Flow Wrapping: The Complete FAQ Guide In 2025

Flow Wrapping: The Complete FAQ Guide In 2025

In the realm of packaging, finding the best option which at times is cost-effective, safe, light-weighted, and vibrant is somehow tricky. But what if you find all these attributes in one packaging format? Of course you would have longed for it! And that is the one and only Flow Wrapping.

Yes, you are at the right place! We are about to disclose on you what basically flow wrapping is, its advantages, different forms, material used, application and lots of other things. So, be ready to transform your business by bringing in it the flow wrapping method. Keep reading and learning!

1.What Is Meant By Flow Wrapping?

Cake rusk flow wrap- Picture Courtesy: designerpeople.com

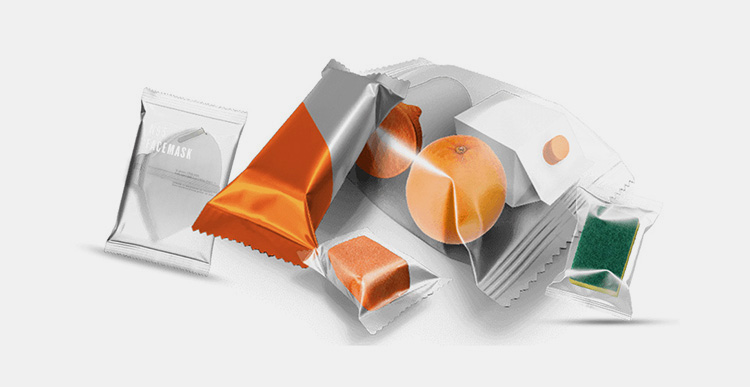

Flow wrapping is one of the prominent methods of flexible packaging which is used to wrap different kinds of solid products in a plastic film such as chocolate bar, cookies, gloves kit and hardware tools etc. This wrapping of goods in a film is carried out horizontally and the package is created by stringently sealing the top, bottom, and back side.

As far as the appearance of flow wrapping is concerned, so, it resembles pillow. That's why it is also called pillow pouch wrapping. This flow wrapping is extremely versatile, convenient to use, and is cost-effective while maintaining attractive visual appeal.

2.Enlist The Benefits Of Flow Wrapping?

Flow wrapping is universally accepted means for packing myriad of goods and objects due to its outstanding benefits. These advantages you will better understand in the upcoming paragraphs:

Versatility

Various sizes of chocolate bar flow wrappers- Picture Courtesy: kissmyketo.com

Flow wrapping is surprisingly a versatile packaging solution. Here, the term versatility is used in dual sense: one for the flow wrapping flexibility to pack unlimited objects including food, hardware, and pharmaceuticals and the other for its resilient material which can be molded in any shape, size, and design.

Enhanced Protection

Opened flow wrap of chocolate coated biscuit- Picture Courtesy: one1brands.com

Another benefit of flow wrapping is its airtight sealing which helps in eliminating the risk of material getting contaminated or affected by external elements such as moisture, air, and pollution. Therefore, the security of products are enhanced and their shelf life is also prolonged.

Cost-effective

Cost-effective icon- Picture Courtesy: newsfrs.top

Unlike rigid packaging where multiple expensive containers like cans, jars, and bottles are used, flow wrapping provide cheap, light-weighted, and easy way for packaging. Hence, your packaging costs are reduced to greater extent.

Marketing

Consumer holding food flow wrappers in hand- Picture Courtesy: worldbranddesign.com

Flow wrapping provide you the chance to print multiple information regarding your brand and product. In this way, you can beautifully design your flow wrapping which will mesmerize the consumers when laying on the shores of shelves on one hand while as communicating the information to them on the other.

3.What Products Are Suitable For Flow Wrapping?

When it comes to enumerate the things compatible for flow wrapping, the list will be long lasting. So, for your convenience we have enlisted them under few headings. Have a look towards them!

Confectioneries

Consumers holding single-unit flow wrappers of chocolate bars

All kinds of confectioneries encompassing long chocolate bars to small single candy, bubble gum, and gummy can be perfectly packed through flow wrapping.

Baked Goods

Flow wrapped breads- Picture Courtesy: papermart.com

Baked goods are also suitable for flow wrapping which can greatly maintain their crisp and delicacy. The common examples here include cookies, biscuits, pastries, and breads etc.

Perishable Food

Various fruits & vegetables in basket- Picture Courtesy: littleyellowwheelbarrow.com

Perishable food whether is it cooked meal, seafood or uncooked meat and chicken are also desirable to be packed using flow wrapping technique. It is because the sealing created through flow wrapping is fully stringent that keeps the inside product intact.

Medical Tools

Different medical tools- Picture Courtesy: adctoday.com

We know that medical tools such as gloves, scissors, blades, and syringes are kept in a safe and protected environment to restrict the bacteria. Therefore, flow wrapping is the ideal means to be adopted for flow wrapping medical equipment in plastic film.

Drugs

Capsules & tablets along with bottles- Picture Courtesy: cremer.com

Drugs including capsules, tablets, and pills can also be packed through flow wrapping because most of the time drugs are combined in one package for customer convenience and their protection against environment.

Cosmetics

Strawberry soap flow wrapping presentation idea- Picture Courtesy: nivea.com

Cosmetics items are among other products which are eligible for flow wrapping. For instance, makeup sponge, lipsticks, and face powder kits are often delivered using flow wrapping.

4.What Type Of Packaging Is Suitable For Flow Wrapping?

Understanding in depth the packaging suitability for your flow wrapping will significantly help you to optimize your packaging process. In this way, we have provided a detailed description regarding the common formats which are practiced with flow wrapping. These are as follows:

Single-Unit Packaging

Individual candy flow wrappers

It refers to the packaging when single item is packed through flow wrapping such as a candy, bread bun, a chocolate bar, or a toy. Similarly, it beautifully encase an individual item and present it in an attractive way.

Multi-Pack Packaging

Biscuits Multi-Pack flow wrapper- Picture Courtesy: packagingoftheworld.com

Flow wrapping is also employed to efficiently pack multiple items together. For instance, you can group the number of biscuits in a single package through flow wrapping while retaining their individual integrity.

Pillow Pouch Packaging

Various chocolate chips cookies pillow pouches- Picture Courtesy: choczero.com

Mostly, flow wrapping is used to create pillow pouches where the package is pumped with air, so, that the product laying inside is completely safe from damage. These pillow pouches have the ability to astonishingly stand upright on market shelves.

Gusseted Pouch Packaging

Gusseted flow wrappers of biscuits- Picture Courtesy: Behance

Gusseted pouches have additional space to hold large size product. Therefore, flow wrapping can form gusseted pouches by folding a flat film inward and create accommodation to carry things like soap, tissue papers, vegetables, and lunchbox etc.

Perforated Tear Strips

Tear strip tissue flow wrapper- Picture Courtesy: temu.com

The most irritating thing about flexible packaging is its rigidity in opening. To end this trouble, perforated tear strips can be formed in flow wrapping to promote convenience in package opening.

Promotional Packs

Flow wrapping of promotional pack- Picture Courtesy: stellerpacking.co.uk

Manufacturers new in the business realm often adopt the strategies to attract consumers. Therefore, they try to gift an additional thing with their main product in order to promote their business. Similarly, flow wrapping can be helpful in this way to aid the process.

Variety Pack

Nestle Variety Pack Chocolate Bar 6- Picture Courtesy: hancock.com

Flow wrapping can form variety pack for products with different flavors and variants. In this way, you can showcase multiple packed items like group of chocolates, candies, and chips etc., in a single flow wrap pack.

5.How Does Flow Wrapping Take Place?

The process of flow wrapping takes place in extremely straight forward way. You can understand it easily by reading the underlying steps attentively:

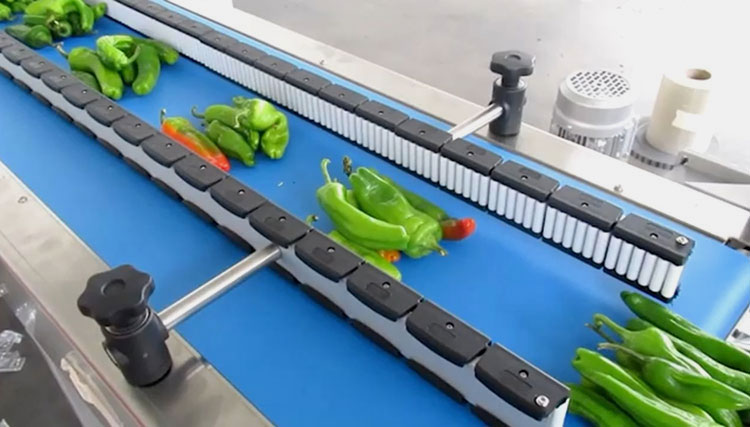

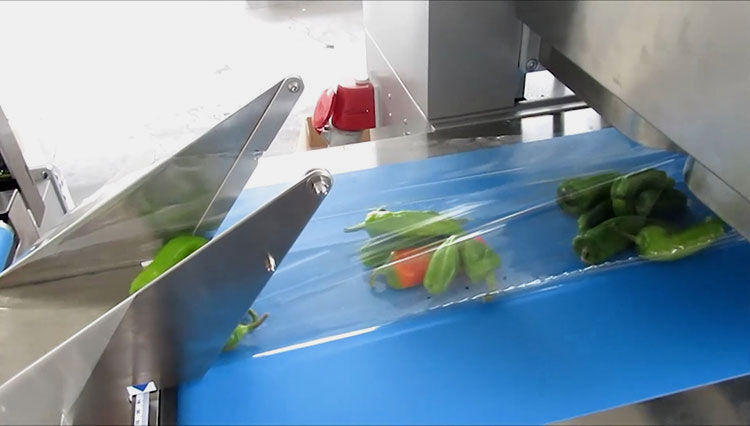

Product Feeding

Product feeding on conveyor belt- Picture Courtesy: mftecno.com

In first step, the product is fed onto the conveyor of flow wrapping machine either manually or automatically. This product is then horizontally transported by an infeed conveyor towards flow wrap forming. Once, it reaches the forming station a pause is taken by the machine.

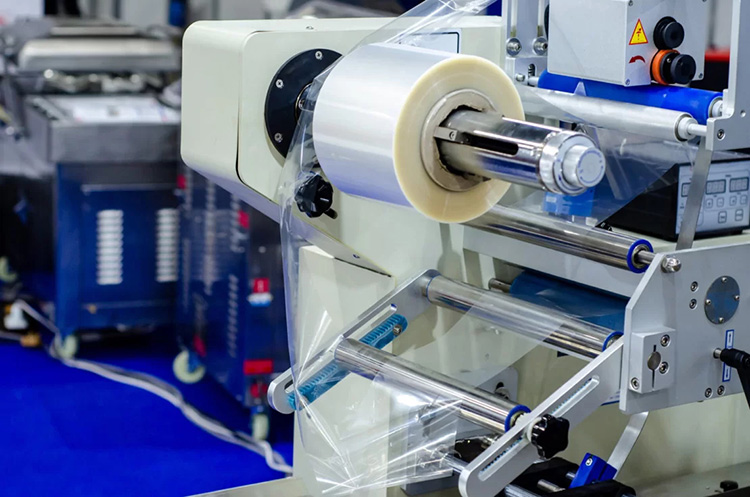

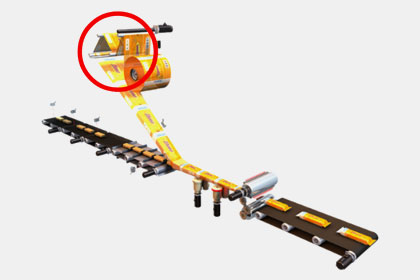

Film Unwinding

Film unwinding- Picture Courtesy: mftecno.com

In second step, the unwinding of film get started through web control whose continuous rotation lead to the release of film over product. During this phase, the driven rotary rubber and nipped steel rollers make sure that the film is not stretched harshly causing breakage.

Flow Wrap Forming

Flow wrap forming- Picture Courtesy: mftecno.com

Moving forward, the film is guided by a forming mechanism and accurately wrapped around the product in such a way that product is fully incorporated inside the film and film is moved in a direction to form tubular shape. At the same time, the edges of film are joined together at the center.

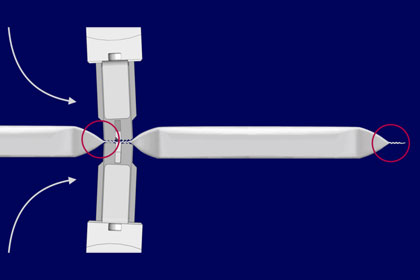

Flow Wrap Sealing & Cutting

Flow wrap sealing & cutting- Picture Courtesy: mftecno.com

In fourth step, the flow wrap along with product is moved ahead and the joined edges of film are sealed at the center in a longitudinal way. The same sealing step is carried out for the start and end of flow wrap and the cutting of flow wrap from rest of the film takes place in this step.

Flow Wrapper Discharging

Flow wrapper discharging- Picture Courtesy: mftecno.com

At last, the finished flow wrap package is moved away from the sealing/ cutting station by a conveyor belt and transported to other equipment for secondary packaging.

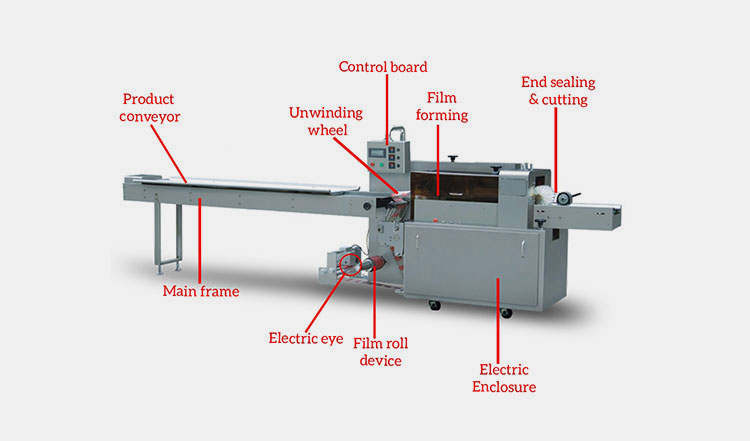

6.Describe The Various Components Of A Flow Wrapping Machine?

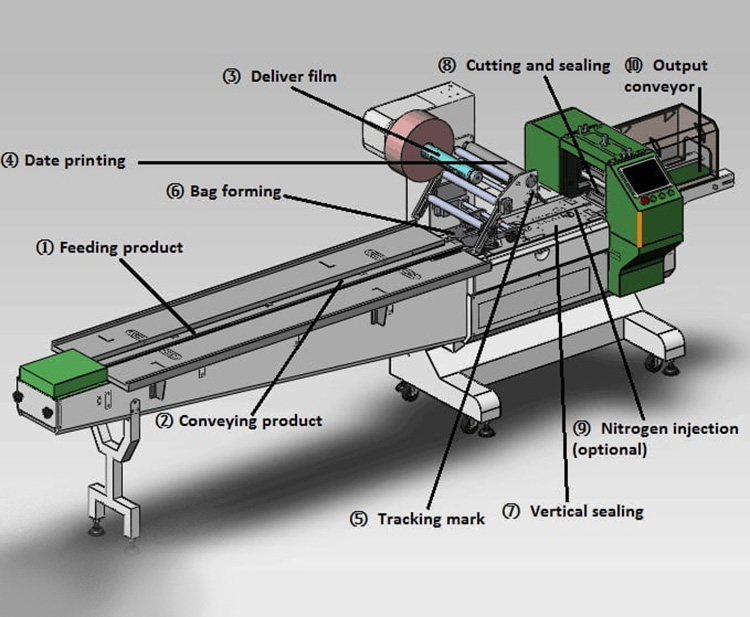

Flow wrapping machine has long horizontal body comprised of several components each performing particular task. These parts along with their functions are described below:

Components of Allpack's APK-450B High speed pillow plate automatic hardware flow wrap machine

Product Conveyor

Product conveyor is a long, flat, and linear conveyor belt attached to the machine. Its function is to supply the machine with product which is meant to be flow wrapped. It also discharge the finished flow pack from machine.

Main Frame

The main frame of flow wrapping machine is the overall supporting body of machine. It is made from corrosion resistant stainless-steel and all the components are integrated to it. Thus, it plays instrumental role in ensuring stable operation.

Film Roll Device

Film roll device is attached to the machine around which the film roll is fitted for providing machine with the film.

Electric Eye

Electric eye is located alongside the film roll device and perform the function of detecting film during unwinding. Moreover, its precise servo registration aids the step of film printing such as date and batch no coding on fixed area.

Unwinding Wheel

Unwinding wheels are movable shafts or known as drive rotary rubber which pull the film from roll and thus carry out film unwinding. This task is accomplished responsibly to eliminate the possible stretching of soft film.

Control Board

Control board is the brain of a flow wrapping machine. It consists of a touch screen interface, through which user set the internal parameters of machine like conveyor speed, sealing heat, and cutting space of film etc., power button, and emergency stop.

Film Forming Mechanism

Film forming mechanism is responsible for wrapping the film around product in a tubular shape, so, that the film can be moved ahead for sealing and cutting.

End Sealing & Cutting

The sealing and cutting station is another important part of the flow wrapping machine which perform the ultimate task of film sealing and cutting. It is important to mention that a longitudinal sealing is located formerly to the right and left side sealing of film. Therefore, cutting is done after sealing.

Electric Enclosure

Electric enclosure is a large box containing inside it the electrical system of flow wrapping machine in form of wires, switches, and fuses. It protects these components and help in preventing the pmachine from shocks.

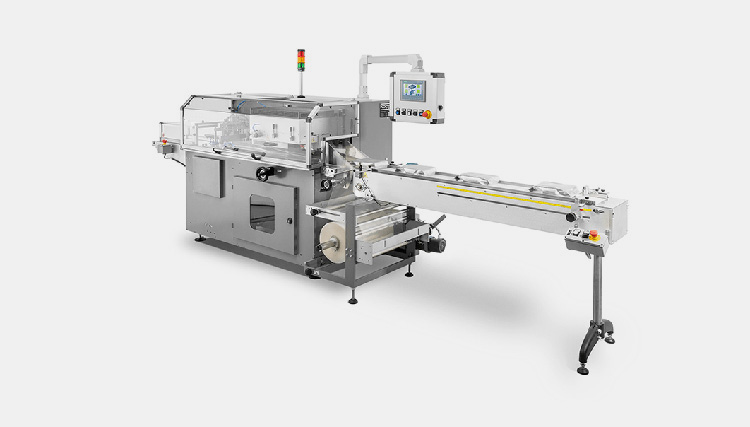

7.What Are The Different Flow Wrapping Machines?

There are number of flow wrapping machines depending upon the type of product. These are mentioned as under:

Capsule/tablet/blister plate Flow Wrap Machine

Allpack APK-350C High speed reciprocating capsule/tablet/blister plate flow wrap machine

This type of flow wrapping machine is used for wrapping the blister pack of tablets and capsules. The machine is fully automated and support integration of other machines with it. Its output ratio stands at packaging up to 150 bags per minute.

Structure

It consists of a stainless-steel body, transparent protection window, blister packs magazine, product feeding conveyor, alarm, film roll, forming station, control board, film sealing, and cutting tools etc.

Process

Its process begins with machine dropping the tablets or capsules' blister packs from magazine onto the conveyor. The conveyor then takes the blister plate towards flow wrapping where film is wrapped around the blister plate, sealed in a longitudinal side, right and left side. Ultimately, the finished flow wrap package is discharged by the machine.

Automatic Card Flow Wrap Machine

Allpack APK-300A-1 Automatic card flow wrap machine

As the name illustrates, this machine has been manufactured to pack the stickers, cards, and plasters in flow wraps. Its speed of forming flow wrap is 40 to 200 bags per minute.

Structure

The structure of machine is made up of two separate units joined by a conveyor and electrical system. The major components include card sucking rotary disc, conveyor, film roll wheel, bag former, horizontal sealing, vertical sealing and cutting devices, control panel, and electrical enclosure etc.

Process

It functions automatically when an operator start the machine. The card sucking rotary disc start moving in circular motion, pick up the cards and place them over conveyor. The conveyor then transport these cards to film forming around them after which the sealing and cutting is carried out.

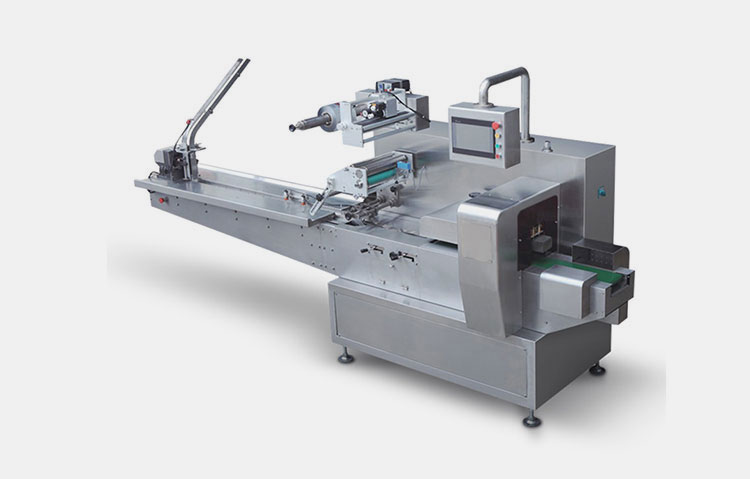

Pillow Plate Hardware Flow Wrap Machine

Allpack APK-450B High speed pillow plate automatic hardware flow wrap machine

Another type of flow wrapping machine is pillow plate hardware flow wrap machine designed to pack different kinds of small to large hardware objects such a as biscuits, rubber bands, sanitary napkins, and paper cups etc. The machine is capable of processing around 160 bags in a single minute.

Structure

The overall structure of machine is compact with long conveyor. It consists of a guide rail, main frame, film feeder, electric eye, film unwinding system, control panel, bag forming, sealing, and cutting tools etc.

Process

Here, the product is either manually or automatically fed to the machine through conveyor. The same product then undergo the phase where film is unwinded and wrapped around it. Similarly, the film is turned into the tubular shape and get sealed for final phase. At the end, individual flow wraps are separated through cutting and discharged from the machine.

Medical Products Flow Wrap Machine

APK-300B High speed full automatic medical products flow wrap machine

This is another type of flow wrapping machine particularly designed to pack medical products like masks, gloves, surgical tools, syringes and food products as well including mooncakes, and fruit pie etc. The machine can also be integrated with other machines to make a line. Its production capacity stood at outstanding ratio of 150 bags per minute.

Structure

It has a comparably composite and stable structure comprising a long conveyor belt, electric detection system, large control unit, film reel, bag former, data printer, bag sealing and cutting tools etc.

Process

Its working principles is similar to the former machine where firstly, the product is conveyed to machine through conveyor and simultaneously, the film start unwinding from reel. Secondly, the product is well wrapped in a film through bag former and moved ahead for sealing. Thirdly, the longitudinal vertical sealing has been introduced to the bag followed by horizontal sealing of the bag top and bottom side, its cutting and discharging.

8.Differentiate Between Cold Sealing Vs Heat Sealing For Flow Wrapping?

Flow wrapping can be sealed in one of two ways: cold sealing and heat sealing. Now, it is important for you to know what these two sealing methods are and how they differ from each other. So, consider the table below:

| No | Aspects | Cold Sealing of Flow Wrapping | Heat Sealing of Flow Wrapping |

| 1 | Definition | Cold sealing is a type of sealing technique employed for flow wrapping where adhesive substance is used to efficiently seal the film and create a strong sealing. | Heat sealing is the common method of binding flow wrap plastic film through the warmth of heat. |

| 2 | Process | Its process is fast where only pressure is needed to join the adhesive edges of flow wrap. | While as, heat sealing process is a bit lengthy with sealing tools getting heated and then pressed to weld the film together. |

| 3 | Material used | A sticky material like glue is used for cold sealing of flow wrapping. | On the other hand, heat sealing require temperature to seal the film. |

| 4 | Suitable for | It is best for sensitive products like chocolates, candies, and drugs to avoid melting and contact with temperature. | Heat sealing is good for hardware objects having low sensitivity to heat such as biscuits, breads, and cakes etc. |

| 5 | Cost | Cold sealing is comparably expensive both due to the film used for it and the adhesive sealing substance. | In contrast, heat sealing is cost-effective and environmentally friendly. |

| 6 | Sample |

Cold sealed chocolate flow wrappers |

Heat sealed choco biscuit flow wrapper- Picture Courtesy: hellosubscription.com |

9.Explain The Applications Of Flow Wrapping?

Flow wrapping can be applied for all kinds of solid products manufactured in different fields. These manufacturing industries have been highlighted below:

Medical Industry

Medical drugs and tools- Picture Courtesy: techbullion.com

Medical industry is an area highly concerned about maintaining the hygiene and sensitivity of different products whether these are medical tools or drugs. Hence, the most cheap and suitable way for fulfilling this aim is flow wrapping which has been practiced in this area since long ago.

Food Industry

Various chocolate bars flow wrappers

Another notable industry is the busiest one on which human survival is dependent, which is indeed food industry. Hence, regardless of the size and shape this sector can greatly take advantage of flow wrapping for the safety of their products and promotion of their respective brands in global food realms.

Cosmetic Industry

Soap flow wrapping- Picture Courtesy: packagingoftheworld.com

Beauty care is among the top preferences of people for which they use cosmetic items including soaps, makeup kits, lipsticks, shampoo packs, and creams etc. These all products can be delivered through flow wrapping either as a primary packaging or secondary packaging.

Hardware Industry

Various highlighters- Picture Courtesy: jetpens.com

Hardware industry is a comprehensive term where toys, kitchen tools, housewares, stationary, and electrical components are considered. Therefore, flow wrapping can be easily employed in these areas for effective packaging.

10.What Packaging Material Is Used For Flow Wrapping?

Flow wrapping use different types of films and packaging materials depending upon the products being packed. For instance, food products are packed in food-grade films. Therefore, the below description will provide valuable insight in this way:

Various types of packaging films- Picture Courtesy: naharpolyfilms.com

Heat Sealing Film

Flow wrapper can be made by using a thin thermoplastic film which is suitable for heat sealing. The most common material used in this way is polyethylene (PE) and Polyethylene terephthalate (PET). These are cheap in price and get easily sealed through application of little heat and pressure.

Cold Sealing Film

Another type of material which can be used for flow wrapping is sort of cold sealing film. These include a metalized film with strong shiny appearance and an aluminum film. Although they are but expensive but these materials are best suitable for cold sealing and offer great protection against moisture and oxygen permeation.

Composite Film

Composite film is the combination of multiple layers of different film including PET, PE, and PP to provide extra safety to the product. Despite its high durability, its recycling of composite film is extremely difficult.

Mono- Film

Mono-film is derived from the multiple layers of same material to increase flow wrapping robustness and quick recycling. However, it may require more heat and is prone to damage due to being made from single type of plastic. Therefore, 5% inculcation of hybrid additive is allowed to end this problem.

Paper Wrap

Paper wrapping material is the most environmentally friendly wrap which can be used along plastic film for the flow wrapping of products.

11.Is Their Any Leak Test For Flow Wrapping?

Vacuum leak tester for flow wrappers- Picture Courtesy: sanatron.com

Definitely yes! There is a proper leak test adopted for checking the possible leaks of flow wrappers. This test is known as vacuum leak test or pressure decay test. It is an important step carried out for quality control of the flow wrapping which can prevent the loss of products caused by their contamination.

In this vacuum leak test, a flow wrap pack is placed inside an empty chamber of vacuum leak tester. The machine then evacuate the air from chamber. At this point, when a flow wrap has any leak, the pressure inside chamber will drop and the size of leakage will be determined by the rate of pressure loss over time. On the other hand, if flow wrapper is not leaked the pressure inside chamber will remain constant.

12.What Are The Labeling Requirements Of Flow Wrapping?

Labeling is an important aspect of flow wrapping that help you attain your goal of communicating with customers. In this question, you will know about how labeling can be beneficial for flow wrapping. Consider the information below:

Enhance Charm

Various cookies flow wrapping packs

By applying effective labeling onto your flow wrapping can grab the attention of potential buyers, because it is the labeling, colors, and fonts that speak and allures the eyes of customers.

Convey Information

As we have talked about the different applications and uses of flow wrapping it is clear that the product inside package must have essential information like its name, the company name and validation date. Similarly, through labeling you can convey your valuable customers regarding the important data about product.

Alarm Customers

Many products come with certain limitations. For example, there are few kinds of toys which are not meant for babies under 1 year. Similarly, some food products have common allergens like gluten, sugar, and wheat etc., about which users must be warned. Therefore, it is the labeling that works for customers safety.

Market Distinction

Consumer holding a chocolate bar flow wrapper- Picture Courtesy: nosh.com

There are hundreds and thousands of flow wrappers laying in shops and markets loaded with multiple goods. How your flow wrappers can be distinguished from other? The answer is through enchanting and customizable labeling.

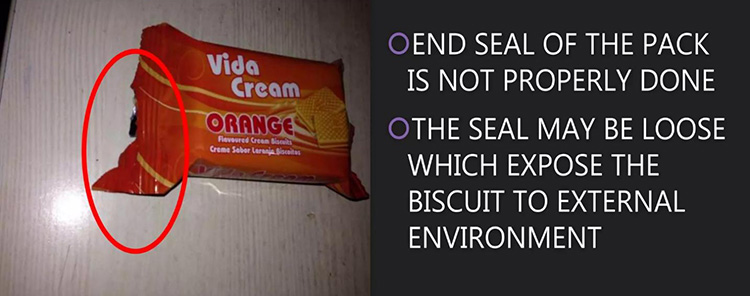

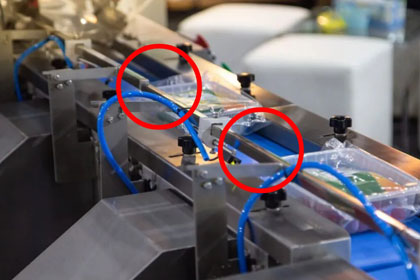

13.How To Tackle The Common Issues Of Flow Wrapping?

During the implementation of flow wrapping you might face issues which can be easily tackled provided that you have information regarding them prior to their occurrence. For this, follow the guidelines given below:

| No | Issue | Cause | Solution | Picture |

| 1 | Film pulling problem | Either the film spindle do not move freely or the film roll is not centered | Check the drive rotary rubber wheel and take measures accordingly if it is stagnant |

Encircled film unwinding of flow wrapping- Picture Courtesy: jochamp.com |

| 2 | Scratches in sealing | Sometimes the blunt knife create scratches while cutting | Make sure the cutting blades are fast and free of debris |

Leaked flow wrapper- Picture Courtesy: greencorp.com |

| 3 | Bad sealing | The distortion of sealing is caused by inappropriate or excessive heat | Modify the temperature of heat sealing jaws to resolve this issue |

Encircled sealing jaws- Picture Courtesy: greenercorp.com |

| 4 | Abnormal sound of transmission parts | It occurs when the transmission gear or chain are damaged | Replace the transmission parts to solve this problem |

encircled transmission/ conveying system- Picture Courtesy: pwrpack.com |

14.Tips To Get Started With Flow Wrapping Packaging?

In the final question of this FAQ guide, we’ll guide you on how to get started with flow wrapping, providing instrumental steps and tips for a successful application of flow wrapping in your respective businesses. These are as follows:

Determining Products

Noddle flow wrap- Picture Courtesy: fiverr.com

Firstly, you need to determine the type of products you are manufacturing or have an intention to produce in near future. Here, it is important that the products or items must be of solid nature.

Examining volume

Stacked gusseted chocolate flow wrappers- Picture Courtesy: Behance

Secondly, it is essential to examine the rate or volume of goods you are manufacturing. For instance, whether you are running a small scale business, medium scale, or large scale.

Reviewing Budget

Reviewing budget icon- Picture Courtesy: startupbiz.co.zw

Thirdly, budget is one of the significant factors to look for before starting a flow wrapping. It is because flow wrapping can be made from different packaging materials along with different machines. So, keeping in mind these aspects you will opt for materials and machines in compatibility with your budget.

Opting for a Machine

APK-350D High speed Four servo reciprocating flow wrap machine

The final step is of purchasing the most suitable flow wrapping machine which is compatible to your production needs regarding the type of goods, the bagging capacity, and price range. It will transform the growth and success of your business if you keep it maintain regularly.

Conclusion

To summarize, it can be drawn into conclusion that this FAQ guide about Flow Wrapping is covering each and every aspect of flow wrapping whether its benefits, applications, working process or machines used for it. We are sure your all queries regarding flow wrapping has been answered and now you are able to bring this effective packaging method into your manufacturing. If you are eager to do so, then don't make any delay and contact us today as Allpack is providing you the world's top flow wrapping machines with one year of warranty!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Flow Wrapping: The Complete FAQ Guide In 2025 Read More »