High Viscosity Filling Machine: The Complete Buying Guide in 2025

Packing of high viscosity products is just like you’re juggling the balls. It is obviously very tricky task as it doesn’t pour in an easiest way. That’s why many of you always trying to find flexible steps to attain a perfect method. Don’t worry friends! We are here to help. This blog is designed to explore ‘high viscosity filling machine’ that works for your liquids. It makes your container or sachet to fill correctly without creating a mess.

So, are you thinking about purchasing a machine which is special featured equipment to ensure your product is treating well? Just read on to explore now.

1.What does high viscosity filling mean?

High viscosity filling materials

High viscosity, by definition means a liquid which will show resistance to flow. To make it easier to understand, consider any thick liquid which comes to your mind, like honey or oil. These liquids are thick and therefore do not flow easily. This means that they are highly viscous liquid unlike water which can flow easily.

Thus, high viscosity filling means filling and packing viscous liquids into various containers.

2.What is a high viscosity filling machine?

High Viscosity Filling Machine

High viscosity filling machine is defined as a specialized device that is equipped with various advanced features to process high-viscosity liquids. This machine fills different kinds of containers with thick, pasty, and sticky liquids. It loads non-free-flowing liquids that do not easily flow into the containers.

These liquids have high resistance to flow and do not dispense easily, hence specialised kinds of fillers are present in the high viscosity filling machine.

This machine is highly hygienic and is made of corrosion-resistant stainless steel that is food-grade, hence; it is used in the safe packaging of both food and non-food liquids. It is routinely adopted in industries beyond food.

3.How significant is a high viscosity filling machine?

The high viscosity filling machine is extremely significant in various industries because it has a broad range of advantages and earns huge profits for businesses. Here is how the significance of high viscosity filling machine is measured.

High Speed and Production Efficiency

High Speed and Production Efficiency

Manual filling of high viscosity liquids can be slow and extremely burdensome. However, a high viscosity filling machine has automated technology and fillers with which it can process and fill high viscosity liquids at much faster rates. Thus, increasing the production efficiency of the systems.

Cost-Effective

Cost-Effective

When it comes to manual labor, there are high labour wages per hour which is extremely difficult to take out from the monthly budget. By adopting a high viscosity filling machine in production, you can minimize the need for labor expense which decreases labour wages. This machine is also cost-effective because it does not waste expensive liquids.

Boosting the Accuracy

Boosting the Accuracy

Tiresome manual labour is prone to error. But not high viscosity filling machine. Extremely sensitive and accurate volume control sensors and loading cells are present in this machine via which it fills the liquid products with high precision and accuracy. This machine has absolutely no chance of error.

Ease of Handling

Ease of Handling

One of the paramount reasons for installing a high viscosity filling machine is its ease of handling. Both during and after operation, this machine is quite easy to handle through its interactive HMI. Moreover, with minimal effort on the operator's part, this machine is easy to clean and maintain.

Protection

Protection by High Viscosity Filling Machine

The high viscosity liquid filling machine confers protection over high viscosity fluids like jams, peanut butter, honey, creams, creams, etc. Contaminants, dust, debris, microbes, oxygen, and moisture destroy open goods. However, it is not possible with a high viscosity liquid filling machine as it safely packs different fluids.

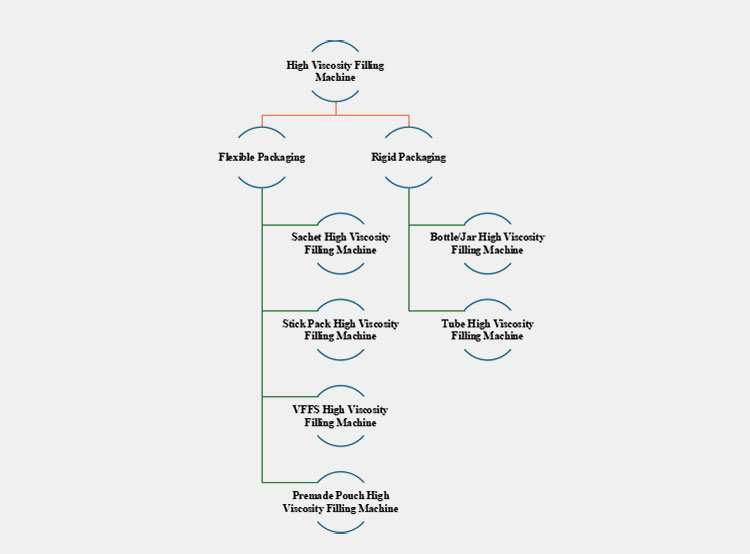

4.How many different types of high viscosity filling machines are there?

There are broad categories of high viscosity filling machines based on the packaging type which are detailed below:

According to Flexible Packaging

Sachet High Viscosity Filling Machine

Sachet High Viscosity Filling Machine

It has a compact working design, requiring minimal care and space for its work. It has single or multiple lanes so form one or numerous sachets in the single cycle. The sachets can be sealed at 2, 3, or 4 sides by this machine.

Working Principle

At the beginning of the operations, the film is unwound and travels to the forming station, where it is folded and shaped into a sachet. Filling and sealing of sachet is carried out by filling devices and sealing jaws. Finally, the finished high-viscosity liquid-filled sachets are eliminated from the machine via discharge conveyors.

Stick Pack High Viscosity Filling Machine

Allpack Stick Pack High Viscosity Filling Machine

Stick pack high viscosity filling machine is characterized by its multiple lanes that speedily carry out various tasks of stick pack forming, filling, and sealing. This machine can create multiple stick packs at a time with 3 or 4 side sealing. It has excellent production capacity and packs 600 packs per minute.

Working Principle

It carries out its work by unwinding film from its film holder and this film goes across guide rollers. The film is transformed into stick packs by doubling and sealing across its sides and bottom. The liquid is fed into the stick packs through filling nozzles and top sealed via sealing jaws. Now the stick pack is ready for discharge.

VFFS High Viscosity Filling Machine

VFFS High Viscosity Filling Machine

It is a remarkable machine having a compact and smaller footprint design. It forms, fills, and seals stunning and vibrant pouch packaging using forming tubes, fillers, and sealing jaws. The pouches formed by this machine have various sizes and shapes. It increases production efficiency by its high-speed working components.

Working Principle

It performs the function of high viscosity liquid filling by unravelling of film using rollers and the dancer’s arms. The film travels in the downward direction and is bottom sealed. Afterwards, the sealed pouch is fed with liquids and finally sealed at the top.

Premade Pouch High Viscosity Filling Machine

Allpack Premade Pouch High Viscosity Filling Machine

This machine is designed to fulfil high production capacity goals because it only fills and seals the pouches, unlike other form, fill, and seal machines. It processes ready-made pouches, hence it is more efficient. It has a rotary structure with which it can process multiple pouches simultaneously.

Working Principle

The working principle of this machine involves easy opening of the already-formed pouches by the grippers and compressed air is introduced for inflating the pouches after opening. Now filling and sealing steps are carried out successively. Afterwards, the finished pouches are ready to be delivered using conveyors.

According to Rigid Packaging

Bottle/Jar High Viscosity Filling Machine

Bottle/Jar High Viscosity Filling Machine

It is one of the oldest high viscosity filling machines that is employed to fill different types of rigid containers like bottles and jars. This machine is equipped with multiple filling heads to carry out non-stop liquid packaging. It ensures consistent and uniform filling of the bottles and jars. By changing its design, bottles of varying dimensions are packed by it.

Working Principle

The machine carries out its work by placing the bottles and jars on the conveyor. This conveyor transports the containers to the filling heads and when their presence is identified by the machine, the filling nozzles dispense the high-viscosity liquids into the container till their target level is attained. Now, the containers are moved to subsequent capping and labelling steps.

Tube High Viscosity Filling Machine

Tube High Viscosity Filling Machine

It has a different design from all other high viscosity filling machines as it is an automatic machine with a rotary structure. This machine is customised to fill high viscosity, thick, and non-free-flowing liquids into the tubes. Tube high viscosity filling machine is an all-rounder machine because it performs different steps like tube placement, filling, sealing, and trimming all in one machine.

Working Principle

The working mechanism of this machine is quite simple with the first step being tube placement in the rotary turret. This station rotates for tube loading, sealing, and coding. All these steps take place one after the other and there is a small machine pause between every step. After coding and trimming, the tubes are ejected from the machine.

5.What is the market scope of high viscosity filling machine?

If you are planning on buying high viscosity filling machine and you are worried whether you can use this machine for different sectors, then don’t worry. Because this equipment can be virtually used in almost all sectors. You name it, and this machine can serve its purpose anywhere. Let us discuss in detail its market scope.

Pharmaceutical Industry

Usage in pharmaceutical industry

If you are a pharmacist, then there’s good news for you! Because high viscosity filling machine will be highly valuable for your industry. It can fill various medicines like lidocaine syrup, cough syrup, eye ointments, lotions, creams etc into bottles and sachets efficiently without any wastage.

Food Industry

High viscosity products in food industry

If you belong to a food industry and deal with items like honey, sauces, jams, tomato puree, maple syrup and much more, then this high viscosity filling machine is the perfect equipment for your business. Because it will properly fill and package them into bottles, pouches and sachets.

Petroleum Industry

Motor oil

It must have been obvious to you by reading the term petroleum that the high viscosity filling machine would be the go to equipment to fill these thick viscous petroleum products like oil, diesel, motor oil into containers, thus ensuring safe and secure packaging.

Paint Industry

Paint industry

High viscosity filling machine can fill thick, colourful paints into jars and containers perfectly. These paints are highly viscous and will require an efficient equipment to handle their chemical composition at room temperature. So if you consider installing this equipment in your paint factory, it will reap huge benefits for you!

Cosmetic Industry

Beauty products

Many beauty products you see in your shopping malls and convenience stores like moisturizers, shampoos and serums require a proper filling machine which can fill and package these viscous products into their appropriate bottles and jars. So if you use high viscosity filling machine, it can easily serve this purpose.

Veterinary industry

Attention to all pet lovers out there! If you are associated with veterinary industry and deal with animal care products, then take a look at the high viscosity filling machine. It will easily fill products like animal medicinal drugs, shampoos, creams, ointments, gels and much more into tubes, jars and containers so your pet will get the best treatment, care and love it needs!

Chemical industry

Chemical industry is quite a versatile industry which manufactures products like acetone slurry, dynstrol (white jell), gum, glues and much more. These viscous chemical product can be smoothly filled into their respective packaging with the help of high viscosity filling machine.

Household products industry

As you would’ve guessed from the title, this industry produces household items. Items like liquid soaps, detergents, fabric softener are carried from the hopper into bottles and containers by the help of high viscosity filling machine with ease. So incorporating it into your production line would be a great initiative for your company.

Textile industry

Textile industry deals with high production clothes and which are also exported in huge quantities to other countries. Products like dresses, towels, bed sheets need dyes and colors which are their crucial raw materials. So if you use high viscosity filling machine to fill these colored pigments and dyes, then it will reap huge benefits for you if you work is textile related.

6.How does a high viscosity filling machine work?

The working of the high viscosity filling machine is fast and effective, and each step is carried out under the guidance of machine PLC unit. In the below-mentioned points, you will be shown the working principle of the sachet high viscosity filling machine.

| Loading | Before beginning the machine operation, it is important to pour high-viscosity liquids into the hopper.

Secondly, for consistent machine operation, it is important to affix the film roll onto the film holder or unwinding disk. For pre-made pouch fix pouches in a magazine, however tubes or jars in holder. |

| Machine Settings | For the smooth and uninterpreted flow of the packaging operation, the operator adjusts basic parameters like bag length, filling volume, sealing temperature, and pressure. These settings are input on the interactive touch screen. |

| Preparation of Filling Material | Now, the machine is turned on and the first part that begins its working is the film unwinding disk. It starts rotating which leads to unwinding of the film. This film is directed by the rollers towards the forming tube. Here vertical and horizontal sealer turns the film layer into the sachet.

In the case of pre-made pouches, the feeding of pouches are manual but gripers are responsible for picking them and vacuum suction cups help in the opening of pouches. However, jars or tubes come in contact with the nozzle by the help of a conveyor. |

| Filling | As soon as the presence of a sachet is recognized under the filling nozzle, the liquids in the hopper are fluidized to the filling devices, where it is measured and then with the help of the filling nozzle dispensed into the sachet, pre-made pouches, bottles or jars. |

| Cutting and Sealing | Upon filling, the horizontal sealing jaws come into action and add a strong seal to the top of the sachet.

In the next step, the appearance of the sachet is enhanced using cutting knives that confer a distinct cut on the sachets. Now, the ready sachets are separated from the rest of the film using cutting. While pre-made pouches are sealed by using heat sealers using one opened end of the pouch to bind them completely. In the case of tubes, or jars, they are secured by caps. |

| Discharging | The filled packets are discharged from the machine by using an outlet. |

7.What type of filler is required for a high viscosity filling machine?

There are two main types of fillers required for high viscosity filling machines. These filters are discussed below:

Positive Displacement Pumps

Positive displacement

These are known as workforces for filling high viscosity fluids. These pump fillers are specially constructed to fill non-free-flowing fluid with high viscosity. A positive displacement pump relies on displacing fluids by force. A specific volume travels within the pump using rotating elements like geas and lobes. This rotation moves the fluids into the pump housing and then filling nozzles, ultimately in the filling containers.

Piston Filler

Piston filler

The second type of filler used in the high viscosity filling machine is the piston filler. It is best for dispensing high viscosity fluids and chunky liquids. Piston filler has a piston and a cylinder. During the upstroke movement of the piston in the cylinder the liquid is forced into the cylinder while the downstroke movement of the piston draws the fluid into the filling nozzle.

8.Why viscosity range chart is essential when using high viscosity filling machine?

Before you buy any high viscosity filling machine, you should consider how viscous (high specific gravity) your product is because it will greatly affect the type of machine you will buy. If your product is thick and viscous like honey or jam, then go for piston high viscosity filling machine because it will accurately pump them into empty containers with high precision.

However if your product is mildly viscous (low specific gravity) and not that thick , then go for gravity high viscosity filling machine which uses gravity to pump the liquid into the empty containers. By keeping these factors in mind, you can buy the right machine for you for optimum results and minimal wastage.

9.What is the difference between a high viscosity filling machine and a regular liquid filling machine?

A high viscosity filling machine and a regular liquid filling machine, both are employed for filling liquids. But these two machines could not be more different from one another. The differences between these two machines are detailed below:

| Features | High Viscosity Filling Machine | Regular Liquid Filling Machine |

| Picture |  |

|

| Handling | It is designed for filling high viscosity liquids. | This machine fills low to medium-viscosity liquids. |

| Operating Principle | High viscosity filling machine operates on the principle of positive displacement. | It operates on the principle of gravity and pressure difference. |

| Filler | Pump and piston fillers are used in the high viscosity filling machine. | Gravity, pressure, and vacuum fillers are used in regular liquid filling machines. |

| Applications | It fills jams, honey, ketchup, sauces, and pastes. | It fills water, solvent, as well as juices. |

| Design | It has complex construction. | It has a simpler design. |

| Cost | It has a high purchase cost. | It has a lower purchase cost. |

10.What are the challenges associated with high viscosity filling machine?

Just like any other machine you buy which has its pros and cons, high viscosity filling machine too has some problems associated. However, these challenges can be solved if you handle them in the right way. Let us take a look at some of these challenges below.

| Inaccurate filling

Sometimes, the machine fills inaccurately due to broken valves or misaligned parameters. |

To solve this, monitor and adjust the incorrect parameters on your control panel. Inspect the valves and if damaged, replace them. Also, check that the air pressure is correct in the pneumatic system and if not then adjust it accordingly. |

| Clogged or damaged nozzles

Often, the continuous flow of product or dust particles can clog or damage the nozzles. |

If the nozzles are not pumping liquid smoothly then check if they have been clogged by the product or have obstructed by a foreign object. If they have, then clean the nozzles or replace them with new ones if they have been worn out. |

| Inconsistent air pressure

Fluctuating air pressure inside the machine can cause defected filling and hence faulty final product. |

This indicates fault in the air pressure system or the compressors. To prevent and solve this, make sure the air filters are clean and look for any inappropriate air pressure levels and change them if necessary. |

Conclusion

In a nutshell, a high viscosity filling machine is a specialized device that performs the filling of high viscosity fluids quickly and efficiently. It is used for its smooth operational principle because it does not create any mess. It accomplishes the trickiest tasks of filling high viscosity liquids with minimal effort on its part. Now, it's time to wrap up this informative buying guide about the high viscosity filling machine. Hope, you have understood all the aspects of this machine. For purchase-related queries, please contact the Allpack customer care centre.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide