Capsule Counting Machine: The Complete FAQ Guide In 2025

With the increasing demand for more efficient and accurate ways to count pills, tablets, and capsules in different industries, machine counting has become an increasingly popular way of getting products out faster and with less human error. At a time when efficiency is key, capsule counting machines are becoming essential equipment as they offer increased accuracy over manual counting processes. But what do you need to know about them before investing in one?

In this complete FAQ guide, we investigate how capsule counting machines work, the benefits such a machine can bring to your business, and the potential technical risks of introducing one into your business’ workflow. So, whether you are just beginning to research your options or already convinced that a capsule counting machine is exactly what you need, we hope this comprehensive guide provides all the answers you seek!

1.What Is A Capsule Counting Machine?

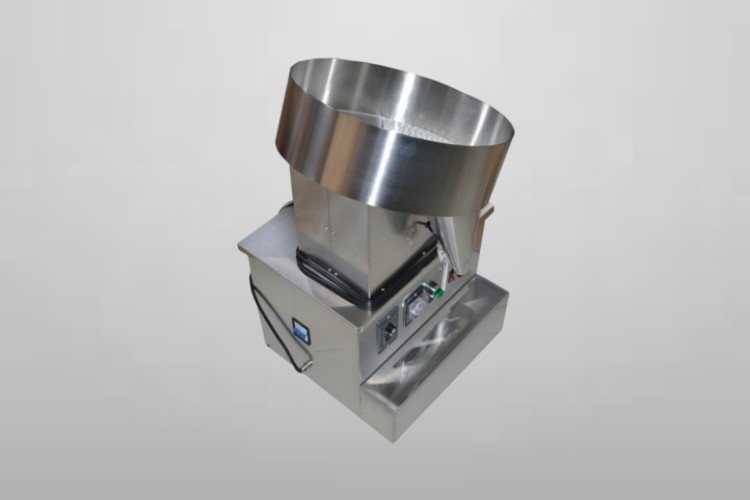

A Capsule Counting Machine is a specialized device designed to accurately count capsules, tablets and other small objects quickly and efficiently. It can help save time and labor by automating the counting process. The machine takes sorted capsules or tablets on an input hopper and then uses a vibratory mechanism to move them into individual cells, where they are counted.

Furthermore, a capsule counting machine is equipped with an LCD display that shows the total number of capsules or tablets counted, and it can be easily operated by pushing button controls. It also offers customizable settings so you can adjust the speed and accuracy of the counting process. With its simple operation, user-friendly design and accurate results, a Capsule Counting Machine can be a valuable asset to any pharmaceutical and manufacturing facility.

2.What Are The Components Of A Capsule Counting Machine?

A capsule counting machine is a device used to sort and count capsules efficiently. It can be used for pharmaceutical, nutraceutical, or other types of applications. Here are the components of a capsule counting machine:

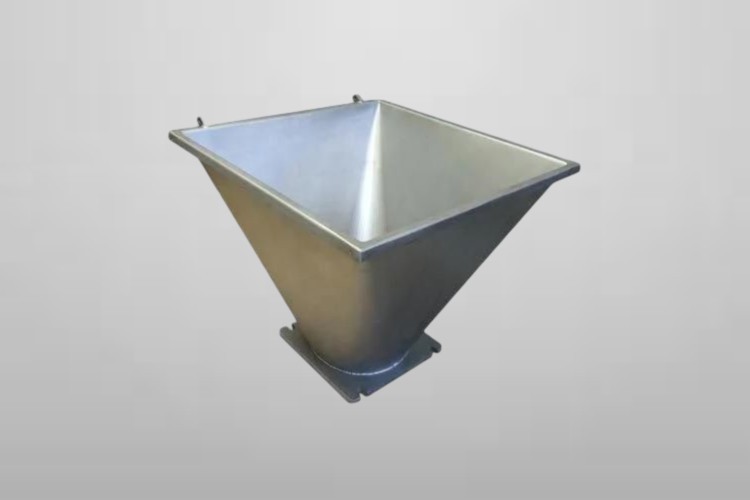

- Hopper

The hopper is the initial feeder for capsules. It’s often made from stainless steel for durability and easy cleaning. The hopper consists of a slanted drum with a hole at the bottom and a spring-loaded gate that allows the operator to regulate the flow of capsules.

- Feeder

The feeder is a device that regulates the number of capsules fed into the counting mechanism. It uses either a vibratory or auger-driven system to push capsules from the hopper into the counting chamber.

- Sorting Drum

The sorting drum is a rotating cylinder with openings on the sides or top. As capsules pass through the openings, they are sorted into their designated counting compartments.

- Counting Chamber

This is where the actual capsule counting occurs. It’s made up of two parts: the upper half, which contains a set of high-precision weighing scales, and the lower chamber, where capsules are dropped. The counting chamber can be configured to count a variety of capsule sizes and types.

- Dispensing Tray

This is the final destination for counted capsules. It’s typically made from stainless steel and designed to resist wear and tear. The dispensing tray can be customized with a variety of features, including removable compartments for different capsule types.

- Control Panel

The control panel is the brain of the operation. It’s where you’ll find a variety of features, including programmable count settings, automated shutoff, digital displays for monitoring counts, and more. Many capsule counting machines are compatible with barcode scanners for easy integration into existing systems.

- Reject Chute

Finally, the reject chute is an optional component for machines that are designed to detect and eject defective or misaligned capsules. This helps ensure that only the highest quality capsules are counted and dispensed.

These are the components of a capsule counting machine. Each component plays an important role in ensuring accurate and efficient counting. By understanding how each part works, you’ll be better equipped to choose the right machine for your needs. With careful selection and maintenance, your capsule counting machine can help you achieve greater accuracy and efficiency in your counting process.

3.How Does A Capsule Counting Machine work?

A capsule counting machine works by feeding a container of capsules into the machine. It uses sensors and optical cameras to detect and count the capsules accurately and quickly. The container can hold up to thousands of capsules and have an automated shut-off switch when it reaches its maximum capacity.

Once the container has reached capacity, the counting machine will scan each capsule for size and orientation. It will use this information to determine the total number of capsules in the container and then output a count on a digital display or on a printed label.

The machine can also be programmed to account for any minor variations in capsule size or orientation, giving you an accurate count every time. This makes it easier to keep up with inventory levels and streamline the production process.

Finally, some capsule counting machines have optional features that can be used to sort capsules before they are counted. This sorting feature ensures that each container has exactly the right amount of capsules and makes sure there is no batch-to-batch variation in the count – giving you peace of mind.

With a capsule counting machine, you can easily and accurately keep up with your inventory and make sure you’re always producing the right amount of capsules. It’s a fast, reliable, and cost-effective way to get the job done!

4.What Are The Advantages Of A Capsule Counting Machine?

When it comes to counting pills and capsules, a capsule counting machine can provide you with a number of advantages. Here are seven of the biggest benefits of using this type of equipment:

- Increased Accuracy

Capsule counting machines are designed to be incredibly accurate at counting and dispensing a specific number of capsules. This ensures you don’t have to worry about over or underfilling the containers, which can lead to unhappy customers and costly waste.

- Improved Efficiency

Capsule counting machines greatly reduce the amount of time and labor required to count large capsules. With a capsule counting machine, you can quickly and accurately count out exact amounts instead of tediously counting by hand.

- Cost Savings

By purchasing a capsule counting machine, you reduce the cost associated with over or under filling containers and equipment costs due to human error. You can also save on labor costs by eliminating the need for extra staff to count capsules.

- Easy To Operate

Capsule counting machines are easy to use and require minimal operator training. This means that even unskilled personnel can quickly learn how to operate the equipment in a short amount of time.

- Consistent Quality

Capsule counting machines are designed to accurately dispense a predetermined amount every time they’re used, ensuring that all containers have the same quality and consistency. This eliminates guesswork and increases customer satisfaction.

- Improved Productivity

By eliminating the need for manual labor, capsule counting machines help you increase overall productivity. You can produce more products in less time and with less effort, resulting in increased efficiency.

- Versatile

Capsule counting machines can be used for a wide variety of tasks, including counting capsules, tablets and other items. This versatility makes them ideal for many different types of businesses and industries. No matter your needs, a capsule counting machine can help you achieve your goals. No matter what type of product you need to count, the versatile nature of these machines makes them an invaluable part of any production line.

5.What Are The Applications Of A Capsule Counting Machine?

A capsule counting machine is an essential part in different industries as they ensure that the right number of pills or capsules are dispensed in each bottle or package. Here are some applications for capsule counting machines:

- Pharmaceutical Production

In the pharmaceutical industry, capsule counting machines are used to quickly and accurately count large numbers of pills or capsules in preparation for distribution. This helps ensure that each customer receives a precise quantity of medication as prescribed by their doctor.

- Cosmetic pills production

In the industry of cosmetic pills production, capsule counting machines are used to accurately and quickly count capsules in preparation for distribution. This helps make sure that each customer receives a desired quantity of pills as per their requirement.

- Food Supplement Production

In the food supplement industry, capsule counting machines are used to accurately count items such as vitamins and minerals in preparation for packaging. This helps to ensure that customers receive an accurate dose of their prescribed supplement each time they purchase it.

6.What Are The Different Types Of Capsule Counting Machines?

There are many types of capsule counting machines available on the market today. Here’s an overview of the most common ones:

- Manual capsule counting machine

Manual capsule counters provide a simple and low-cost solution to counting capsules quickly and accurately. The user manually counts how many capsules are present and enters that number into the machine, which then prints out a label with the capsule count. Manual machines are often used for smaller batches or when accuracy is not as important.

- Automatic capsule counting machine

More complex than manual counters, automated capsule counting machines are designed to count capsules of different sizes, shapes and weights with an accuracy rate as high as 99%. The machine automatically calculates the capsule count and prints out a label with the capsule count without requiring manual counting. Automatic machines are often used for larger batches where accuracy is important.

- Vibratory capsule counting machine

This type of machine uses vibrations to separate the capsules and count them. The machine vibrates the container, which causes the capsules to separate, allowing the user to quickly and accurately count the number of capsules in a container. Vibratory machines are often used for larger batches where accuracy is important.

- Rotary capsule counting machine

These machines use a rotating disc to count capsules quickly and accurately. The disc has several slots that capsules drop into as it rotates, which allows for accurate counting of the capsules. Rotary counters are usually highly accurate and can count up to 100,000 capsules per hour.

7.How Can I Maximize The Performance Of My Capsule Counting Machine?

- Understand the machine’s capability and limits

Before you start using your capsule counting machine, it is important to understand its capability and limitations. Knowing the characteristics of your machine can help ensure that any adjustments you make will be effective in improving its performance.

- Use quality capsules

Choosing lower quality capsules can lead to discounts and jamming. Ensure that you use the best capsules available with your capsule counting machine so that it can count accurately and efficiently.

- Avoid overloading

Overloading can cause jams and mis-counts, so make sure not to put too much strain on the machine. Stick to the recommended load capacity and it will help keep your capsule counting machine running optimally.

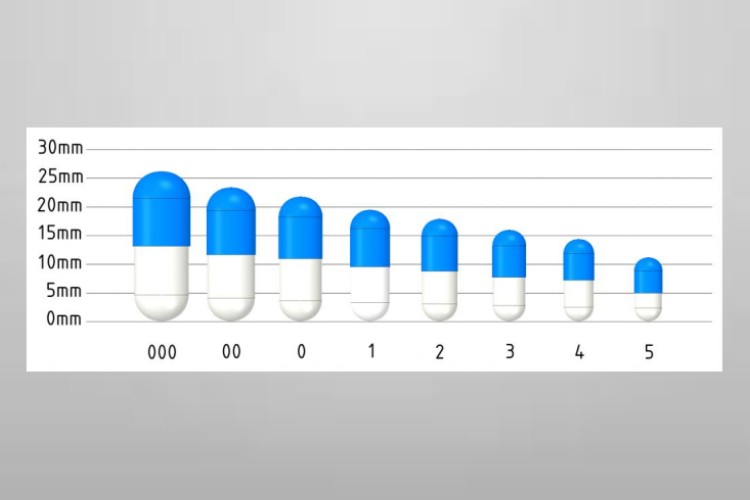

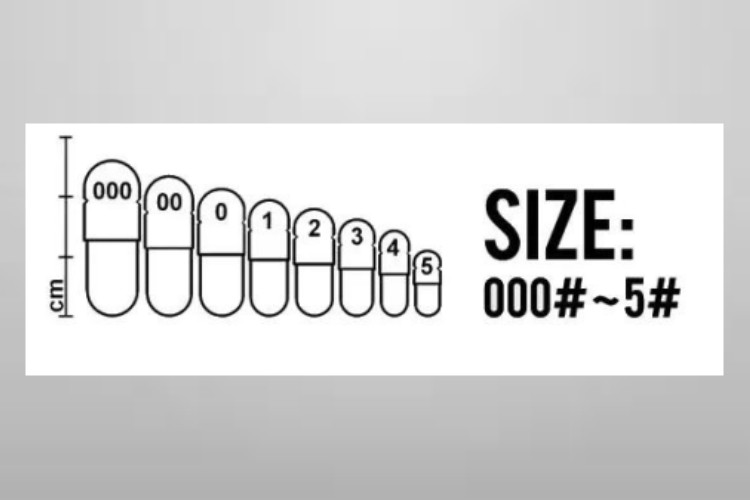

- Properly size capsules

Using too large or small capsules for your Capsule Counting Machine can lead to inaccurate counts and slower performance. Make sure that all capsules you use are the correct size for your machine.

- Keep your counting area clear

If there is clutter around your Capsule Counting Machine, it can affect its accuracy and speed. Make sure to keep the counting area free from debris and other distractions that could interfere with the machine’s performance.

- Regularly calibrate your Capsule Counting Machine

If you want to consistently achieve accurate counts and faster speeds, it is important to regularly calibrate your Capsule Counting Machine. This will ensure that all components are properly aligned and functioning at optimal levels.

By following these simple tips, you can keep your Capsule Counting Machine running smoothly and efficiently and get the most out of it.

8.How Is A Capsule Counting Machine Different From Standard Counting Machines?

A capsule counting machine is specifically designed for counting small objects such as pills and capsules, whereas a standard counting machine can be used to count any kind of object. The main difference between the two is that a capsule counting machine uses a vibratory feed system, which separates out individual objects from an upstream supply onto a conveyor belt or chute, making it easier to count them accurately.

In addition, capsule counting machines are designed with a higher accuracy rate than standard counting machines, typically ranging from 99.9-100%. For example, if you were trying to count 100 pills by hand versus using a capsule counting machine, the machine would be able to count them much faster and with greater accuracy. This makes them ideal for use in medical and pharmaceutical industries where accuracy is of utmost importance.

Another advantage of capsule counting machines is that they can sort out defective capsules or pills, as well as provide a packaging solution in the form of containers such as bottles, vials, and blister packs.

Finally, capsule counting machines are designed with features that enable them to maintain speed and accuracy even when dealing with large volumes of capsules. Therefore, if you need to count small objects accurately and quickly, then a capsule counting machine is the ideal choice.

9.What Factors Should Be Considered Before Purchasing A Capsule Counting Machine?

When buying a capsule counting machine, several factors need to be considered to ensure successful implementation and satisfactory results. The following seven points should be taken into account before deciding which capsule counting machine will best serve your needs:

- Cost

Cost is an important factor that should be considered when purchasing a capsule counting machine. The price of these machines can vary significantly depending on the type and features they offer. It’s important to evaluate your needs and budget before making a purchase. Some machines are more expensive upfront, but may save money in the long run due to their higher efficiency or greater accuracy.

Others may be more affordable, but not offer the features you need or the same level of precision. Therefore, it’s essential to compare different models and decide which one best meets your requirements and budget before making a purchase.

- Accuracy, precision and reliability

These three elements are essential when it comes to selecting a capsule counting machine. Research the accuracy, precision and reliability ratings of your potential machine to ensure you are getting the most accurate results.

- Speed

A faster machine will help increase production, reduce labor costs and improve accuracy. The speed of the machine depends on a variety of factors like the size and type of capsules being counted, how many capsules need to be counted at once, and other considerations like weight and shape.

When looking for a capsule counting machine, it’s important to take all these factors into consideration and find one with the speed that is suitable for your needs. You also want to make sure that the machine can handle different types of capsules and sizes easily. It should be able to count accurately and quickly in order to reduce labor costs and maximize production.

- Size

Depending on the size of your capsules, you will need to determine what type of size sorting capabilities are necessary for the machine in order to accommodate them.

- Capacity

The capacity of the machine is essential to consider, as it will determine how many capsules can be processed at once. A higher-capacity machine may be necessary if you plan on producing high volumes of capsules.

- Maintenance and Support

Proper maintenance is vital to ensure that your capsule counting machine will work correctly and accurately over time. Make sure there is adequate customer service and technical support available from the manufacturer or reseller of your machine should you ever need it.

- Durability

It’s important to make sure that the machine you purchase is capable of withstanding the wear and tear associated with regular use in a production environment. Make sure you know how long the machine should last, as well as any warranties or guarantees offered by the manufacturer.

- Compatibility

Make sure that the capsule counting machine you purchase is compatible with any other equipment or software you may already have in place. It’s important to make sure that the machine is able to integrate into your existing systems without any issues.

- User-friendliness

The ease of use of the machine is an important factor to consider when making a purchase decision. Investigate how user-friendly the interface and operation of the capsule counting machine are in order to ensure that your staff will be able to use it effectively.

Conclusion

Capsule counting machines have become an indispensable part of any business looking to quickly and efficiently count pills and capsules. Whether you are new to these devices or already have some experience, we hope this guide has provided an in-depth look into what capsule counting machine technology can offer your business in 2025. So, if you still need to decide who to turn to, contact Allpack for all your capsule counting machine needs. They offer the latest technology so don’t hesitate because time is ticking!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide