Flowability Tester: The Complete Buying Guide In 2025

From morning breakfast till ending our house chores and taking self-care, we constantly use powders either in form of condiments, detergent powder, cosmetics, or supplements. By this, we simply get how important role the various powders play in our lives. But have you ever wondered how they maintain their originality for months? The answer is simple by going through a Flowability Tester!

This innovative equipment represents cutting-edge technology which provide you to conduct flowability testing for your powders in multiple testing conditions. It is a perfect tool to give information about powders in advance, so, that you won't be bothered to face the complexities during production. Moreover, its precise structure, convenient operation, and quick maintenance further extend its worth. So, let's start exploring all about Flowability Tester in this guide!

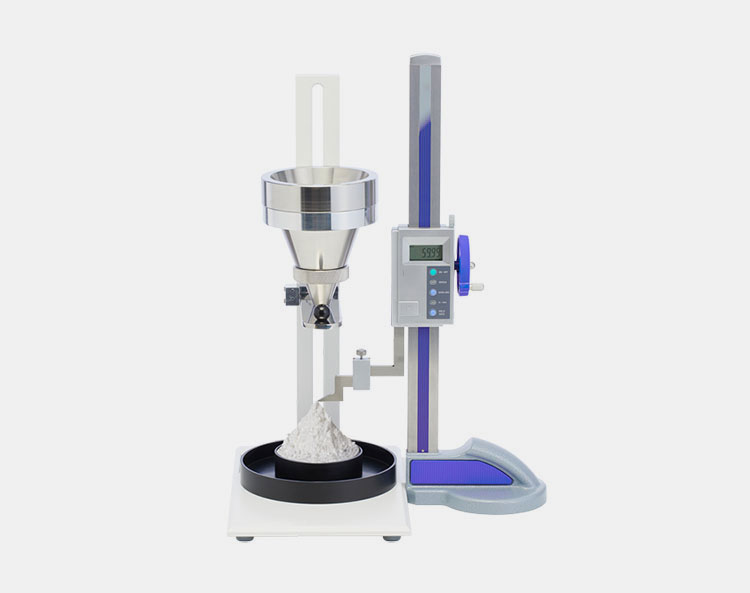

1.What Is A Flowability Tester?

Powder flowability tester- Picture Courtesy: erweka.com

Flowability tester can be easily defined as equipment designed to determine the flow rate of various types of powders and granules. It consists of several parts for carrying out the function of measuring flowability.

The process simply involves stirring the powder in hopper which pushes the powder to adopt continuous flow downward in the collection tray. This nonstop flow of particles is kept noticing by various methods like laser beam and information is provided over digital screen. The entire operation is efficient as well as safe, thus, you can employ it for any kind of small to large dry particulates.

2.Why Flowability Tester Is Important In Pharmaceutical Industry?

Pharmaceutical solid dosage form- Picture Courtesy: askthescientists.com/qa

As a matter of common observation, pharmaceutical industry is a field constantly involved in the manufacturing, processing, and development of drugs. Now, these drugs are most of the time categorized as oral dosage form and liquid dosage form. Due to effective drug release and convenient drug administration, solid dosage form is always on top which include capsules, tablets, and pills etc.

Although, the amount of powder each tablet or capsule hold is low but it is still valuable because of a pharmaceutical mixture. That's the reason, each particle play effective role in drug formulation. For this reason, flowability tester is eminent in pharmaceutical industry to determine the flow of powders, so, the equipment like tablet press and encapsulation machine may be settled accordingly.

3.What Are The Benefits Of A Flowability Tester?

Well, a flowability tester has many features which in turn become its benefits for you. So, let's enumerate few of the notable ones!

Precise Structure

Precise flowability tester- Picture Courtesy: copleyscientific.com

With small footprint and compact design, flowability tester has a precise structure which is easy to mobilize. It covers less space thus you can place it anywhere you want. Moreover, it also makes the setting and maintenance of the equipment more handy.

User-friendly

User operating a flowability tester- Picture Courtesy: erweka.com

Another benefit of a flowability tester is associated with its large panel which holds over it multiple knobs and a screen. Similarly, by using simple software system, it is possible for every layman to operate the device by just getting the basic information.

Customization

Customization is important for many reasons because most of the time a single machine is meant to be used for multiple purposes. In this way, a flowability tester can be easily customized by changing the size of hopper, type of stirrer, and measurement methods.

Flexibility

Various food powders- Picture Courtesy: hanningfield.com

Flowability tester is best known for its adaptability and versatility that it is able to process both powder and granules with varying degrees of particles size and flowability.

Safety

Stainless steel hopper & stirrer- Picture Courtesy: erweka.com

The contact parts of the tester including stirrer, hopper, and collection container are made from quality stainless steel which are fully protected against corrosion and bacteria. So, the processed powders are safe during operation.

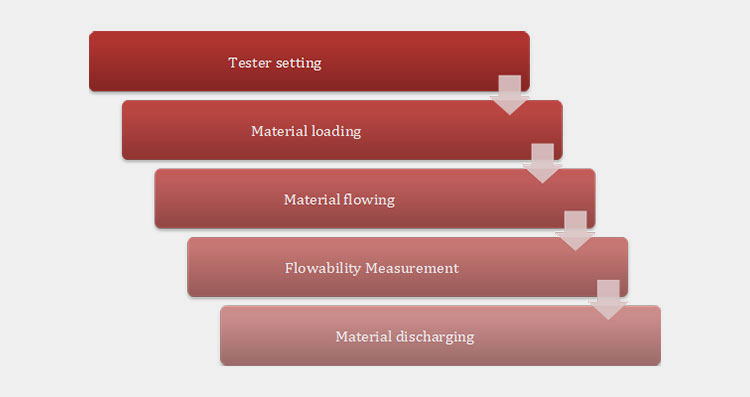

4.Explain The Working Principles Of A Flowability Tester?

The working principles of a flowability tester can be easily understood by looking into the underlying steps:

Tester Setting

Flowability tester setting- Picture Courtesy: erweka.com

First, you need to set your flowability tester by integrating the necessary parts like stirrier, funnel, and collection plate etc. Then adjust the parameters by bringing in use the control panel.

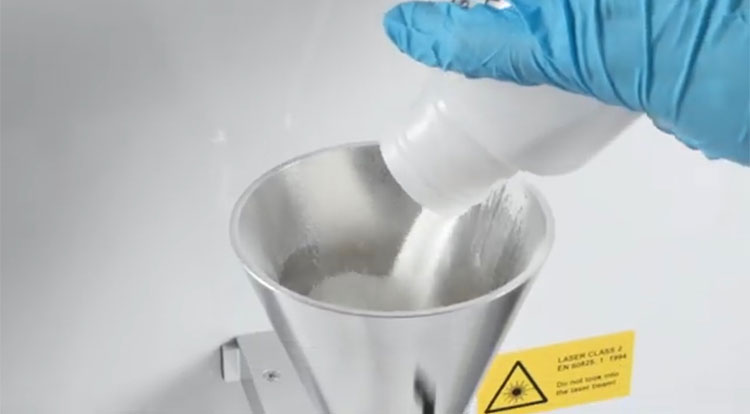

Material Loading

Powder loading into hopper- Picture Courtesy: erweka.com

Now, close the outlet of hopper and load desired material which can be powder or granules. Make sure not to overload the hopper as it will cause poor flow or blockage of the nozzle.

Material Flowing

Powder flowing into container- Picture Courtesy: erweka.com

Upon successful material loading, just switch on the tester and open the outlet nozzle. The stirrer will start rotation inside funnel which will cause the particles to adopt continuous gravitational movement downward.

Flowability Measurement

Powder flow measuring- Picture Courtesy: erweka.com

At this point, the flowability tester will keep measuring the flow of material by using different techniques which vary from employing a laser beam to timer. Similarly, the angle of material flow as well as the overall weight of material collected in tray will also be shown at the end of operation.

Material Discharging

Operator discharging collection plate from powder flowability tester- Picture Courtesy: bulksolids-portal.com

Once you are done with a cycle of flowability testing, just remove the material filled plate from tester. You may also get the complete output data in form of print by using USB printing.

5.What Are The Components Of A Flowability Tester?

Flowability tester has a compact body which is composed of several small to large components. These parts along with their functions are described below:

Components of a flowability tester- Picture Courtesy: erweka.com

Electric System

This part of the flowability tester refers to its collective power system which helps it to carry out the function. It consists of wires, fuses, and other electrical parts like USB connection area for printing etc.

LCD Display

LCD display is a flat screen that show over it the tester data by illuminating. It displays information about the test during and after information.

Numerical Membrane Keypad

It refers to the panel which consists of large number of buttons indicating alphabets, numbers, and directions etc. This keypad enables the user to adjust the parameters of flowability tester for conducting a test on desired measurements setting.

Stainless Steel Hopper

The tester also has a stainless steel hopper or funnel which is usually of small size. It is used to hold the powder or granule before testing and during testing the powder is released from the hopper through narrow outlet.

Stirrer Unit

Flowability tester come with optional but important stirrer unit which is useful for making the lumpy and cohesive powders flow easy. The stirrer is attached to adjustable unit, so, its height can be easily adjusted.

Built-up Cone

Built-up cone is a conical tool which is placed inside the powder collection tray for checking the angle of substance flow during test.

Powder Collection Tray

It is a collection container located right under the powder flowing nozzle. Here, the desired substance whether powder or granule is dispensed.

Balance

Flowability tester has an integrated automatic balance with pre-set sample weight. Thus, it helps in determining the weight of flowing particles.

Main Frame

The main frame of the tester is made from durable and quality material. It is strong enough to keep all the parts together as a single equipment.

Stable Foot

Four feet are attached to the flowability tester on the bottom side. These enable the tester to stand up right and function smoothly by avoiding vibration and shaking.

6.What Are The Three Methods For A Flowability Tester?

Although, flowability tester is used for determining the flow properties of powders and granules, it is not always necessary that a single method will help in finding the exact flow behavior. For this purpose, three different techniques are used by the same flowability tester to check the flow. These are explained below:

Angle of Repose

Angle of repose method- Picture Courtesy: sotax.com

Angle of repose is a critical setup which is adopted for a flowability tester. In this method, additional built-up cone is placed inside the collection tray right below the funnel. Similarly, the flowability of particulates is checked by the horizontal angle of repose in degrees after adjusting the height of cone.

Orifice with Cylinder Setup

Orifice with cylinder setup- Picture Courtesy: sotax.com

Orifice with cylinder setup is another method employed to measure the flow of powder moving over powder. In this method, cylinder is used instead of cone and flowability is measured as mass per time flowing from any container. The flowability greatly depends upon the the type of hopper as well as the shape of orifice being used.

Orifice with Funnel Setup

Orifice with funnel setup- Picture Courtesy: sotax.com

Orifice with funnel setup is a frequently used method to stimulate the flow of materials during testing. Here, a single orifice at the end of funnel helps in the continuous flowing of particulates by just contacting the wall of hopper.

7.Where Can You Use A Flowability Tester?

Almost every industry, where there is processing of powders and granules, the need for a flowability tester can be realized to know their exact flow ratio. Similarly, we have highlighted some of the applications of a flowability tester in the upcoming paragraphs:

Pharmaceutical Industry

Various pharmaceutical solid dosage form- Picture Courtesy: anton-paar.com

Knowing the accurate flow of powders and granules is inevitable for the production of various pharmaceutical and nutraceutical dosage. Similarly, a flowability tester is always used in pharmaceutical laboratories and research centers to carry out this task.

Veterinary Industry

Veterinary oral powder sache- Picture Courtesy: bioveta.eu

Medications prepared for treating animals also need to be properly examined and made after thorough processing. Thus, the use of a flowability tester is also practiced in veterinary industry.

Herbal Industry

Herbal powder- Picture Courtesy: silverrootsagro.com

Herbs are often obtained from leaves and the inner parts of plants. That's why, most of the time you get a crushed mixture which is cohesive and rough. For this reason, an advanced equipment like flowability tester that comes with stirrer, can better help in the processing of herbal powder.

Detergent Industry

Scoop in detergent powder- Picture Courtesy: stock.adobe.com

The use of a flowability tester is also prevalent in detergent powder manufacturing industries. Here, the flow behavior of different solid cleaning agents like laundry powder and dish washing powder is examined in order to use compatible filling system for their packaging.

Food Industry

Various spice powders in spoons- Picture Courtesy: womenshealthmag.com

Flour, sugar, spices, coffee powder, and milk powder all are available in either powder or granules form. However, each substance has different flow ratio but how you will know that? Simply by using a flowability tester! It will help you employ the type of filling machine, technology, and hopper which is compatible to the type of ingredients.

Cosmetic Industry

Various cosmetic powders- Picture Courtesy: treehugger.com

We also have great variation of powders and granules in cosmetic industry. Similarly to find their flow properties, a flowability tester can be used for substances like compact powder, bleach powder, and eyeshades etc.

8.How To Clean And Maintain A Flowability Tester?

Regular cleaning and maintenance enable you to optimize the performance of your flowability tester and manage issues before they escalate. So, be careful not to skip these steps:

Operator setting a flowability tester- Picture Courtesy: collegedunia.com

Cleaning:Clean the washable parts of your flowability tester on regular basis which simply include the hopper, orifice, and container etc. For other external parts, use a soft moist cloth to remove the dust.

Monitoring:Keep evaluating the tester during operation for noise and abnormalities and try to find the root cause for effective troubleshooting.

Parts Changeover:As flowability tester use different tools for different methods, it is necessary to keep changing the parts in accordance with material requirements. In case of part damage, simply replace it with new one.

Adjustment:Conduct adjustment for your flowability tester both structurally and parameters wise. For instance, adjust the height of hopper, place of stirrer, and measurement setting of the control panel.

9.What Quality Standards Should A Flowability Tester Comply To?

Flowability tester must comply to internationally recognized quality standards in order to be termed as safe for pharmaceutical and other powders. Some of these quality standards include:

FDA logo surrounded by medicines- Picture Courtesy: pharmaoffer.com

International Organization for Standardization (ISO)

Good Manufacturing Practices (GMP)

Food and Drugs Administration (FDA)

Conformate European (CE)

American Society for Testing and Materials (ASTM)

10.Troubleshoot The Common Problems Of A Flowability Tester?

Flow problems of powder and granules cause frustration and result in huge time losses. That's why, flowability tester is tailored to counter these issues in advance and let you know the favorable environmental conditions and flowing method for your concerned particulates. So, let's know the troubleshooting of a flowability tester!

| i. Material not flowing | ||

Encircled agitator inside the hopper- Picture Courtesy: erweka.com |

Cause:

High environmental humidity causes blockage of material. Powders with high moisture content. Irregular shape particulates. |

Solution:

Operate the tester in an environment with no humidity. Reduce the moisture level. Use mechanical agitator. |

| ii. Slow flow of substance | ||

Granules filled hopper- Picture Courtesy: erweka.com |

Cause:

The hopper is small or overfilled causing poor material flow. There is error in flow volume setting. |

Solution:

Use large size hopper or leave the 1/3 area empty for effective delivery of particles. Adjust the setting by increasing volume at slow speed. |

| iii. Decreasing flow | ||

Highlighting decreasing powder flow- Picture Courtesy: erweka.com |

Cause:

Buildup of static charge can stick the particles to hopper surface. Too dry and fast-moving particles often cause electrostatic charges. |

Solution:

Eliminate the static by using electro-polish or adding Teflon coating to feeder surface. You may reduce the dryness level granulation. |

| iv. Material clumping | ||

Powder clumping- Picture Courtesy: azom.com |

Cause:

High humidity level often leads to particles coalescence. Production of electrostatic charges. Cohesive particles form lumps. |

Solution:

Reduce the humidity level. Ground the feeder to avoid static buildup. Reduce particles cohesion. |

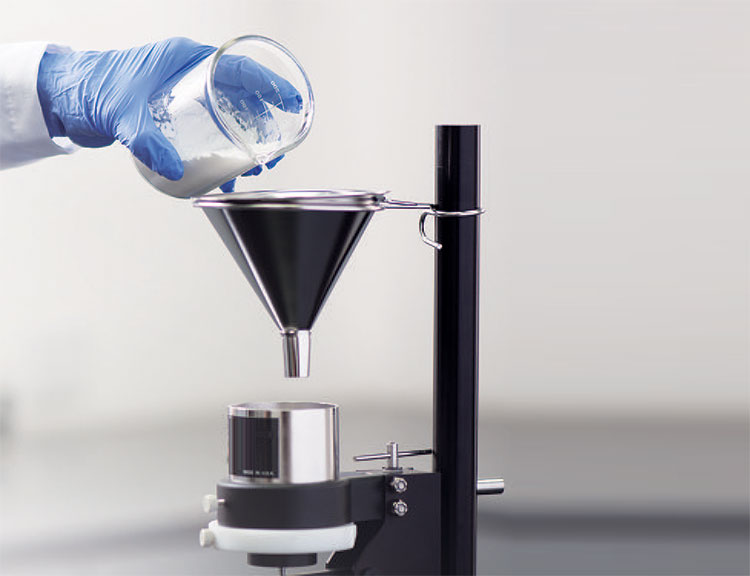

11.What Are The Top Considerations For A Flowability Tester?

Whenever you intend to purchase a flowability tester, make sure to consider some of the crucial factors that may help you in finding your ideal flowability tester for powder and granules. Here, we have enlisted few tips for you:

Degree of Automation

Operator feeding the funnel- Picture Courtesy: teledynelabs.com

Flowability testers come in varying degrees of automation and specifications. So, you meet to determine what type of equipment you are aspiring for. It will simply relate to your current production scale. For example, if you are running large size manufacturing then opting for latest flowability tester will be a good choice. In contrast, a semi-automatic or hand operated tester may well good for you.

Adaptability

Adaptability is the key for selecting an effective flowability tester. It relates to all kinds of testers as it deals with the type and volume of material you want to process. So, must check if you can conduct modification for the desired tester like changing the hopper size and adding an agitator etc.

Quality Compliance

Quality icon- Picture Courtesy: adobe.stock.com

It is important for every flowability tester to comply established standards and adhere to their policies. So, make sure to check the quality compliance along with necessary certifications.

Cost

Estimating cost & placing coins in a jar- Picture Courtesy: brother.co.uk

Cost also matters a lot! After all the game is all about profit. So, ask your vendor to show you flowability testers with different prices along with their operation and maintenance cost and then take a final decision.

Conclusion

Let's wrap up this informative review about a Flowability Tester: The Complete Buying Guide In 2024! We hope you have understood all the above-mentioned information in a well manner. No doubt, the discoveries in science and technology has also raised concerns regarding the products safety especially in a sensitive field like pharmaceutical industry. In such a case, the use of a flowability tester become inevitable. Thus, we are aiming to meet your needs by designing sophisticated flowability testers which come along with one year of warranty. So, if you are interested in purchasing it, don't forget to contact us!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide