such a large amount to meet the global requirements?

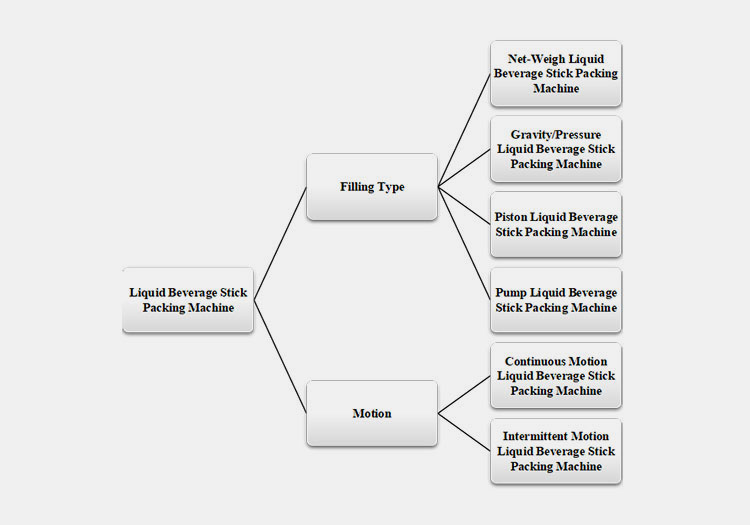

The answer is simple! A Multi-Lane 4 Side Sealing Powder Packaging Machine! This machine is one of the significant inventions of modern technology which enable you to efficiently pack your numerous powders in easy-to-use 4 side seal bags with low expenses. You can get substantial benefits by using it in the best way as explained below. So, make sure not to miss any question and get complete information about A Multi-Lane 4 Side Sealing Powder Packaging Machine!

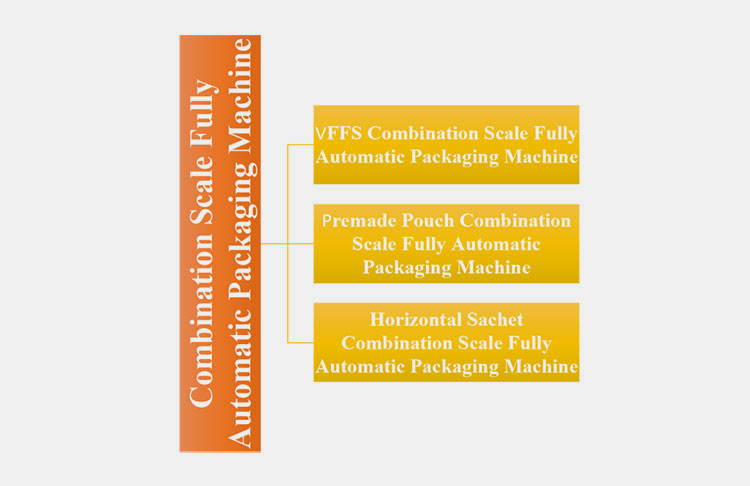

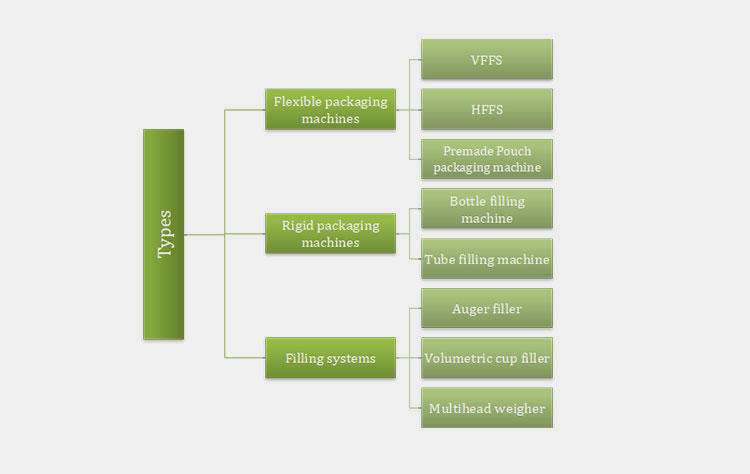

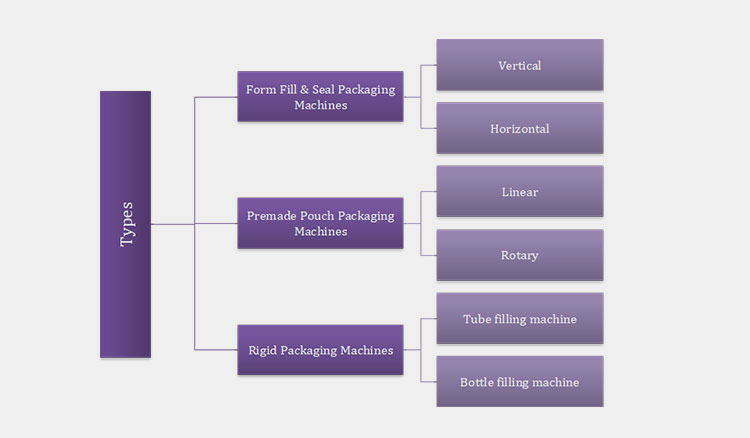

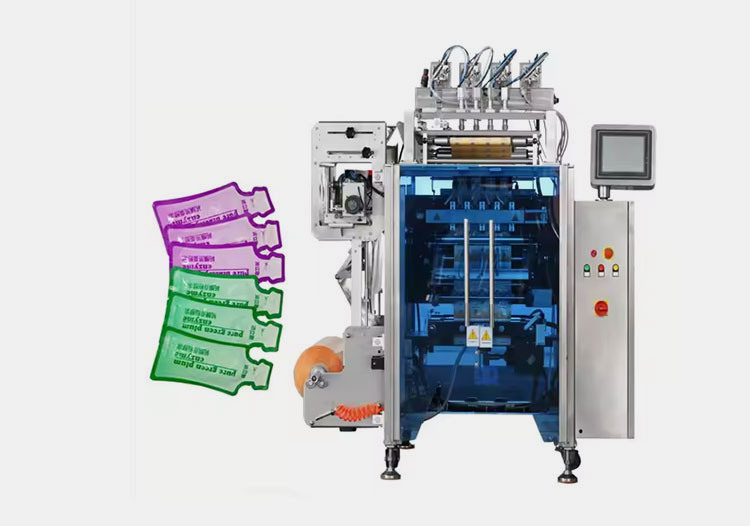

1.What Is Multi-Lane 4 Side Sealing Powder Packaging Machine?

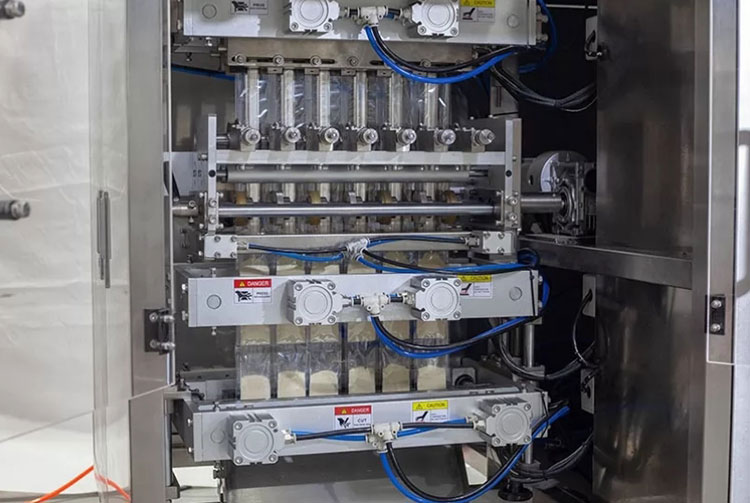

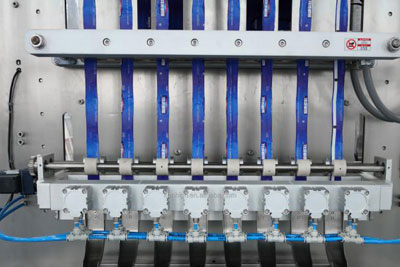

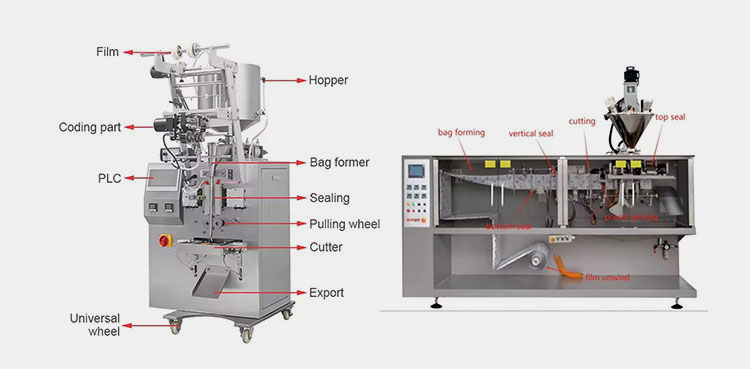

Multi row four side sealing powder packaging machine- Picture Courtesy: chengyipacking.com

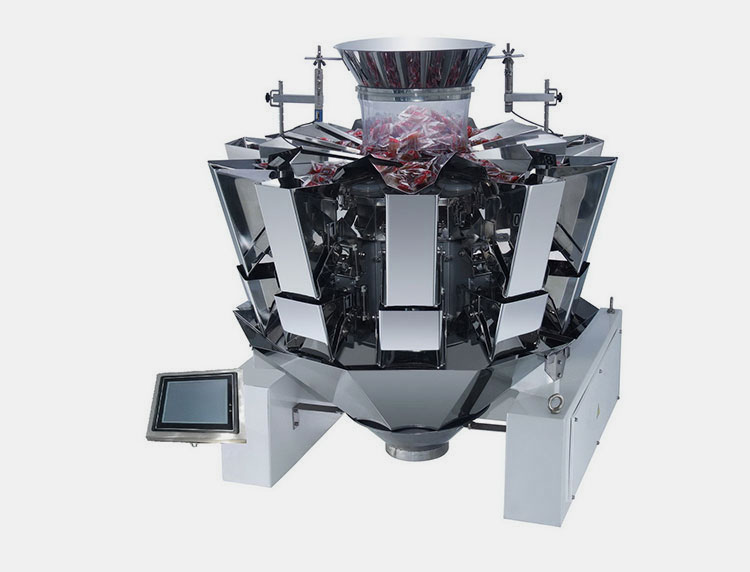

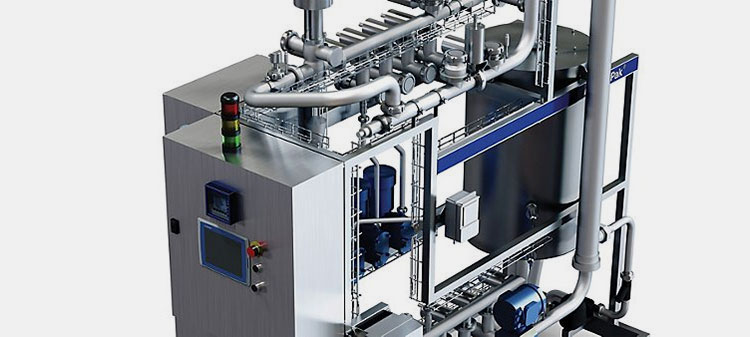

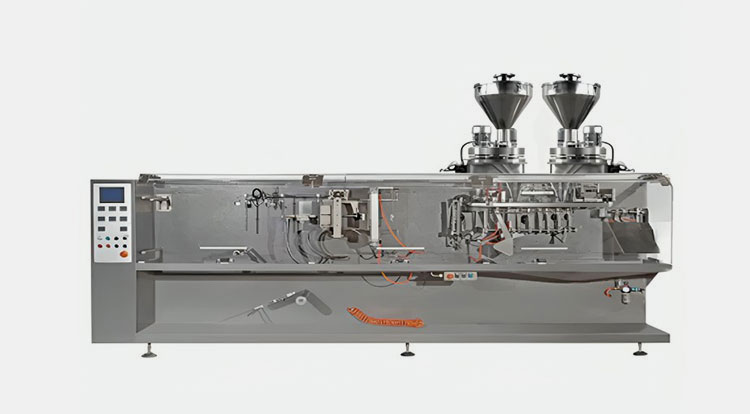

Multi-lane 4 side sealing powder packaging machine refers to the sophisticated equipment which is applicable to the complete packaging of powders. It has multiple lanes for simultaneous bags forming, powder filling, and their sealing. These functions, when performed efficiently, enhance the production throughput.

As far as the structure of machine is concerned, so, it is constructed with hygienic stainless steel and is equipped with advance controlling system to process all kinds of soft and abrasive powders in numerous industries. In this way, the machine maintains the efficiency and safety of products as well as users.

2.Enlist The Features And Benefits Of Multi-Lane 4 Side Sealing Powder Packaging Machine?

Multi-lane 4 side sealing powder packaging machine is made with innovative features which give you substantial benefits. These are as follows:

Efficiency

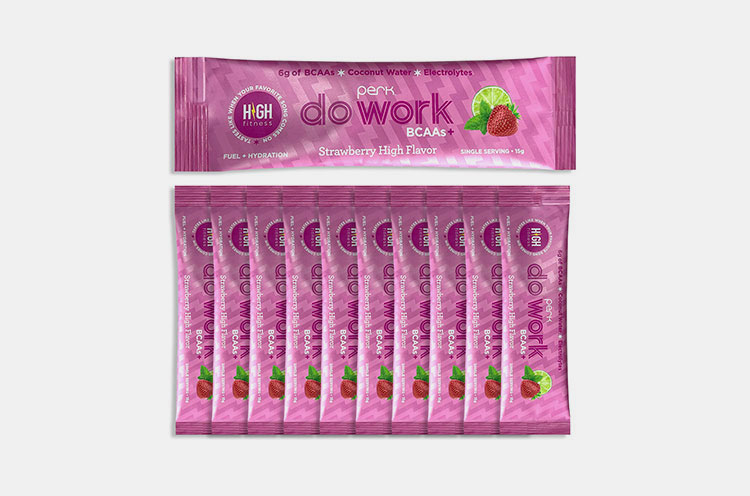

Multiple drink powder sachets- Picture Courtesy: emanagro.com

The machine is equipped with multiple channels for bags forming, powder filling, bags sealing, coding, and cutting. These multiple functioning lanes when perform different tasks simultaneously lead to the enhanced packaging efficiency.

Durability

Durable Multi Lane Sachet Packaging Machine for Powder- Picture Courtesy: SED Pharma

Multi-lane 4 side sealing powder packaging machine is built up with high resistance stainless steel and long durability parts which make it compact against shaking. All its components can be easily accessed without any difficulty due to which it has a stable operation.

High Protection

Protection icon- Picture Courtesy: Hp Wolf Security Blog

Another attribute of the multi-lane 4 side sealing powder packaging machine is its protection against corrosion, sudden breakdown, and pollution. It thus ensures the safety of your product as well as the operator.

Consistency

Consistently packed powder sachets- Picture Courtesy: chengyipacking.com

The machine has automatic system for accurate weighing and filling of powders into each bag along with the formation of same size bags. In this way, all the finished sachets are of similar size containing equal dosage of product.

Resilience

Multi-lane 4 side sealing powder packaging machine offers diversity in sealing and cutting types for sachets by mere changing the tools and switching setting. Moreover, you can process different types of powders while using the same machine.

3.What Products Are Processed By Multi-Lane 4 Side Sealing Powder Packaging Machine?

A multi-lane 4 side sealing powder packaging machine can be used to pack free-flowing, non-free-flowing, fine, and granulated powders. Few notable examples are enumerated below:

Coffee Powder

Coffee powder presentation idea

Coffee is the most favored drink all around the world and advancements in technology has also touched this staple due to which now you can have instant coffee in form of powder. So, this machine provides you with small amount of instant coffee powder bag which you can take with yourself anywhere you want.

Milk Powder

Liquid milk & milk powder- Picture Courtesy: livestrong.com

Milk powder is also commonly packed in single serving 4 side sealed sachets especially for kids use. Therefore, you can process milk powder by using a multi-lane 4 side sealing powder packaging machine.

Condiments

Various powered condiments- Picture Courtesy: Freepik

Condiments are among other things which must require a stringent packaging to stay fresh for longer. Moreover, table seasoning like salt and pepper which are used far beyond home tables like in aeroplane, restaurants, and hotels. Therefore, a multi-lane 4 side sealing powder packaging machine is best suitable for their remarkable packaging.

Detergent Powder

Detergent powder- Picture Courtesy: inspirationalmomma.com

Detergent powder contains chemical substances which, if not handled properly, can flow into air and be harmful for your health. However, as a multi-lane 4 side sealing powder packaging machine has enclosed structure, the entire processing will be carried out safely. So, you can pack your daily chemical agents by using this machine.

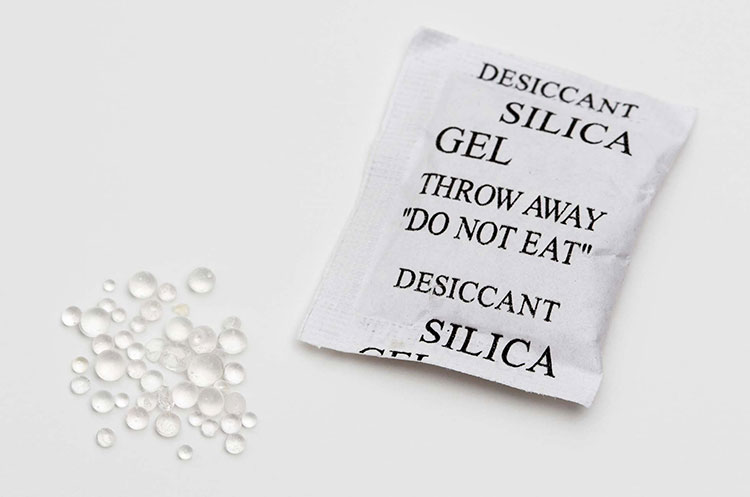

Dye Powder

Various dye powders- Picture Courtesy: epicurious.com

Dye powders whether edible or nonedible are composed of tiny particles which requires extra care while packaging. That's why, different types of dyes, pigments, and colorants are suitable to be packed by this machine.

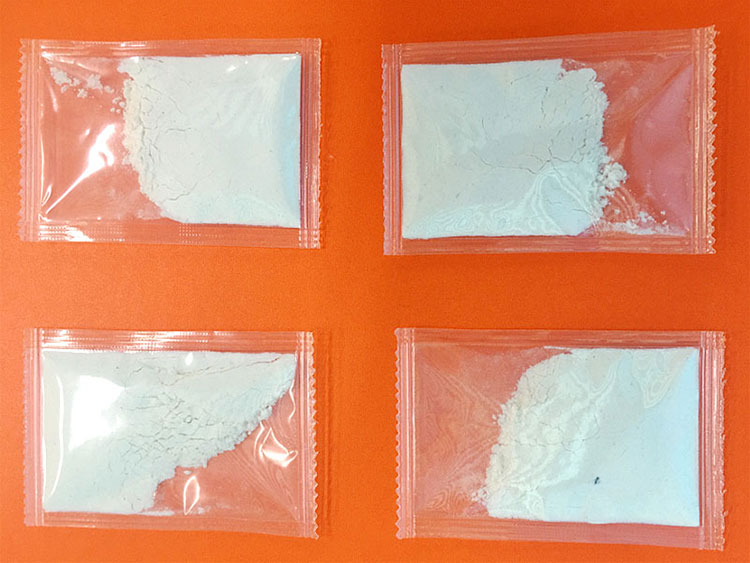

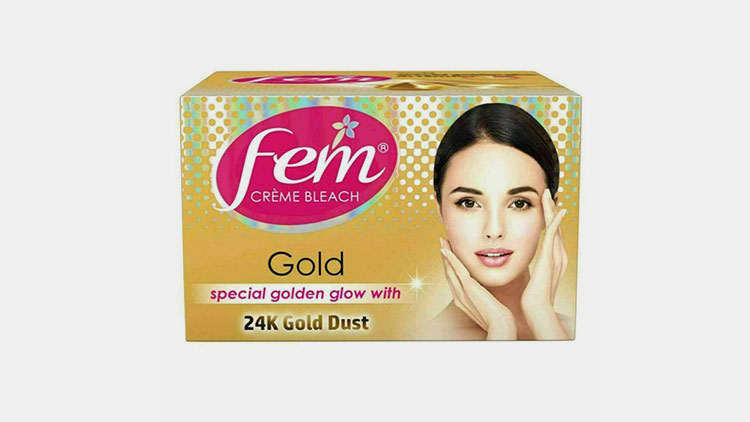

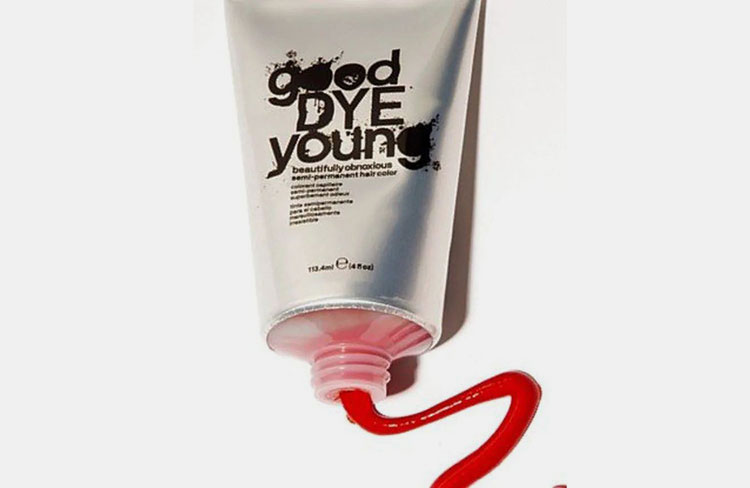

Bleach Powder

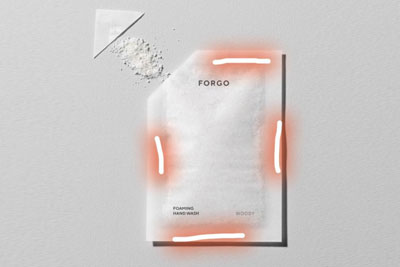

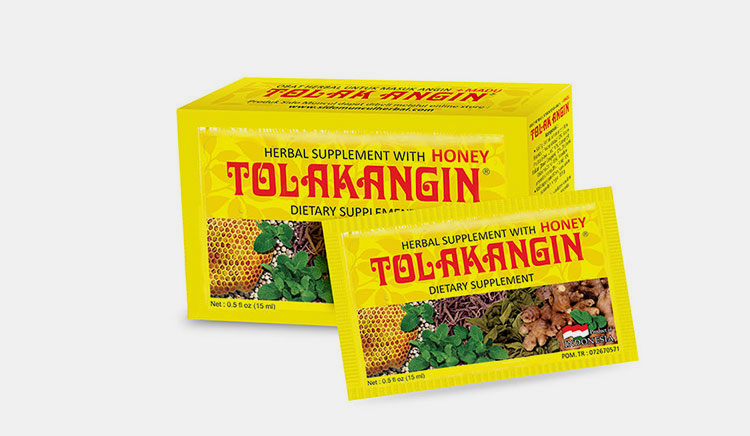

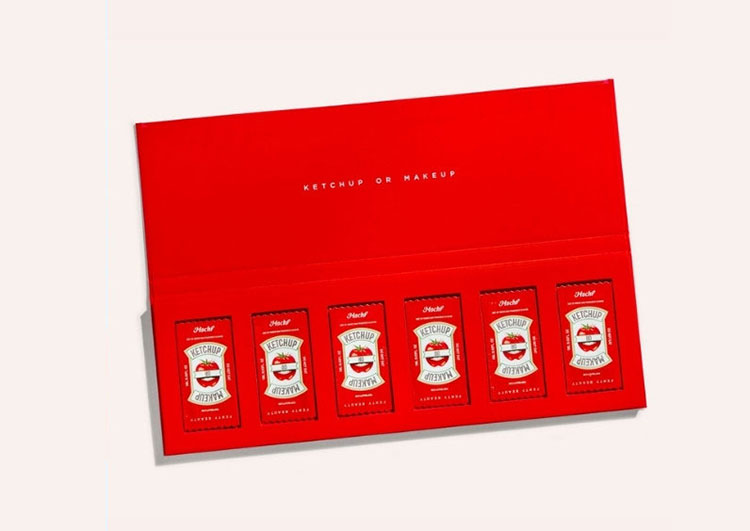

Bleach powder sachet box

Bleach powder is a beauty care powder formula often employed for dying hairs or applying on skin to give a clear skin. It is commonly delivered in small sachets for single application, therefore, can be processed by a multi-lane 4 side sealing powder packaging machine.

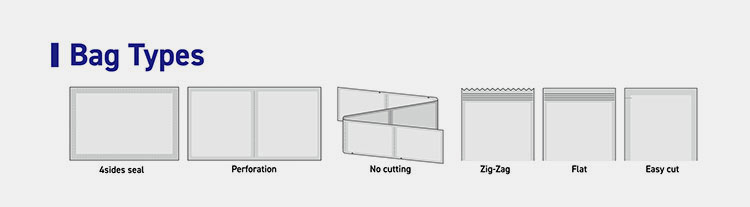

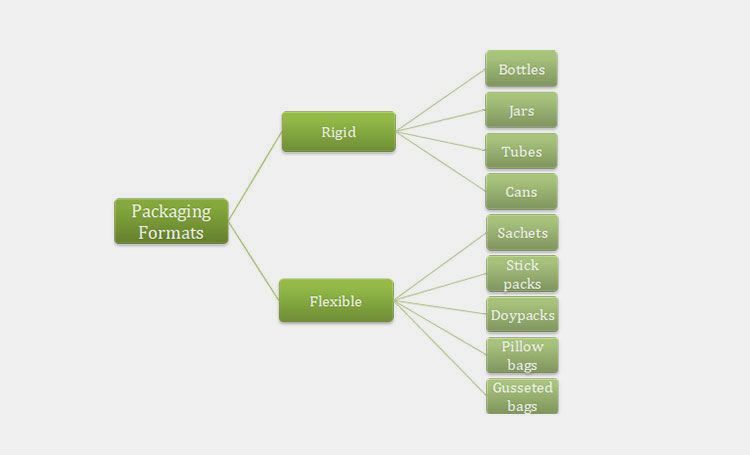

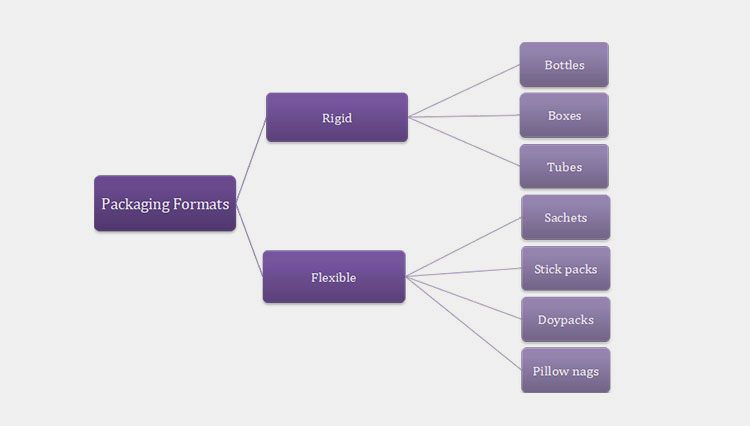

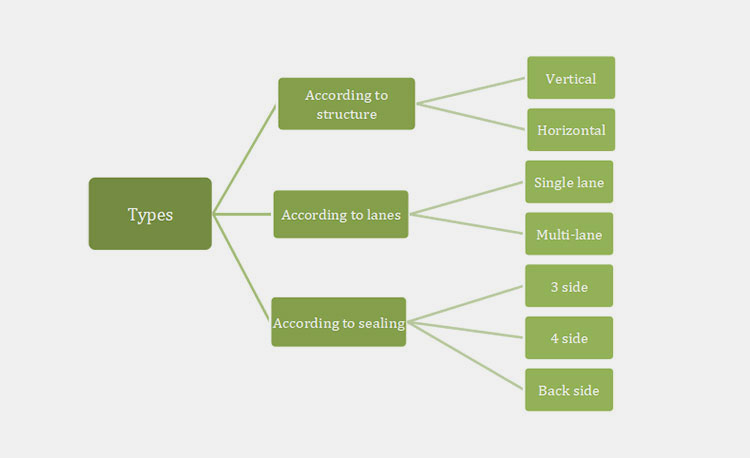

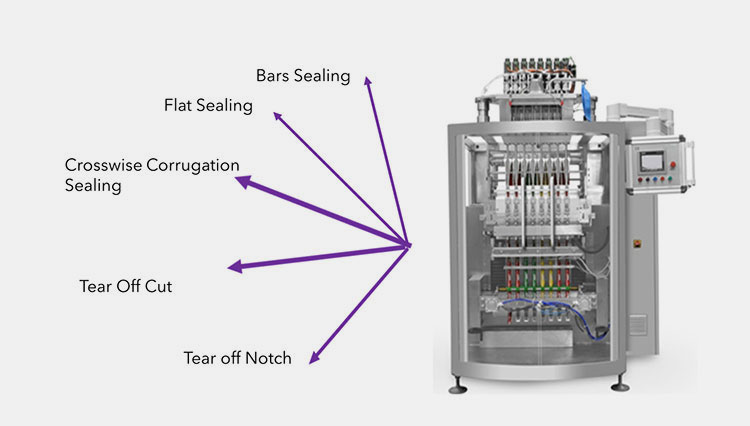

4.What Type of Packaging And Sealing Formats Are Offered By Multi-Lane 4 Side Sealing Powder Packaging Machine?

A multi-lane 4 side sealing powder packaging machine offers great variations in packaging formats. You can employ any of these depending upon your needs and requirements. Below, you will know these formats along with their advantages:

Standard 4 Side Seal Bags

Standard 4 side seal sachet- Picture Courtesy: emanagro.com

Standard 4 side seal sachets are characterized by their square or rectangular shape having four distinct sealings on each side: two horizontal and two vertical sides. Such type of sealing is best suitable for all single serving powders like coffee powder, dyes, milk powder, and seasoning etc.

Continuous Bags with Perforation

Continuous bags of raspberry juice powder- Picture Courtesy: emanagro.com

Continuous bags with perforation refer to interconnected bags bifurcated by the line of perforation. You will be amazed, that a multi-lane 4 side sealing powder packaging machine is able to make these vibrant design sachets which are extremely easy to handle. They can be used for beverage powder, spices, milk powder, and detergent powder.

Zigzag Cut

Zigzag cut display- Picture Courtesy: solpac.co.kr

A multi-lane 4 side sealing powder packaging machine also support zigzag cutting of sachets where the edges of bags are angled depicting the stylish cutting with hermetic sealing. This type of cutting format is recommended for products that are meant for merchandising.

Flat Cut

Flat cut instant coffee powder sachet- Picture Courtesy: Etsy

Flat cutting of bags is simply characterized by smooth cutting with no angled edges. This type of cutting is often employed for pharmaceutical and cosmetic powders.

Easy Tear Cut

Tear notch sachet- Picture Courtesy: Etsy

Easy tear cut is known for its convenient handling where a small cut is added into the top horizontal side of the bag for easy tearing. It is useful for daily use powders like milk powder, coffee powder, and drink powder etc.

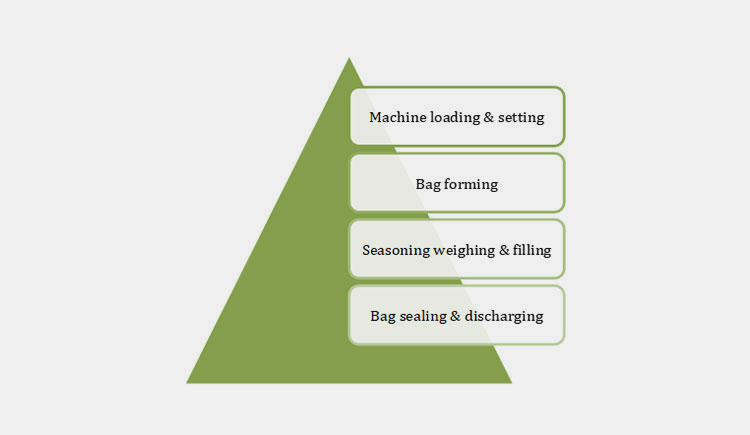

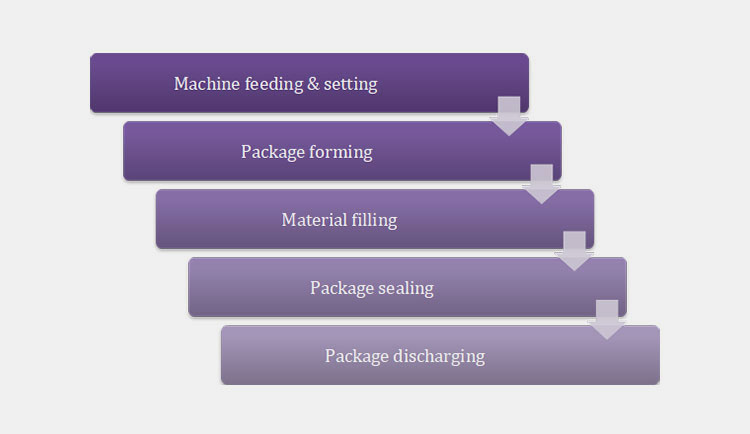

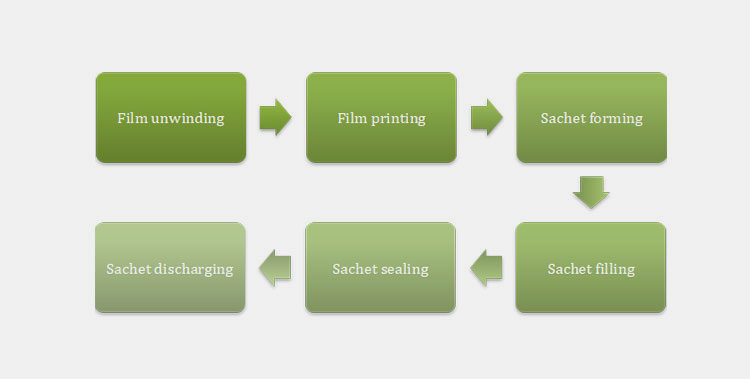

5.What Are The Working Principles Of Multi-Lane 4 Side Sealing Powder Packaging Machine?

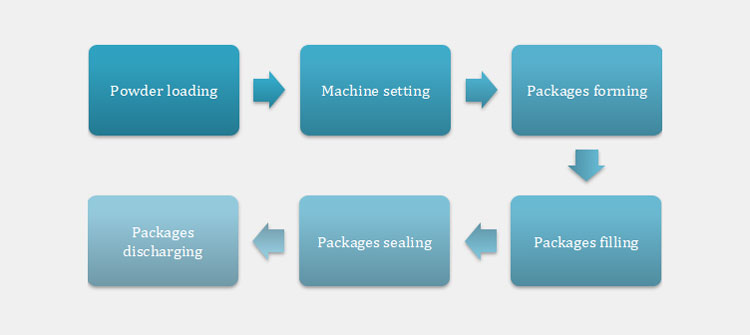

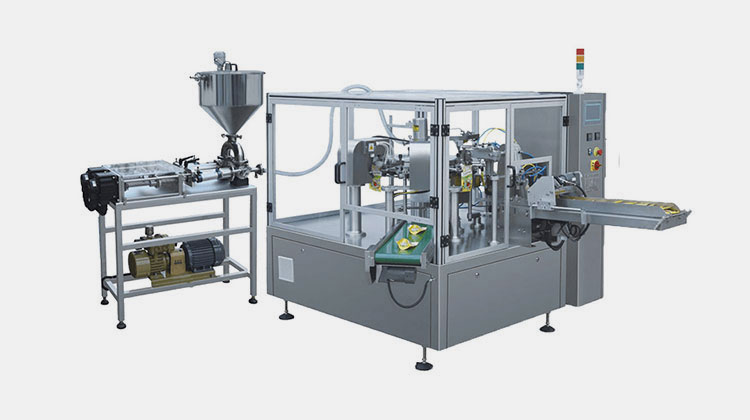

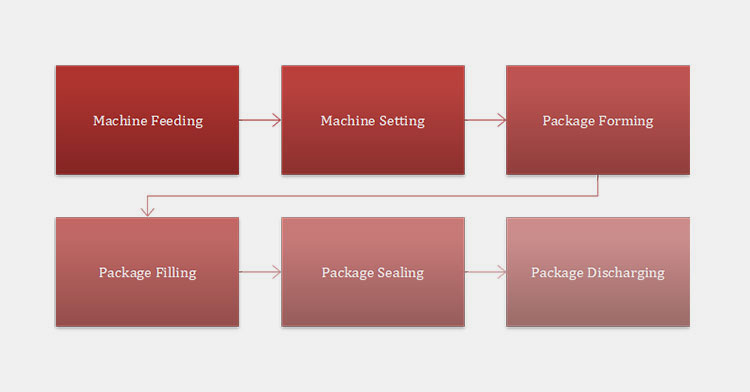

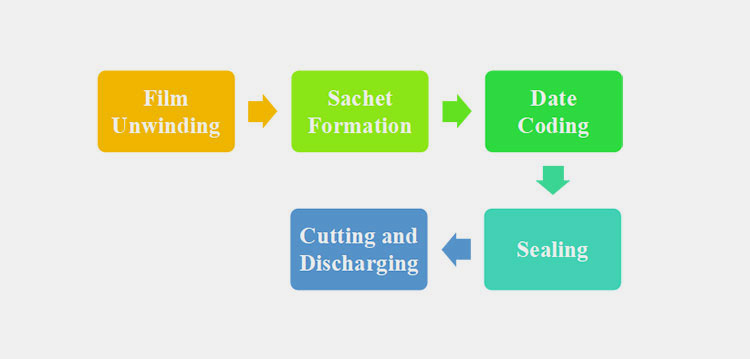

Multi-lane 4 side sealing powder packaging machine has an automatic system to carry out the packaging function. It follows an easy way which can be understand by looking into the underlying working principles:

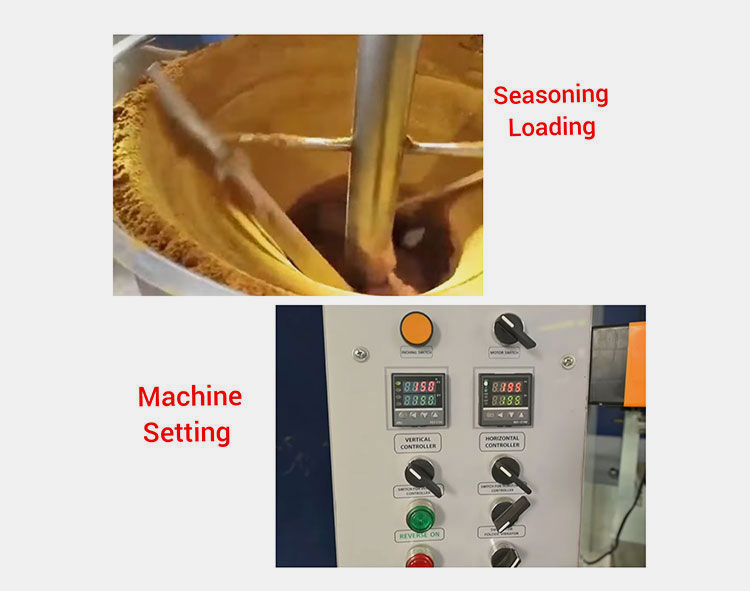

Powder Loading

Powder loading in hopper- Picture Courtesy: chengyipacking.com

Before you begin the operation, make sure to load your multi-lane 4 side sealing powder packaging machine with enough volume of powders. You can either load the powder in hopper of the machine or attach a separate feeding station in case of large amount of product.

Machine Setting

Setting machine- Picture Courtesy: chengyipacking.com

Similarly, after the loading of machine takes place, you need to manually set the commands in machine via intuitive human machine interface. It will display multiple information regarding the dosage of powder for filling in each bag, the length of bag, temperature of sealing jaws, and the speed of auger filler etc. So, this step will cover the basic setting requirement of machine which must be fulfilled before operation.

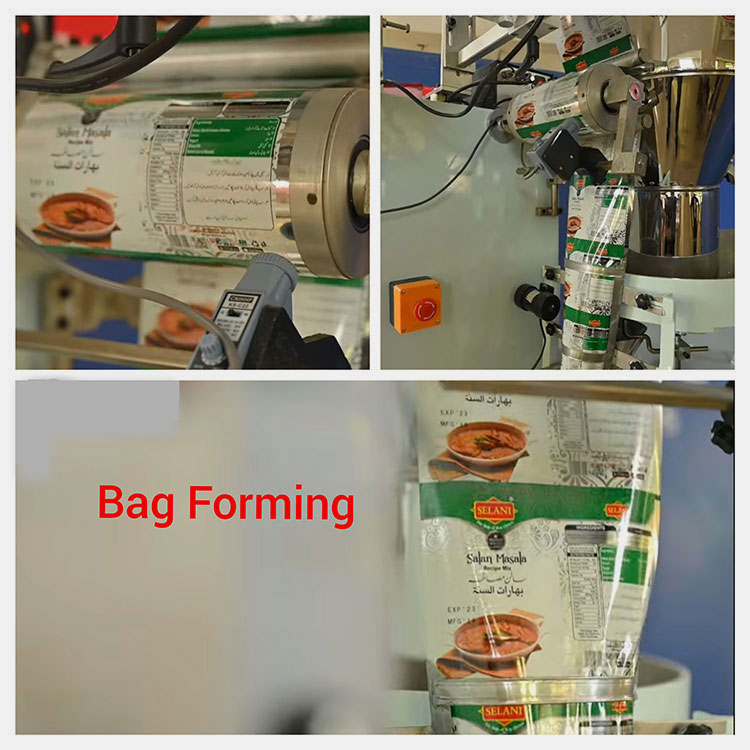

Packages Forming

Package forming from transparent films- Picture Courtesy: chengyipacking.com

From here the actual process of powder packaging get started when machine is powered on. The unwinding of film releases the film from roll which is then guided by intermittent film guides or pulleys. Afterwards, the flat layer of film is turned into sachets in a way that their horizontal bottom and vertical sides are tightly sealed and top opening is left for powder filling.

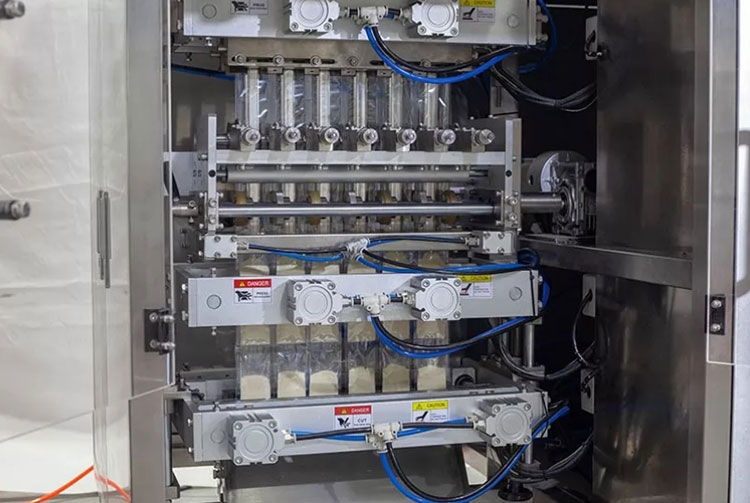

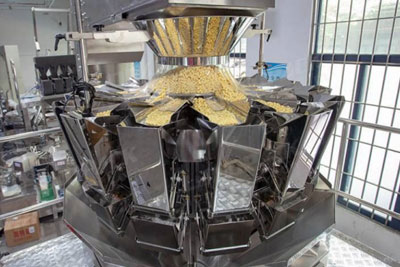

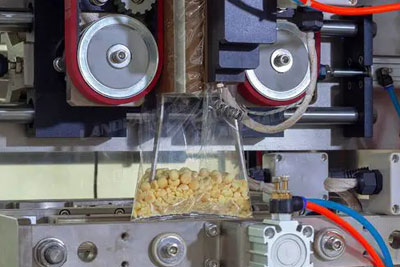

Packages Filling

Powder filling into sachets- Picture Courtesy: landpack.com

When the formation of sachets takes place, the machine start weighing powder by first processing it inside the hopper through auger and then weighing it through pump. Similarly, the precisely measured volume of powder is dispensed into the sachets through filling funnels.

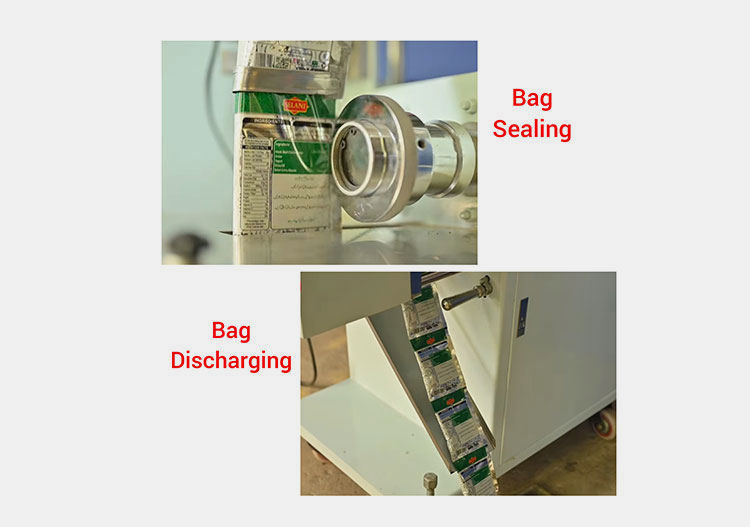

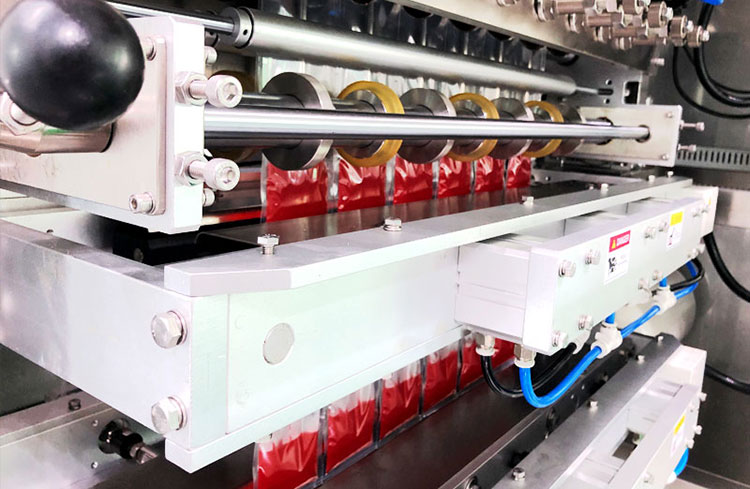

Packages Sealing

4 side seal packages sealing- Picture Courtesy: kenhighpack.com

At this point, the transverse heated sealers come into action and create a stringent sealing on the top of filled sachets and simultaneously forming the bottom sealing of next sachets. As the sealing of sachets is realized, either the interconnected sachets are separated from one another through cutting, or a perforation is made to retain the continuity of packages.

Packages Discharging

Packages Discharging through conveyor- Picture Courtesy: chengyipacking.com

Once the packaging gets completed, now it's the time for their safe discharging from machine into a collection container or for the further packaging through integrated machines.

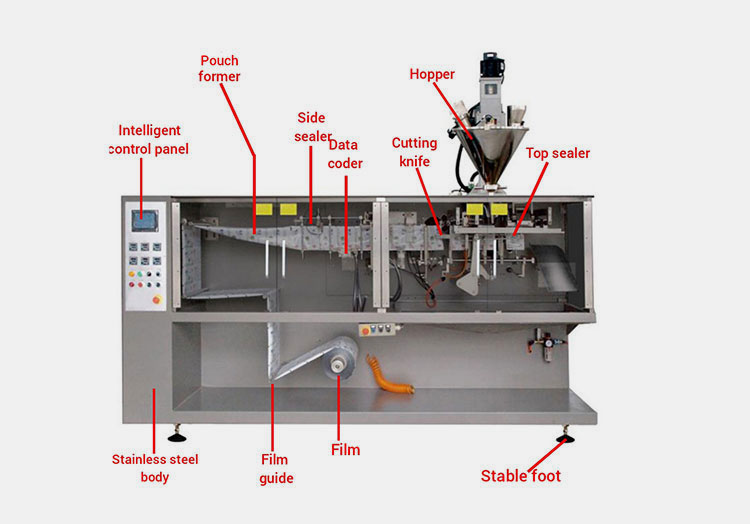

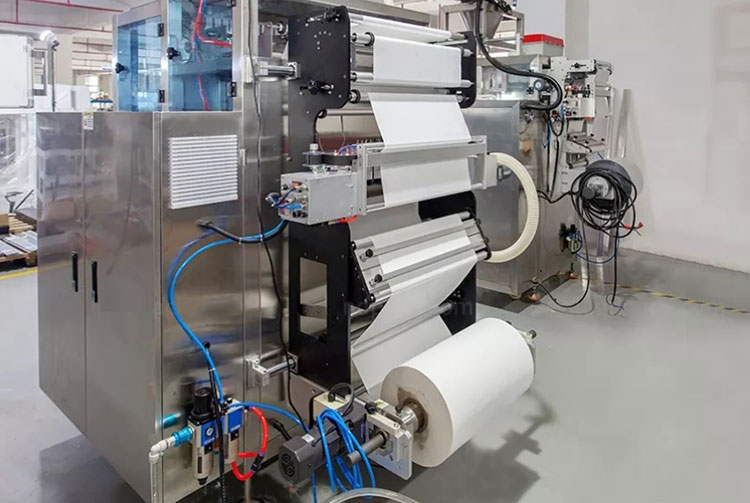

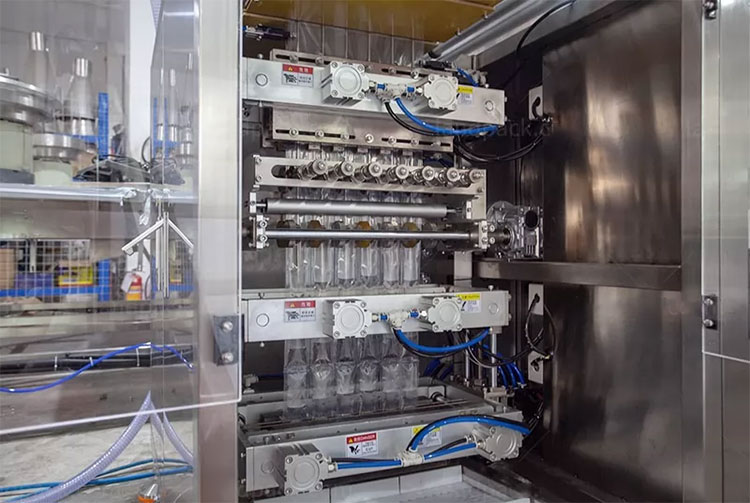

6.Describe The Major Parts Of Multi-Lane 4 Side Sealing Powder Packaging Machine?

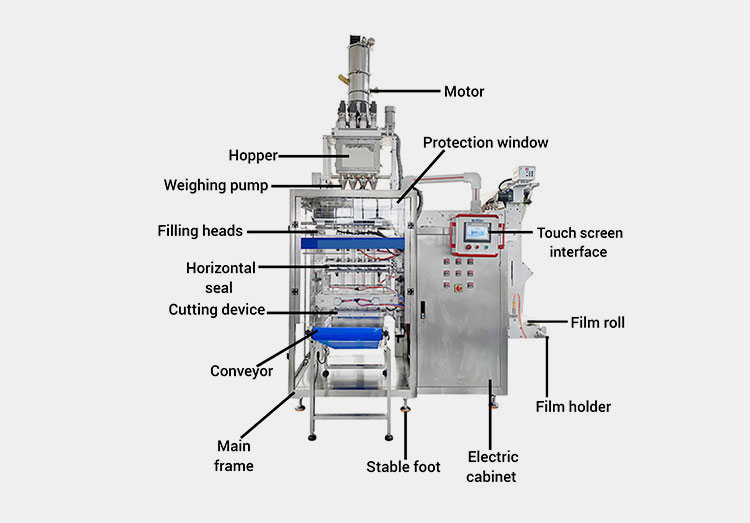

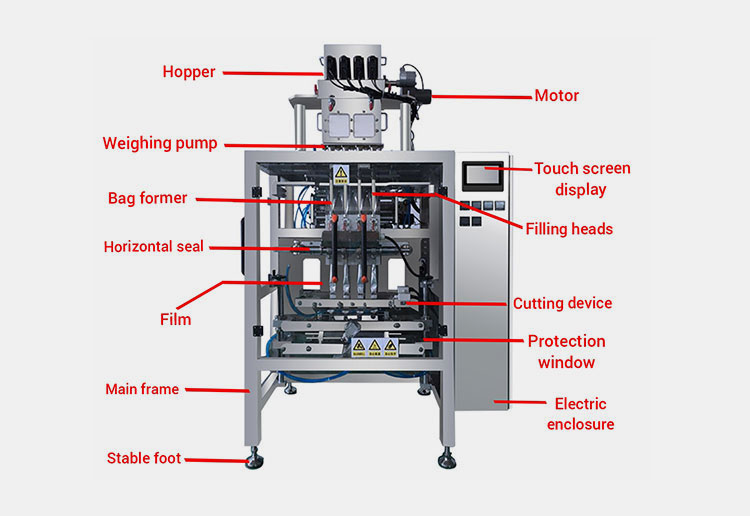

Although, a multi-lane 4 side sealing powder packaging machine perform multiple tasks and give extremely high throughput, yet its structure is compact, precise, and cover less space. The components which make it body are described below in detail.

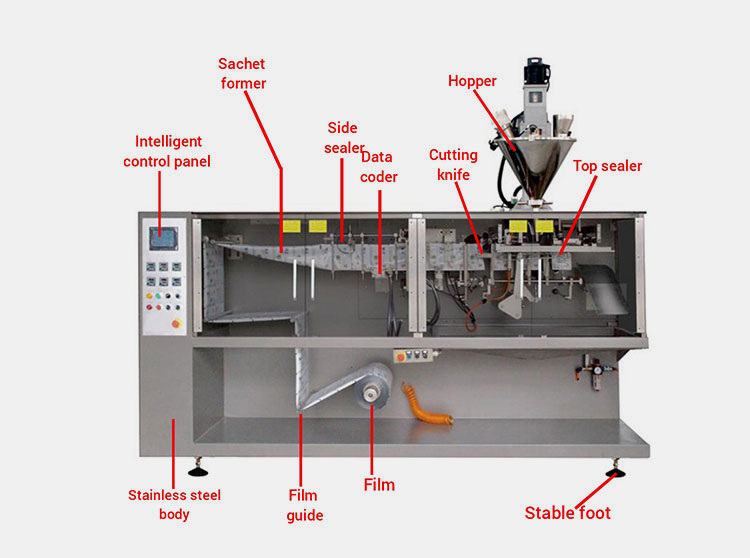

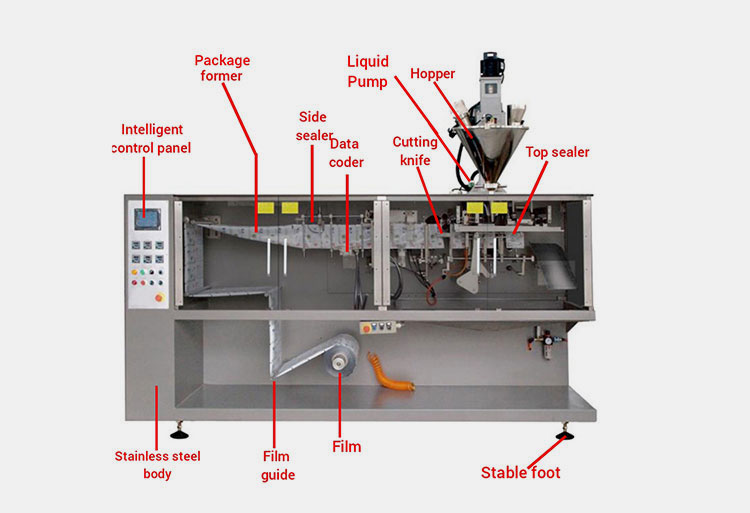

Components of Multi-lane sachet four sides sealed packaging machine- Picture Courtesy: samfull.net

Motor

Motor is one of the core components of a multi-lane 4 side sealing powder packaging machine located on the top of machine. It provides the machine with mechanical energy to accomplish the packaging tasks. For instance, it moves the auger shaft inside hopper and helps in the powder weighing and filling etc.

Hopper

Hopper is another significant part of the machine where powders are loaded in bulk to supply the machine with product required for filling. Therefore, it helps in uninterrupted flow of powder packaging.

Protected Window

Multi-lane 4 side sealing powder packaging machine has a transparent safety window on its front side. It keeps the inside working parts of machine intact from external environment and thereby ensuring the dust free operation.

Weighing Pump

This device is situated right below the powder hopper with main aim to weigh the exact volume of powder to be filled in each bag.

Filling Heads

Filling heads are small size narrow funnels attached to the hopper. Their function is to dispense accurate amount of powder into formed bags. The number of filling heads in a multi-lane 4 side sealing powder packaging machine vary from 4-12.

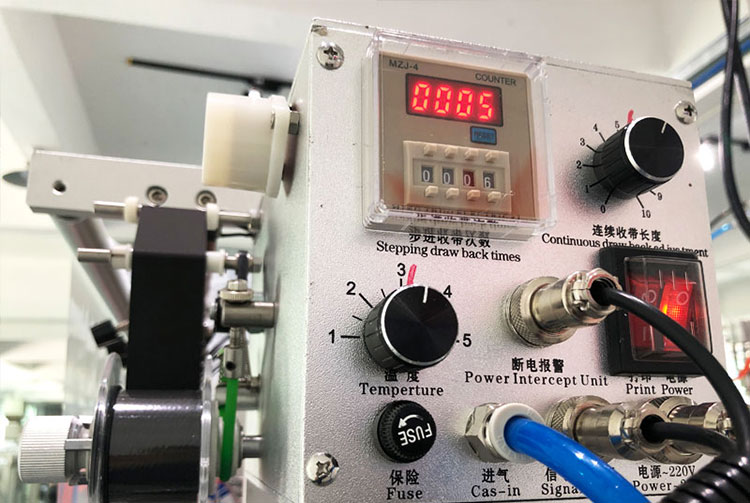

Touch Screen Interface

The machine has another critical component responsible for the setting and controlling of the machine and it is known as touch screen interface. By contacting this part, user will be able to set the parameters of machine for operation such as the speed of auger, volume of each dosage, data to be coded, and temperature of sealing etc.

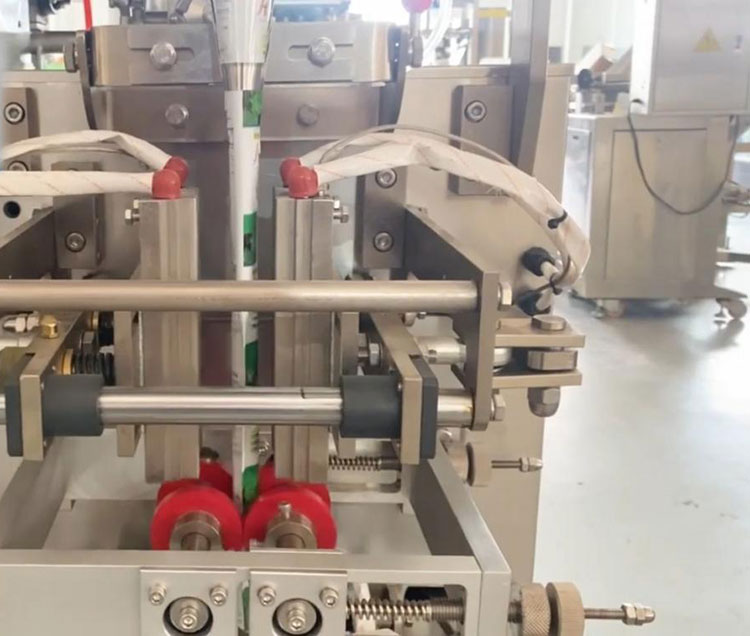

Horizontal Seal

Horizontal seal is a segment in machine through which the top and bottom sealing of 4 side seal packages is accomplished.

Cutting Device

Under the horizontal sealer, there is a cutting device fitted in machine to separate the finished powder packages from the rest of film through sharp cutting. These may come in various forms such as zigzag cutters, flat cutters, or perforation device.

Conveyor

Conveyor is a separate tool or mechanism attached to the multi-lane 4 side sealing powder packaging machine which takes the finished packages from machine and discharge or move them toward further packaging.

Film Roll

Film roll is the stock of thin plastic, aluminum, or laminated paper layer that is supplied to the machine for forming packages and encasing in them the powder processed by machine.

Film Holder

Film holder is a frame where film roll is fixed. When machine is started, this device initiates rotary movement which result in film unfurling.

Main Frame

Main frames constitute the overall structure of a multi-lane 4 side sealing powder packaging machine. It is made up of antibacterial and quality stainless steel that is fully resistant to corrosion and other environmental effects.

Stable Foot

Number of stable feet are attached to the machine for its even placement on surface and smooth performance during operation.

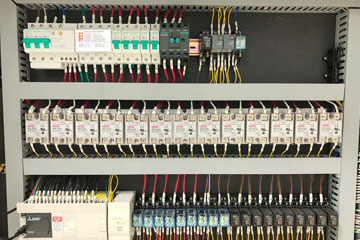

Electric Cabinet

Electric cabinet is the powerhouse of the machine inside which all the electrical components are fitted.

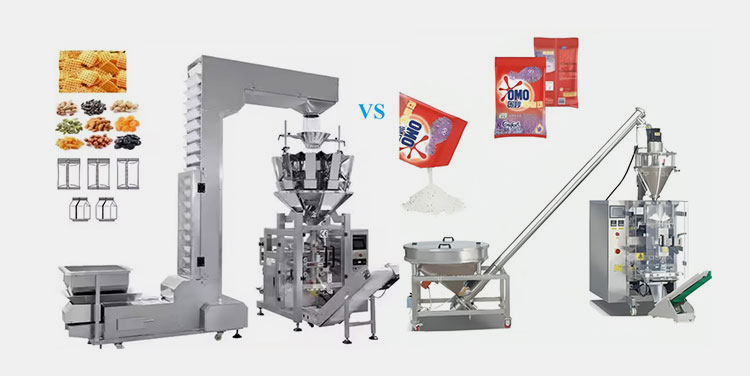

7.Differentiate Between Multi-Lane 4 Side Sealing Powder Packaging Machine And Multi-Lane 3 Side Sealing Powder Packaging Machine?

Both multi-lane 4 side sealing powder packaging machine and multi-lane 3 side sealing powder packaging machine are used for the same purpose of powder packaging. The thing which differs one from another is the number of sealing. So, let's know it!

| No | Aspects | Multi-Lane 4 Side Sealing Powder Packaging Machine | Multi-Lane 3 Side Sealing Powder Packaging Machine |

| 1 | Definition | Multi-lane 4 side sealing powder packaging machine is an equipment designed for packing bags and sachets of 4 side with powder. | Multi-lane 3 side sealing powder packaging machine is used for creating 3 side sealed bags and filling them with different types of powders. |

| 2 | Capacity of bags | Bags produced by this machine hold low amount of product. | Bags created by the machine has a comparatively higher capacity. |

| 3 | Bag forming mechanism | It has flat tools for forming bags from film. | While as, this machine has conical shape devices for forming sachets. |

| 4 | Number of film layer | The machine has single film roll which is then equally divided into two layers. Therefore, sachets are formed from double layers of film. | On the other hand, it only requires a single layer of film which is folded once to form 3 side sealing bags. |

| 5 | Benefits | High strength against resistant. | Cost-effective and easy-to-use. |

| 6 | Picture |

Automatic Multi Lane Sachet Packaging Machine for Powder SED-FDB- Picture Courtesy: SED Pharma |

Multi row three side sealing powder packaging machine- Picture Courtesy: chengyipacking.com |

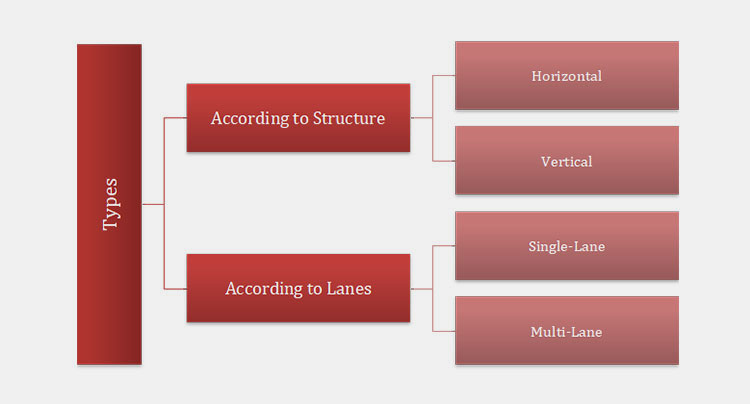

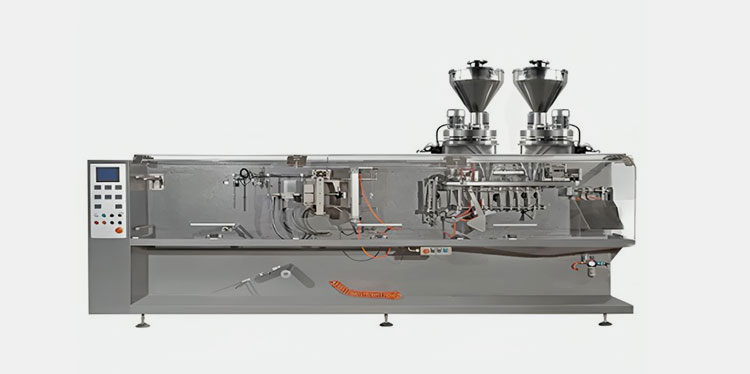

8.Differentiate Between Multi-Lane 4 Side Sealing Powder Packaging Machine And Single-Lane 4 Side Sealing Powder Packaging Machine?

There are machines available which are used for the same purpose of 4 side sealing powder packaging, however, their structure, production efficiency, and similarly degree of automation differentiates them from multi-lane 4 side sealing powder packaging machine. Consider these differences in table below:

| No | Aspects | Multi-Lane 4 Side Sealing Powder Packaging Machine | Single-Lane 4 Side Sealing Powder Packaging Machine |

| 1 | Definition | It is a machine employed for packaging multiple sachets of 4 side sealing. | Single-lane 4 side sealing powder packaging machine is designed for packing single powder sachet at a time. |

| 2 | Structure | It has a large structure with heavy-duty machinery. | While as, a single-lane 4 side sealing powder packaging machine has a small footprint. |

| 3 | Process | The machine has simple and continuous working process. | It may have continuous or intermittent working. |

| 4 | Number of lanes | Multiple channels for forming bags and packaging powder. | Only single lane for packaging that can be vertical or horizontal, depending upon the structure of machine. |

| 5 | Degree of automation | It is available in fully automatic form. | It may be in fully automatic or semi-automatic automatic technology. |

| 6 | Productivity | High production efficiency. | Low manufacturing output. |

| 7 | Application | Suitable for large and extra-large industries. | Good for small to medium size production facilities. |

| 8 | Picture |

Multi-lane sachet packing machine- Picture Courtesy: senieer.com |

LMSTS-450 Semi-Automatic Sachet Packaging Machine- Picture Courtesy: lenismachines.com |

9.Highlight The Applications Of Multi-Lane 4 Side Sealing Powder Packaging Machine?

There are wide range of industries associated with powder production and processing. These all can utilize a multi-lane 4 side sealing powder packaging machine to deliver precise volume of powders into sachets. Some of the notable sectors are enlisted below:

Condiments Industry

Seasoning powder- Picture Courtesy: Immaculate Bites

Spices and condiments are in large part used to be delivered in small size 4 side sealed sachets for convenient usability. Therefore, a multi-lane 4 side sealing powder packaging machine is employed to pack chilli powder, salt, pepper, and other spice powder into small bags.

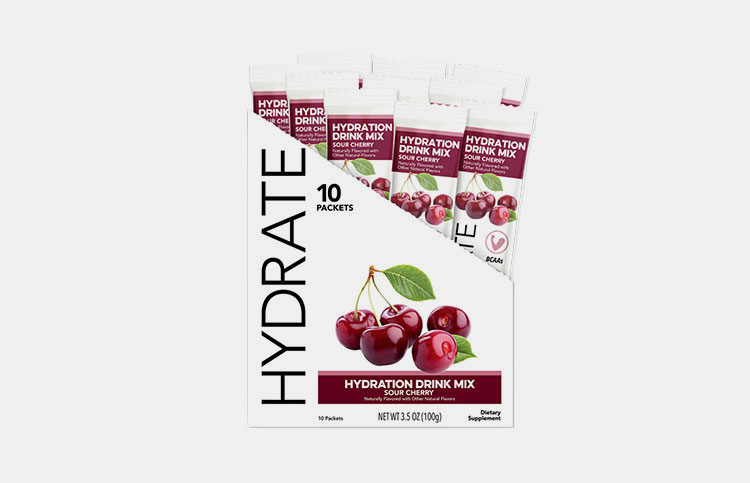

Food Industry

Beverage powder sachets- Picture Courtesy: topito.com

Food industry is a broad term under which sectors such as milk powder, coffee powder, beverage powder, and tea powder processing industries are covered. That's why, the use of a multi-lane 4 side sealing powder packaging machine is inevitably used in these areas.

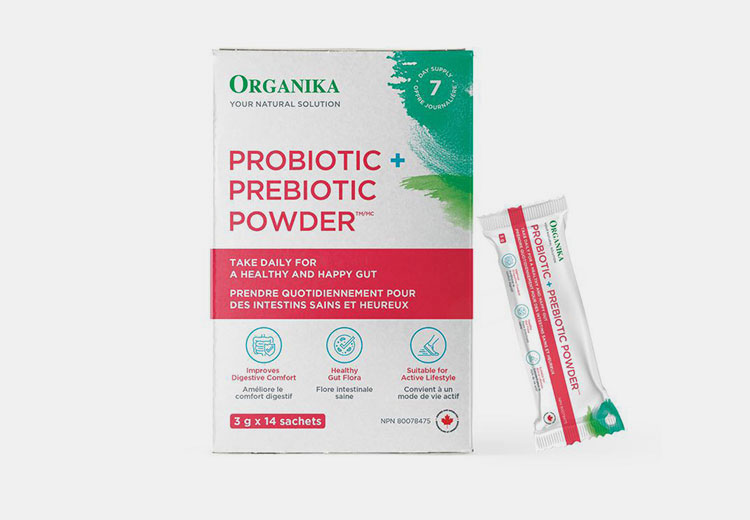

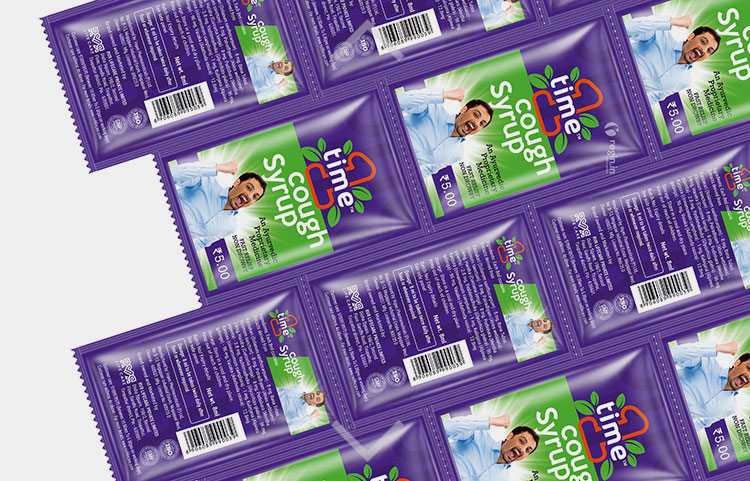

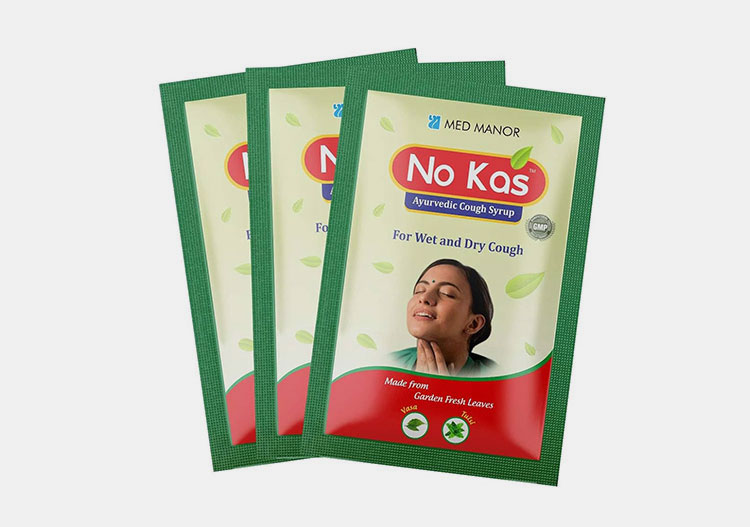

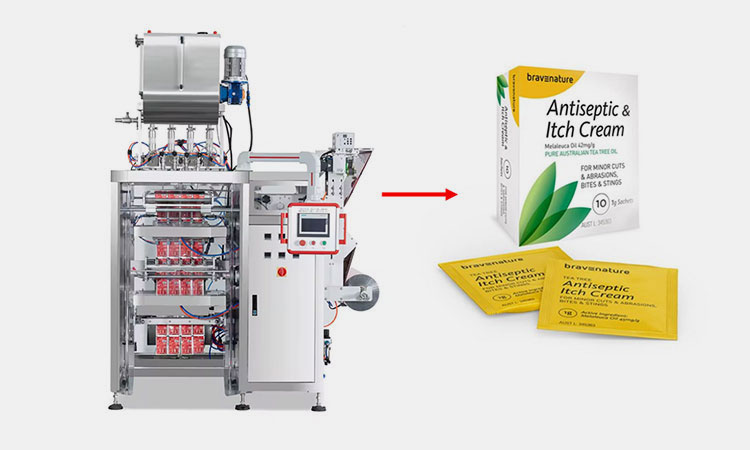

Medical Industry

Probiotic powder sachet packaging- Picture Courtesy: organika.com

Drugs are now delivered in every possible way from tablets to capsules, injections, and powders. As, powders are easy to take with water and have instant effects, so, most of the pharmaceutical, nutraceucal, and herbal medications are now delivered in form of powders for which the use of a multi-lane 4 side sealing powder packaging machine is always taken.

Pesticide Industry

Plants pesticide powder- Picture Courtesy: fb.watch

Although, the increase in agriculture has reduced the food shortage and unemployment, the unanticipated attack of pests, pathogens, and insects has raised concerns regarding the survival of crops so as the farmers. In this way, manufacturers are now trying to provide pesticides and insecticides in small to large volume for which they take help of a multi-lane 4 side sealing powder packaging machine.

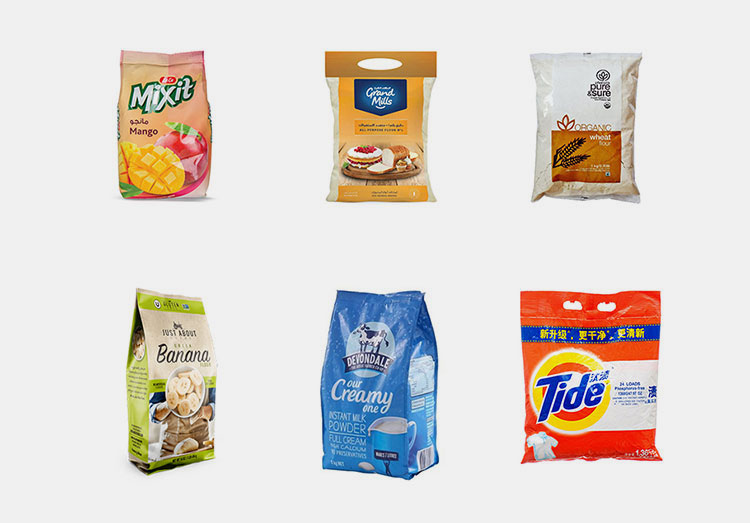

Detergent Industry

Detergent powder sachet

Multi-lane 4 side sealing powder packaging machine is designed in such a way to process both free-flowing and adhesive powders. Similarly, it can perfectly pack granulated detergent powders, dish washing powder, and floor cleaning powder in small size sachets.

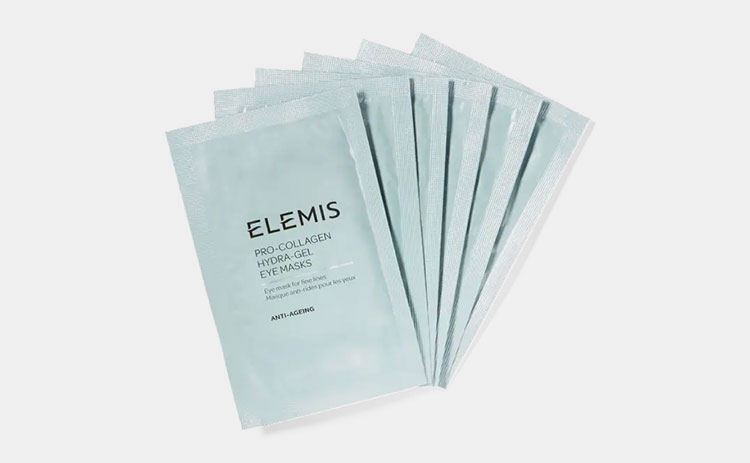

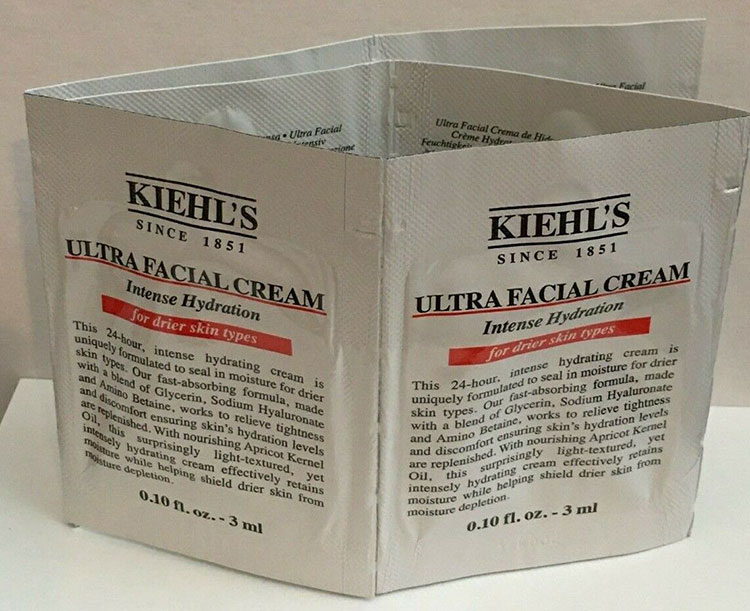

Cosmetic Industry

Henna powder for hair dying

Beauty care products like facial powder, henna powder, and bleach powder are often stored in small, protected sachets for convenient usage. Therefore, a multi-lane 4 side sealing powder packaging machine is used to carry out this task.

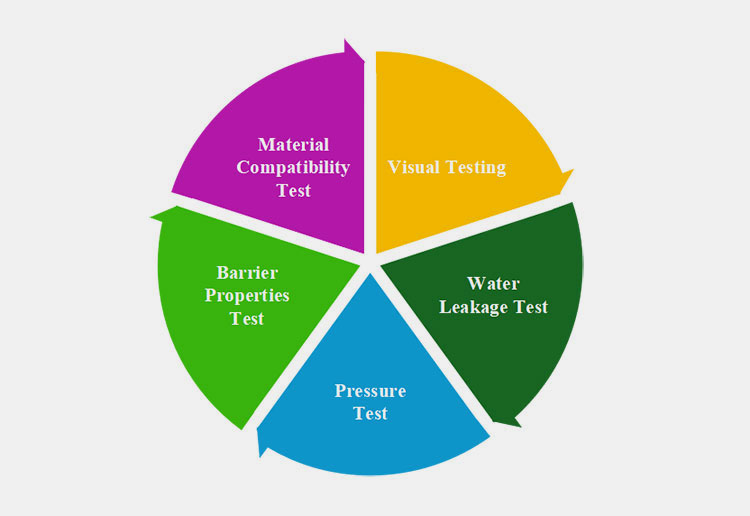

10.How To Examine The Quality Of Multi-Lane 4 Side Sealing Powder Packaging Machine?

It is pertinent to make sure that a multi-lane 4 side sealing powder packaging machine you are going to purchase is of high quality. The purpose behind doing so is to have quality equipment that not only benefit your business in terms of production growth and packaging accuracy but also retain the characteristics of powders being processed.

It is only possible if the machine is a product of professional level tools and components. To know this, you need to check if the machine is adhering certain national and international quality standards including:

Quality assurance presentation idea- Picture Courtesy: inspiredpharma.com

ISO:International Organization for Standardization.

GMP:Good Manufacturing Practices.

FDA:Food and Drug Administration.

CE:European Conformity.

11.How To Maintain And Clean Multi-Lane 4 Side Sealing Powder Packaging Machine?

Cleaning and maintenance of a multi-lane 4 side sealing powder packaging machine is the prerequisite for its smooth functioning and long working life. Let's explore these under few headings:

Lubrication of engine- Picture Courtesy: theramreview.com

Cleaning: Disconnect the machine from power source. Then disassemble the parts of machine such as hopper, filling heads, and sealing bars etc. Remove out the dirt or residues while using a vacuum cleaner or brush. For cleaning external parts, you may use a damp cloth or sponge with a mild detergent. After cleaning, let the parts of machine be properly dried for accurate functioning.

Maintenance: For proper maintenance of a multi-lane 4 side sealing powder packaging machine, you need to keep examining the structural integrity of the machine. For instance, it is crucial that each part of the machine is on right location along with tight screws and nuts.

Moreover, daily observation of your machine enables you to take note of the unusual noise caused by the machine during operation. In such case, you must check the wear and tear of machine and replace the damaged parts with new ones. Along with that, keep your machine lubricated reduce the risk of friction.

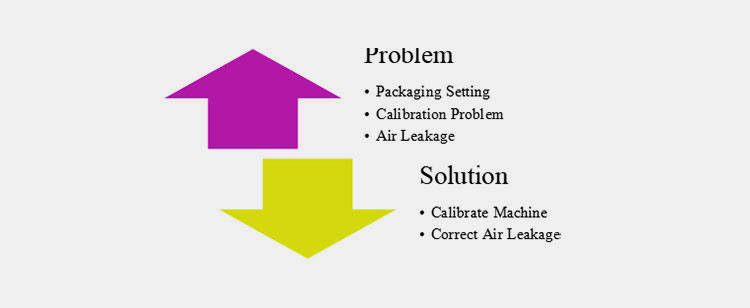

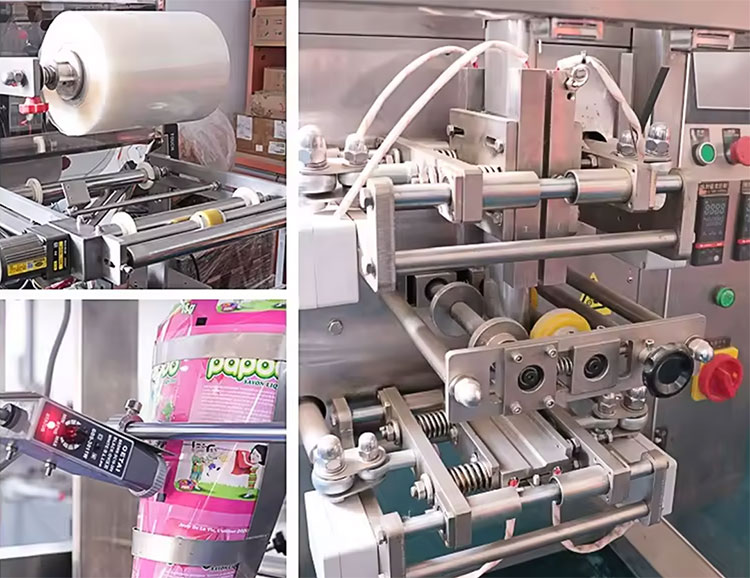

12.Troubleshoot The Common Pitfalls Of Multi-Lane 4 Side Sealing Powder Packaging Machine?

There might appear some technical problems when operating a multi-lane 4 side sealing powder packaging machine. However, these pitfalls can be easily solved if you have relevant knowledge in advance. So, be ready to understand some of the common issues and their troubleshooting:

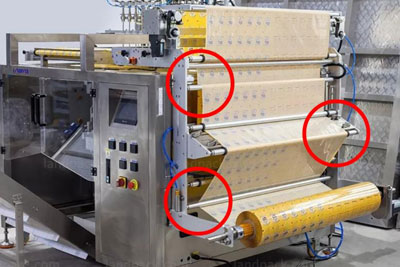

| False tracking of film | ||

Displaying tracking of film- Picture Courtesy: chengyipacking.com |

Cause:

Film carriage is not moving freely Improper settlement of film roll on spindle Automatic film tracking is not working Film is loose on one side and tight on the other |

Solution:

Check the film carriage for free moving Place the film roll on center of spindle Clean the auto film tracking sensor Check the film pulleys and rollers for possible friction |

| Bad vertical and horizontal seals | ||

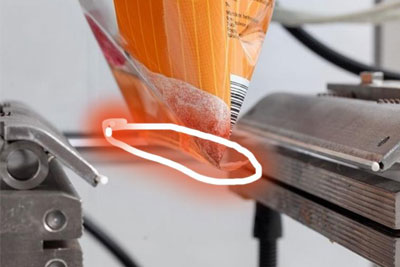

Displaying vertical & horizontal sealing of 4 side seal sachet |

Cause:

Jaws are not aligned properly There may be wrinkles on film due to tension Time, pressure, and temperature are not correctly settled |

Solution:

Align the sealing jaws in way that they are parallel to each other Reduce the tension on film Adjust the time, pressure, and temperature of sealing jaws for effective sealing |

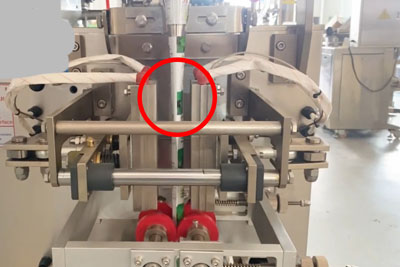

| Sealing jaws are not opening properly | ||

Encircled sealing jaws- Picture Courtesy: samfull.net |

Cause:

The assembly is unable to function freely An emergency stop might be active during operation Incorrect timing of bags sealing |

Solution:

Check if the screws of sealing jaw are loose or inaccurately positioned and take action accordingly Turn off the emergency stop Adjust the sealing time of machine |

| Squeak during operation | ||

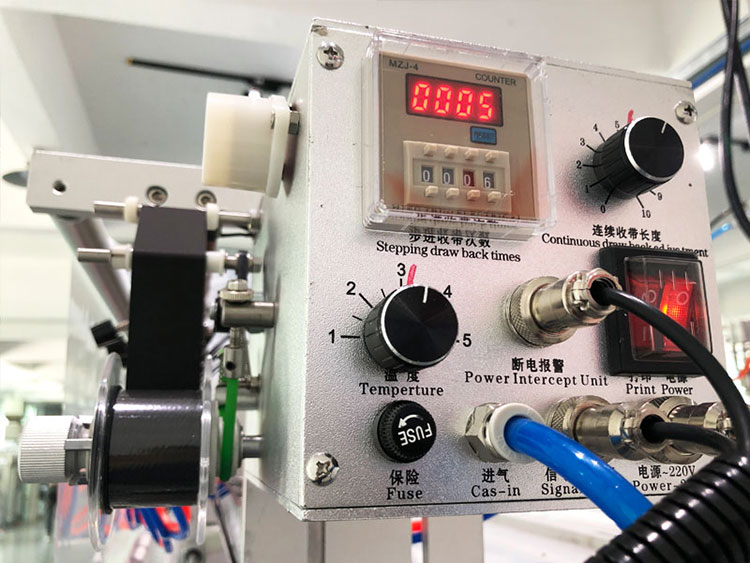

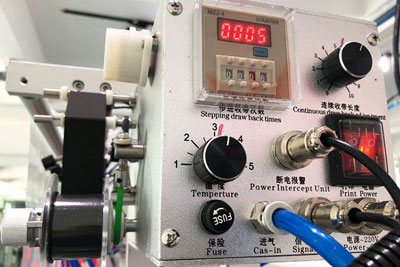

Power unit of the multi-lane 4 side sealing powder packaging machine- Picture Courtesy: chengyipacking.com |

Cause:

Sudden squeak might mean the damage of any part of the machine The hardening of grease in box due to lack of lubrication Loose connectivity to power supply The surface of machine is dirty |

Solution:

Check the wear and tearing of parts in machine and replace them timely Add lubrication to the machine on regular basis to avoid drying or hardening of grease Keep the surface of machine and surrounding environment clean |

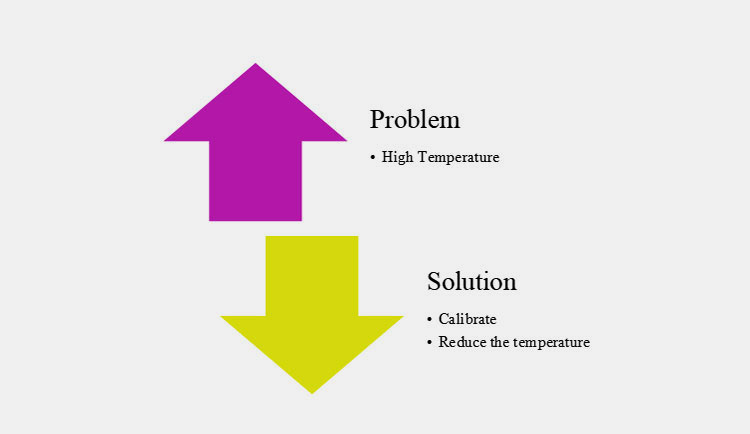

| The temperature of machine is uncontrollable | ||

Displaying the temperature system of a multi-row 4 side seal packaging machine- Picture Courtesy: chengyipacking.com |

Cause:

The thermometer of machine is out of order Non uniform heat sealing pressure Damaging of thermocouple |

Solution:

Repair or replace the damaged thermometer Uniform the pressure of heat sealing You need to change the current thermocouple with new on having same specifications |

13.Factors to Consider When Buying Multi-Lane 4 Side Sealing Powder Packaging Machine?

For making a sound and effective purchase of multi-lane 4 side sealing powder packaging machine, just consider few factors which are inevitable in your way for buying a sophisticated machine. These are as follows:

Product Type

Various free-flowing and adhesive powders- Picture Courtesy: Syntegon

The first and foremost thing to consider is the nature or type of product. For instance, you are required to determine, either you want to process free-flowing powders or non-free-flowing powders. Undergoing this step will enable you to choose the machine with right filling system such a net weigh auger filler or servo auger filler.

Capacity of Machine

Multiple 4 side sealed beverage powder sachets- Picture Courtesy: emanagro.com

Despite being multi-lane in structure, multi-lane 4 side sealing powder packaging machine come with 4 to 12 lanes. Therefore, you need to examine the production capacity of machine and pick for one which is most compatible to your existing needs.

Cost

Cost icon- Picture Courtesy: bcas.co.za

As a multi-lane 4 side sealing powder packaging machine has heavy-duty machinery with multi tasking capabilities, the machine has a bit expensive price. However, as discussed in the point above, you can choose among the different types of machines according to the number of lanes. Apart from this, a secondhand machine will be another cost-effective option to look for.

Supplier Reputation

Supplier reputation is another important factor to consider after all you are investing a big amount on your machine. So, in this case, you are obliged to have established confidence in the supplier by looking into their experience, certification, customer service, and warranty policy.

Conclusion

After thoroughly reading this buying guide about a Multi-lane 4 Side Sealing Powder Packaging Machine, it is now clear that you have got a complete overview of the machine. This machine can greatly aid you in uplifting your business and making it is more trustable one through its precise packaging. But, if you are still confused in getting the right machine for your production, then no need to worry. Just contact us through the given link and we will come up with outstanding machines which will suit your demands!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Multi-Lane 4 Side Sealing Powder Packaging Machine: The Complete Buying Guide In 2025 Read More »