Gummy Manufacturing Equipment: The Complete Buying Guide in 2025

The gummy bear candies have been extremely popular and have been in demand for many decades, and they’re great to indulge if they offer some energy, happiness, taste, and benefits.

The small, enticing, chewy, and vibrant gummy candies with a rubbery texture and sugary layer are everyone’s love in a variety of events and celebrations. Due to its high marketing demand, running a business gummy manufacturing production line is undoubtedly worthwhile.

But how to begin with gummy manufacturing equipment purchasing? Do you know the number of essential types of machinery required to make gummy candies?

This blog is primarily designed for those businesses and enterprises who are looking to run their business cost-effectively and fruitfully. Let’s begin with important details:

1.What are Gummies? What Ingredients Make Gummy Bear?

Gummies are tiny confectionaries, favoured by both grownups and little kids. These are chewy, soft, and elastic candies that are often consumed as a snack and as a supplement. They are available in diverse shapes such as bears, worms, fruits, letters, circles, squares, and many more. They also come in different colours and flavours.

They are easy to chew and nowadays, they are used by the pharmaceutical and nutraceutical industry as a source of delivery dietary minerals, vitamins, proteins, and other active pharmaceutical ingredients.

The ingredients of gummy bears are listed below:

Gelatin

Gelatin- Picture Courtesy: Rousselot

It is a main thickening agent, widely used in gummy formation. It is obtained from tissues and bones of animals like cows and pigs. It is a translucent milky white powder that gives gummy their chewy and elastic texture.

Pectin

Pectin- Picture Courtesy: Treehugger

It is gaining popularity because of its use in making vegan, halal, or Kosher gummies for people who cannot consume animal-based Gelatin. It is also a gelling agent but is acquired from peels of fruits like apples and pears. It is a carbohydrate and is generally brown in colour and bitter in taste.

Sugar

Sugar

It is used for imparting sweetness in gummy recipes as gelatin and pectin are tasteless and bitter in flavour, respectively. However, fructose and glucose -both reducing sugars- can be used instead of common sugars for sweetness.

Corn Syrup

Corn Syrup

It is usually obtained from corn which is a staple crop. This thick viscous gold-in-color liquid is used in gummy preparation to prevent dehydration or loss of moisture content. It also maintains the freshness and elasticity of gummies.

Food Colours and Dyes

Food Colours and Dyes

These are FDA-approved food colours, dyes, and pigments that give gummies their colourful lustrous sheen. They are available in different colours like red, yellow, orange, green, etc. Food dyes are obtained from both natural and artificial sources like beet and purple carrot.

Natural and Artificial Flavoring Agents

Natural and Artificial Flavoring Agents

The purpose of adding flavouring agents in the gummy formulation is to have a characteristic fruity, sour, and mouth-watering taste. Both naturally occurring and synthetic food flavours are incorporated in gummies like fruit juice extracts and vanilla.

2.What is Gummy Manufacturing Equipment?

Gummy Manufacturing Equipment

It is an efficient equipment that has a key value in the home-based and commercial gummy industries. It efficiently works to automate every step of gummy formation. It is used for mixing key ingredients, heating and dissolving them, depositing them on gummy moulds, and then setting them for solidification.

Gummy manufacturing equipment has the same simple steps and it works to give exceptional quality results in the end. With modern and advanced technology, it can easily handle large batches of gummies in perfect time duration. Incorporation of this machine in production lines brings high profitability and it is known for formulating diverse gummy shapes that captivate and appeal to end-users.

3.Where can You use Gummy Manufacturing Equipment?

Wherever, there is moulding and depositing involved to create elastic products, gummy manufacturing equipment is employed in those industries. This equipment has versatile applications in wide-ranging industries, for instance:

Confectionary Industries

Use of Gummy Manufacturing Equipment in Cofectionery Industry

Jellies, chocolates, hard candies, soft gummies, choco balls, and many more are created using gummy manufacturing equipment in the confectionery industries. It makes different treats having unique miscellaneous shapes. A wide assortment of moulding in gummy manufacturing equipment is used for forming all-sundry elastic and soft toffees.

Nutraceutical Industry

Use of Gummy Manufacturing Equipment in Nutraceutical Industry

Are you tired of old and traditional supplement capsules and pills? Well, now you can take your daily vitamins and minerals in the form of gummies. This is possible because of the application of gummy manufacturing equipment in the nutraceutical industry. This machine can add vitamins, minerals, herbal formulations, biotin, prebiotics, probiotics, and many dietary supplements in gummy recipes.

Pharmaceutical Industries

Use of Gummy Manufacturing Equipment in Pharmaceutical Industry

This industry also incorporates gummy manufacturing equipment to produce cannabis gummies. These gummies are formed with different cannabis materials like THC, hemp, and cannabidiol (CBD) oils. These are extremely beneficial in treating anxiety, depression, pain, inflammation, sleeping trouble, epilepsy, etc.

Personal Care Industry

Use of Gummy Manufacturing Equipment in Personal Care Industry- Picture Courtesy: Happiness is Homemade

Yes, although it seems strange, however, personal care industry also uses gummy manufacturing equipment to formulate innovative and appealing shower gels, bath bombs, body washes, and soaps. These rainbow-coloured personal care products are well-liked by people of all age groups.

Pet Care Industry

Use of Gummy Manufacturing Equipment in Pet Care Industry- Picture Courtesy: Candy Nation

To tempt pet animals for eating their medication, these drugs and supplements are delivered in enticing colours and shapes, such as bones, claws, squares, etc by the gummy manufacturing equipment in the pet care industry. These treats are not only enjoyed as a snack by the pets but also aid in treating their nutritional deficiencies. Moreover, pet gummies are a convenient way for pet lovers to add healthy nutrients to their pet diet.

4.What are the Benefits of using Gummy Manufacturing Equipment?

Gummy manufacturing equipment is an exceptional equipment that offers a huge range of advantages to industries. With the innovations, modern industries have moved from the traditional mixing of gummies and now the brands use gummy manufacturing equipment as it has superb quality results with low error margins. Some of its benefits are listed below for your information.

Gummies in Complex Shapes are Now Possible

Complex Gummy Shapes

If you want to produce complex and diverse shapes gummies then it is best to use gummy manufacturing equipment. This machine has different kinds of moulding and depositing systems that formulate magnitudes of shape and colour gummies. Both two- and three-dimensional gummies are possible with this equipment. Replaceable moulds allow you to produce customized gummies.

Tiring Job in No Time

Tiring Job in No Time

Gummy manufacturing equipment can run 24/7 without taking a break. Adding this machine to production allows businesses to produce large batches of gummies in a short duration. Moreover, you do not have to worry about hiring more workforce for the gummy formulating job, this machine works best alone.

Best-Quality Results

Best-Quality Results

Yes, gummy manufacturing equipment has a hygienic design that is made using safe materials that do not get dirty easily. This machine has stainless steel construction and it is made with good manufacturing practices that ensure safe and excellent quality gummies with no risk of contamination. Furthermore, it is quite easy to clean sticky syrup residues from the hopper and deposit nozzles which guarantees hygienic gummies.

No Compromise on Precision

No Compromise on Precision- Picture Courtesy: Carpol

This machine is designed to critically determine the quality of gummy syrup. It carefully mixes, cooks, monitors heat and places gummy formulation in moulds to have consistent and precise results in every batch. This machine has computerized controls to evaluate its performance at each step which offers precise outcomes every time.

Efficiency is Every Thing

Efficiency is Every Thing

Gummy manufacturing steps are automated with gummy manufacturing equipment, consequently offering high-speed gummy productions. This machine is less labour-demanding, saving much when it comes to labour wages. With mechanized systems, this machine produces gummies more swiftly than manual labour-intensive methods of the past.

5.What are Important Parts of Gummy Manufacturing Equipment?

Gummy manufacturing equipment mainly consists of three parts, each performing different functions. These are:

Parts of Gummy Manufacturing Equipment

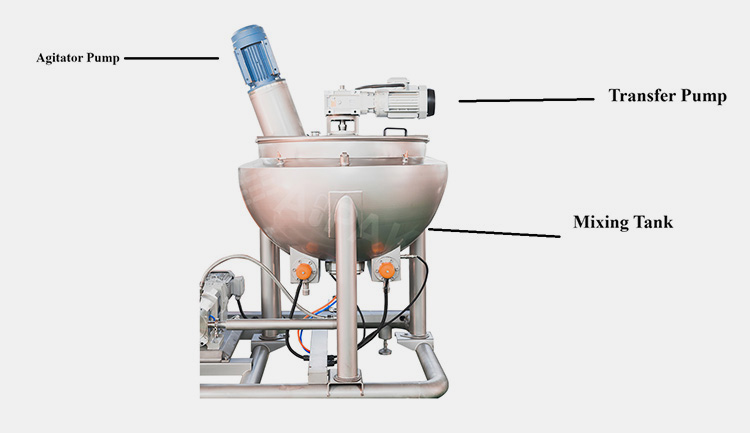

Mixing Tank

It is a cooking device that has double-jacket insulation that helps in mixing and heating ingredients. This machine is heated to a temperature of 121°C which helps in keeping ingredients in their melted state. The temperature in this tank is maintained by a boiler sensor that heats and cools the mixing tank on need. There are the following parts of the mixing tank:

Parts of Mixing Tank

| Agitator Pump | It is a stirrer-like device that performs the same mixing as that of a normal stirrer. It rotates to uniformly mix the ingredients. |

| Transfer Pump | This motor provides mechanical energy for rotating the agitator. It aids in the transferring of materials. |

| Mixing Tank | It is a cooking device that stores and melts the ingredients and is essential in forming and mixing gummy syrup. It is made with stainless steel that provides insulation for maintaining the proper temperature inside the cooking tank. |

Depositing Section

It is the main part of the gummy manufacturing equipment that deposits the gummy syrup into the gummy moulds. These moulds move on the conveyors that transport the moulds to the next part of the machine. Some parts of depositor are:

Parts of Gummy Depositing Section- Picture Courtesy: Aipak

| Dynamic Colour and Flavour Mixer | It mixes different colouring agents, flavouring agents, and food additives. It helps in the continuous and uniform mixing of different substances in the gummy formulation. |

| Plunger | The gummy depositor sectors come with plunger devices that lift and lower to adjust the quantity of syrup in the filling nozzles. |

| Filling Nozzle | These are the cylindrical tubes that pour a precise amount of gummy syrup into the moulds. |

| Transmission Chain | This chain part is integral in the transportation of gummy moulds from the depositor to the cooling station. The chains support the conveyor and ascertain its smooth motion. |

| Hopper | It is a tank-like part that stores the gummy mixture for deposition. This part subjects gummy liquor to the plunger part. |

| Discharge Pump | It is a cleansing pump that removes gummy residues and product waste from the machine during gummy deposition. |

| HMI Touch Screen | Different depositing inputs like filling speed, volume, and temperature are adjusted using this touch screen. It provides ease of use and stores different formulation data for quick changeovers. |

| Electric Cabinet | This part is a safety cabinet that holds relays, switches, breakers, etc that powers the machine. It is made of fire-proof materials that ensure the safety of operators. |

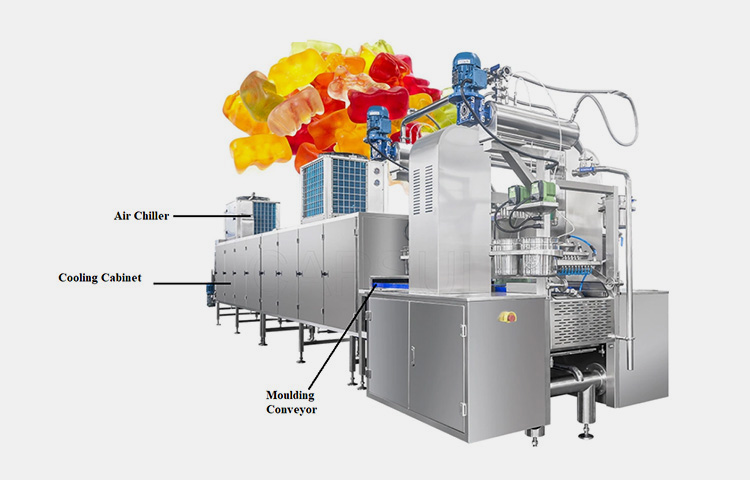

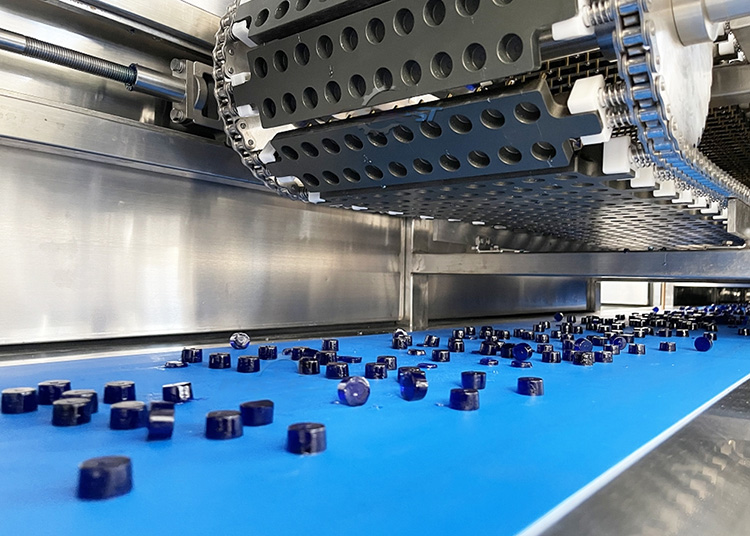

Cooling Tunnel

It is a big device that resembles a tunnel. It is equipped with air conditioners, chillers, and ventilation systems that facilitate the appropriate solidification of gummies. It has a temperature of 5-10°C that allows them to set and freeze. It has a central place for acquiring the right shape. The sections of cooling tunnels are discussed below:

Parts of Cooling Tunnel

| Air Chiller | This part lowers the temperature of the cooling station which aids in the solidification of gummy liquor. Cold air blown by the air chiller freezes the gummies. |

| Cooling Cabinet | It is a robust unit made using stainless steel and is designed in multiple levels that allow the uniform distribution of cold air to every part of the tunnel. |

| Moulding Conveyor | This conveyor system supports the gummy moulds and transports them steadily and consistently to the cooling tunnel |

6.How to Make Gummy from Gummy Manufacturing Equipment?

Three main working stages are involved in gummy production from gummy manufacturing equipment. Let’s discuss these stages one by one.

Step 1: Mixing and Cooking of Raw Ingredients

Mixing of Ingredient- Picture Courtesy: hubspotusercontent00.net

At the start of gummy manufacturing, at first ingredients such as gelatin, sugar, water, and corn syrup are weighed and poured into the cooker. This unit is heated at a steady temperature and ingredients are uniformly mixed with the agitator. The temperature of this double-jacket unit is around 108-110°C. The ingredients are mixed in this mixing and cooking tank for about 15-20 minutes to obtain thick viscous gummy syrup. After that, the temperature of gummy liquor is lowered to about 60-70 °C for the deposition step.

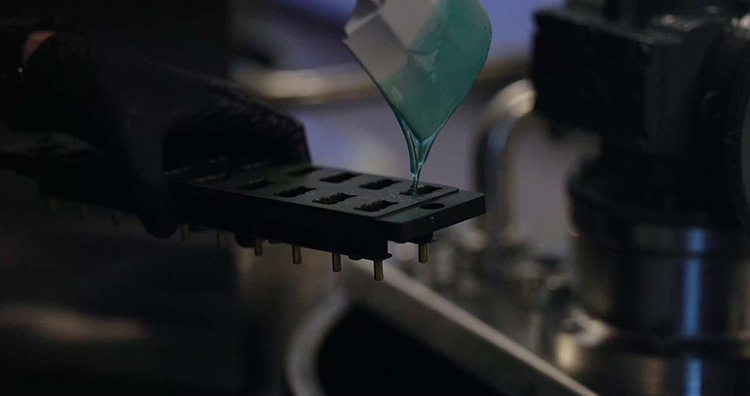

Step 2: Pouring of Gummy Syrup

Gummy Deposition- Picture Courtesy: ABM Equipment

After cooling, the high-temperature gummy slurry is poured inside the depositor hopper via transfer pumps. It is the main working step of gummy manufacturing equipment in which gummy syrup is dropped down into the moulds by the continuous movement of the plunger and filling nozzles. The latter assists in pouring a fixed amount of gummy liquid into each pocket of moulds. With the uniform movement of conveyors, every mould cavity receives the right volume of syrup.

Step 3: Cooling and Drying

Gummy Demoulding- Picture Courtesy: gummymakingmachine.com

The moulding trays are transported to the cooling tunnel after filling each cavity. A temperature of below zero is employed inside the cooling tunnel to attain a perfect gummy shape. After proper setting, a de-moulding brush is used to remove gummies from their moulds. These solidified gummies are carried to a drying room where they are stored for 8-24 hours. The purpose of this step is to remove unnecessary water content from gummies by evaporation.

7.What are Other Accessories that Improve the Gummy Manufacturing Equipment Process?

Several accessories are offered with gummy manufacturing equipment that improves its performance and working. The detail of these accessories is penned below:

Elevating Conveyor

Elevating Conveyor- Picture Courtesy: Nercon

This type of conveyor is typically the part of gummy manufacturing equipment production line and is utilized for conveying gummies from the polishing and coating section to drying rooms. It offers a narrow passage for the transference of gummies.

Tray Dollies

Tray Dolly- Picture Courtesy: Aipak

Tray dollies are essential in moving gummies from the polishing, coating or cooling area to the drying room. It is a tray cart with four wheels that aid in transportation. These are available in diverse size ranges to accommodate different loads of gummies.

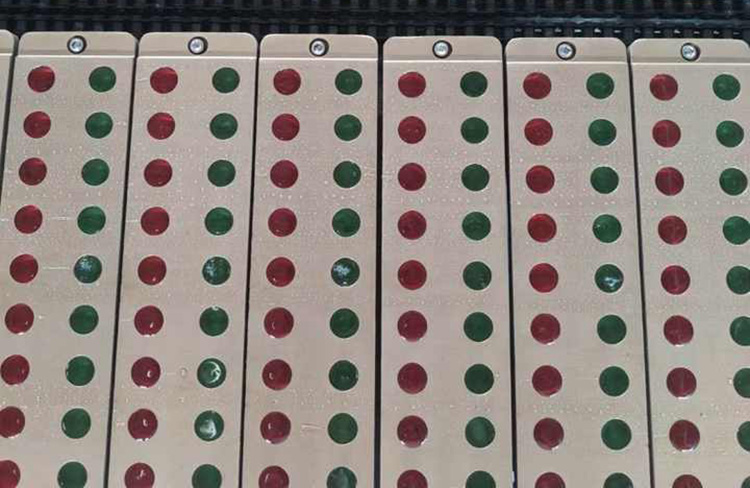

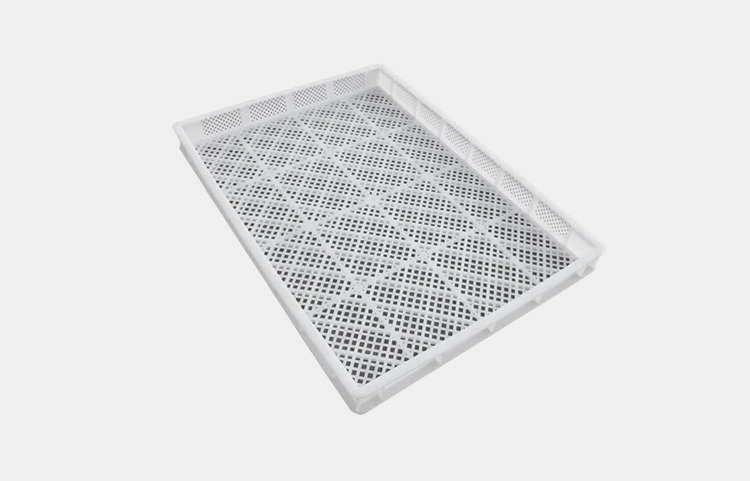

Drying Trays

Drying Tray

They are used in the drying room to properly dry gummies. These trays are manufactured using food-grade silicon and have small perforations through which dry air can easily pass to evaporate water content from gummies.

Oil, Wax, and Sugar, Spraying, Coating, and Polishing Machine

Oil and Wax Spraying Machine- Picture Courtesy: Aipak

It is a rotary pan-like machine that is used for spraying and coating gummies with wax, oil, and sugar. Its main purpose is to prevent the sticking of gummies and to boost the visual appearance of gummies. It completely coats gummies and covers their entire surface area with decorative substances.

8.What are The Basics to know for the Maximum Shelf Life of Gummy Manufacturing Equipment?

Gummy manufacturing equipment costs a lot, hence; manufacturer prefer to take long time advantage of their investment. So, to prolong the operational life of gummy manufacturing equipment, let’s discuss some tips:

Scheduled Maintenance

Maintenance of Gummy Manufacturing Equipment- Picture Courtesy: gummytechnologies.com

To increase the shelf life of the gummy manufacturing equipment, it is important to plan a maintenance schedule and regularly act upon it. With daily maintenance, like lubricating joints, motors, tightening nuts, screws, cables, wires, etc, unexpected issues in the equipment can be foreseen beforehand and then the right measures are adopted to prevent the breakdown of machinery.

Proper Cleaning

CIP System- Picture Courtesy: TMI INOX

Traditional cleaning was slow and unthorough as operators had to dismantle every part of gummy manufacturing equipment which was quite tiresome and prone to mistakes.

However, investing in CIP (Clean-in-Place) and SIP (Steam-in-Place) systems provides complete and automatic cleaning. This will prevent the clogging of nozzles, hoppers, pumps, and other parts which could lead to failure in those components.

In the CIP system, the gummy manufacturing equipment is thoroughly rinsed with water and then with detergent. After that, it is cleaned with acid and then rinsed again with water. The machine is sterilized either using chemicals or a high temperature of 100°C.

SIP is an additional sterilization step in which microbes are killed using a high temperature of greater than 121°C. in this step, steam is used to sterilize the equipment. This step is significant in the hygienic working of gummy manufacturing equipment.

9.What are the basic Problems and Solutions for Gummy Manufacturing Equipment?

Unanticipated problems can arise in any machine and gummy manufacturing equipment is not exempt from these issues. Nevertheless, some protective measures can be taken to deal with such problems. Here is a list of some basic problems in gummy manufacturing equipment and their protective measures:

| Cause | Solution | Image |

| Sticking of Gummies Together | ||

| High amount of reducing sugar like glucose and fructose in the gummy formulation

High quantity of moisture Low drying time Poor-quality disintegrated gelatin |

Decrease the amount of reducing sugars

Lower the humectant amount Provide sufficient time for drying Use higher-quality gelatin in gummy recipe |

Sticking of Gummy Together |

| Premature Gummy Setting | ||

| It is because of insufficient cooking temperature | The processing temperature of heating, cooking and depositing gummies should be around 65.5° C (150°F) |

Premature Gummy Setting |

| Non-Uniform Deposition of Gummy Liquor | ||

| Clogged or dirty filling nozzles

Non-uniform pressure distribution in the depositor |

Properly clean the filling nozzles

Change pressure settings for proper distribution |

Non-Uniform Deposition of Gummy Liquor- Picture Courtesy: beneleaves.com |

| Gummy Syrup Get Accumulated in Depositors | ||

| The oil spray system is defective

The ingredients in the formulation are not in the right proportion |

Repair or replace the faulty oil spray system

Reformulate the gummy recipe |

Gummy Syrup in Depositor- Picture Courtesy: Aipak |

| Inconsistency in Shape and Sizes of Gummies | ||

| The cavity sizes in the moulding system are not consistent and there is a defect in the moulding

Parameters for deposition are not accurately programmed |

Use moulding trays with the right sizes

Recalibrate the deposition parameters |

Variation in Gummy Shapes and Sizes |

| Connecting Pump Fail to Move Materials | ||

| Clogging of pumps due to poor cleaning practices

Untighten cables could also cause failure in working of connecting pumps |

Maintain proper cleaning schedule to avoid gummy buildup in pumps

Tighten wires for proper working of transfer pumps |

Connecting Pump Failure- Picture Courtesy: sugarprocessingmachine.com |

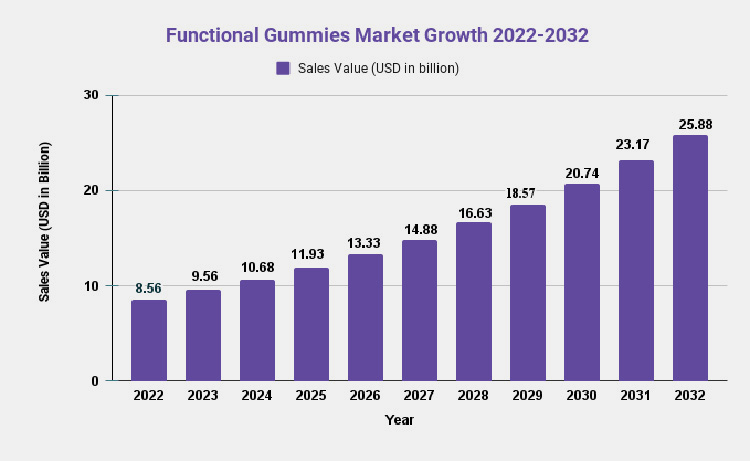

10.What are the Future Trends of Gummy Manufacturing Equipment?

Growth in Gummy Market- Picture Courtesy: nappystiches.com

Gummy manufacturing equipment is employed in industrial and home-based settings because of convenience and quick processing. Its future looks promising as demand for gummies is increasing day by day because of their medical and herbal use, consequently, this also increases the demand for gummy manufacturing equipment.

The market size of gummy manufacturing equipment is expanding and it is predicted in coming years it will be worth billions of US dollars.

In future, gummy manufacturing equipment will be developed using machine learning and techniques of artificial intelligence. It will be equipped with robotics and different advanced sensors that will have accuracy and precision in gummy making.

Conclusion

Gummy manufacturing equipment is a perfect addition to production plants because it mixes, pours, and solidifies gummies without heavy supervision. Its automation and efficiency are two main features that make this equipment favoured among manufacturers. Furthermore, this machine is capable of mixing ingredients in perfect ratios to create exceptional quality gummies. Allpack customizes machines according to your needs so let us know about your preferences, we will supply you with an ideal solution. For more details, please contact us through our website or telephone helpline.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide