Honey Packaging: The Complete FAQ Guide In 2025

Honey Packaging Ideas - Picture Courtesy: 99Designs

Are you interested in knowing what honey packaging is? Do you know about honey packaging methods? Do you want to learn how the honey packaging process is carried out? Does your production involve honey packaging? If your answer is yes; then this is the right platform where all your queries regarding honey packaging will be solved. This FAQ guide will help you know more about honey packaging and its related information. For better understanding, read the complete article in detail which includes

1.What Is Honey Packaging?

Honey Packaging - Picture Courtesy: Packaging Bee

Honey packaging is a process carried out globally to secure honey products for long storage and transportation requirements. It ensures that honey is packed in a way that the customer enjoys fresh, preserved, pure, and quality products. The process is done using different types of machines and packaging materials. Most commonly sachets, jars, and bottles of different sizes and shapes are used for the honey packaging process.

2.What Industries Involve Honey Packaging

Most of the industries that involve honey and its by-products have honey packaging methods as an essential part of their process. Some of them are

Food Industry

Honey Packaging For Food Industry - Picture Courtesy: Dars

The food industry involves honey packaging on an extended level. Pure honey that is collected from honey beehives is completely purified and then packaged in different types of packaging. The food industry uses this process to make their products look presentable and attract more and more customers to their brand.

Pharmaceutical Industry

Care Honey Lotion- Picture Courtesy: Care Cosmetics

Medications that are viscous and involve honey as a curing element have honey packaging in their production setups. These products are mostly used for personal protection as honey behaves as an essential skin care substance.

Agricultural Industry

Honey Bee Farming - Picture Courtesy: Agri Farming

This type of industry is the actual place where the honey is stored and collected. Multiple beehives with pure honey extraction facilities are present in modern agricultural industries. These honey products are packaged to prevent contamination and to make it feasible to travel longer distances.

Catering And Hoteling

Honey Sachet Packaging For Small Business- Picture Courtesy: Tianjin Honda

On a smaller level, the catering and hoteling industry also does honey packaging in sachets, pouches, and jars. They usually use these for their customers and to cater to local demand.

3.What Are The Benefits Of Doing Honey Packaging?

There are numerous advantages of honey packaging due to its preservation and contamination-free aspect. Some of the most common benefits are

Quality Preservation

Preserving Honey - Picture Courtesy: Hobby Farms

Honey whether it is in the form of crystals or viscous nature can be preserved with proper honey packaging processes. The quality of honey has remained the same over the years and has remained free from contamination, dust, and environmental influence.

Product Shelf Life

No Expiry Date - Picture Courtesy: Manila Bulletin

Honey packaging ensures that proper sealing is provided to the honey product so that no air, humidity, dust, or moisture enters inside it. This makes the product airtight increases its shelf life for longer periods and prevents spoilage.

Product Presentation

Raw Honey In Preserve - Picture Courtesy: BeeHype Honey

The most important benefit of honey packaging is that it makes the product look presentable to both the retailer and the consumer. The honey products when filled in retail store shelves look attractive by doing efficient honey packaging.

Brand Marketing

Marketing By Honey Packaging Business- Picture Courtesy: Welp Magazine

Honey product manufacturers can get the most from honey packaging processes. As honey packaging involves detailed product and brand information on its labels, it allows the manufacturer to market as much as they can. Honey packaging appeals to the customer's eyes and also creates brand marketing options.

4.What Are The Common Types Of Machines Used For Honey Packaging?

A machine that is automatic in working provides efficient and effective honey packaging results as compared to manual processes. Some of the common types of machines that are used in industries for honey packaging are

Piston Honey Filling Machine

Piston Honey Filling Machine

As the name indicates, this type of machine is used to fill honey products with the help of forward and backward movement of pistons. The movement of pistons allows honey to be filled into the packaging and stops when the desired limit is met. Piston fillers are ideal for packaging viscous honey in small- and large-scale industries.

Working Principle

- Initially honey is filled into the hopper of a piston honey filling machine and allowed to traveled through the filling lines.

- Once the honey packaging material reaches the filling nozzle, the piston starts moving the cylinder to create vacuum.

- This vacuum helps in drawing out honey from the filling nozzle into the packaging. Simultaneously the backward movement pushes to bring more honey from the filling lines.

- The speed for piston movement is set in a way that accurate amount of honey is dispense into the honey packaging.

- Finally, sealing and labeling of honey packaging is done to give it a pleasant look.

Gravity Honey Filling Machine

Gravity Honey Filling Machine

Gravity honey-filling machines follow the principle of gravity and ensure that honey flows in the direction of gravity without any external influence. These machines are highly accurate and precise in their processes and perform honey packaging with greater productivity.

Working Principle

- Firstly, the hopper present at the top is filled honey and it travels towards the nozzle by the principle of gravity and depending on its viscosity.

- On the same time the packaging material is created and allowed to be placed beneath the filling nozzle. For containers and jars conveying system is associated with a gravity honey filling machine.

- Valves are placed to control the dispensing of honey so that the flow stops once the maximum limit is achieved.

- Lastly, sealing and labeling is applied on the honey packaging so that customer can be familiar with the product details and to give it a pleasant look.

Volume Honey Filling Machine

Volume Honey Filling Machine - Picture Courtesy: Carlo Migliavacca

Volume honey-filling machines are there for the filling of accurate volumes of honey depending upon the size and type of packaging. The machine releases the exact volume of honey so that no spillage or leakage may occur.

Working Principle

- Volume honey filling machine is designed to dispense exact amount of honey by entering the value in the system.

- Same like other type of filling machines the hopper of a volume honey filling machine is filled with honey and allowed to travel towards the filling nozzle.

- The amount of volume that is to be dispensed is set into the system and once packaging material reaches the filling nozzle the honey is dispensed by the efficient working of pumps.

- Sensors, actuators and valves are used to control this flow of honey so that accurate amount can be filled into the packaging material.

- As the filling gets completed, the packaging material is moved further for application of seal and labels so the spoilage can be avoided and customer can be attracted towards the product.

Jar Or Bottle Packing Machine

Honey Jar Bottle Filling Capping & Labeling Machine - Picture Courtesy: Shangai iPanda International

This type of honey filling machines has highly precise shut-off valves associated with the filling nozzle that stops the flow once it reaches its maximum level. Different sizes and shapes of jars and bottle of either glass or plastic can easily be filled and packed using this type of machine.

Working Principle

- A proper conveying system is used in a jar or bottle packing machine that is used to travel jar or bottles within the system.

- Once the packaging material reaches the filling nozzle, accurate amount of honey is dispensed into it with the help of piston or gravity filler mechanism.

- After filling process is carried out, the conveyor moves toward the next process of seal and label application.

- Fully packaged honey packaging is received at the offloading side of conveyor and packed in boxes and cartons of different sizes to carry out the logistics process.

VFFS Liquid Packaging Machine

VFFS Liquid Packaging Machine - Picture Courtesy: Soontrue

Vertical form fill seal liquid packaging machines have a servo mechanism in their process that is highly suitable for honey packaging due to its support to viscous material. The viscous material in an efficient manner flows through the filling lines of machine and with a certain vacuum pressure is released from filling nozzle.

Working Principle

- In a VFFS liquid filling machine pouches and sachets filling of honey is carried out depending upon its viscosity.

- The feeding roller contains the film that is to be shaped into pouches or sachets. On the same time the hopper is also filled with honey.

- Vertically the bags are formed and honey is released into it in high speed through the filling nozzle.

- After filling process bags, pouches or sachets are seal packed using two heated electrodes that give highly precise sealing to prevent spoilage.

- Cutting of film roll is done after sealing and the honey packaging is packed in different sizes of cartons and boxes.

Honey Stick Packing Machine

Honey Stick Machine

Honey stick packing machines are used to fill and pack stick type honey packaging. It has proper filling, sealing, and cutting of sticks that makes it look pleasant. Sticks are precisely seal so that the shelf life of honey can be increased.

Working Principle

- Same like other packing machines, a honey stick packing machine involves both sticks making and filling processes.

- Sticks of different sizes are formed from the film roll placed at the feeding roller of the machine.

- Honey present at the hopper travels into these different sizes of sticks by the pressure created through pumps.

- As the sensor present in filling nozzle detects the availability of sticks, the honey is dispensed into them and sealed after the process gets completed.

- Sticks are cut by sharp edged cutters to separate them from each other and to give the sticks a pleasant look.

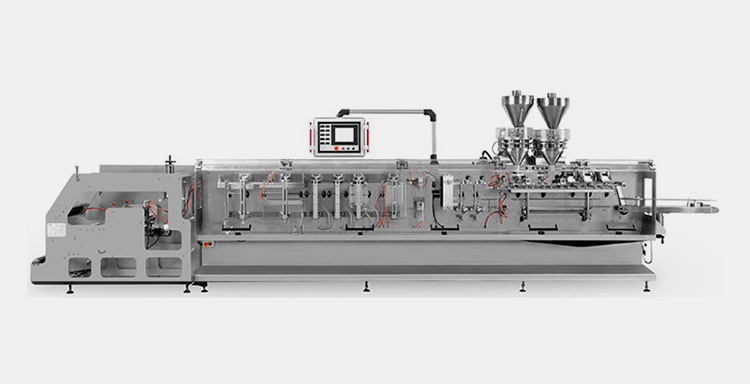

Premade Pouch Filling

Premade Pouch Packing Machine

Premade pouch packing machines are designed in a way that accurate amount of honey can be filled and packed efficiently. These machines are completely automatic and work at a very high speed. Premade pouch packing machine ensures that honey packaging is done ideally in food, cosmetics, and pharmaceutical industries.

Working Principle

- As the name suggest premade pouches of flexible material are used for honey packaging in this type of machine.

- These pouches move with the help of proper conveying system that takes it towards the filling nozzle.

- Honey from hoppers travels through the filling system and as the pouch reaches the filling nozzle it is dispensed into it in an accurate volume.

- The filled honey packaging is carried to the capping system where cap is applied onto it. Further labeling and sealing of edges is also incorporated in the same machine.

Overflow Honey Bottle Filling Machine

Honey Filling Machine - Picture Courtesy: VKPAK

In an overflow honey bottle filling machine, the principle of overflow is obeyed in which the excess honey travels back to the feeding mechanism and maintains the aesthetic of the system. In this way, the excess material is prevented from spoilage and does not fall out of the system. This also maintains the quality of the system and product.

Working Principle

- Overflow honey bottle filling machine has a reverse feeding process that avoids material wastage and spoilage.

- Initially the packaging material is placed beneath the filling nozzle and is filled with honey through it. Pumping mechanism is used for accurate filling of honey.

- During the pumping mechanism, if any excess liquid is dispensed off the machine, it is collected and carried back to the hopper so that it can be reused.

- The machine avoids any spoilage even if the honey packaging has irregular shape.

- The filled honey packaging is carried further for capping, labeling and sealing process to make honey packaging attract customers towards it.

5.How Is The Quality Of Honey Maintained While Performing Honey Packaging?

Honey Quality Packaging - Picture Courtesy: 99Designs

Honey packaging ensures that properly filtered and clean honey is filled into the packaging material. This honey is packaged using clean and sanitized equipment so that no microbial sign can enter the processing honey.

Sealing applied in honey packaging prohibits entrance to oxidation reaction, the path to ultraviolet radiations, moisture content, contaminants, and environmental factors. In this way, the honey remains fresh for years and its quality is maintained at the same standard.

6.In What Different Styles Honey Packaging Is Done?

Some of the ways how honey packaging is done are

Sachets

Sachet Honey Packaging - Picture Courtesy: Dribbble

The most basic type of honey packaging is in different sizes of sachets. Sachets are often used to package honey ranging from 10 to 15 grams and are a greater option for taking it while traveling.

Stick Form

Busy Bee Honey Straws

The stick is the basic way of doing honey packaging. Simple sticks mostly made up of plastic material are filled with honey products for a customer that can consume it readily in their breakfast or any meal.

Pouches

Honey Pouch Packaging - Picture Courtesy: Packaging Strategies

Pouches are enlarged forms of sachets and are usually used to fill greater amounts of honey material. Pouches are pleasant in appearance and are ideal for home application.

Jars

Glass & Plastic Honey Packaging Jars- Picture Courtesy: SKS Bottle

Jars whether they are hive, queening, hex, or classic are one of the most desired forms of honey packaging. These jars are present in different sizes and shapes and are prepared for all types of industries.

Bottles

Plastic Honey Bottles - Picture Courtesy: Desertcart

The most advanced type of honey packaging is in bottles of different materials. Both glass and plastic bottles are used for honey packaging and are easy to consume using a spoon or any utensil.

7.What Are The Important Considerations While Doing Honey Packaging?

Some of the important considerations while doing honey packaging are

Total Budget

Net Budget

The manufacturer should be completely aware of the in hand budget and its way of expense. While doing honey packaging it is an important thing that what type of filling material will be used and what packaging style should be selected according to the budget. Expensive things can cause early failure or damage to business.

Packaging Design

Honey Packaging Design

Design of honey packaging requires a deep concern and expertise as it can bring customer towards and product and generate profit. Unique designs and packaging can make its presence stand out compare to other products.

Honey Viscosity

Viscosity Of Honey - Picture Courtesy: P.I.

As different type of honey is available globally, it is important to choose the honey packaging material and process according to it. Honey with high viscosity can not be adjusted in paper or light weighted plastic material as it will leak out from it during transportation.

Packaging Material

Honey Packaging - Picture Courtesy: Design and Packaging

The manufacturer should select the right type of honey packaging material according to its requirements and available resources. It is ideal to launch products in all sachets, pouches, and jars so that people can buy them according to their needs.

Customer Expectations

Pure Honey For Sale - Picture Courtesy: Honey Source

In the current scenario where greater marketing competition occurs, it is always a challenge to meet the customer's expectations. The manufacturer should show a greater concern according to the consumer needs and make them satisfied with it. A less concern can easily convert the consumer to another brand or product.

Conclusion

Honey is consumed in each part of the world no matter what age group it is. It is a broad market that can make a lot of revenue. This is why honey packaging holds a greater importance in terms of customer satisfaction and attraction. But it remains a query that what honey packaging is done and how can it be done in a better way. To solve these queries, this FAQ guide contains all the necessary information you require. For more detail and information contact All pack as our customer representatives are always there for you 24/7.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours