Grease Tube Filler: The Complete Buying Guide in 2025

Are you in the business of processing oily thick grease and want an efficient machine for packaging it? Then grease tube filler is best for you. This machine has automated feeding, filling, and sealing stations that allow for quick and accurate fill. This machine will transform your productions with its extraordinary speed, excellent quality results, and high production capacity. Moreover, the grease tube filler will have consistency in every batch allowing you to exceed customer satisfaction.

Want to learn more about this useful piece of equipment then read this guide where we will explain every aspect of grease tube filler in great detail.

1.How Can You Define Grease Tube Filler?

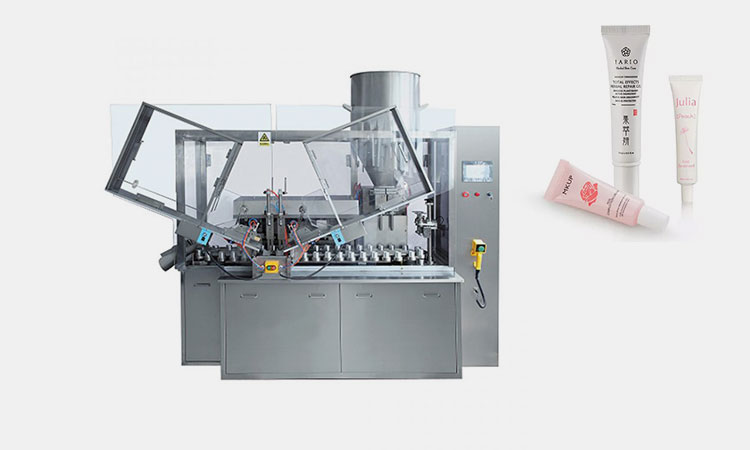

Grease Tube Filler- Picture Courtesy: Marchesini Group

Grease products are quite difficult to handle if they are not properly packaged. Hence, grease tube filler is essential in this regard. It accurately and precisely doses grease inside squeezable containers, for instance, tubes. Grease tube filler is known for its superior flexibility and subpar productivity.

A grease tube filler is essential in containing grease to prevent its loss during shipment. With tubes, grease is easily dispensed through squeezing of tubes hence this machine is the vital component where grease processing is involved. It consists of specialized units that work in sync to automate grease packaging.

2.How Does Grease Tube Filler Prove Useful in Businesses?

The grease tube filler is manufactured using reliable materials that enhance service life and generate a high return on investment. There are various advantages of this machine that prove its worth in businesses.

Some benefits of grease tube filler are:

High Speed

High Speed of Grease Tube Filler- Picture Courtesy: bzmachinery.net

This machine is widely used in different industries because of its soaring speed. PLC systems, HMI, and easily changed parts assist in fast format change which in turn boosts production efficiency and lowers the downtimes. Rotary tables and different stations like feeding, filling, coding, and sealing work as well as oil machinery thus filling thousands of grease tubes in one hour.

Visual Appeal

Visual Appeal of Grease Tube Filler- Picture Courtesy: Filling Machine

Grease tube filler is equipped with tube sealing and coding units that play a vital role in boosting the end appeal of the product. The tube sealing station gently irons the ends of tubes and embosss them with beautiful patterns. Moreover, unwanted edges are trimmed with scissors to give customers a pleasant visual experience

Safety

Safety of Grease Tube Filler- Picture Courtesy: Filling Machine

The grease tube filler with high productivity and also has safety components that provide a safe operational experience for operators and lower the chances of accidents. This machine has acrylic doors with interlocking joints that aid in visual monitoring of operation without direct contact. It also has anti-vibration legs that prevent machine jolting.

Fill Accuracy

Fill Accuracy of Grease Tube Filler- Picture Courtesy: tubefillingmachine

One of the biggest advantages of grease tube filler is its fill accuracy. Manual filling is full of errors, causing wastage of valuable products as well as underfilling. However, piston filler and pump filler in this machine provide fill precision in every grease tube. In addition, sensors in the grease tube filler aid in determining the exact level of grease in tubes.

Robust Design

Robust Design Grease Tube Filler

Grease tube filler is manufactured using stainless steel alloy that not only results in a robust design with high functioning life but also has hygienic construction. Moreover, cam drives present in this machine aid in gently jolt-free tube movement. Its clean-in-place unit offers quick cleaning in a matter of minutes.

Versatility

Versatility of Grease Tube Filler

Industries with fast-changing tube styles often require machines that are extremely flexible and versatile in their processing. Grease tube filler is diligent in fulfilling this part. Purchasing this instrument does not satisfy present tube processing needs but can accommodate future needs as well because it can process tubes of various designs, shapes, sizes, and materials.

3.What Industry Does Grease Tube Filler Serve?

Grease tube filler is highly popular in various industries because of their mechanization, flexibility, and changeability. Grease tube filler is increasingly employed in different businesses for packaging pastes in elegant tubes.

Some industrial applications of grease tube filler are:

Chemical Industry

Grease Tube Filler in Chemical Industry

Grease tube filler is designed with extendable nozzles that lower product wastage during the filling of viscous chemicals such as fertilizers, polishes, coloring agents, lubricants, pesticides, etc., in the chemical industry. This machine easily processes viscous chemicals through the use of support bearings in the rotary valve.

Automotive Industry

Grease Tube Filler in Automotive Industry

In the automotive industry, different products, for instance, grease, lubricants, engine oils, coolants, and varnishes are packed in the tube by the grease tube filler. Automotive products are quite corrosive, so this machine has a special kind of technology such as a resistant frame to fill such products. This machine carries out automotive chemical filling with high speed and great caution.

Food Industry

Grease Tube Filler in Food Industry

Quality standards such as GMP are of immense importance in the food industry to avoid food contamination and to retain its quality therefore grease tube filler having a hygienic design is routinely employed in this industry. This design construction decreases the cross-contamination. It fills spreads, condiments, pastes, jams, sauces, and dressings in tubes.

Cosmetic Industry

Grease Tube Filler in Cosmetic Industry

Elegance and sophistication are important features of the cosmetic industry. Thus, grease tube filler is popular in the cosmetic industry for its packaging of masks, foundations, creams, lip gloss, dyes, shampoos, and soaps, in classy squeezable tubes.

Construction Industry

Grease Tube Filler in Construction Industry

It may come as a surprise but the construction industry also uses this hefty machine for filling sealants, glues, adhesives, caulking compounds, oils, etc., in the tubes for ease of use. This equipment has a special filling system to handle these sticky liquids.

Health Care Industry

Grease Tube Filler in Health Care Industry

In the healthcare industry, different kinds of healing pastes, gels, creams, ointments, and salves are routinely packed inside the pharmaceutical tube by the grease tube filler. Its compact construction and safety doors decrease microbial and chemical contamination of different pharmaceutical, nutraceutical, and dermal products.

Stationery Industry

Grease Tube Filler in the Stationery Industry

Today, grease tube filler is a common equipment in the stationery industry. This machine is used for packaging acrylic paints, watercolors, glues, highlighters, gel pens, etc. These stationery products are non-free-flowing substances so with the help of pistons and pumps, they are filled inside tubes.

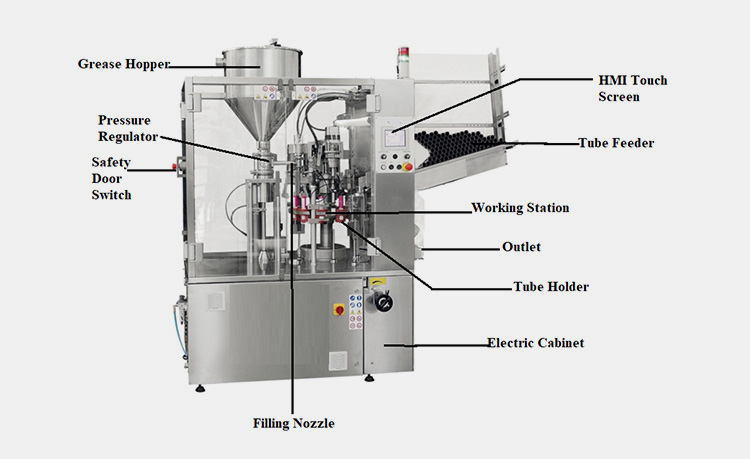

4.What Type of Components are Present in the Grease Tube Filler?

Grease tubes-Picture Courtesy: Istock

Grease tube filler is comprised of high-tech advanced control units, servo drives, and filling systems that provide automation in grease filling.

A list of important parts is given below for your information.

| Grease Hopper | It is a funnel-like structure usually found at the upper portion of the machine. Its function is to store grease for the duration of the machine run. |

| Pressure Regulator | It is a knob-like structure, located at the bottom of the grease hopper. It controls the speed and flow of grease from the hopper to the filling station. By adjusting the knob, a perfect filling speed is achieved. |

| Safety Door Switch | This is a small button located on the safety glass door. It is a safety feature that allows users to monitor grease filling while protecting them from any accidents. |

| Filling Nozzle | Its main function is to dispense grease inside the tube. This is an elongated pipe-like device that could be extended to the bottom of the tube for drip-free dosing. This reduces the wastage of grease. |

| Electric Cabinet | Different kinds of electric components such as cables, wires, relays, and switches required for running a grease tube filler are placed inside a sturdy electric cabinet. This part supplies the electric energy to all parts. |

| Tube Holder | This component is a pocket-like structure in which tubes are firmly secured, preventing the tubes from falling and losing expensive products. |

| Discharge Outlet | It is a chute-like part in which filled and sealed grease tubes are collected after ejection from the machine. |

| Working Station | It is the main work area in which different components like filling nozzles, tube holders, sealing jaws, trimming knives, etc. It is a turntable that rotates to fill multiple tubes. |

| Tube Feeder | Bulk quantities of tubes are loaded inside a rectangular device called a tube feeder before the beginning of operation. This part lowers the delay in operation. |

| HMI Touch Screen | It is a smart screen display having different programmable options that ensure quick and easy adjustment of filling parameters. |

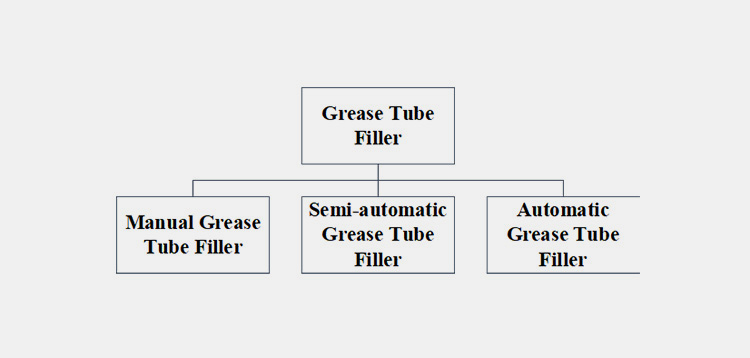

5.What are the Different Types of Grease Tube Filler?

Grease tubes- Picture Courtesy: Earthmoving

Grease tube filler is divided into three main types based on the level of automation.

Manual Grease Tube Filler

Manual Grease Tube Filler- Picture Courtesy: Kalvac Catalog

It is a small-scale benchtop machine usually found in small home-based settings. The advantage of this machine is that it does not require electricity and compressed air to run. However, every grease filling function is manual in this type of grease tube filler. It is labor intensive as it needs operators for loading, and unloading tubes, and pressing levers or handles for filling.

Semi-automatic Grease Tube Filler

Semi-automatic Grease Tube Filler- Picture Courtesy: SZHX Machine

It is a medium-scale compact machine ideal for settings where middle-level productivity is required. In this machine, operators load tubes by hand while the filling operator is automatic. It has a turntable with different stations, such as filling, coding, sealing, etc. It also comes with nozzles that are efficient in reducing fill. Maintaining and cleaning this equipment does not involve much effort.

Automatic Grease Tube Filler

Automatic Grease Tube Filler- Picture Courtesy: Sama Engineering

It is a state-of-the-art machine with the latest controls and advanced technology that improves grease grease-filling process. It requires minimal human supervision and thus is less labor intensive. Operators simply have to load bulk quantities of tubes and grease products in the hopper while the rest of the filling steps are carried out by the machine independently. With smart touch screens, operators can easily change filling inputs leading to fast changeovers.

6.What are the Different Stages in Working of a Grease Tube Filler?

A grease tube filler is a mechanical system that works as one unit to optimize grease filling. The working stages of this machine are penned below:

Grease Loading in Hopper

Grease Hopper- Picture Courtesy: iPharmachine

At first, the bulk quantity of grease is loaded inside the hopper. The grease is moved to the filling station by the movement of pistons or pressure pumps. A sensor located inside the hopper measures the grease level and signals once the grease reaches below the threshold level.

Empty Tube Feeding and Orientation

Tube Feeding

Empty tubes are loaded inside the tube feeder from where they are lifted by a vacuum prism swing that positions them standing tall and are loaded in the tube holders. These tubes are also put on the conveyors manually by the operator. Afterward, these tubes are rotated to their proper orientation by scanning the print mark on their end.

Grease Filing in Tube

Grease Tube Filling- Picture Courtesy: Zungwan

When a sensor detects the availability of a tube under the filling nozzle, it signals the start of filling. The grease from the hopper moves to the filling nozzle that dispenses an correct amount of grease inside the tube. High precision in grease filling is ensured by the pump drive.

Tube Heating and Sealing

Grease Tube Sealing

In this area, the inner sealing side of the tube is heated via hot air. At the same time, cold water sockets are employed for cooling the exterior surface of the tube resulting in their smooth finishing. For sealing, the heated part of the tube is pressed with high pressure by sealing jaws.

Tube Trimming

Tube Trimming- Picture Courtesy: Jornen Machinery

After sealing, the tubes are then moved to a trimming station where the non-uniform ends of tubes are cut to acquire a smooth and neat packaging look. Sometimes, after trimming tubes are coded with batch number, expiry date, etc.

Tube Ejection

Finally, grease tubes are removed from the machine at the ejection unit and are collected at the discharge chute for down-the-line packaging.

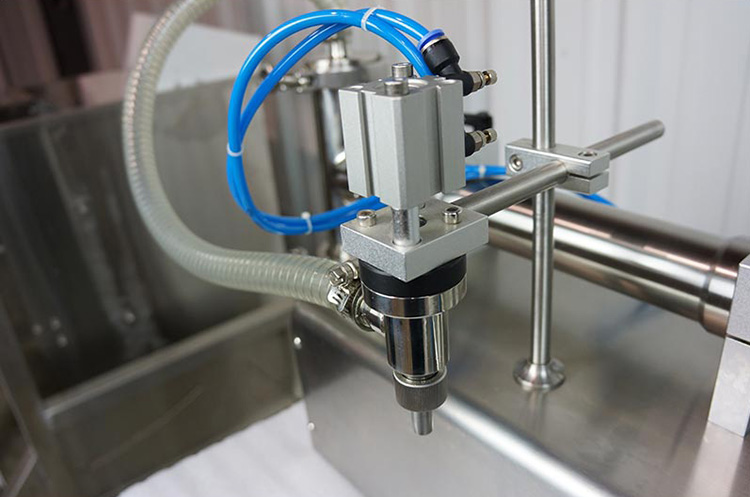

7.What are Different Filling Approaches in Grease Tube Filler?

As grease is a thick viscous liquid that requires extra help in loading, special kinds of fillers are present in grease tube fillers for dispensing grease. Some examples of these fillers are:

Pump Filling

Pump Grease Filling- Picture Courtesy: MSD Ltd

It is the perfect approach for handling viscous grease. Different types of pumps are available to customize The grease tube filler, for instance, rotor pumps, lobe pumps, cavity pumps, gear pumps, etc., Every filling nozzle has its pump that forces the grease inside the tube. There are two main pump-filling approaches:

Time-based pump filling, the grease is simply loaded for the preset duration in each cycle. Built-in stopwatches, timers, or settings on the PLC system allow the operator to program the time limit for filling. Conversely, pulse-based pump filling is a popular type of pump filling in which pump movement such as gear rotation during each cycle is preset for filling.

Piston Filling

Piston Grease Filling- Picture Courtesy: APACKS

It is a versatile filling approach that can handle a wide range of liquids. It uses a check valve or rotary valve to directly load grease inside the tube. A piston-cylinder that moves back and forth to force the grease from hoppers inside the filling nozzles and ultimately into the tubes. A volumetric filling is acquired by the movement of the cylinder and piston and also by altering stroke adjustment. Piston filling has an accuracy of ±0.5% and results in quick dispensing.

Pressure Filling

Pressure Grease Filling- Picture Courtesy: Shreetech Engineers & Consultants

This filling approach works best for medium and thick viscosity liquids such as grease. In this filling, gravity is used for filling grease but with high pressure because of grease viscosity. The grease tube filler is at a higher pressure than the atmosphere so a positive pressure is placed on the top of the hopper for fluidity of grease and sometimes pumps are employed for moving grease.

8.What are the Different Tube Materials Handled by Grease Tube Filler?

Grease tube filler is proficient in handling different tube materials, examples of these materials are penned below for your understanding.

Aluminum

Aluminum Tubes

Mostly grease is filled in aluminum tubes by the grease tube filler. It is an inert metal with strong barrier properties. Aluminum metal is easily molded into shapes and has characteristics metallic sheen thus, is widely popular in chemical packaging. Furthermore, it is a recyclable material and, consequently, a favorite in sustainable packaging.

Plastic

Plastic Tubes

More and more businesses are opting for plastics because of their affordability and availability. There are different types of plastics used for fabricating plastic grease tubes such as HDPE, PET, PP, and PVC. The grease plastic tube is light in weight and can be customized with finishes for sophisticated shelf appeal. Plastic is resilient and does not react with packed grease.

Laminate

Laminate Tubes- Picture Courtesy Freshpack Solution

This grease tube is two in one package as it combines the benefits of both plastics and aluminum, which is the barrier properties of aluminum with the presentation and functionality of plastics. It is made with multilayer laminates and aluminum or plastic is inserted between two layers for high protection. The grease tube filler is modified to handle these tube materials for increased tear resistance.

9.What are the Sizes, Shapes, and Sealings of Tubes Processed by Grease Tube Filler?

Grease tube filler is an adaptable machine and with few changes of parts, it can be altered to handle diverse tube shapes and sizes.

Tube Size

This machine fills tubes of various sizes, depending upon the size of the tube holder present in it. Tube size is usually determined by its filling capacity, which is the volume filled inside the grease tube.

The smallest tube size filled by grease tube filler is about 13.5 while the largest sized tube packed by this equipment is 50. The smallest tube fills about -10ml of grease while the largest tube fills about 400 ml of product.

| Tube Size | Length Range | Filling Capacity |

| 13.5 | 65-82 mm | 3-10 ml |

| 16 | 80-95 mm | 5-12 ml |

| 19 | 70-110 mm | 8.8- 20 ml |

| 22 | 90-120 mm | 10-30 ml |

| 25 | 105-150 mm | 30-50 ml |

| 30 | 115-155 mm | 50-80 ml |

| 32 | 155-165 mm | 60-80 ml |

| 35 | 175 mm | 150-180 ml |

| 40 | 165-190 mm | 100-200 ml |

| 50 | 185-210mm | 200-400 ml |

Tube Shapes

Grease Tube Shapes

A grease tube filler can process tubes with oval, round, and cylindrical. Furthermore, today, grease tube filler is designed in such a way that it can handle tubes with rectangular and square shapes as well.

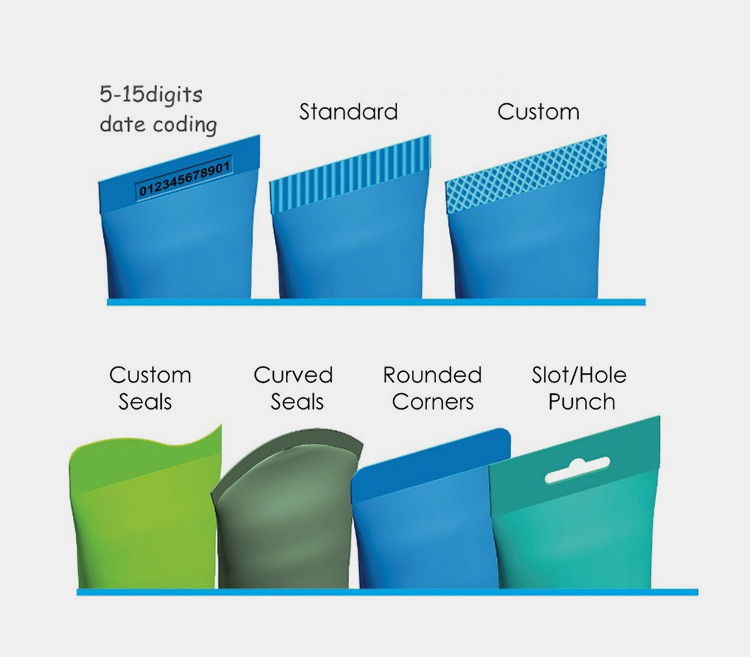

Tube Sealing

Grease Tube Sealing

Grease tube filler has specific kinds of sealing components to date code, and print letters A-Z or numbers 0-9 on the tube seal. Moreover, this machine can make a typical patterned seal. The seal shapes formed by this equipment are also different, for example, rounded corners with bottom round edges and custom seals with special seal shapes. This machine can also create a curve seal and euro slot seal with a hole in the center.

10.What is the Maintenance Schedule of the Grease Tube Filler?

Maintaining Grease Tube Filler

For increasing and prolonging the operational life of the grease tube filler, it must be routinely cleaned and maintained. This preventive maintenance is not only useful in preventing failure or breakdown of grease tube filler but also in improving the safety of the operator.

The maintenance schedule of the grease tube filler is detailed below:

| Daily | To prevent the mixing of foreign particles in grease, regularly clean the machine before use.

Wipe the exterior of an instrument with alcohol to keep the frame smooth and shiny. Tighten any loose nuts and bolts. Check the grounding of the grease tube filler. Inspect the water level and oil vapors in the pneumatic pipeline. |

| Weekly | Inspect the level of lubricating fluid in the grease box, if needed then load it up with 320 lubricating fluids.

Inspect loose cables and wires and properly tighten them. Inspect the synchronicity of the level sensor and pneumatic valve. Check for the leakage in pneumatic system. |

| Monthly | Replace the old seal rings of the piston cylinder.

Inspect and grease gear links. Lubricate star wheels. |

| Half -Yearly | Examine electric switches, fuses, and buttons in the electric cabinet. If worn out then replace them.

Inspect motor connections and properly secure them. Inspect the running conditions of pneumatic valves. |

| Yearly | Inspect the damage to gearbox bearings and replace them.

Examine the working conditions of pumps, motors, and cooling fans. If defective then replace them. Switch the lubricating fluid in the reducing motor. |

11.What are the Defects and their Troubleshooting in the Grease Tube Filler?

Grease Tubes

During the normal running of grease tube filler problems can arise, however, with careful analysis and inspection, they can be easily resolved. Some basic problems and their troubleshooting are detailed below:

| Cause | Remedy | Picture |

| Sharp Ends on Flanks of Grease Tube | ||

| The heating bar is not positioned precisely

Inadequate temperature |

The heating bar should be in a vertical position in the middle of the pocket on the turntable

Fix the quantity of cooled water and decrease the temperature |

Sharp Edges on Grease Tubes |

| Heating Spray Interact with Grease | ||

| Overflow of grease

Grease sticks to the edges of the tube |

Alter the filling rate

Avoid material spattering |

Heating Spray- Picture Courtesy:Huizhou PingFang Trading Co.,Ltd |

| Overfilling of Grease | ||

| The transformer and measuring lever are at a higher position than normal

Inaccurate filling pressure

|

Adjust the position of the transformer and measuring lever

Adjust the pressure regulator to attain the right pressure |

Filling of Grease- Picture Courtesy: tubefillingmachine.net |

| Leakage in Pressure Valve | ||

| Wear and tear of old diaphragm

Leakage in the diaphragm of a pressure regulator Incorrect installation of diaphragm |

Replace old diaphragm

Repair perforation in diaphragm Reinstall diaphragm

|

Pressure Valve- Picture Courtesy: Makewell |

| Poor Sealing of Grease Tubes | ||

| High suction volume or poor blowing volume

The decreased heating temperature of the hose Unclean tube wall The airflow rate is too low resulting in poor air pressure Inconsistency in the level of heating belt |

Adjust the air metering device

Maintain adequate heating temperature Properly clean the exterior of tubes Maintain air pressure as per the limit Properly level the heating belt

|

Tube Sealing- Picture Courtesy: The Tube Council |

12.What are the Best Practices to Purchase an Ideal Grease Tube Filler?

If you want to purchase a new grease tube filler or upgrade an existing one first it is best to carefully do your research and see what make and models of this machine are available in the market. This is the way to get more profit from your purchase.

Some best practices to buy an ideal grease tube filler are:

Big Question: Budget

Budget Estimation for Grease Tube Filler

First, set aside the necessary budget for buying a grease tube filler, also calculate the budget for maintenance and energy consumption. Determine which kind of machine model is within your budget. It is important to justify the purchase by estimating whether it will bring you profit at the end of the day.

Technology For Efficiency

Technology in Greas Tube Filler

If you want to buy an ideal grease filler that is fast and efficient then do a little homework to discover the latest innovations in this machine. PLC systems, HMI, and robotics may cost a little extra but they are worth having in your production as they meet your increasing production demands.

Type of Tubes

Grease Tube-Picture Courtesy: Biederman Packaging

Today, the packaging industry is using different tube styles for packaging grease. Every grease tube filler has its tube specialty with which it works best. Therefore, it is important to select the tube kind beforehand. A grease tube filler compatible with your selected tubes is worth its weight in gold.

Design of Machine

Grease Tube Filler- Picture Courtesy: Adelphi Group of Companies

It is an important aspect of grease tube filler. An ideal machine should be modular built, meaning it is composed of a smaller number of parts that are easily disassembled for maintenance and cleaning. Moreover, the design of your selected machine should be such that is it easily integrated into your production lines with minimal fuss.

Reputable Manufacturer and Customer Support

Customer Feedback about Grease Tube Filler Manufacturer

It is a vital aspect that makes or breaks your business. Before going to buy a grease tube filler, go online and carefully read the reviews and ratings of customers about different manufacturers. Then shortlist manufacturers with the best reviews. Also search about their customer service quality, repair support, problem diagnosis, and part warranty while shortlisting manufacturers.

Conclusion

Tired of manual handling grease then invest in grease tube filler. A highly robust, flexible, and efficient instrument that fully automates your productions. However, when it comes to buying a perfect grease tube filler solution, thorough research, planning, and investment are required. But it will be fruitful in the longer run as the grease tube filler generates substantial profit. If you are confused about selecting a reputable manufacturer of a grease tube filler then do visit our Allpack website for high-quality machines with excellent recommendations. Here you will find top-notch services and solutions at affordable prices.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply to you ASAP within 24 hours