Heat Shrink Wrapping Machine:The Complete Buying Guide In 2025

When considering heat wrapping machine, the heat shrink wrapping type will surely meet all your needs. When considering buying a new heat shrink wrapping machine, you need to take the time to do your homework and conduct due diligence on the process.

ALLPACK Heat Shrink Wrapping Machine

How many types of heat shrink wrapping machine can be used for your choice and how they are applied? If you want to know what materials they run, their proper and safe operating procedures, this guide will provide you with all the information that you are looking for. Let's take a look now and add more!

1.What Is Heat Shrink Wrapping?

Heat Shrink Wrapping-sourced: shorr

Heat shrink wrapping, also known as shrink wrapping, mainly uses the wrap films which are made of polymer plastic to tightly covers any object on the application of heat. When the shrink wrapping material is heated, and the film can shrink and fit your packaged product.

In addition to being mainly used in food and pharmaceutical industry, it can also be used in various industries such as cosmetics, beverages, toys, hardware, etc. In addition to heat shrink wrapping of small products, it can also be applied to industrial shrink wrapping purposes, such as winterizing ships, wrapping large objects, etc.

2.What Are The Benefits Of Heat Shrink Wrapping?

By applying the heat shrink wrapping, you can get the benefits of:

Well Protection

Well Protection-sourced: shrinkwrappingnews

The heat shrink wrapping forms a very tight seal around your products, and can help you hold the product together. This seal completely protects the contents of the shrink wrapping. Not only does it protect the contents from dust and weathering, but it also provides UV protection from the sun's harmful rays.

Good Durability

Good Durability-sourced: sontex

The heat shrink wrapping is generally made from one of three durable plastics, PVC, PP, or POF. Not only are they used to wrap food, they are also used for more advanced retail applications. Because the material is very thick and strong, it is very durable and long-lasting.

Tamper-proofing

Tamper-proofing-sourced: sontex

The heat shrink wrapping not only seals the product, but it also maintains its shape. Any tampering will affect the seal and seal quality of the shrink wrap, thereby improving your product quality and brand awareness.

Easy For Preservation

Easy For Preservation-sourced: sontex

High-quality heat shrink wrapping can hold the product in place for easy transportation and preservation. By utilizing a certain thickness of film wraps, it can preserve the product well and extend its shelf life.

3.What Is Heat Shrink Wrapping Machine?

ALLPACK Heat Shrink Wrapping Machine

The heat shrink wrapping machine is an easy and efficient way to secure or bundle your multiple products at once using heat using a multi-layer polymer plastic compound. It is commonly used to package software supplies, printed products, books, CDs and DVDs, food and many other consumer products.

The most common heat shrink wrapping machines are usually equipped with a heat gun or other type of heat device to apply a co-adhesive clear coating when bundling a range of your goods. The automatic heat shrink wrapping machine consists of a sealer and a heat source that allows heat to shrink the package tightly around your product.

4.What Are The Application Of Heat Shrink Wrapping Machine?

The heat shrink wrapping machine is suitable for your various disposable products packaging. They are mainly applied in the industries, including:

Food Industry

Food Industry-sourced: vikingfoodsolutions

All kinds of snacks, biscuits, bread, candy, meat, vegetables, fruits, cakes, nuts, dry food, seafood, grain and oil products, beverages, etc. can use the heat shrink wrapping machine for packaging. It can ensure you safe packaging process without pollution, and improve the products appearance.

Beverage Industry

Beverage Industry-sourced: neopack

Most of the beverages and alcoholic drinks on the market can also be packaged using the heat shrink wrapping machine, including mineral water, honey, alcohol, soda water, carbonated drinks, juice and other liquid drinks. This packaging method can better protect your products color, taste and nutrition.

Pharmaceutical Industry

Pharmaceutical Industry-sourced: njmpackaging

The heat shrink wrapping machine has been successfully applied to major pharmaceutical enterprise groups. It can complete your shrink wrapping of various boxed tablets, capsules, bottled solid and liquid products, as well as various injections, ampoule bottles, suppositories and other products.

Daily Necessities Industry

Daily Necessities Industry-sourced: quickpak

The products that can be packaged by the heat shrink wrapping machine in the daily necessities industry include detergents, oral hygiene products, household cleaning products, etc. It can not only ensure your products integrity and non-deformation appearance, but also limit the moisture inside the products to a certain range.

Cosmetics Industry

Cosmetics Industry-sourced: hollandpkg

The heat shrink wrapping machine is also widely used in the cosmetics field, such as lipstick, perfume, shampoo, shower gel and other products. The shrink wrap can prevent your products from being affected by factors such as light and oxidation, extending the shelf life of the product, and thus improve the competitiveness.

Electronics Industry

Electronics Industry-sourced: darleepackage

In the electronics industry, the heat shrink wrapping machine is widely applied to electronic products such as computers, televisions, air conditioners, washing machines, etc., and various remote controls, electric fans, headphones, mobile phones, chargers, cameras and other equipment.

5.What Are The Materials Mainly Applied For Heat Shrink Wrapping Machine?

The three most common materials used for heat shrink wrapping machine are polyvinyl chloride (PVC), polyethylene (PE), and polyolefin (POF).

PVC Shrink Film

PVC Shrink Film-sourced: risingstarpack

PVC shrink film was once one of the most commonly used heat shrink wrapping materials in the world. It is lightweight, inexpensive, and versatile, but now is replaced by materials such as PE and POF. Rigid PVC is durable and can be used to your products shrink wrapping in the food and medical industries.

POF Shrink Film

POF-sourced: superbrightengineering

POF shrink film is an FDA-approved, food-safe, high-definition decorative heat shrink wrapping material. It is made from 100% recyclable material. In addition to giving your products outstanding clarity and a glossy shelf appearance, it also provides additional strength and product support.

PE/LDPE Shrink Film

PE/LDPE-sourced: yantai

PE shrink film can be used in many forms of flexible protective packaging, including heat shrink wrapping and stretch wrap. PE comes in many forms, and its LDPE form is well suited for shrink wrapping in almost every industry. Because it can add strength and durability to heavier, larger items, such as multi-packs of beverages.

6.What Can Heat Shrink Wrapping Machine Bring You?

Choosing the heat shrink wrapping machine, you can get the multiple benefits of:

Versatile

Versatile-sourced: polymerall

The heat shrink wrapping machine can be applied to shrink wrapping of various containers in various industries such as pharmaceutical industry, personal care industry, home care industry, food industry, beverage industry, etc. It can not only meet the needs of bottles, cans, cartons, cups, trays, and even irregular shaped containers.

Cost Effective

Cost Effective-sourced: TODAYMACH

The shrink wrap is a relatively low-cost and affordable packaging material. The heat shrink wrapping machine can provide you with different packaging forms. Not only can it be used as a single machine, it can also be connected with other equipment to form a complete shrink wrapping and packaging line.

Sustainability

Sustainability-sourced: agnext

The heat shrink wrapping machine uses 100% recyclable films. Using more sustainable packaging methods can greatly improve the development of your company.

7.How Many Types Of Heat Shrink Wrapping Machines Are There?

The choice of different heat shrink wrapping machines determines the efficiency of your shrink wrapping and the cost. They are divided into three types depending on the working automation and output rate.

Manual type with low output for beginner:

I-Bar Shrink Wrapping Machine With Heat Gun

I-Bar Shrink Wrapping Machine With Heat Gun-sourced: lovesivs

The I-bar shrink wrapping machine with heat gun is suitable for shrink packaging of small items like books, cosmetics, beverage, etc. Equipped with a sealer and round wire, it can be used for shrink films cutting and sealing. It mainly consists of a timer, a heat gun holder, a film, a roller, a film separator, and a sliding cutter.

Semi-automatic type with medium output:

L-Seal Heat Shrink Wrapping Machine

ALLPACK L-Seal Heat Shrink Wrapping Machine

The L-seal heat shrink wrapping machine combines functions of sealing and shrinking packaging. Through the transparent cover, the whole process of sealing, cutting and shrinking process are clear for your glance. This heat shrink wrapping machine is suitable for heat shrink films such as PVC, POF, PP, etc.

It is widely used in the outer shrink packaging of various products such as food, beverages, medicines, DVDs, hardware, cosmetics, books, toys, electronic products, etc.

Heat Shrink Tunnel

ALLPACK Heat Shrink Tunnel

The heat shrink tunnel is ideal for sealing, packaging and shrink wrapping your larger products such as large boxes of beverages, wine boxes, express boxes, etc. It can accommodate faster speeds and longer shrink times or films that require lower shrink temperatures.

With a high-performance tunnel design, this heat shrink tunnel can optimize the airflow in the tunnel to ensure more precise temperature and speed control.

Automatic type for high output:

Automatic Heat Shrink Wrapping Machine

Automatic Heat Shrink Wrapping Machine-sourced: rypacker

The automatic heating shrink wrapping machine can complete film stretching, bag making, sealing, cutting, conveying and heat shrinkage, which can provide you customized packaging scheme according to customer requirements.

It is suitable for large quantity shrink wrapping industries such as stationery, food, cosmetic, metal industries, etc. This shrink wrapping machine can be connected with the production line, and no need additional operators.

8.What Are The Components Of Heat Shrink Wrapping Machine?

The heat shrink wrapping machine has different components for different functions. There are the different main parts from different types of heat shrink wrapping machine.

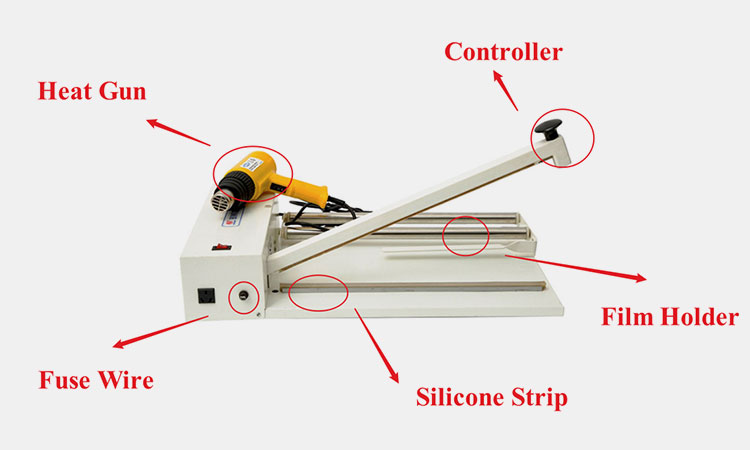

Components Of I-Bar Shrink Wrapping Machine With Heat Gun

Components Of I-Bar Shrink Wrapping Machine With Heat Gun-sourced: lovesivs

Heat Gun

The heat gun with dual high temperature heating wires, can heat up quickly without preheating. It can easily heat and shrink your packaging film of various products. The temperature can be adjusted for the heating and shrinking of packaging film according to your packaging film type and product type.

Controller

When your products are wrapped with shrink film, you can manual make use of the controller to cut the roll film according to your requirements. The small and flexible design makes it easy for you to control and use.

Film Holder

The film holder can fix the roll film you need on the roller. By stretching the shrink films, you can wrap the product with the roll film on the roller easily and then cut it with the blade.

Fuse Wire

The fuse wire can safely protect your product cutting and heat shrinking of the wrapping film. When the temperature exceeds the set temperature, the fuse wire will automatically melt to protect your products and equipment from high temperature damage.

Silicone Strip

With good elasticity and softness, the silicone strip plays a good buffering role when cutting shrink film wrap. At the same time, it can also protect your blade from damage.

Components Of L-Seal Heat Shrink Wrapping Machine

Components Of ALLPACK L-Seal Heat Shrink Wrapping Machine

Control Panel

The independent control panel is easy for you to operate with high quality digital display temperature control, and it is quick and easy to set the temperature automatically that saves your energy. The control panel can help you with all power switch setting, sealing time setting, and feeding length setting.

Transparent Cover

The transparent cover is easy and simple for your inspection with good sealing effect. Made of high quality plastic material, it can provide your products a closed space for heat shrink wrapping which is durable.

Bracket

The bracket can be adjusted according to product size which can help you apply the heat shrink wrapping for more product types.

Heating Wire

The heating wire is controlled by the electricity that can offer you the instant heat sealing and cutting without any trace. It can offer your products with good appearacne for better display and shrink wrapping.

Magnet

The magnet can help firmly suck the transparent cover to prevent the temperature of the shrinking chamber from leaking, which effectively improves the working efficiency of the shrink wrapping machine.

Shrink Film Wheel

The shrink film wheel, also called as shrink film roller, it can hold the shrink film for your easy use, and separate the two layers of the double-layer film by passing through the middle of the double-layer film to prevent the shrink film from sticking together.

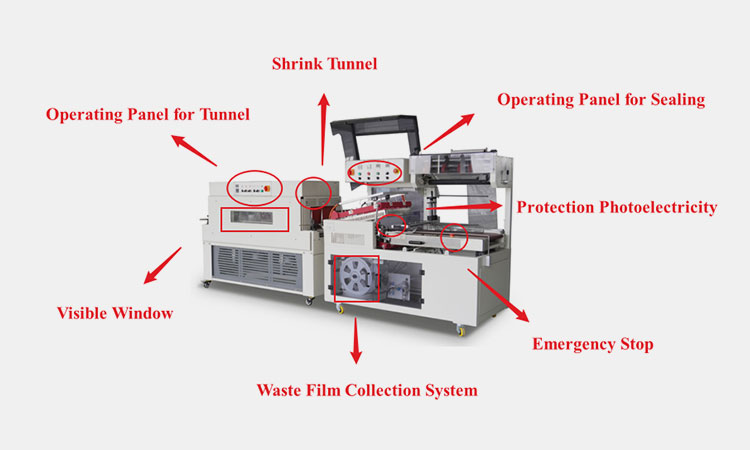

Components Of Automatic Heat Shrink Wrapping Machine

Components Of Automatic Heat Shrink Wrapping Machine-sourced: rypacker

Operating Panel For Sealing

The operating panel for sealing easy for you to make setting, checking the running status and errors with the sealing system with solved solutions on it.

Operating Panel For Tunnel

The operating panel for tunnel is convenient for you to control the shrinking temperature and time for your products.

Emergency Stop

The emergency stop switch in side sealer of automatic heat shrink wrapping machine can help you stop the whole working process during operation if there are any emergencies. This design is for coping with emergencies.

Protection Photo-electricity

There are 2pcs of protection photo-electricity for protecting workers or products damage when machine went wrong action. The shrink wrapping machine will stop working immediately after the photo-electrity got signal if there are workers or products damage.

L-Bar Sealing System

The L-bar sealing system is capable of performing smooth and firm sealing line for your various products with safety protection and alarm system attached. It can effectively prevent products from being sealed by mistake.

Visible Window

The visible window is simple and clear for your inspection of products shrinkage.

Shrink Tunnel

The heating tunnel uses high-temperature resistance material covering the conveyor rollers, which is better for your products transporting without plastic sticker and stable.

Waste Film Collection System

There are waste films which can be collected by the waste film collection system.

9.What Is The Working Principle Of Heat Shrink Wrapping Machine?

Place your products on the conveyor system, which moves it to the packaging area;

The conveyor system usually consists of belts or rollers, and its speed can be adjusted to accommodate your products of different sizes and shapes;

Set a roll of shrink wrap film on the reel and pulled under the sealing strip. After wrapping your product, all edges are sealed using the sealing strip;

The sealed product is then fed into the hot air system, which will heat your film by blowing hot air at it;

The heat sealing system uses a heating element to directly heat the film;

Once the film is heated, it begins to shrink. The speed and degree of film shrinkage depends on the heat you applied, as well as the material and thickness of the film;

The film shrinks first from the sides of the packaging machine and then extends to the top and bottom of the product;

When the film is fully shrunk and conforms to the surface of your product, the packaging process is complete;

The heat shrink wrapping machine's conveyor system will move the packaged product out of the machine for further processing or shipping.

10.What Are The Difference Between Stretch Wrapping Machine And Heat Shrink Wrapping Machine?

The stretch wrapping machine and heat shrink wrapping machine look very similar, but their performance is completely different.

| Heat Shrink Wrapping Machine | Stretch Wrapping Machine | |

| Images |

ALLPACK Heat Shrink Wrapping Machine |

Stretch Wrapping Machine-sourced: vestil |

| Explain | l Wrap the product with heat shrink film and heat it to shrink the film; | l Apply the plastic film to a pallet or a group of products and then wrap the product tightly; |

| Application | l Applied in various industries;

l Usually used on various bulk items; l Used for single products or small batches of products; |

l Usually used for palletizing;

l Put multiple items on a pallet to prevent them from moving during transportation; l Usually used for larger goods; |

| Features | l Strong and transparent;

l Used for bulk foods, frozen foods, printed materials, etc.; |

l Thicker, providing greater stretching capacity;

l Used for low-end applications, replacement of corrugated paper shipping boxes, larger items, etc.; |

| Advantages | l Approved for food contact;

l Lightweight, durable, waterproof; l Sealed, moisture-proof, impact-proof; l Suitable for packaging of regular or irregular items; |

l Durable;

l Can stretch about 100-300%; l Provides excellent stability and protection during transportation; |

| Disadvantages | l Poor oxygen resistance; | l More expensive;

l Not suitable for packaging of irregular items; |

| Working Principle | l The shrink films are loosely placed over one or more items;

l When heated, they shrink to form a tight, tamper-proof protective seal around the product; |

l The stretch films are able to stretch around the item;

l The elastic memory of the package and its ability to adhere to itself provide a tight protective layer around the item; |

11.What Are The Common Shrink Wrapping Issues And Possible Fixes?

As with any type of machinery, there are some common problems with shrink wrapping.

Common Shrink Wrapping Issues And Possible Fixes-sourced: maripak

| Shrink Wrapping Issues | Possible Reason | Possible Fixes |

| l Shrink film expansion; | l Too much air is trapped in the sealed shrink film;

l The shrink film is exposed to hot air after sealing; |

l Purchase pre-perforated heat shrink film;

l Increase the number of vent holes on the film you have already purchased; l Slow down the conveyor speed of the heat shrink wrapping machine and shrink tunnel; l Increase the temperature of the shrink tunnel to increase the speed at which air is exhausted from the heat shrink package; |

| l Dog ears on shrink wrap; | l This is a common problem when shrinking packaging; | l Wrap the product with fewer shrink film rolls to reduce the width of the film;

l Increase the heat tunnel temperature; l Increase the blower speed; |

| l Fish eyes on shrink wrap; | l It is a wrinkle extending from the corner of the package; | l Use smaller heat shrink wrap rolls;

l Slow down the conveyor speed to allow enough time for the shrink film to heat up; |

| l The heat shrink film seal line is not strong; | l The seal is not sealing well;

l The heat shrink film seal line is not strong; |

l Reduce the shrink machine hot knife temperature;

l The seal line height should be in the middle of the package height; l The seal pressure on the film is uneven, adjust the seal level, and replace damaged gaskets; |

12.What Are The Important Considerations For Purchasing Heat Shrink Wrapping Machines?

Factors such as production volume, packaging requirements, shrink wrapping machine maintenance, and budget constraints play a vital role when choosing a heat shrink wrapping machine.

Production Volume

Production Volume-sourced: dmspack

Knowing your own production level is crucial to determining what type of heat shrink wrapping machine you need. Efficiency and size are the two main factors that determine the cost of machines. By determining your own production volume and machine size, you can roughly understand the direction of your choice.

Packaging Requirements

Packaging Requirements-sourced: clysar

Figuring out the size of largest item you need for your own packaging will help you find a machine that can wrap all your products. There are three main types of shrink wrapping forms including tubes, bags, and inserts. When choosing a shrink wrapping machine, it is crucial to determine the best type of shrink wrap you needs.

Budgetary Constraints

Budgetary Constraints-sourced: vecteezy

How much does a heat shrink wrapping machine cost? This mainly depends on your own budget cost. The main components of shrink wrapping include shrink film, sealer, and heating element. The price and size of the shrink wrapper are directly related to the production level.

Conclusion:

You may get a better understanding of the heat shrink wrapping machine through this complete guide. There is a promising future for you to invest in this type machine. And there may have a plenty choices for you in the heat shrink wrapping machine market now. If there are more you want to know, please come to us now!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide