Filling Machine for Powder: The Complete Buying Guide In 2025

Why is a filling machine for powder so important for any industry?

Formulating any effective product begins with powder, and it must be of good quality with correct packaging. Whether it is clinically based laboratories, research units, or designing any product, you cannot ignore filling machine for powder.

In this blog, you will find extensive knowledge about this machine and various aspects related to the filling machine for powder.

Do not worry if you’re planning to purchase, this guide will help you to understand the equipment so you will be capable enough to choose the right one! Without wasting your time, let's begin with Filling Machine for Powder: The Complete Buying Guide In 2024.

1.What Is a Filling Machine for Powder?

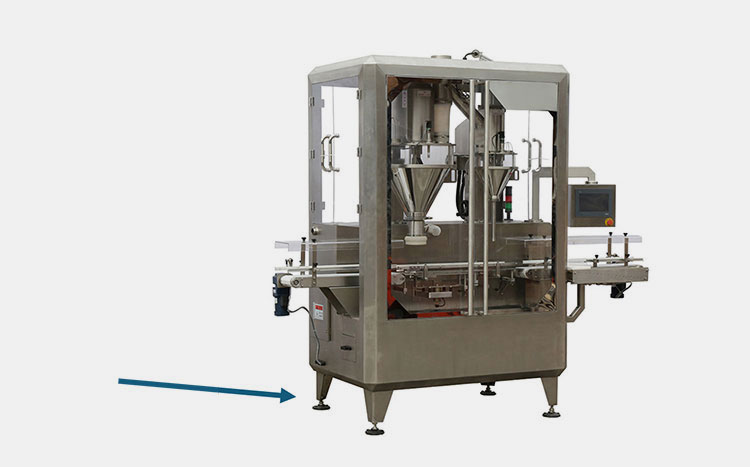

Allpack Single Head Filling Machine for Powder

A filling machine for powder is a reliable piece of equipment that is preferably used to pack powder materials in a very precise amount without any unprofessional deviation. It is a widely used machine bringing the filling task safely and smoothly.

2.Where Filling Machine for Powder Can Be Used?

Powder Containers- Picture Courtesy: inStyle

The filling machine for powder is hooked to a major industrial era belonging to various different manufacturing and packaging of items.

Below below-mentioned description is about specific industries where production and packaging are impossible without this machine.

Food Industry

Food Powder-Picture Courtesy: Drink Eat Live

In the food industry, countless products are manufactured and packed. This includes flour, pulses, rice, spices, milk powder, sugar powder, salts, condiments and so much more. The filling machine for powder is an ideal and ‘must-have’ equipment to carry these tasks perfectly.

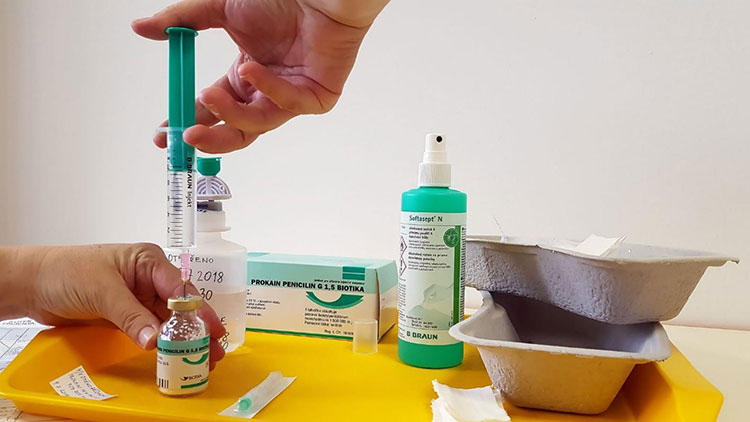

Medicinal & Healthcare Industry

Medical Powder-Picture Courtesy: Basic of Nursing Practise

This is the world’s leading production sector where 60% of manufacturing relies on filling machine for powder. Whether it is making tablets, capsules, or ointments, all sections highly demand this equipment for accurate filling for powders.

Nutraceutical Industry

Health supplement powder-Picture Courtesy: Delta Formulation

This is another demanding sector where filling machines for powder require equal importance as its manufacturing and marketing of items. Protein powder, health supplements, prebiotics, probiotics, enzymes, and well-being boosters can be packed by using this equipment.

Chemical Industry

Chemical Powder -Picture Courtesy: Bürkle Gmbh

You can observe various chemicals packed in each hour in the chemical industry by using the filling machine for powder. Here, harsh and reactive chemical powder can safely be dispensed in containers without harming the ecosystem and work environment. This includes buffer salts, bleach powders, acidic, and alkaline powders, disinfectants etc.,

Agricultural Industry

Agriculture powder- Picture Courtesy: Express Tribune

There are a number of agricultural products in the form of powders and granules that are commonly packed by using a filling machine for powder. This includes pesticides, insecticides, urea, crop boosters, seeds, and other related items.

Cosmetic Industry

Various Cosmetic Powder-Picture Courtesy: Tribe Skincare

In the cosmetic industry, dusting powders, shiners, eyeshadows, blush, and related powdery substances need a filling machine for powder during their manufacturing. On the other hand, packing of granular products such as beans, manicure, and pedicure products, waxing beads, etc. needs this robust machine for packaging.

3.How Filling Machine for Powder Can Be Advantageous?

You can enjoy countless business marketing and success if add a filling machine for powder in your production line. How? There are some important benefits it offers to its customers:

Dealing Large Production

Various Production Capacities-Picture Courtesy: Powbab

A filling machine for powder is featured with exclusive automation, multi-head filler, a fast conveyor, a highly intelligent touch screen, and high sensitivity for accuracy and outstanding speed. Considering all these points can collectively give high throughput and make high productivity in exceptionally low time.

Convenient to Use

Containers With Powders-Picture Courtesy: Dieline

A filling machine for powder is perfect for every type of filling material. Such as whether small or large containers, filling bottles or cans, this machine is ideal for modulating its design in order to accommodate them flexibly. The presence of adjustable screws Allows wider options for packaging material with different sizes and shapes.

Cost-effective

Cost-Effective -Picture Courtesy: World Brand Design

The machine is very cost-effective in many ways; it reduces your labor cost, saves your time, can deal with high production batches, and reduces product wastage, etc.,

The mentioned accountability can overall impact higher on your budget and save expenditures.

High Accuracy

Powder With High Accuracy-Picture Courtesy: The Beauty Chef

A filling machine for powder is equipped with an agitating hopper with a meter screw which allows a very particular amount of powder to be filled in each container. Side by side, a high inspecting system and mechanical excellence lead to producing 100% filling accuracy.

No Dust Formation

Dust Free Filling of Powder

The filling machine for powder is constructed in a specialized way which limits the progression of dust during filling, so users and work facilities can enjoy dust- a free environment.

4.What is the Working Procedure for Filling Machine for Powder?

The working process of filling the machine for powder doesn’t need any rocket science. Anyone can operate it but one must understand the basic steps. The below description is about the working step of the filling machine for powder.

Step 1: Loading

Loading

An adequate volume of powder is supplied to the hopper of the filling machine for powder. This can be achieved by manual loading or using an automatic feed unit for supplying bulk concentration of powder.

Step 2: Infeed Filling Material

Filling Process

Packaging materials such as bottles, containers, cans, or other items get subjected to the machine with the help of a conveyor. This unit assists in the flow of material from one machine to another easily. The conveyor steadily brings the container and stops at the filling station.

Step 3: Powder Metering

Powder Metering

The required volume of powder to be filled in the container is adjusted and set using the machine’s setting. This includes speed, metering, and movement of the agitator. Once they’re adjusted, a sufficient volume of powder gently swirls down from the hopper toward the filling nozzle.

Step 4: Filling

Filling

The filling nozzle is a gateway that offers a direct supply of powder toward the filling container accurately without risk of leakage, spillage, or dust formation.

Step 5: Discharging

Discharging

Once containers are filled with the required volume, the conveyor starts movement and lets the batch of containers leave the system along with bringing of new set of empty containers for repeating the same task.

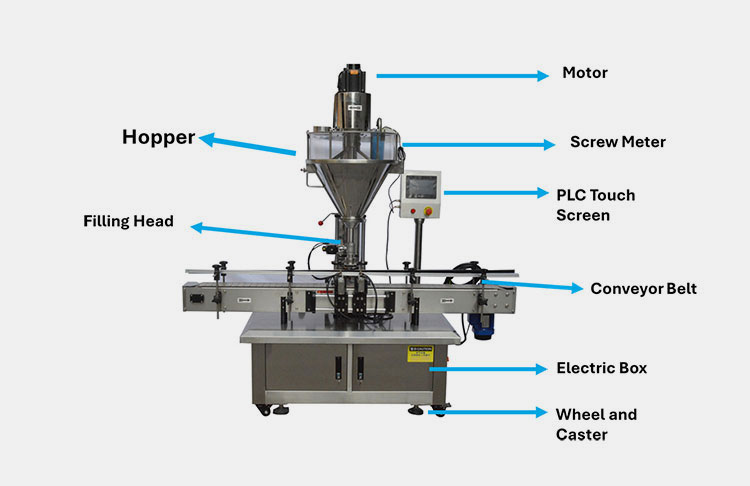

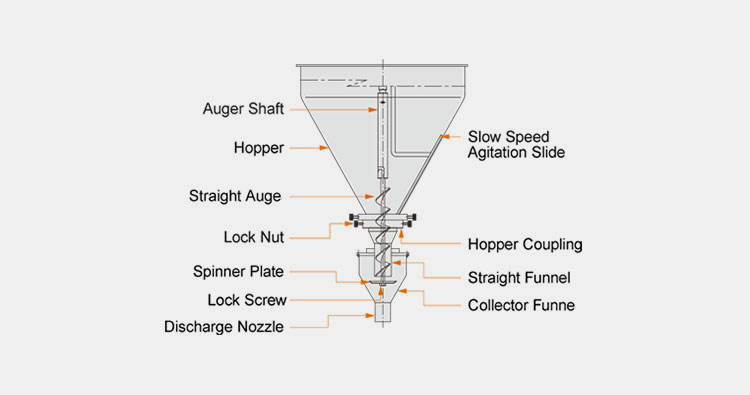

5.Can You Explain the Structure of the Filling Machine For Powder?

The filling machine for powder is composed of a simple structure, for your understanding we have demonstrated Allpack equipment with cleared labeling with respective functions.

Allpack Filling Machine for Powder

Motor

Motor- Picture Courtesy: IVS Engineering

This is the major component that serves as an engine to run the whole system. This part is located at the uppermost portion of the machine which is capable to generating electric circulation all over the unit and running the process effectively and safely.

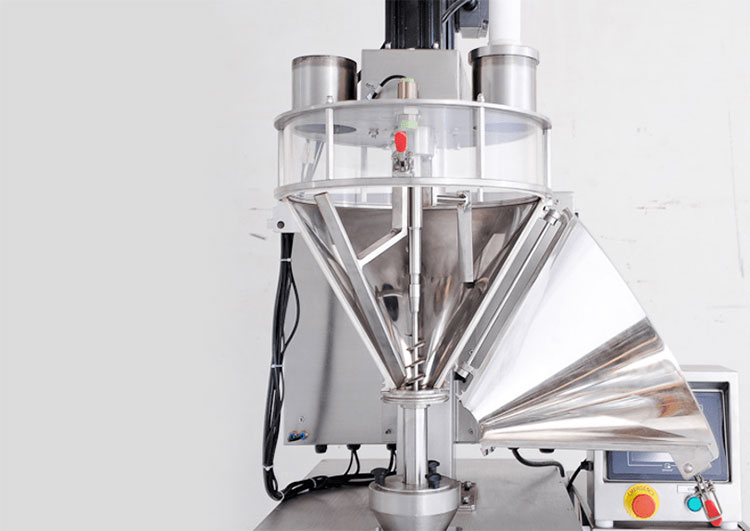

Hopper

Hopper- Picture Courtesy: Paxiom

The hopper is an integral part of the machine where the powder to be packed is stored. You can see hoppers available in various measurements and designs. This is featured with topmost transparent glass allowing you to visualize the clear view of the procedure inside. This is mostly made up of 304 stainless steel material but for corrosive materials, it is also upgraded with 316 stainless steel.

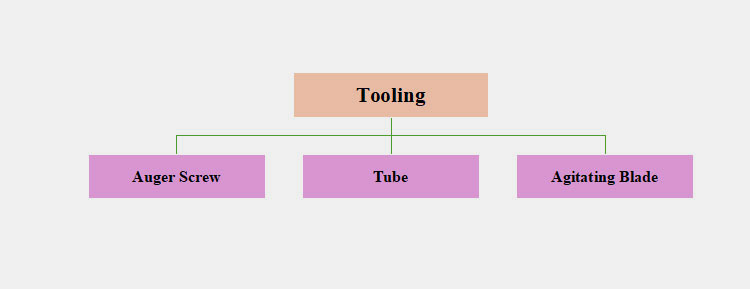

The tooling of the hopper is divided into the following.

Hopper is composed of the following set of tooling that are easy to replace which relies on the characterisation of powder you use.

Auger Screw

Auger Screw- Picture Courtesy: Atlantic Supply

It circulates gently to encourage the flexible movement of the product towards the tubing.

Tube

Tube or Funnel- Picture Courtesy: Professional Pouch Packaging

It assures an accurate and dust free movement by narrowing the path hence you can obtain proper dosing.

Agitating Blade

Blade- Picture Courtesy: Auger Fabrication

It helps in the dispensing of powder into the container.

Screw Meter

Screw Meter- Picture Courtesy: Shenzen Penglai

A specific amount of powder can be filled into each container with proper metering and measurement. This can be done by utilizing the help of a screw meter. By its name, it is a movable screw that helps in delivering requires concentration of powder gently. Simply, you can think of it as taking a particular amount of product with the help of a spoon or scoop.

PLC Touchscreen

PLC Touch screen- Picture Courtesy: Prepod.VD

When you’re using a mobile phone, you can run various applications just by touching the screen.

Similarly, this machine is equipped with a PLC touch screen which allows control options where you will need to put the command, for example., speed of filling, speed of conveyor, amount of filling powder, etc.,

Side by side, this screen is helpful in displaying the internal situation of the machine., like heating up, notifications, alarms, memory, and other options.

Filling Head

Filling Head- Picture Courtesy: Wedderburn

This part serves as a filler which allows free and flexible movement of powder directly into the filing container, this is a gateway where product can easily transfer without spillage or leakage,

Conveyor Belt

Conveyor- Picture Courtesy: BigPac

The container can be carried to the filling section with the help of a conveyor this is the kind of passage that allows the easy and direct supply of filling material and once it is filled, the conveyor allows discharging and bringing of the fresh batch into the machine.

Electric Box

Electrical Box- Picture Courtesy: Aipak

You can consider this machine safe, the major electrical components of the unit are firmly enclosed in a box. It is designed with a perforated wall to allow air exhaust and an insulated wall ensuring a high level of safety.

This box is mainly composed of wires, connections, plugging, and relevant components that collectively make the filling machine for powder extremely user-safe.

Supporter

Supporter- Picture Courtesy: Aipak

These portion serves as feet and support which helps in a smooth movement, firm installation, and vibration-proof running of the machine. if you want to relocate the unit, the universal wheel allows easy movement from one place to another. The presence of hooks facilitates the locking of wheels, so the machine stands stable.

6.What is the Classification of Filling Machine for Powder?

Along with broad applications, a filling machine for powder is also presented with a huge classification. However, the major concept for filling is similar, though you can observe every machine differs by modification, the addition of some components, and operational modulations. Let’s see them now:

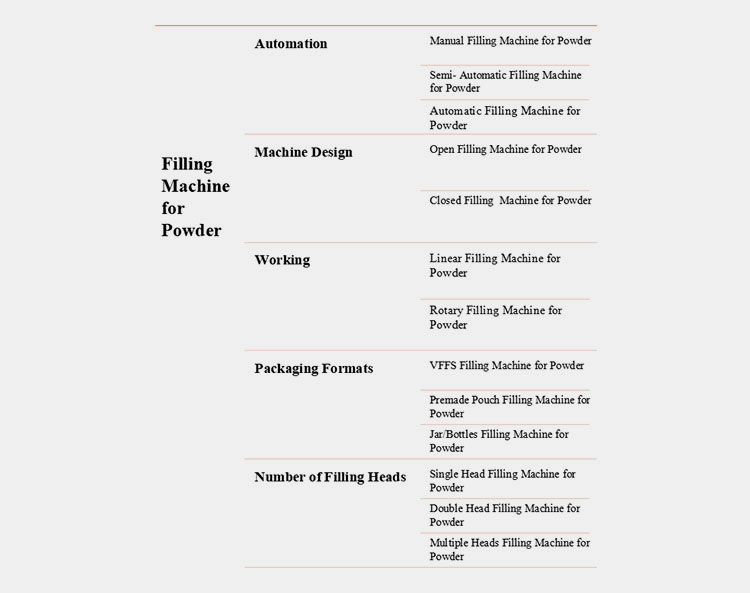

A Broad Classification of Filling Machines for Powder

Types of Filling Machine for Powder- According to Automation

In the past, a filling machine for powder was very simple without any automation., recent advancements and the emergence of new equipment have grabbed greater levels of automation. Mean, how advanced your machine is, based on automation, a filling machine for powder is categorized into the following:

Manual Filling Machine for Powder

Manual Filling Machine for Powder

This is the simplest version of a filling machine for powder.

Here, you need to follow three basic steps, such as you must load a desirable amount of powder into the hopper and fix the lid. Placing of container and pulling the lever can lead to filling a precise quantity of material depending on your requirement.

As you can see picture, this is a small and compact solution to fill a precise quantity of material. that’s the reason it is still high in demand for small businesses as it assures safe and clean filling without any extra energy expense.

Semi- Automatic Filling Machine for Powder

Allpack Semi-automatic filling machine for powder

Semi automatic filling machines for powder possess a half glimpse of modern features and half of conventional machines. This is a useful solution for running medium businesses as the machine is helpful in the filling material associated with moderate batch sizes. for instance, hundreds of containers per hour.

Its working is involved in manual placement and removal of packaging materials, rest of the task is performed automatically. For example, the amount of powder to be poured inside the material is done by the machine as data is already fed into it by the HMI touchscreen.

Automatic Filling Machine for Powder

Allpack Automatic Filling Machine for powder

Recent advancements have revolutionized the packaging world, the automatic filling machine for powder is a good example of it as this machine is today’s most demanding equipment in manufacturing companies.

This is a one-stop solution where the product is measured and dispensed into each container followed by discharging from the machine is takes place automatically. The machine is featured with high integration compliance capacities where you can fix other types of machinery easily to bring jobs faster.

Yes, machines can be expensive at first purchase, but later on, they can be very economical as they save your time, energy, and labor costs, and offer high productivity.

Types of Filling Machine for Powder- Based on Design

When using a filling machine for powder in general packaging sectors you will find them very simple and flexible working. instead, filling powder in sensitive areas like medicines needs extra precautions. That’s why the types of filling machines for powder are divided into 2 different designs. For example,

Open Filling Machine for Powder

Allpack open filling machine for powder

This is a standard machine design featuring the usual structure with an open frame. This machine can be used in various packaging departments except those that are required with extra caution because an open structure may cause health problems.

Closed Filling Machine for Powder

Closed Filling Machine for Powder- Picture Courtesy: Shingai Machinery

This is a sterile and reliable solution when you’re subjecting the machine to pharmaceutical powders such as antibiotics, chemotherapeutic drugs, anti-fungal, etc. This is always challenging to deal with such powder. The closed filling machine for powder is designed excellently where the entire structure of the machine is compact and enclosed in a stainless steel and glass material that assures high sterility and safety of user and product.

Types of Filling Machine for Powder- Based on Working

The filling machine for powder is featured with different working patterns. It is up to your choice and type of filling production that requires a specific type of machine to give greater throughput.

There are two basic types depending on the working of the machine, for example:

Linear Filling Machine for Powder

Linear Filling Machine for Powder

This is a standard machine where working from feeding, filling, and discharging are linearly taken place. This machine is commonly used in various manufacturing and production facilities as it is fast, robust, with greater automation, and simple.

Rotary Filling Machine for Powder

Rotary Filling Machine for Powder- Picture Courtesy: CVC Tech

If you are looking for quicker filling equipment, then rotary is a good option. In this machine, bottles come, feed, and leave the machine by following a circular working pattern. Therefore, the working principle leads to a faster filling process. That’s why it is mostly preferred in a larger production area where rapid throughput is essential.

Types of Filling Machine for Powder- Based on Packaging Formats

If you are filling powder in bottles, jars, vials, or pouches; then it is not possible to use the same machine for each of the packaging materials. Yes, to solve this problem, you will have various other options to pick on. Just see below to check the filling machine for powder for various packaging formats.

Vertical Form Fill Seal Filling Machine for Powder

Types of Filling Machine for Powder- Based on Packaging Formats

As its name depicts, the formation of a sachet or stick pack, filling of powder, and sealing of packaging takes place following a vertical fashion.

This machine is also available in semi-automatic and automatic versions demonstrating a high demand in the market due to its simplicity and easy usage.

The machine follows a few steps working with the formation of a bag by unwinding a film roll hooked in the machine.

Once it is unwinding a tube former causes sachet formation with sealing around 3 sides and filling of powder. Once it is filled, the final sealing is done along with separation using cutters.

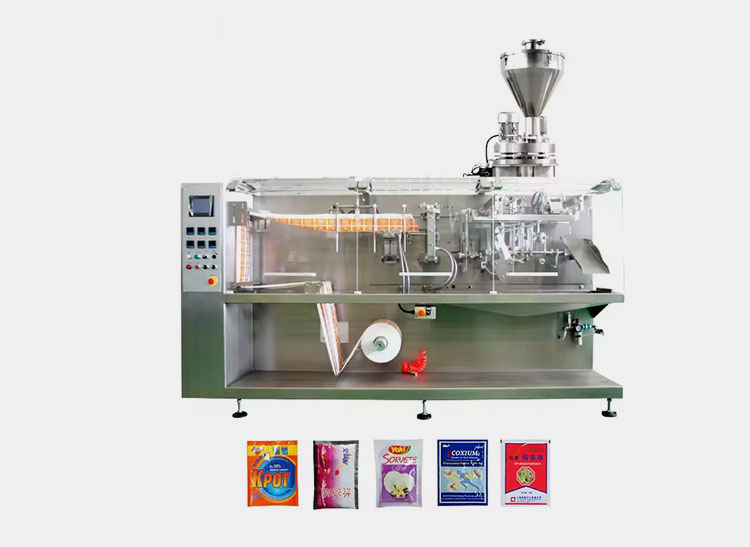

Horizontal Form Fill Seal Filling Machine for Powder

Horizontal Form Fill Seal Filling Machine for Powder

This is another popular filling machine for a powder that allows the formation of pack, filling, and sealing by following horizontal working patterns.

This machine is mainly used to make flow wrap packaging and occupies a large footprint., as compared to the VFFS machine, this machine is very expensive too.

This is commonly used in large industries where various type of packaging is required by using a single machine.

Pre-Made Pouch Filling Machine for Powder

Pre-Made Pouch Filling Machine for Powder

This machine is used for large production batches in a shorter time. Pre-made pouches are loaded into the magazine of the machine, the clipper picks each pouch and the inflator helps in the opening followed by the insertion of powder material simultaneously.

The machine commonly follows rotary working hence entire throughput is fast and huge.

Jars/Bottle/Container Filling Machine for Powder

Jars/Bottle/Container Filling Machine for Powder

All those companies that are hooked to manufacturing and packaging powder material must utilize this equipment. Here, upright-positioned bottles come in contact with a machine using a conveyor.

Once they’re reached, the sensor detects the presence of a bottle and pre-determines the concentration of powder poured down into it. The container leaves the system and goes toward the next machine for capping and induction sealing.

Types of Filling Machine for Powder- Based on Number of Filling Heads

As discussed earlier, the new technologies and amendments in filling machines for powder keep going; as a result, you see various modern features in this equipment. Similarly, you have an absolute solution if running a high-production batches. That’s a machine with various numbers of filling heads to keep your working feasible and smooth. Let’s see the filling machine for powder with filling heads.

Single Head Filling Machine for Powder

Single Head Filling Machine for Powder

A conventional and simplest version of the equipment which is accompanied by a single filling head. This machine is available with various automation such as manual, semi-, and automatic machines and is ideal for small, medium, and large productions.

Double Head Filling Machine for Powder

Double Head Filling Machine for Powder

This is another new advancement that comes in the emergence to deal non-stop production or large production batches as the machine is featuring double filling heads. The structure of the machine is almost the same as conventional instead number of filling heads for fast filling.

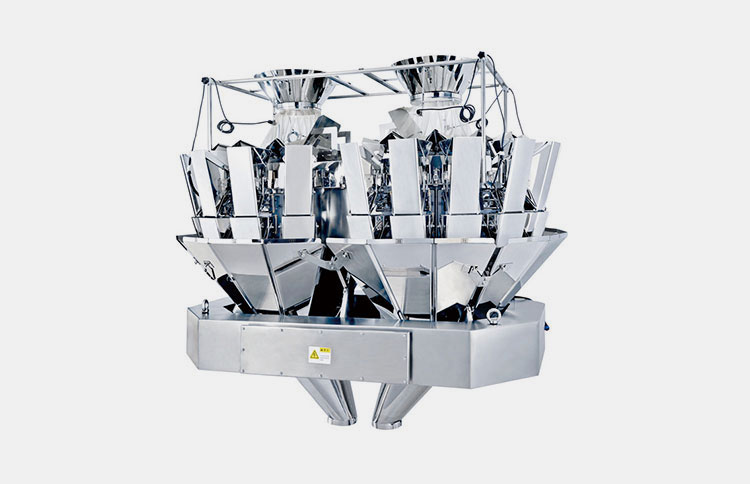

Multiple Head Filling Machine for Powder

Multiple head filling machine for powder- Picture Courtesy: Micoop

This is the fastest version of the filling machine for powder that features more than double filling heads. Hence it is ideal for the largest companies dealing with packaging of powder with higher capacity requirements.

7.What are the best materials to packed by filling machine for powder?

Analysis of product characteristics- Picture Courtesy: Stable Micro System

To identify what characteristics of the product are suitable for filling the machine for powder, let's do a small experiment, this test is easy, 100% reliable, and needs manual handling.

Take your product and insert a pencil inside, now remove and assess if there’s no hole left behind, it shows free-flowing powder. If the impression is left behind, it demonstrates non-free-flowing powders.

The filling machine for powder can allow the following materials:

Free-Flowing Products

Free-Flowing Products

The granular powder or products are easily filled using a filling machine for powder where a specialized design in auger is attached that is spinner disc helps in the flowability of powders.

For example, salts, sugar, and related products can be applied for the filling process.

Non-Free-Flowing Powders

Non- Free-Flowing Powders- Picture Courtesy: 3M Australia

The non-free flowing products hopper is set up with slight variation means in this machine it is accompanied by a broad agitating blade that helps in the flow of powder without jamming. This design auger is helpful in the movement of powder downward without overload and minimizes the compaction. The continuous running of agitating blades reduces the chances of aeration that mostly occurs in the non-free flowing powders.

Examples of products are Talc, bakery mixes, carbon, coal, etc.,

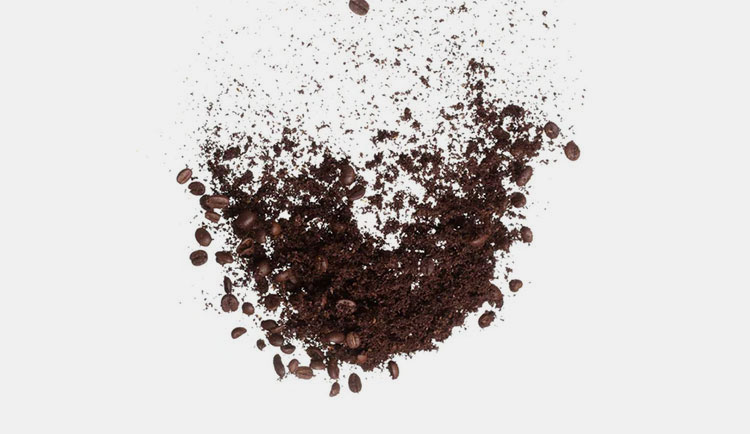

Semi-Free-Flowing Powders

Semi-Free-Flowing Powders- Picture Courtesy: Cylonies

This category is the one where granulated products with slight non-free flowing properties. The filling machine for powder tends to fill such products by creating pressure and non-stop movement of the agitating blade to correct the filling process without overloading. The products in this category include coffee, tooth powders, etc.,

8.Filling Machine for Powder: Is There Any Tooling Difference for Free Flowing and Non-Free Flowing Materials?

Yes, the filling machine for powder is expressing their dispensing procedure by following the different tooling. For example:

Straight Auger

Straight Auger- Picture Courtesy: Auger Filling

This is the type of specification that is ideal for dispensing free-flowing materials. This is particularly composed of a straight auger that revolves in order to flow powder from the hopper toward the packaging container. The rate of rotation and degree of filling powder are consistent and ensure smooth dispensing of powder associated with different textures and particle sizes.

Self-Feeding Auger

Self Feed Auger- Picture Courtesy: Augerfab

This type of tooling is composed of a particular construction of accessories that is suitable for dealing with non-free flowing powder. There is a special structure accompanied by a paddle or agitator which is meant for breaking lumps or aggregate present in the powder.

This is specifically helpful in managing powders confined to poor flowability, as self-feeding auger promotes a smooth flow of powders without clogging inside the machine.

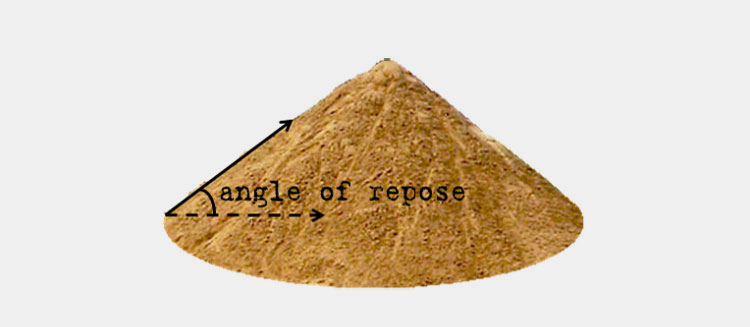

9.Why Angle of Repose Is Critical When Using a Filling Machine for Powder?

Angle of Repose- Picture Courtesy: Wikicoarse

The angle of repose is essential to identify as it helps you in characterizing the flow rate of the materials that are meant to be subject to a machine for the filling procedure.

Moreover, measuring the angle of repose helps you offer a quick and reproducible way to fill powder by selecting the correct tooling for their packaging.

Means, that this is the fast way to determine whether your filling material possesses free-flowing, non-free-flowing, or semi-free flowing properties. Hence, you can easily manage the right machine to accomplish production tasks in an efficient manner.

10.What Is the Difference Between Manual and Automatic Filling Machine for Powder?

Manual VS Automatic Filling Machine for Powder

| Points | Manual Filling Machine For Powder | Automatic Filling Machine For Powder |

| Working | The machine requires manual handling throughout the procedure. | Except for setup, no human involvement is needed. |

| Efficiency | The working efficiency is slower due to slow handling. | It has faster working efficiency due to high filling speed and automation. |

| Accuracy | Machine accuracy depends upon the energy and skills of the operator. | The machine provides 99.99% high accuracy and precision through an automatic and sharp control center. |

| Cost | This is an affordable and simple machine. | This is an expensive machine causing high costs initially. |

| Production Capacity | This is ideal for small labs or production as it yields a small filling capacity. | Due to its high production capacity, it is suitable for large manufacturing companies. |

11.What Is the Production Line of Filling Machine for Powder?

Production Line Of Filling Machine For Powder

To bring a complete filling and packaging process, there is a refined workflow pattern confined to filling the production line. The set of machineries include are mentioned below:

Bottle Unscrambler Machine

Allpack Bottle Unscrambler Machine

This machine is suitable for bottles, jars, and containers with round shape, square shape, or irregular shapes to make them upright position and provide it to the filling machine for the powder to achieve the desirable process without interruption.

The unit is capable of unscrambling the mess of bottles into the correct position by using a vibratory disc and blower system which helps in attaining the orientation of containers.

Capping Machine

Allpack Capping Machine

A capping machine is integrated with a filling machine for powder as the product is filled with materials and is passed towards the capping section.

This machine is suitable for applying caps of various shapes, such as round, randoms, squares, etc., this machine plays an important role in securing your product and extending its shelf life.

It is helpful in providing a high speed capping process in lesser time without requiring the tiresome job of manual capping with chances of losing product, cap breakage, or extra burr.

Induction Sealing Machine

Allpack Induction Sealing Machine

This machine is used for the purpose of making products safe from humidity, mildew, and tampering. Once the caps are fixed over the containers, they reach the induction sealing machine where the emergence of electromagnetic radiation warmth the lid of caps and melts the inner lining of caps. Upon cooling, the melted lining becomes hardened and forms a firm sealing over the bottleneck and offers better and stronger sealing to your product till its end-user.

Labeling Machine or Coding Machine

Allpack Semi-Automatic Labeling Machine

The conveyor helps in transferring bottles to the labeling machine which helps in the application of proper labeling in a confined position followed by a presser to firm the label properly over the surface.

This is an essential unit of the production line that assures branding, and critical and necessary information on the bottle.

12.What Essential Things Can Control Dust When Using Filling Machine for Powders?

Dust control ways- Picture Courtesy: UL Prospect

The formation of dust during the powder filling process is not uncommon. However, there are certain things that can overcome dust. For example,

Fully Closed Filling Section

The filling machine for powder design must be compact and enclosed to protect powder dispersion in the workplace.

Dust Accumulator

A vacuum system or dust accumulator unit must be incorporated into the system to grab dispersed particles during the filling process therefore you can find a clean work environment.

Enclosed and Packed Hopper

If the hopper is sealed, it prevents the emission of powders into the air during the procedure.

Dust Suppressor

By application of dust spray suppressors, it can overcome the generation and spreading of dust when using filling machine for powder.

Anti-static Materials

Using anti-static materials can reduce the chances of static progression in material that causes dust production.

Integrated Dust Control Accessories

Dust control shades and shrouds or relevant tooling can help in the reduction of dust very well.

Ventilation

The arrangement of the proper ventilation and unit design can effectively pick up and eliminate dust.

13.What Are Basic Challenges and Solutions Related to Filling Machine For Powder?

The powder-filling task is always considered as the challenging one, however, every challenge is counteracted with a suitable solution. There are some major challenges with solutions are discussed below:

Inaccurate Filling of Powder

Inaccurate Filling- Picture Courtesy: Wakacoffee

This problem commonly occurs with non-free flowing powders due to poor flow rate. Moreover, granules with weight and size variations can also lead to inaccurate filling. sometimes, when your machine needs calibration but you might be ignoring can cause this problem.

Solution

There are various types of agitating blades available in the market that help you in controlling flowability by continuous agitation which overcomes lumps formation.

Secondly, if you premix your raw ingredient properly can help in uniformity among particle sizes hence allowing flexible filling with precision.

Thirdly, always try timely calibration of the machine to obtain sharp and accurate results.

Jamming of Powder in the Filling Head

Powder Jamming- Picture Courtesy: Depositphoto

This is pretty clear that the texture of various powders is sticky in nature which stuck to the walls of the filling machine due to certain reasons such as moisture, heat, and others. This problem can lead to clogging of narrow tubes thereby affecting the overall filling process.

Solution

A routine cleaning of the machine is a standard solution to avoid this problem. Try to evaluate the moisture content holding capacity of powders then modulate the setting by fixing low humidity (feature) in the machine that will help to control moisture and keep the system warm and dry.

Powder Spillage

Powder Spillage- Picture Courtesy: Corn Free Contessa

If the speed of the conveyor is fast, the containers find lesser stay time for proper filling. This is the reason why spillage takes place, Moreover, there are some other reasons as well which include, high filling speed, poor sensor detection, and low maintenance, which can directly result in such problems.

Solution

It is always recommended that the speed of the conveyor must be proportion to the filling speed of the container to make this process gentle and smooth. Moreover, if you calibrate the machine regularly, the mentioned problem can be controlled. Always assess and add correct settings related to the product’s flowability ratio. The cleaning of sensors and re-testing can give a sharp filling result.

Conclusion

Nevertheless, a filling machine for powder is always significant for your production business. We hope after this informative blog, you will be able to decide what category filling machine for powder is best for your production line. Pharmaceuticals, foods, and related companies have been trusting Aipak for more than a decade to bring their filling processes safely and efficiently via selecting our innovative and advanced machine for powder. If you’re interested in joining this journey with us then send us a message to enjoy our expert guidance and equipment series.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide