The Best Quality Feeding Machine

- Frequency Converter

- Open Frame Structure

- 90-degree Transmission

Feeding Machine

Feeding Machine is widely used in various materials, including powder, fiber, and flake materials with poor fluidity. All parts in contact with the material are made of stainless steel. The feeder is easy to clean and replace parts. Equipped with horizontal mixing to improve the flow of material to screw propulsion for more accurate feeding. For materials with poor fluidity and easy bridging, vertical mixing will be arranged. The improved screw design is easy to install and disassemble, and the screw root will not accumulate materials. The feeding machine uses a hopper to load materials to avoid scattering and can realize automatic material feeding while working together with a packing machine and muti-steelyard. It can be supported by all kinds of extruders, high-speed mixers, plastic mixers, etc.

Feeding Machine

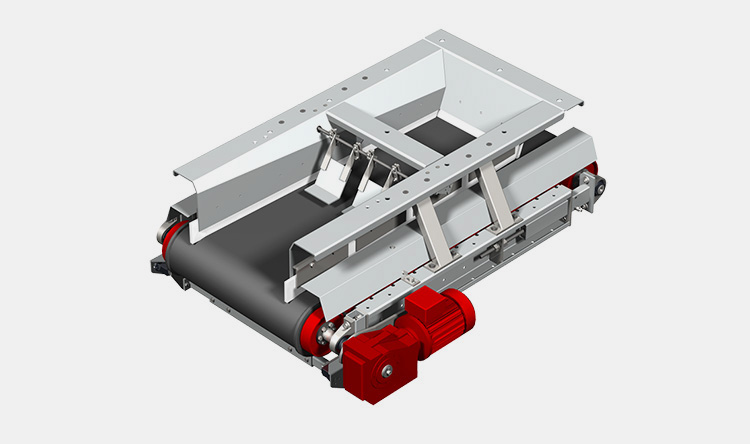

Mesh belt elevator Feeding Machine

Allpack mesh belt elevator feeding machine adopts an open frame structure, which is clean and not suitable for dust accumulation. It also adopts a frequency converter to control and drive, and the transmission speed can be adjusted according to on-site materials. It has a large conveying capacity and good fluidity. The device is made of stainless steel 304. The devices are 3 meters high, but they can be adjusted to the customer's order. Vertical feeder designed for transporting loose products. The speed of it is adjustable. and It can be customized according to customer requirements. The length, width, height all can be designed.

Machine frame: #304 / #316 stainless steel or carbon steel

PVC, PP, PU, stainless steel belt

Make as per client's requirements

Vertical feeder/ Feeding Machine

Allpack vertical feeder/feeding machine adopts vertical lifting, and 90-degree transmission, which can save coverage area and reduce power consumption. The feeding machine uses a hopper to load materials to avoid scattering and can realize automatic material feeding while working together with a packing machine and muti-steelyard. The vertical feeder is designed for transporting loose products and granules, such as sugar, coffee, nuts and dried fruits to the container of the packaging, dispensing device.

Simple structure&strong

Strong adaptability

Easy control start and stop, speed

Z Model Lifter Feeding Machine

Allpack Z model lifter feeding machine is applicable for the lifting of frangible and non-frangible material such as potato slice, prawn cracker, crispy rice, etc. The elevator and electronic metering scale should be used together and control circuit is used to control the position of the material, to make it an automatic feeding and automatic stopping function. The device is made of stainless steel 304. It is 3 meters high, but they can be adjusted to the customer's order.

Energy saving

Environmental protection

Long service life and low maintenance

ZH-P3 Feeding Machine for Granule with Hopper Intermittent Chute Lifter

Allpack ZH-P3 feeding machine is the most ideal feeding equipment in the market at present, with the features of quick transmission speed, energy-saving, and ease of operation. It can be supported by all kinds of extruders, high-speed mixers, plastic mixers, etc. Transmit plastic powder or particles in a container automatically to high place (feeding height of the screw feeder can be customized according to users). The material feeding is controlled by a level indicator, which has the characteristics of automation, fast feeding, labor saving, safe, and reliability. The speed and height of the feeder is adjustable. It is made of stainless steel 304 and 3 meters high, but can be adjusted to the customer's order. The vertical feeder is designed for transporting loose products and granules, such as sugar, coffee, nuts and dried fruits to the container of the packaging, dispensing device.

All Stainless Steel Construction

Meet GMP Standard

Be suitable for many industries

ZS-P3 Feeding Machine

Allpack ZS-P3 feeding machine is suitable for upper feeding all kinds of powder-like material onto the hopper of the feeder, and it's used for the automatic packing line. It is the most ideal feeding equipment in the market at present, with the features of quick transmission speed, energy-saving, and easy operation. It can be supported by all kinds of extruders, high-speed mixers, plastic mixers, etc. Transmit plastic powder or particles in container automatically to the mixers of high place. It can work with EWM machines.

Material feeding controlled by level indicator

Fast feeding&labor saving

Safe and reliable

The Buyer's Guide

Feeding Machine:the Complete FAQ Guide in 2025

Industrial machinery has been around since the dawn of the industrial revolution, and over time, more demands have been placed on it. One of the most revolutionary pieces of equipment we’ve seen is the Feeding Machine, which allows for seamless batch production with minimal human contact. It’s an extremely efficient way to quickly feed products into automated manufacturing processes, resulting in major cost savings and higher-quality products through improved accuracy.

In this blog post, we’re going to explore all there is to know about Feeding Machines: what they can do, how they work, installation tips, and more! So if you’re interested in experiencing increased productivity while saving money on labor costs, read on to get your questions answered!

1.What Is A Feeding Machine?

A feeding machine is an industrial automation equipment used in the production and manufacturing industry. It can be programmed to feed parts, components, and materials into an assembly line in a certain order. By automating this process, drastically increases production speed and reduces labor costs. Additionally, a feeding machine helps improve safety by eliminating the manual handling of heavy materials and parts.

Feeding machines are typically programmed to be accurate and precise, meaning that parts can be fed into assemblies with high accuracy. This eliminates the need for manual sorting or counting of parts throughout the production process, increasing production speed and efficiency. By streamlining the material handling process, feeding machines can reduce errors, increase throughput and improve the overall quality of end products.

2.What Are The Components Of A Feeding Machine?

When it comes to industrial production, having a reliable and efficient feeding machine is essential. The components of an industrial feeding machine include:

Hoppers

Hoppers are containers designed to hold materials while they are waiting to be transferred to the next station. These containers have a large capacity and are usually made of heavy-duty plastic or metal. Hoppers can also be used to store excess material until it is needed.

Feeders

Feeders are devices designed to transfer materials from one station to another. They come in many different shapes and sizes and can accommodate a variety of materials, including liquids, powders, and granules. Feeders typically use mechanical or pneumatic systems to move the material from one station to another.

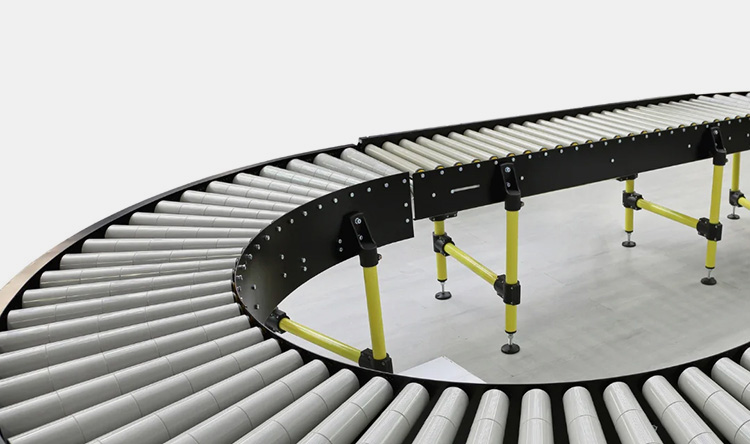

Conveyor Belts

Conveyor belts are used to transport materials from one station to another within the production line. They come in a variety of sizes and shapes depending on the specific application. The belt is made up of two or more pulleys, with a continuous loop of material that travels around them.

Pushers

Pushers are machines designed to push materials along the production line. They are usually powered by hydraulic or electric motors and can quickly move large amounts of material. Pushers are typically used to continuously transfer materials from one station to another, making them an essential part of the feeding machine.

Sensors

Sensors are devices designed to detect and record changes in the environment. In a feeding machine, sensors are used to measure the speed and pressure of material moving along the production line. Sensors can also detect blockages or other irregularities that may affect the production process.

Control systems

Feeding machines are often equipped with control systems that regulate the transfer speed and quantity of material. These systems use a variety of sensors, timers, and other components to monitor the production process and adjust the rate of material transfer as needed. The control system is an integral part of the feeding machine and ensures that materials are moved accurately and efficiently from one station to another.

3.How Does A Feeding Machine Work?

Industrial feeding machines help automate production lines and make manufacturing processes faster, easier, and more efficient. These machines feed raw materials into production machines or other processing devices. They can easily handle bulky items such as granular powders, liquids, chips, or pellets. The mechanical parts of the industrial feeding machine work together to ensure that the materials being fed into the production line are of a consistent size and shape.

The feeding machine has a hopper at its top where raw materials are stored. A screw conveyor is then used to bring the materials from the hopper down in an orderly fashion while regulating their flow rate. The feed rate can be adjusted depending on the production speed and the size of the materials being processed. A vibratory bowl feeder is also installed to ensure that the individual items are orientated in the right direction before they enter the production line.

The actual feeding process is powered by a motor that can be adjusted according to the needs of each different production line. It activates a set of gears that rotate the screw conveyor and move the items along its length. As each item moves along the screw, it is monitored by a sensor that can detect any flaws or impurities in the material. If there are any irregularities, they can be removed before the production process begins.

4.What Are The Applications Of A Feeding Machine?

Feeding machines can be used in various industries, including food processing, manufacturing, industrial assembly, and packaging. Here are some of the most common applications for feeding machines.

Food Processing

In food processing, feeding machines are used to deliver ingredients into mixers, grinders, and other food production equipment. These machines can accurately measure ingredients for precise measurements and help ensure consistent quality of the finished product.

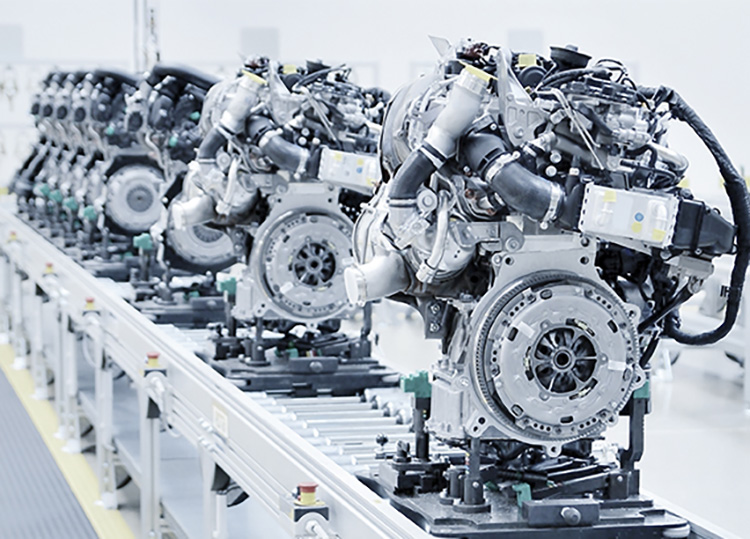

Industrial Assembly

Feeding machines are an integral part of industrial assembly operations, such as automotive production. The automated handling of components can increase accuracy, speed up assembly time, and reduce the risk of workplace injuries associated with the manual handling of parts.

cosmetics

Feeding machines are also used in the cosmetic industry. They are designed to feed a wide variety of materials into production lines and can help automate processes for high-precision product finishing. The automation offered by these machines helps improve consistency and reduce labor costs.

Pharmaceutical Production

In pharmaceutical production, a feeding machine can be used to measure, mix, and combine ingredients for medicines or supplements. They can help automate processes for precise dosage and ensure the accuracy and consistency of the final product.

Agriculture

Feeding machines are also used in agriculture to feed animals on farms. They can help reduce the labor costs associated with animal care and provide accurate feeding times that may be required for certain livestock species.

5.What Are The Advantages Of A Feeding Machine?

There are numerous advantages to having an industrial feeding machine. Here are some of the most significant:

Increased Productivity

By eliminating manual labor from repetitive tasks, the use of a feeding machine can help increase productivity significantly. The machine is able to work faster and more efficiently, leading to increased production speeds while also reducing costs associated with manual labor.

Improved Accuracy

With a feeding machine, the accuracy of the feed is greatly improved due to the precision of the machine and its ability to make small adjustments in order to guarantee a consistent product size. It ensures that each product or material is precisely fed into an assembly line or other processing machinery.

Reduced Material Waste

As the feeder can make precise adjustments to ensure consistent product size and uniformity, it helps reduce material waste that would otherwise occur from manual feeding operations. This helps companies to save on costs associated with wasted materials and can help increase overall profitability.

Improved Safety

The use of a feeding machine ensures that employees are not exposed to potentially hazardous conditions during manual feeding tasks, as the machine does all of the work for them. This helps keep workers safe and healthy while also minimizing the risk of injury or illness.

Versatile

Feeding machines can be used in a variety of settings, ranging from small assembly lines to large manufacturing plants. They can also handle different types of materials, such as plastics, metals, and more. This allows companies to customize their feeding operations according to their specific needs.

Easy to Maintain

Feeding machines are easy to maintain and can be kept in good working order with regular cleaning and lubrication. This helps companies save on repairs and maintenance and reduce any downtime that could occur due to unexpected machine failures.

Easy integration

Industrial feeding machines are designed to integrate seamlessly into existing production systems. It helps companies save on time and money associated with customizing their assembly lines or purchasing additional equipment for the installation process. In addition, the machines can also be modified to fit specific applications, making them even more versatile and cost-effective.

6.What Are The Different Types Of Feeding Machines Available?

Feeding machines come in many different types, each designed to suit a specific purpose. Here are the most common types of industrial feeding machines available:

Rotary Feeder

A rotary feeder is a type of machine used to feed materials into another device, such as an extruder or packaging machine, with precision and accuracy. It consists of a rotating drum filled with the material to be fed. The drum rotates at an adjustable speed, allowing the materials to feed into the device in a controlled and consistent manner.

Vibratory Feeders

Vibratory feeders are designed to provide a steady flow of material into another machine by vibrating or shaking the material. This type of machine is commonly used in various industrial applications, especially sorting and packing parts.

Pneumatic Feeders

Pneumatic feeders are designed to feed materials into a machine using compressed air as the power source. This type of machine is often used in assembly lines and other applications requiring precise and consistent material feeds.

Auger Feeders

An auger feeder is a type of machine used to provide an accurate and continuous flow of material from a hopper or container into another device, such as an extruder. It consists of two parts: the auger, a rotating screw-like device, and the hopper or container. The auger spins at a controlled speed and pushes the material into the device.

Belt Feeders

A belt feeder is a machine used to move materials along a conveyor belt system. This type of machine can be used to feed various types of materials, such as wood chips, grains, and metal components. It is commonly used in industrial applications and in the construction of large objects such as bridges or buildings.

7.What Types of Products Can Be Fed By a Feeding Machine?

Feeding machines can handle products of different shapes, sizes, and weights, allowing manufacturers to quickly and reliably automate their production processes. Here are some examples of the types of products that a feeding machine can feed:

Fruits and Vegetables

When it comes to fruits and vegetables, a feeding machine is essential for sorting, positioning and orienting them before they are cooked or processed. In addition to helping manufacturers keep up with high demand and reduce labor costs, industrial feeding machines also help to ensure product quality by reducing human contact with food products.

Snacks and Cereals

Snacks and cereals are some of the most commonly fed products by feeding machines. From potato chips to cereal pellets, a feeding machine can sort, count, and orient different types of snacks and cereals quickly and accurately.

Clothing

Another popular product that a feeding machine can feed is clothing. From sorting and counting garments to positioning them for sewing, a feeding machine can help reduce labor costs and increase the efficiency of garment manufacturing processes.

Electronic Components

A variety of electronic components, including chips, resistors, connectors and capacitors, can also be fed by a feeding machine. It is an essential tool for electronic manufacturers to quickly and accurately position components during assembly operations.

Medical Devices

A wide range of medical devices, such as pacemakers, catheters and implants, can also be fed by a feeding machine. This helps ensure product quality while accelerating the production process, making it more efficient and cost-effective.

Screws and Bolts

A feeding machine is also used in the production of screws and bolts. It helps to sort, count and orient the fasteners accurately before they are inserted into other components.

Lotions

cosmetic products can also be fed by a feeding machine. It helps to accurately dose and dispense the products without human contact, improving accuracy and increasing efficiency in production processes.

8.Are There Any Tips For Maintaining A Feeding Machine?

While industrial feeding machines are intended to save time and money, proper maintenance is essential for them to run smoothly and reliably. Here are some tips for maintaining your industrial feeding machine:

Check the Machine Regularly

Monitor the feeding machine regularly for any clogging, jamming, or unusual sounds that indicate a malfunction. This can help you catch problems before they become serious and save time and money on repairs.

Clean and Lubricate Parts

Food particles can accumulate on parts of your feeder over time, so it’s important to keep all moving parts clean and lubricated. Use a cleaning solution specifically designed for industrial machinery, and pay special attention to the conveyor belt, feed screw, and other parts constantly in motion.

Monitor Feed Rates

Make sure you are monitoring feed rates accurately to avoid overfeeding or underfeeding. Overfeeding can cause jams in the machine, while underfeeding can slow production.

Check Electrical Components

Examine the electrical components of the feeding machine regularly for any signs of corrosion or damage. If there are any visible problems, you may need to replace the wires or other parts before they cause more serious damage.

Replace Worn or Broken Parts

When inspecting your machine regularly, check for any worn, loose, or broken parts that need to be replaced. This can help prevent further damage and ensure the smooth operation of your feeding machine.

9.What Are The Common Problems Associated With Feeding Machines And How Can They Be Fixed?

A feeding machine is an essential part of any industrial production line, and maintenance should be a priority. Unfortunately, problems can arise with the feeding machine that could disrupt or even halt production. Check out some common problems associated with industrial feeding machines and how they can be fixed.

Wear and tear

Normal wear and tear are unavoidable in industrial production, but they can cause problems for feeding machines if not addressed promptly. The constant operation causes parts to wear down and become less effective, resulting in reduced performance.

Solution: Regular maintenance, such as lubrication and inspection of worn parts, should be done to keep the feeding machine running smoothly. Replacement of worn-out components may also be necessary.

Poor accuracy

Accurate feeding is an essential part of any industrial process and can affect the quality of the output. Poor accuracy in a feeding machine can cause production delays or poor-quality products.

Solution: Make sure your feeder is calibrated to the correct settings, and adjust it as needed if it starts to drift out of specification. Additionally, use a reliable hopper and vibratory bin level system to ensure proper fill levels.

Jammed Parts

Feeding machines may get jammed because of foreign particles or debris, preventing parts from moving correctly. They can also jam up if the parts are too tight, which inhibits movement.

Solution: First, check that the parts are not too close together. If necessary, adjust the spacing to allow for better movement. Also, clean any excess debris or particles that have built up on the machine and the surrounding area.

Incorrect Timing

Feeding machines require precise timing in order to function properly and may need to correct their timing if they are calibrated correctly.

Solution: Check all the settings on the machine to ensure they are set to the correct values. If necessary, recalibrate or reset any parameters that could be causing issues with the timing.

Sensor Issues

If a feeding machine is not working properly, it could be due to sensor issues. These sensors need to be working correctly in order for the machine to detect the presence of parts and adjust its operation accordingly.

Solution: Make sure that all the sensors are clean and functioning properly by testing them one at a time. If necessary, replace any faulty or broken sensors and readjust the settings for optimal performance.

10.How Do I Troubleshoot Common Issues With A Feeding Machine?

If you’re having trouble with your industrial feeding machine, there are a few steps you need to take to troubleshoot the problem. The first step is to identify which component of the feeding machine is malfunctioning. Are you experiencing problems with the hopper, auger, motor, or control panel? Once you have identified the problem area, you can target the specific issue and begin troubleshooting.

The next step is to check all visible components of the feeding machine. Look for any signs of wear and tear, as well as any debris that may have built up over time. Clean out any dirt or dust collected in the system, and ensure all moving parts are properly lubricated.

Once all the components have been checked and cleaned, it’s time to move on to deeper troubleshooting. You can begin by testing the control panel on your industrial feeding machine. Check that each setting is configured correctly and make necessary adjustments if required. Then, run some tests to see if the machine is operating as expected. If the issue persists, you can check for any system errors or malfunctions.

If the problem still isn’t resolved, it may be necessary to contact a repair technician who can inspect and diagnose the machine more thoroughly. A qualified technician will have experience with industrial feeding machines and should be able to identify and address the underlying problem quickly.

Conclusion

Feeding machines are a valuable asset for any industry, helping to reduce labor costs, improve efficiency and productivity. With their customizable features, they can be tailored to fit any production line and help increase the productivity of any organization. So, if your industry needs a reliable and efficient feeding machine, consider buying from a reliable supplier such as Allpack today. You won’t regret it!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours