Frozen Food Counting Machine: The Complete Buying Guide In 2025

Among many other food preservation methods, freezing is a popular one. That's why, manufacturers of food industries often employ this technique and freeze their fruits, vegetables, meat, and sea food etc., to enhance their shelf life while retaining their nutritional value as well as taste. Similarly, this frozen food is subjected to thorough processing and especially counting for which a Frozen Food Counting Machine is used.

This machine is highly qualified to deal with all kinds of frozen food regardless of their shape and size. With compact structure, it follows simple working procedure and is easy to maintain. The machine is highly efficient, cost-effective, and reliable to be used in number of sectors. Depending upon your production needs, you can opt for the most compatible type of machine. So, take start and know everything about a Frozen Food Counting Machine!

1.What Is A Frozen Food Counting Machine?

Allpack- APC-16 High speed frozen food counting machine

Frozen food counting machine refers to an advanced cutting-edge machine which is used to count wide range of frozen food encompassing vegetables, fruits, meat, and chicken etc. It has special structure that can easily process small to large size frozen food with varying shapes.

The machine works by following automatic way where operator is only required to set the machine. It thus counts the frozen food products by detection. Moreover, its robust and hygienic body is fully safe for your sensitive food products and that's why you can also employ it for your medical and other stuff.

2.How Do A Frozen Food Counting Machine Benefits You?

When it comes to highlight the benefits of a frozen food counting machine, you will be amazed to have a long lasting list. However, we are going to summarize its vary features and advantages in few headings. So, let's have a look towards these all!

Increase Productivity

Frozen food feeding for counting- Picture Courtesy: affi.org

As the machine is product of sophisticated technology, so, it is designed with automatic features in form of multiple sensors, intuitive control panel, and counting system. Together, these enable the machine to continue non-stop counting of frozen food while reducing manual intervention. Hence, it can greatly enhance your production growth.

High Accuracy

High counting accuracy- Picture Courtesy: hastamat.com

Another significant aspect of a frozen food counting machine is its high level accuracy which can be seen in the form of precise counting with zero error. It does so by taking help from the sensors which restrict the alien objects from getting into counting compartments by storing it in a separate chamber. Similarly, it maintains consistency in counting.

User-friendly

User-friendly icon- Picture Courtesy: gs1.se

Frozen food counting machine is extremely easy to use. It has a simple operational procedure which can be activated by using user-friendly interface. In addition to it, the machine support multiple settings to ease operator in executing machine.

Robust Construction

Robust Construction of frozen food counting machine- Picture Courtesy: Allpack

The machine has a rigid and durable construction with all the parts being made from quality stainless steel and contact parts are specifically made from food grade stainless steel to avoid product contamination. Moreover, over the counting channel, there is a large transparent window which is very useful for protecting frozen food during counting.

Adaptability

Adaptability of frozen food counting machine- Picture Courtesy: Allpack

Adaptability is the most crucial feature which almost every entrepreneur looks for. Luckily, frozen food counting machine is made with such attributes which can process numerous products regardless of their shape and size. Apart from this, frozen food counting machine support the integration of other machines to aid packaging process of the counted products.

3.What Food Products Can Be Counted By A Frozen Food Counting Machine?

From frozen vegetables to fruits, seafood, and pastries, a frozen food counting machine is best eligible to count all kinds of products. It is applicable to wide range of fresh to processed food items which are enumerated below:

Vegetables

Frozen vegetables- Picture Courtesy: izeselet.hu

Vegetables are among basic food which we need for our survival on daily basis. However, their perishable nature made them prone to spoilage. To counter this issue, freezing is considered the most handy and quick method. Now, most of the countries store their vegetables in such manner. Hence, for their counting a frozen food counting machine is suitable.

Fruits

Frozen strawberries- Picture Courtesy: wholefully.com

Fruits are also consumed on regular basis and their freshness life is limited like vegetables. That's why, many fruits are frozen and then transported for selling. During this process, their counting is one of the important step for which a frozen food counting machine can be employed.

Bakery Products

Bakery products- Picture Courtesy: allontario.ca

You may be surprised to know that backed products can also be freezed, but its true. In fact, most of the large industries and super markets used to freeze their processed or raw bakery products such as pastries, pretzels, donuts, and baguettes etc. Hence, to count them accurately, a frozen food counting machine is eligible.

Seafood

Seafood is rich in protein, nutrients, and certain vitamins. However, it is not possible for everyone to access them directly like other staple food. Therefore, seafood is supposed to be mobilized from one part of the world to another. In such a case it is very essential to stop the microbial and pathogens growth through freezing, which is why frozen fishes, crabs, prawns, and mussels are brought for counting by this machine.

Meat & Chicken

Frozen meat & chicken- Picture Courtesy: hip pressure cooking

Beef, mutton, and chicken in all their forms are now often frozen. Similarly, they need thorough processing and counting for which a frozen food counting machine is always desirable.

Dairy Products

Dairy products- Picture Courtesy: women health magazine

Frozen cheese sticks, cream, butter cubes, and eggs etc., are also counted before their packaging. As a frozen food counting machine is highly safe and food grade, it is always preferred to be employed for counting frozen dairy products in row and processed form.

Ready to eat Meals

Ready to eat meals- Picture Courtesy: hip pressure cooking

Due to busy routine and the growing proclivity for comfortable life, people are now preferring ready to eat meals. Answering to this demand, food processing industries are now delivering premade meals in frozen form. In this way, a frozen food counting machine is capable of counting frozen chicken nuggets, pizza, and rolls etc.

Frozen Confectioneries

Frozen confectionery

Almost all kinds of confectioneries are sensitive to heat and light due to which they are frozen, so, that their structure and quality could be well retained. Similarly, for their counting, a frozen food counting machine is used.

Medical Instruments

Medical equipment and tools- Picture Courtesy: thehealthcareinsights.com

Apart from food products, a frozen food counting machine can also be used in medical industry to count medical equipment, drugs, and syringes etc.

Hardware

Clothes wooden clips

Hardware is another notable application of a frozen food counting machine. It can easily count hardware objects encompassing stationary items, screws, nuts, and other daily use goods.

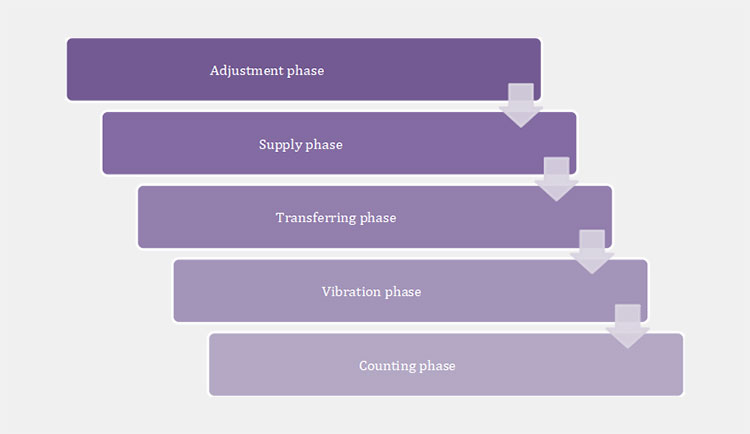

4.Explain The Working Principles Of A Frozen Food Counting Machine?

The success of a frozen food counting machine, to a greater extent, depends upon the way it is operated. Since, it follows automatic way for working it is necessary to understand the working principles which are quite easy to understand. These are as follows:

Adjustment Phase

funtionpacking.com

The very initial step required for operating a frozen food counting machine is adjusting the machine. This adjustment includes its structural adjustment like tightening the screws and rightly placing vibratory trays etc., and the parameters setting of the machine such as the number of frozen food pieces to be counted in each cycle. It must be carried out responsibly to avoid machine malfunctioning during operation.

Supply Phase

Once the machine is rightly adjusted, you can supply it with bulk of frozen food. For this, you can either load the hopper of machine by leaving some space unfilled for smooth flow or you can integrate a feeding unit of the production is large. After supplying machine with material, you can turn the machine on.

Transferring Phase

Transferring phase- Picture Courtesy: hastamat.com

Upon switching the machine on, the very first step which will be taken place is the transferring phase. It involves the mobilization of frozen food from hopper or feeding station towards the machine. This step is undertaken automatically by machine in a steady manner to avoid jamming.

Vibration Phase

Vibration phase- Picture Courtesy: funtionpacking.com

When products are transferred from hopper towards the working area, they are gradually pushed ahead where the vibratory trays are in constant state of vibration. This vibration results in the segregation of food products and consequently, they are serialized in individual rows.

Counting Phase

Counting phase- Picture Courtesy: funtionpacking.com

Moving forward, the vibration of channels lead the frozen food products towards counting compartments where the counting step is accomplished with the help of sensors. The sensors allow counting and depositing of this food into compartments and deformed products are separated. Similarly, the counting of single batch get finished and the same process goes on for others.

Discharging Phase

Discharging phase- Picture Courtesy: funtionpacking.com

At the end, counted frozen food products are discharged from the machine into awaited packages and containers which are then further processed for transportation.

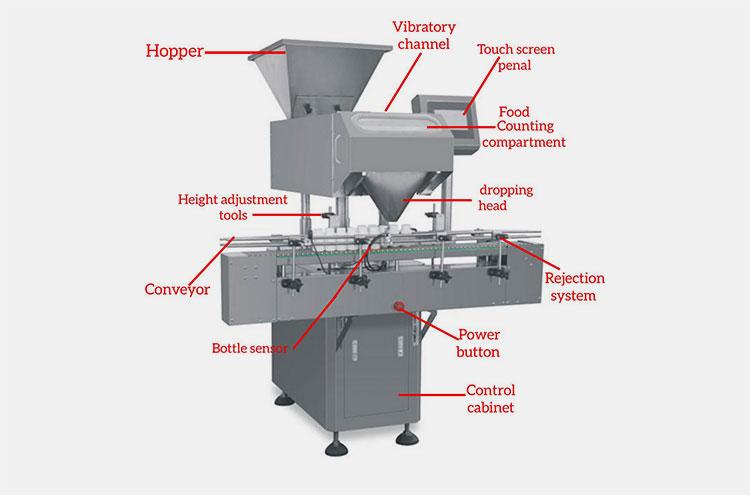

5.Describe The Structure Of A Frozen Food Counting Machine?

Frozen food counting machine is best known for its durable and precise structure. Its structure greatly resembles the body of a pill or tablets counting machine. In the below explanation, you will get to know the various components along with their functions which make up the body of a frozen food counting machine:

Allpack's APC-12 Automatic Tablet/ Frozen Food Counting Machine

Hopper

Hopper is a large size container made up of food grade stainless steel. It is a reservoir where large volume of frozen food is collectively loaded before starting operation. Thus, its function is to keep the products inside and supply it to machine during working.

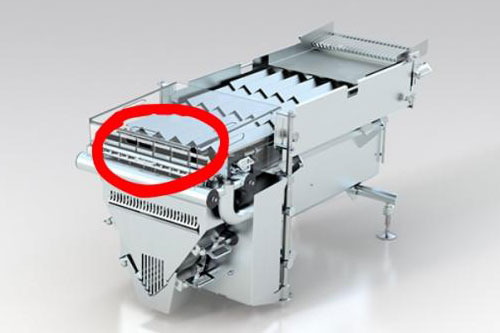

Vibratory Channel

Vibratory channel is one of the main components of a frozen food counting machine. It consists of two to three channels having corrugations for products aligning. Its main function is to separate the stock of food into serialized way by using its channels.

Food Counting Compartment

This part of the machine is located directly to the vibratory channels and is responsible for the accurate counting of frozen food products. It has a detection system installed inside through which it counts the consistent food pieces and reject the deformed ones. Along with it, this part also undertakes the depositing of counted products into separate compartments.

Touch Screen Penal

The machine has an intuitive touch screen penal located in front of it. This part has a key role in the machine execution and controlling. It provides multiple options through its display whose selection determine the machine tasks.

Power Button

There is a large size red color button situated on the front on machine. It is used to switch on the machine once parameters are fixed.

Conveyor

Frozen food counting machine has a transportation device naming conveyor. It is used to mobilize the filled containers from machine towards discharging or further packaging.

Height Adjustment Tool

To adjust the machine structure in accordance with packages needs, it has several tools among which one important eis height adjustment tool. It helps the machine to accommodate different shapes and sizes of containers.

Control Cabinet

Control cabinet is the electric box of a frozen food counting machine which encases all the electrical connections of machine in form of wires, fuses, and power controlling device etc.

Dropping Head

It is also known as filling head or filling nozzle which is located under the counting compartment of machine. Inside dropping head has a flap to keep the counted products inside until container arrives. Therefore, it is used to discharge the counted products from machine into different packages and containers.

Rejection System

Frozen food counting machine has a rejection system which is installed to reject the empty containers.

6.What Is The Classification Of A Frozen Food Counting Machine?

A frozen food counting machine can be classified into two types which are explained below in detail:

Multi Channel Frozen Food Counting Machine

Allpack- ALPK High Speed Fully Automatic Seed Counting Machine

This multi channel frozen food counting machine by Allpack is full fledged automatic machine which is specifically tailored to count small to large size frozen food products. It has multi channel vibratory system through which products are counted. This machine is highly efficient in its performance and maintain product counting accuracy. You can easily connect it with any packaging machine which you want.

Main Components

The machine itself has small footprint with major components including a hopper, vibratory channels, counting head, sensors, and filling nozzle etc. However, when combined with other devices as shown in the picture above, its size may seem more complex.

Working Process

It has simple working procedure by following automatic method for counting. It starts working by transferring frozen food products from hopper onto plate and then vibratory channels. Afterwards, the food is counted via sensors and discharged out of machine.

Industrial Vision Frozen Food Counting Machine

KCS-C Conveyor Counting System- Picture Courtesy: robrosystems.com

Industrial vision frozen food counting machine is another type which is characterized by its conveyor and advanced vision system. It is applicable to different types of frozen food such as chicken nuggets, pizza, rolls, confectionery, and cheese sticks etc. Moreover, the machine is very fast in its performance. That's why, it can be employed in numerous sectors.

Major Components

The structure of machine is precise and cover less space. Its major parts include a hopper, industrial vision system, touch screen display, alarm light, conveyor, electric cabinet, and discharge chute etc.

Working Process

The machine can be easily operated by loading the hopper and setting parameters. Once done, just simply switch on the machine and it will start taking frozen food from hopper towards conveyor. During its transportation, the food is detected by the visual inspection device and display information over the scree. Similarly, counted food products are collected into a container.

7.Differentiate Between Frozen Food Counting And Frozen Food Weighing Machine?

You might have heard about frozen food counting machine and frozen food weighing machine and there is possibility that you may have considered both the same. However, that's not the case! In fact, both these machines are entirely different from each other. Therefore, we have explained these differences in table below for your clear understanding:

| No | Aspects | Frozen Food Counting Machine | Frozen Food Weighing Machine |

| 1 | Definition | Frozen food counting machine is sensor based automatic machine which is used to count the individual frozen food pieces. | Frozen food weighing machine in turn is an equipment with multi head weigher as a principal tool for weighing the frozen food collectively. |

| 2 | Structure | It is made up of a vibratory channel, sensors, and counting compartments along with other components and has a simple structure. | While as, frozen food weighing machine has complex body with major parts including multi head weigher, hopper, control system, and discharge funnel etc. |

| 3 | Process | Its process is consistent with product transmission from hopper to vibratory channels, their counting, and ultimate discharging. | In contrast, this machine has complicated process where loaded bulk of food volume is divided into parts by undergoing them through different weighing chutes. |

| 4 | Accuracy | Frozen food counting machine has high accuracy in terms of counting, and it provides you with the exact figure of products. | Contrary to that, the products weighed by frozen food weighing machine may have variation. For example, one pack may contain 50 pieces while the other 51 or 49. |

| 5 | Application | It is best for all the expensive and and large size products like frozen seafood, meat, chicken, olives, and premade meals etc. | On the other hand, it is good for small frozen products like pulses, seeds, and few kinds of vegetables and fruits. |

| 6 | Picture |

Allpack- ALPK-8 Automatic seed counting machine |

Allpack- Frozen Food Weighing Machine |

8.What Quality Standards Should A Frozen Food Counting Machine Meet With?

When buying a frozen food counting machine, it is always crucial to consider its quality. After all, you are going to process your sensitive frozen food products by this machine. In this way, it is always preferred to check its quality and that can be done by looking into different aspects. These aspects can simply by checked by examining the quality standards which a frozen food counting machine should meet with. These include:

Quality control icon- Picture Courtesy:Vecteezy

ISO:ISO stands for International Organization for Standardization which is a standard body for ensuring the safety and consistency of machines in accordance with consumers expectations. So, this machine should be certified by ISO.

GMP:Good Manufacturing Practices is another quality standard which has established a long list of guidelines for machines safety which deals with food and drugs. Hence, a frozen food counting machine complying GMP's regulations will be the quality machine.

NSF International:National Sanitation Foundation International is yet another quality standard created to check the equipment structural hygiene against bacteria. In this way, a frozen food counting machine being certified by it will be of high quality.

UL:UL certification deals with the electric system of the machine. Having this mark means that a frozen food counting machine is fully safe against electric damages.

9.How To Clean & Maintain A Frozen Food Counting Machine?

Cleaning and maintenance go side by side with the operation of a frozen food counting machine. So, whenever you operate your machine you are bound to conduct its cleaning and maintenance or else its performance will go backward. So, to enable you with the easiest way, we have explained both under the following headings:

Operator maintaining machine- Picture Courtesy: Getty Images

Cleaning:

Cleaning your frozen food counting machine on regular basis can help you continue the dirt-free counting of your edible food products. For this, you need to disassemble the parts of machine like hopper, vibratory channels, and glass window etc.

Once done, wash these parts with non acidic water and dry them via tidy cloth. For other attached parts of the machine, you can use a cloth and clean them through wiping it. Hence, your machine will be free from pollution and debris. Now, assemble all the parts on their fixed location.

Maintenance:

Maintenance includes both the preventive maintenance and maintenance after any mishap occurs. For the former, you need to keep adjusting the structural components of machine each time when operating the machine. Make sure to add lubrication oil to prevent friction and wear tear.

As far as the maintenance after breakdown is concerned, so, you need to shut down your machine and look for the defective parts. Replace these damaged parts timely with new functioning one and troubleshoot other spontaneous problems by taking help from the machine's operation manual.

10.Give Remedies To The Common Errors Of A Frozen Food Counting Machine?

Let's discuss some of the common errors that you may encounter when operating a frozen food counting machine!

| i. Frozen food jamming | ||

Frozen food jamming during operation- Picture Courtesy: coldterminal.lv |

Cause:

Hopper is overloaded. Vibratory channels are misaligned. The speed of vibratory motor is excessive. |

Solution:

Reduce the volume of frozen food inside hopper to 2/3. Remove the vibratory channels and locate them in a right way. Reduce the speed of vibratory motor to suitable level. |

| ii. Sensor problem | ||

Sensor fault- Picture Courtesy: cremer.com |

Cause:

There is accumulation of dirt and pollution over sensor. The sensor may have lost its connection to machine. It may be damaged. |

Cause:

Clean the sensor by removing out dirt and debris. Recheck its connection and activate it through control panel. Replace the sensor. |

| iii. Sudden Noise | ||

Encircled alarm- Picture Courtesy: ipharmachine.com |

Cause:

The alarm may ring due to sensor issue. The setting is not done. Loose parts of machine may be the reason for noise. |

Solution:

Clean the sensors. Make sure to keep the machine parameters fixed all the time. Tight the parts of machine like vibratory channels and screws etc. |

| iv. Counting error | ||

Food counting issue- Picture Courtesy: innovamarketinsights360.com |

Cause:

You may have not fixed the counting number. There might be sensor fault. |

Solution:

Set the number of products to be counted in each cycle. Check the sensor. |

| v. Power Issues | ||

Highlighting power issue- Picture Courtesy: Allpack |

Cause:

The incoming power voltage is lower than required for machine. Machine is not properly connected to power. The software of machine is not updated. |

Solution:

Provide required power voltage to machine. Check the machine power connection and reconnect it. Update the software of machine. |

11.Factors Essential For Selecting The Best Frozen Food Counting Machine?

Whenever you intend to choose a frozen food counting machine for your business, make sure to consider some essential factors regarding it. Among these factors, we have highlighted few in the upcoming paragraphs:

Production Needs

Frozen food discharging through conveyor- Picture Courtesy: cremer.com

First of all, it is important to have a look towards your existing production line. You need to examine its length that whether it is large scale, medium scale, or small scale. Similarly, you will be able to determine which type of machine you will require for it.

Packaging Mode

Different types of frozen food packages- Picture Courtesy: designerpeople.com

Frozen foods are packed in small to large packages. These packages can be flexible or rigid such as pillow bags, standup pouches, bottles, and jars etc. Hence, depending upon your packaging mode, you can choose a frozen food counting machine with form, fill, and seal machine, premade pouch packaging machine, or conveying system for other containers.

Cost

Considering cost of the machine is also very important. As most of the time, when selecting a frozen food counting machine, we only ask for the price of machine and forget to have deep look into the operational cost and maintenance cost etc.

Warranty

Warranty icon- Picture Courtesy: didunstore.com

Quality assurance is the most important aspect of every machine and similar is the case with frozen food counting machine. And what could be more reliable in this way than having a warranty policy. So, make sure to get the warranty of at least one year for your machine.

Conclusion

To put in a nutshell, Frozen Food Counting Machine is the modern day need of almost every food processing industry. It is because this machine provides a safer, quicker, and easier way to count all kinds of food products. The adaptability and resilience of machine has further expanded its scope and now you can also employ it to various non-food sectors. Apart from this, the machine's handy operational procedure, precise structure, and easy maintenance is making it more appealing to manufacturers. So, if you are also among them and looking for a top class frozen food counting machine then don't forget to consider Allpack. For further information contact us through our website!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide