Film Wrapping Equipment: The Complete FAQ Guide In 2025

Film Food Wrapping Equipment - Picture Courtesy: Packaging Machine

Do you know about a film wrapping equipment? Are you interested in buying a film wrapping machine? Do your production processes require a film wrapping machine? Are you confused in buying the right type of film wrapping machine for your process? This platform where you will get all your queries solved. This FAQ guide will help you in know about what is a film wrapping equipment and how does it work. This guide is for your assistance so take the most of it.

1.What Is Film Wrapping Equipment?

Automatic Film Food Wrapping Equipment- Picture Courtesy: Packaging Machine

A film wrapping equipment is a modern type of wrapping equipment that is used for packaging purpose to maintain quality of product and avoid contamination. Large number of industries whether in small scale or large scale are using different types of film wrapping equipment to make their product look presentable and to ensure product freshness for longer period of time. It usually prevents the entrance to moisture, humidity dust and microbes that can cause spoilage and wastage.

2.What Are The Industrial Applications Of A Film Wrapping Equipment?

Film wrapping equipment is nowadays globally used in many types of process and packaging industries. Various types of product irrespective of their shape can easily be wrapped using a film wrapping equipment. Some of the industries that use film wrapping equipment in their packaging processes are

Food Industry

Automatic Film Wrapping Equipment

Food industry mostly consumes film wrapping equipment to pack different types of food product as they can easily get contaminated if any of the environmental factors enter it. Food products like fruits, vegetables, meat, cookies, bakery products and others are packaged using a film wrapping equipment.

Beverage Industry

Film Wrap For Packaging- Picture Courtesy: Packaging GURUji

Some of the juice, water and other of the beverages industry products that are filled in sizes of bottles, cans and jars are finally film wrapped using a film wrapping equipment. These products can be secured for a longer period while they are travelled around the globe.

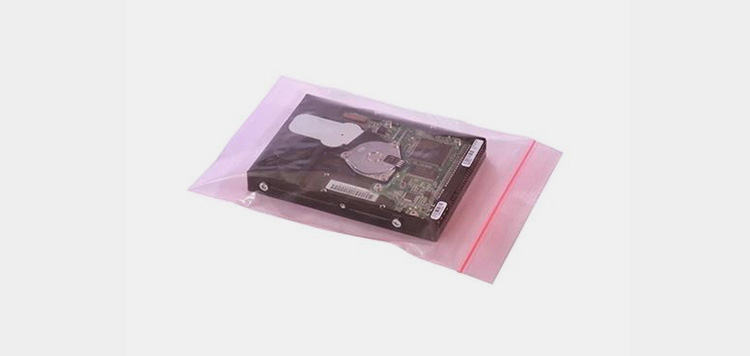

Electronics Industry

Electronics Product Film Wrap - Picture Courtesy: Rocket Industrial

In electronics industry, many parts and components can easily get affected once they get in contact with moisture or humidity. To counter this problem while they are travelled globally, film wrapping equipment is used to pack them in a highly precise and efficient manner.

Pharmaceutical Industry

Pharmaceutical Wrap - Picture Courtesy: ME Shrink-wrap

Pharmaceutical also uses film wrapping equipment to secure the quality and chemical composition of medicines. The wrapping ensures that products remain tamper free and strong seal is provided to these products.

Cosmetics Industry

Film Wrap Plastic - Picture Courtesy: The Stadel

Chemical and cosmetics industry also use film wrapping equipment for packaging of seeds, creams, bottles and other products so that their quality remains the same for a longer period.

3.What Are Benefits We Can Get From A Film Wrapping Equipment?

Some of the benefits of a film wrapping equipment are

Protection

Plastic Film Wrap - Picture Courtesy: Thong Guan

The most important benefit of a film wrapping equipment is that is provides complete protection to the products that are wrapped using it. Any type of microbial or environmental impact can be blocked for a longer period and products can reached their destination safely.

Shelf Life

Role Of Packaging - Picture Courtesy: Printon Pack

Products that are film wrapped have greater shelf life as compare to those which are transported openly. The external elements are prevented by the tight seal of film wrap and products freshness remains the same with extending its shelf life.

Productivity

Productivity

Either it’s a manual or automatic film wrapping equipment; both of them are highly versatile that thousands of products can be wrapped in a fraction of time. The wrapping process is operated at a very high speed that any manufacturer can be benefited by a film wrapping equipment to increase its productivity.

Quality Packaging

Film Wrapping Machine- Picture Courtesy: Packaging Machine

One of the most unique advantages of a film wrapping equipment is that it shows consistency in its packaging process and results in fine quality products. The process remains synchronous and high standards of quality are ensured through the wrapping process that directly attracts the customer and increases market demand.

4.What Are The Working Principle Steps Of A Film Wrapping Equipment?

Cling Film Wrapping Machine

A film wrapping equipment works in a highly precise and efficient manner. The steps involved in the wrapping process of a film wrapping equipment are

Initially, the product is fed into the system either manually or automatically. For automated film wrapping equipment, the products are placed on conveyor so that it can enter the system.

The wrapping film is placed on the film roller on the same time so that once the product reaches the wrapping area it can easily be dispensed off.

Once the product reaches the wrapping area of system, the sensors detects it movement and holds it for properly wrapping. Film is than applied onto its surface both vertically and horizontally so each of the area can be covered properly.

For some of the products sealing process is also done in the heat tunnel or by manual heat guns so that the film can be placed uniformly on products.

Finally, the cutting of film is done by sharp blades and the products are taken out of the system. Conveyors in the automatic film wrapping equipment are used to perform this task.

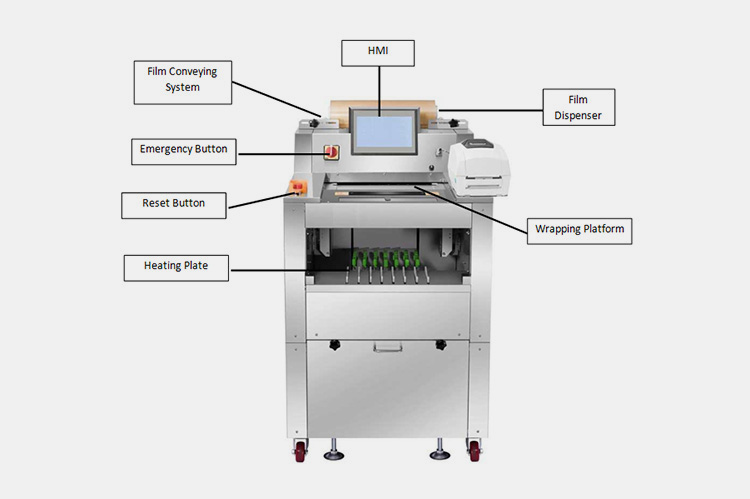

5.What Are The Main Components Of A Film Wrapping Equipment?

Film Wrapping Machine- Picture Courtesy: Packaging Machine

A film wrapping equipment is highly precise and accurate equipment for applying film on products. Each of its components performs a special task. The components are

Film Conveying System

In a film wrapping equipment, film rollers in film conveying systems that holds the film that has to be dispensed. The film roll is uniformly dispensed from this conveying system that avoid any type of burr or irregular sealing.

Film Dispenser

This is the part in which the wrapping film is loaded. The dispenser holds the film and makes possible and continuous supply of film throughout the wrapping process. The tension is film is created here so that no extra or less amount of film is applied.

Wrapping Platform

A film wrapping equipment has a unique platform where the wrapping process is done. It can be easily seen in manual film wrapping equipment whereas in an automatic one the platform is inside the tunnel or room for perfect placement and film on each surfaces of the product.

Heating Plate

Hot plate or heating plates are mostly found in manual film wrapping machines where the final wrapped product is placed on this plate so that the film can be gripped properly due to heating. It keeps the material when travelled for longer distances.

Human Machine Interface (HMI)

All the machines operational parameters can be easily monitored and set through this human machine interface. From conveyor speed to film wrapping dispensing duration, each of the machine’s operation can be controlled by the operator using this HMI.

Buttons

Both emergency and reset buttons have their own individual operation. A reset button is used to offset the system in case of any problem or troubleshooting whereas the emergency button is used to stop the system if any unwanted scenario is scene.

6.What Are The Common Types Of Film Wrapping Equipment Available Globally?

Some of the common types of film wrapping equipment according to its automation are as following

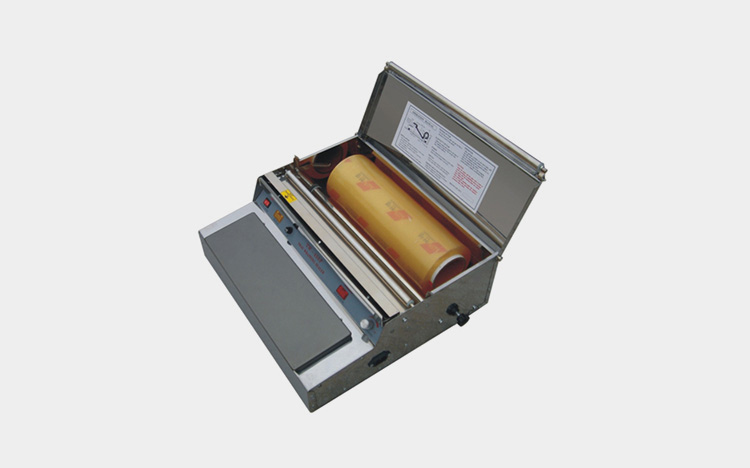

Manual Film Wrapping Equipment

A manual film wrapping equipment is most commonly used in small scale industries where the production requirements are marginally low. This type of equipment requires complete human involvement in each of its operational step and is low in cost.

Working Principle Of Manual Film Wrapping Equipment

- The product is carried by the operator to the system and placed on wrapping platform.

- The wrapping film is then placed on the product by the operator that is placed on the dispenser roller.

- Once all the sides of product are wrapped properly the edges of it are sealed wither by hot iron rods or in heat tunnel.

- Finally, the product is placed on the hot plate for properly sealing and then taken out of the equipment to check its quality. The products are then moved towards transportation.

Semi-Automatic Film Wrapping Equipment

The other type of a film wrapping equipment is a semi-automatic one. In this type of machine both manual and automatic involvement is present and is flexible for production setups that are medium in size.

Working Principle Of Semi-Automatic Film Wrapping Equipment

- The operator initially places the film roll on the roller that is to be dispensed in the system. The products are placed on the conveyor so that they can be smoothly entered into the system.

- Once the product reached the wrapping station, the wrapping film is then dispensed on it in a way that all of its areas are covered properly.

- As the wrapping process gets complete the products are taken out of the station and the operator is responsible to cut all of its excess film to make it look presentable.

- Sealing is also done of the cutting surface using hot plates to make it tight and contamination free.

- Finally, the products are taken out of the equipment to check its quality. The products are then moved towards transportation.

Automatic Film Wrapping Equipment

Industries or manufacturers that have high amount of film wrapping process and requires thousands of wrapped products in a day prefer using a fully automatic film wrapping equipment. A fully automatic film wrapping equipment works in a highly precise and efficient manner to meet the high production with pure quality.

Working Principle Of Automatic Film Wrapping Equipment

- The operator initially places the film roll on the roller that is to be dispensed in the system. The products are placed on the conveyor so that they can be smoothly entered into the system.

- Once the product reached the wrapping station, the sensors get activated and wrapping film is then dispensed on its surfaces in a way that all of its areas are covered properly.

- As the wrapping process gets complete the products move towards the cutting process where all of its excess film is cut to make it look presentable.

- Sealing is done in the next process in heat tanks so that the film gets tight and makes the product contamination free.

- Finally, the products are taken out of the equipment via conveying system and its quality is checked. 99% of the products are identical in their appearance and are then moved globally.

7.What Type Of Films Are Wrapped Using Film Wrapping Equipment?

There are numerous types of films available in the global market but are you familiar that which type of the film can be used by a film wrapping equipment. Let’s see some of the common types of wrapping films that meet the requirement of a film wrapping machine

PVC

PVC is the commonly used film wrap material while using a film wrapping equipment. It is found in abundant quantity and can easily be shaped in any irregularity depending upon the shape of product. Most of the food, electronics and other products are wrapped using a PVC film.

Polyethylene

Polyethylene Film Wrap - Picture Courtesy: Shorr Packaging

When it comes to strength wrapping with greater durability, polyethylene material is the most suitable one to be wrapped. Many of the industrial products are wrapped using a film wrapping equipment just because of this reason.

Polyolefin

Polyolefin Film Wrap - Picture Courtesy: Fakoory

Polyolefin is commonly used on products that are to be displayed in open spaces and require greater presentation looks. The material has high result of clarity and this is why it is used for wrapping of food and beverage products that are to be displayed in different locations to attract customers.

Biodegradable

Compostable Film Wrap - Picture Courtesy: Eco Green Living

In the current conditions where environment protection has become a greater concern for each manufacturing process, film wrapping equipment also can wrap using a biodegradable material to make the product environment friendly. It cannot cause harmful radiations and can be recycled when required.

8.What Are The Differences Between A Shrink-Wrapping Machine And A Film Wrapping Equipment?

Some of the differences of a shrink-wrapping machine and a film wrapping equipment are

Purpose

A shrink-wrapping machine is used for packaging using a shrink or stretched film mostly made up of plastic material. The film shrinks on the product and forms an airtight packaging so that any type of microbes can be blocked. Machine is used for both small and large size products including pallets and bundles.

Whereas a film wrapping equipment has a simple design structure and accompanies small products that can be easily transported from one place to another. The equipment uses thin type of film that is wrapped over the material and then its edges are heated to provide an airtight sealing.

Stretching Limit

A shrink-wrapping machine has a unique type of feature that it stretches the film to its maximum limit and then applied on the product.

On the other hand, a film wrapping equipment simply implies the film without any stretching or shrinking. The maximum material is applied on products so that each of its side remains secure for longer period.

Sealing Mechanism

In a shrink-wrapping machine a proper sealer mechanism in incorporated with the machine and performs directly to provide sealing to the applied film.

A film wrapping equipment specifically does not use any sealing mechanism. It mostly has a hot plate or heating plate in it with whom the sealing of film edges is done.

9.What Are The Auxiliary Machines Associated With A Film Wrapping Equipment In A Processing Line?

Film wrapping equipment has a wide application in packaging and processing industries. It is used along with other auxiliary machines like

Labeling Machine

Film Labeling Machine - Picture Courtesy: SR Packaging

Most of the film wrapping equipment are directly associated with labeling machines. This is due to the implementation of labels that carries products, brands and manufacturers details in it. Customers can easily get aware of all product related information through these printed labels.

Coding Machine

Code Printer For Film - Picture Courtesy: AROJET

Other type of auxiliary machines is a coding machine. Products that are wrapped using a film wrapping equipment are transported and supplied globally. The complete information regarding the product and its origin is printed on products in terms of a bar code or QR code using this coding machine.

Carton Sealer Machine

Once the products are completely wrapped by films and made airtight, they are then packed in different sizes of cartons. These cartons carry large number of products and makes sure that he product reaches its destination safely. For this a carton sealer machine is used that packs and seals the carton in an efficient manner.

10.How Different Types Of Films Are Processed In A Single Film Wrapping Equipment?

Film wrapping equipment is a highly versatile and unique type of wrapping machine that can easily process different types of films in a single device. It can adjust these films by having a domain to add film roller of any size and shape. We can replace these film rollers to ensure proper dispensing of film during the wrapping process.

No matter what thickness of film is, the roller dimension can adjust any of these. Secondly, the changeover process also takes no time. Within seconds the process films and pistons can be changed and we just need to switch the program of specific product through the HMI.

11.What Are The Common Factors To Be Considered Before Buying Film Wrapping Equipment?

Are you interested in buying in film wrapping equipment and confused in selecting the best one? Following are some important factors that should be considered before buying a film wrapping equipment.

Productivity

Productivity

Film wrapping equipment that have higher productivity are best to be considered. The most important thing before buying a film wrapping equipment is that will it be suitable for required productions setup or not. One should consider this factor with complete forecast and market demand.

Film Type

Film Types And Sizes

After productivity the most important factor to be considered is that the film wrapping equipment is suitable to what type of film materials. The manufacturers should consider the best equipment that can accommodate the desired film materials. Some machines that are not suitable to different type of films can be just a loss of money.

Automation Level

Automation

The automation level of a machine should also be considered before buying a film wrapping equipment. It is also an important factor that what type of automation level weathers its manual, semi-automatic or automatic should be considered and this completely depends upon the productivity and available manpower within the organization.

Brand Warranty

Warranty

Another important factor to be considered is brand warranty. Manufacturers with more brand warranty duration and customer support service are best ones to be selected. One should not consider any local brand that does not gives warranty or after cell services. Brand or manufacturers with greater market coverage are the most reliable one.

Maintenance And Service

Maintenance, Repair And Service

Lastly, machine maintenance and operation services are also one of the things that should be considered. Machines with greater maintenance can cause more trouble shooting and loss. Ideal machines with less trouble shooting and maintenance are the best one to be chosen.

Conclusion

Are you now completely familiar with a film wrapping equipment? Have you got that how a film wrapping equipment operates and what are its types? If there is still confusion in your mind regarding a film wrapping equipment and want to get more information, and then feel free to contact us. Our customer representative service operates 24/7 and is always available to reply your queries. Get the best film wrapping equipment for your process and make a presentable product using it.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide