Gummy Depositor Machine: The Complete Buying Guide In 2025

Are you new to the world of gummy manufacturing and facing difficultly in understanding the required machines? If it's the case, you are at the perfect place where everything about a gummy depositor is going to be exposed along with its importance in gummy manufacturing.

Gummy depositor machine is an excellent and innovative equipment designed with distinctive features to undertake the crucial task of filling gummy into the mold trays of various shapes and sizes. It is proficient in maintaining the precision, filling speed as well as uniformity during operation. Therefore, it is highly important machine in gummy making. To better understand its structure, working mechanism, and benefits, read this review carefully!

1.What Is A Gummy Depositor Machine?

Gummy Depositor Machine-Aipak

Gummy depositor machine, also known as semi-automatic gummy making machine, is an electromechanical device made with several components to perform the function of depositing uniform and precise liquid gummy gel into empty molds. These molds vary in shapes and sizes, thus, gummy depositor machine is versatile enough to dispense required amount of gummy into molds.

The machine undertake this task quite responsibly by keeping the gummy liquid hopper heated to avoid jamming. From here, the process get started when machine takes the gummy material from hopper into long narrow nozzles and pour the gummy liquid into mold trays. Besides that, the machine is capable of depositing uni color, dual color, and multicolor gummies, so, that it can be used for delicious flavored gummies, candies, and jellies in range of industries.

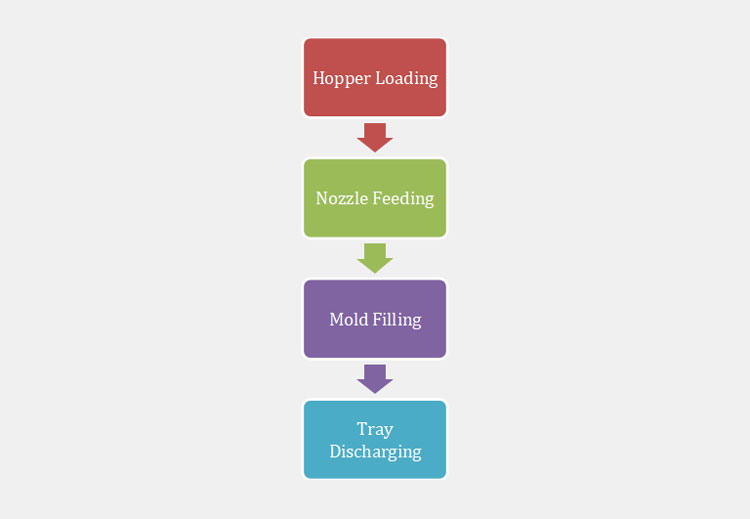

2.How Does A Gummy Depositor Machine Work?

A gummy depositor machine works through sequential order which can be easily understood by looking into the underlying principles:

Hopper Loading

Hopper loading with gummy slurry-Picture Courtesy: Aipak

The initial step includes the loading of hopper with well cooked gummy mixture. This is carried either automatically through a transportation machine or manually by operator. The hopper of the machine keep the gummy syrup heated for forming uniform gummies.

Nozzle Feeding

In second step, the transfer of gummy syrup from hopper to filling nozzles takes place. Here, the plungers in hopper move upward and downward due to which the filling nozzles get desired volume of gummy fondant for depositing.

Mold Filling

Gummy mold trays filling-Picture Courtesy: Aipak

Finally, the filled nozzles will start depositing gummy fondant into number of gummy molds for formation of precise and consistent gummies.

Tray Discharging

Gummy filled mold trays discharging-Picture Courtesy: Aipak

After the gummy molds get filled, the filled mold trays will be manually picked up by the operator for cooling process.

Gummy Demoulding

Gummy demoulding-Aipak

At the end, when gummies are cool down, the operator will put the gummy filled trays in demoulding station one by one. With the help of pedal, the gummy filled trays will be demoulded and gummies will be collected in a tray.

3.What Are The Essential Characteristics Of A Gummy Depositor Machine?

A gummy depositor machine is featured with certain characteristics which can give you and your business wonderful benefits such as:

Durable & Hygienic

Hygienic gummy depositor machine-Aipak

Gummy depositor machine is made with durable stainless steel which is corrosion resistant and fully hygienic to process all types of eatable gummies, candies, and chocolates etc. Moreover, Allpack's gummy depositor machine which is certified by FDA, GMP, and ISO assures the products safety and quality.

Flexible

Various gummy snacks-Picture Courtesy: mashable.com

Gummy depositor machine is extremely versatile in a way that it is capable of depositing various color, shape, and size gummies into molds. Apart from that, the same machine can be used for depositing hard candies, jellies, and chocolates. Hence, its area of application is quite resilient and extensive.

Small Footprint

Gummy depositor machines-Aipak

This compact and durable gummy depositor machine has small footprint which makes it easy to handle and occupies less space for installation. Similarly, it does not require multiple additional tools to be changed continuously.

Accuracy

Gummies in jar-Picture Courtesy: vermontcountrystore.com

The most favorable attributes of a gummy depositor machine is its excellent precision for forming consistent and uniform gummies despite changing the nature of gummy syrup. This perfectly resulted in the creation of beautiful and neat gummies.

Low Waste & Maintenance

Gummy molds filling-Picture Courtesy: capol.de

Gummy depositor machine uses automatic technology which remains vigilant during operation and cut down the material waste. In addition, the machine is easy to operate with a PLC control system which allows user to keep an eye on the machine without any additional maintenance.

4.Which Kind Of Gummies Are Deposited By A Gummy Depositor Machine?

A gummy depositor machine is smart enough to deposit broad range of gummies with varying shapes, colors, flavors, and sizes. So, let's discover these all with the help of details given below:

a) On the basis of colors

Different colors gummies in bowls- pharmaceutical i-pinimg.com

There are different types of gummies on the basis of colors or flavors which a gummy depositor is capable of processing including:

- Uni color

- Dual color

- Multi-color

- Center filled gummies

b) On the basis of shapes

Various shapes gummies-Picture Courtesy: freepik.com

When it comes to enlist the shapes of gummies formed by a gummy depositor machine, the numbers become unlimited. However, certain commonly used shapes are:

- Fruits

- Vegetables

- Toys

- Animals

- Egg

- Bear

- Worms

c) On the basis of size

Large to small size gummies-Picture courtesy: vat19.com

Gummies are available in small to large size and each size of gummy is associated with particular reference. The popular sizes of gummies along with their uses are as follows:

- 26 LBS- the party bear

- 5 LBS- the world's largest gummy bear

- 0.5 LBS- giant gummy bear

- 2.3 OZ- big gummy bear

- 0.13 OZ- regular gummy bear

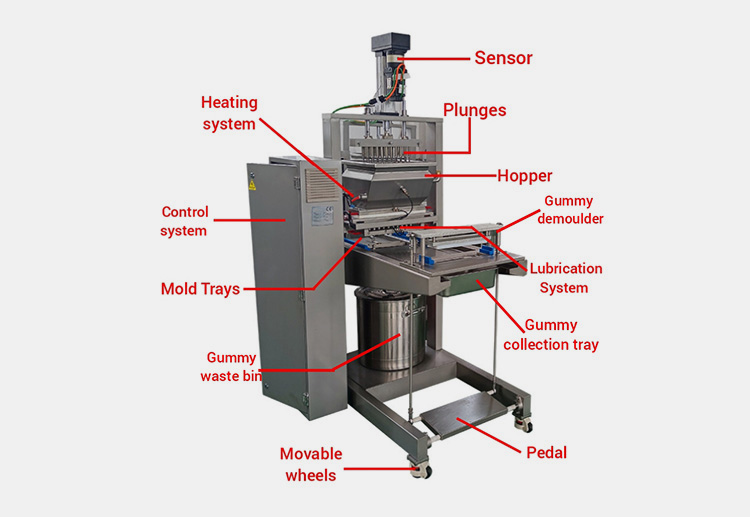

5.Describe The Components Of A Gummy Depositor Machine?

Structure of gummy depositor machine-Aipak

Gummy depositor machine consists of several components including:

Sensor

Sensor detects the presence of gummy mold trays and dispense the gummy slurry accordingly. It thus helps in eliminating product waste and incorrect filling.

Hopper

Hopper is a hollow container attached to the machine for holding gummy slurry. This hopper has a heating system to keep the temperature of gummy slurry favorable to avoid gummy mixture jamming and blockage etc.

Plunges

Plunges are long narrow stainless steel tubes whose function is to dive into the gummy slurry filled hopper for the purpose of facilitating free flowing gummy depositing.

Control System

Control system includes the control panel, a computerized touch screen display with the help of which operator execute the machine, and a control cabinet, which is the power house of a gummy depositor machine which holds in it all the electrical parts of machine including wires, knobs, and fuses etc. This part of the machine keep the gummy depositor machine under suitable condition for smooth running.

Filling Nozzles

Filling nozzles are small narrow tubes made up of stainless steel which are used for depositing gummy syrup into molds precisely.

Gummy Waste Bin

Gummy waste bin is a stainless steel container which is kept right under the gummy filling station to store the gummy material if wasted during depositing.

Mold Trays

Mold trays are important components required for gummy depositor machine. They are made from flexible plastic or silicone in range of shapes in order to make beautiful gummies shapes.

Lubrication System

Lubrication system refers to the spraying starch or other substances over empty gummy molds before filling to reduce the gummy stickiness to trays.

Gummy Collection Tray

Gummy collection tray is kept under the demoulder unit. All the demoulded gummies are collected in this tray.

Movable Wheels

Movable wheels are attached to the bottom of machine which helps in convenient mobilization of machine.

Pedal

Pedal is fixed at the lower side of machine which is used for operating the gummy demoulder unit.

6.Explain The Various Types Of A Gummy Depositor Machine Available In Market?

Gummy depositor machine can be broadly categorized into two types which are explained below:

Gummy Depositor Machine

Semi-automatic gummy depositor machine-Picture Courtesy: tgmachine.com

Gummy depositor machine is also called a semi-automatic gummy making machine which has been made with adequate automatic features to facilitate fast gummy depositing. It consists of a heating hopper, filling nozzles, stainless steel body, control board, and a conveyor belt. The machine requires human intervention for loading and picking the gummy mold trays under filling nozzles. It has small footprint and is cost-effective. Therefore, medium scale confectionary, cosmetic, and pharmaceutical industries can better take advantage of this machine.

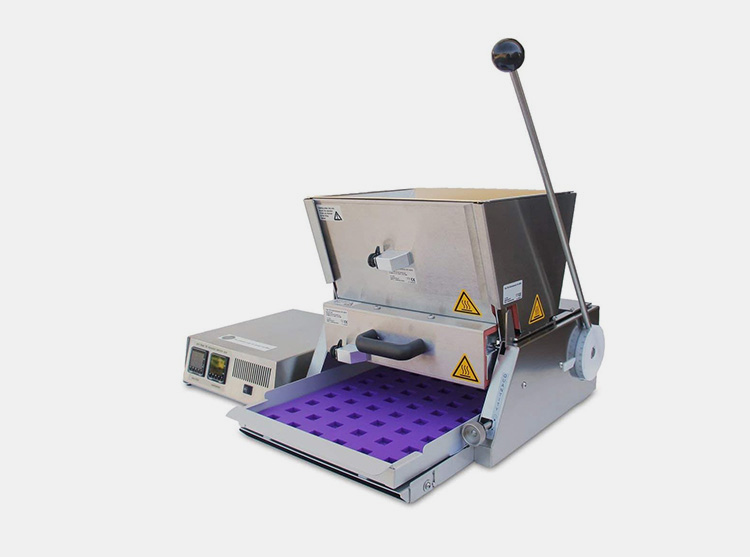

Manual Gummy Depositor Machine

Manual gummy depositor machine-Picture Courtesy: ubuy.com

Manual gummy depositor is a handy machine used for depositing small batch gummy production. It has small tabletop construction with few components including a hopper, filling nozzles, mainframe, and a handle. This machine does require any electrical energy for operation, rather operator pushes the handle for filling gummy molds with gummy mixture. Moreover, the hopper of machine is kept heated by pouring hot water around the hopper in jacket. Hence, this compact manual gummy depositor machine is the best suitable for low volume gummy production.

7.What Are The Applications Of A Gummy Depositor Machine?

Gummy depositor machine has wide range of applications in various industrial sectors such as:

Confectionary Industry

Various confectionaries in tin box-Picture Courtesy:food52.com

The term confectionary covers most of the sweets which are processed by a gummy depositor machine such as gummies, chocolates, candies, and jellies etc. It thus proves the applicability of this machine in confectionary industry.

Pharmaceutical Industry

Sleep gummies-Picture Courtesy: medium.com

Among other sectors, pharmaceutical industry is also focused on employing new techniques to deliver drugs while using the same effect. For this, the most desirable means to deliver drugs is indeed in gummy form. Hence, a gummy depositor machine is often used in pharmaceutical industry.

Nutraceutical Industry

Lemon nutraceutical gummies-Picture Courtesy: Behance

Most of the gummies are now available for boosting immunity, supplementing daily nutrition intake, and reducing the risk of getting chronic diseases. These gummies are known as nutritional or vitamin gummies which are made with the help of a gummy depositor machine.

Cosmetic Industry

Beauty gummies-Picture Courtesy: teamiblends.com

Gummy depositor machine has also good demand in cosmetic industry due to wide production of beauty gummies. These beauty gummies are now popularly used for strengthening hairs, nails, removing dark circles and aging skin.

Hardware Industry

Colorful bear hair clips-Picture Courtesy: AliExpress

Gummy depositor machine may also be used for the formation of hardware products such as plastic teddy bears, erasers, and small toys etc.

8.What Is The Production Line For A Gummy Depositor Machine?

While using a gummy depositor machine you may also need other associated machines to make a production line and carry out gummy manufacturing with all the essential steps required for it. These machines are as follows:

| No | Machines | Description | Pictures |

| 1 | Gummy Cooking Pot | Gummy cooking pot works as a cooker for preparation of gummy liquid formula which usually consists of water, gelatin, and sugar. The machine undertake the gummy syrup cooking with the help of mixing agitator and a heating motor which keeps the temperature of machine hot to prepare gummy slurry. |

Gummy cooking pot-Aipak |

| 2 | Gummy Storage/ Mixing Tank | Gummy storage tank is used for storing the prepared gummy syrup into tank until it is needed for depositing. Apart from that, it also functions as a mixer for mixing colorants, flavors, and other agents into the gummy slurry. It consists of a stainless steel tank with inlet and outlet valve for convenient transportation of gummy slurry, mixer agitator, and a scraper. |

Gummy storage/ mixing tank-Aipak |

| 3 | Gummy Depositor Machine | Gummy depositor machine is an important unit of the entire production line which has been employed to fulfill the task of depositing gummy mixture into molds for forming precise gummies. |

Gummy depositor machine-Aipak |

| 4 | Gummy Cooling Tunnel | Gummy cooling tunnel is a cooling unit with integrated air system which is used for blowing air around the gummy filled trays to reduce their temperature. |

Gummy cooling tunnel-Aipak |

| 5 | Gummy Drying Tray | Gummy drying is an important step as extreme moisture can deteriorate the quality of gummies. Therefore, formed gummies are laid in perforated trays and kept in a drying room to reduce the water content in gummies. |

Gummy drying tray-Aipak |

9.How To Clean And Maintain A Gummy Depositor Machine?

Regular cleaning and maintenance of a gummy depositor machine is necessary to keep the machine on track and prolong its work life. Therefore, to better understand the cleaning and maintenance procedure for a gummy depositor machine read the underlying instructions carefully:

Cleaning

Cleaning with water-Picture Courtesy: www.angi.com

It is important to clean your gummy depositor machine after completing daily processing. For this, operator must have information regarding the various components of the machine in order to disassemble the parts accurately. After that, machine should be flushed with hot water to remove out all the residues left during gummy depositing. Once, the machine is well cleaned, various parts which were separated from machine should be joined accurately.

Maintenance

Machine maintenance-Picture Courtesy: upkeep.com

Maintenance include the overall inspection and adjustment of a gummy depositor machine. Firstly, it is essential to check the external components of machine such as wires, valves, conveyor belt, and nuts etc. Secondly, the internal parameters of machine which are responsible for processing the gummy such as heating system, amount of gummy for molds, and the speed of conveyor belt should be adjusted accordingly. Apart from that, lubrication of moving parts is also necessary to avoid stagnancy during operation.

10.What Are The Quality Standards For A Gummy Depositor Machine?

Standard icon-Picture Courtesy: businessprocessincubator.com

There are certain quality standards which are established for the regulation of safe machinery for drugs and foods. These standards are also necessary for assessing the quality of a gummy depositor. These are as follows:

Good Manufacturing Practices (GMP)

Good manufacturing practices is the most popular organization created for ensuring the health safety by establishing certain quality standards for machines manufacturing such as the use of stainless steel and high quality raw materials.

International Standard Organization (ISO)

International Standard Organization is a global platform which has been established to ensure that all types of machines are complying hygienic regulations. Hence, ISO approved gummy depositor machine is fully safe for your gummies manufacturing.

Food And Drug Administration (FDA)

Food and Drug Administration is an international organization formed for the purpose of promoting safe goods and drugs processing machines. Therefore, a gummy depositor machine certified by FDA is made up of quality material.

11.What Factors Should Be Considered For Purchasing A Topnotch Gummy Depositor Machine?

If you really want to choose a cutting edge gummy depositor machine, there is no need to rush. Just take time and consider some of the crucial factors which will surely lead you to make a sound purchase. These are as follows:

Production Volume

Gummies bulk-Picture Courtesy: key.net

The prime question that you must have to keep in mind is the area of your existing production volume. Whether it is large scale, medium size or small size? Answering this question will definitely take you to determine on which area you are standing. So, that you will have a good mapping of your production volume in your mind.

Price Range

Price range scale-Picture Courtesy: support.wix.com

It is an undeniable fact that every manufacturer must have proper estimation regarding their business budget which also includes the investment on purchasing capital. Therefore, it is crucial to check your financial status when looking for a gummy depositor. If you have sufficient budget, and well-established business than it is better to go for a new machine with innovative features. However, for starting new and small business, cost-effective solutions are always preferable.

Spare Parts

Spare parts display-Picture Courtesy: danlescogroup.com

Gummy depositor machine always need spare parts and other machines for making production line, especially, if the machine is automatic. Hence, it is important to know about the requirements of machine in advance.

Conclusion

To summarize, gummy depositor machine is the crucial equipment ever needed for precise, consistent, and uniform gummies manufacturing. The machine's attributes, types, structure, and working are the different aspects which have been separately explained in the above buying guide. Moreover, a gummy depositor machine may be found in full-fledged production line form for totally automatic processing. So, if you are interested in purchasing or exploring more about a gummy depositor, don't forget to leave your message through our website!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide