FAT And SAT:The Complete FAQ Guide In 2025

There are many processes involved in the production and commissioning of equipment. Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT) serve as two vital stages. The completion of acceptance at these two stage represents that the machine is qualified.

How much do you know about these two types of acceptance testings? Why are these two acceptance testing means so important? Are you curious about the similarities and differences between them? Do you know their procedures?

Well, today, let’s explore the complete FAQ guide of FAT and SAT.

1.What is FAT?

Factory Acceptance Testing - Sourced: NSFLOW

The full name of FAT is Factory Acceptance Testing. As the name shows, FAT refers to the inspection of equipment at factory, that is, before it is delivered to customers.

During the factory acceptance testing stage, both the customer and manufacturer will take part in the acceptance at the manufacturer’s factory. The goal of this testing is to confirm whether the equipment meets the specifications as expected.

2.What is SAT?

Site Acceptance Testing - Sourced: Issuu

SAT, officially known as Site Acceptance Testing, is conducted after implementing FAT. This testing means refers to checking whether the equipment is functioning properly at the customer’s site.

There are several content involved in SAT. Generally, SAT includes inspections of the mechanical appearance, electrical wiring, and other aspects of the equipment.

3.Why is FAT and SAT so Important?

As two vital stages in the acceptance testing of equipment, do you know why FAT and SAT are important processes? If you are curious about it, let’s move on the importance of FAT and SAT.

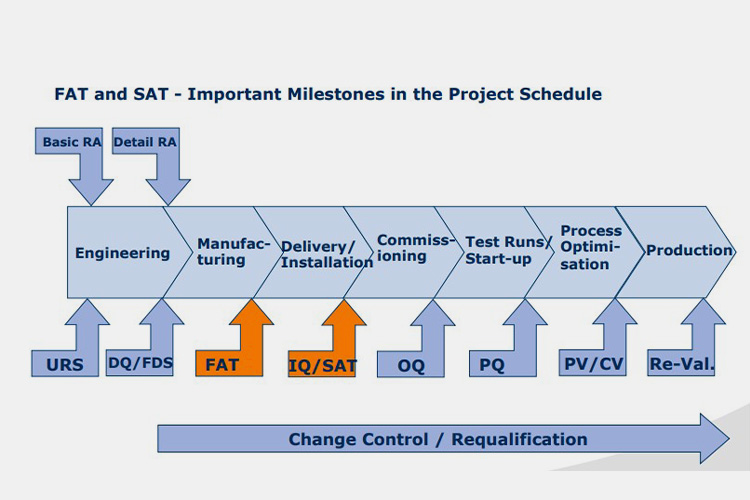

Importance of FAT and SAT - Sourced: BF Group

According to the above figure, FAT and SAT are two important acceptance stages in the equipment production to delivery process. Strict acceptance criteria and detailed testing data are key to the successful execution of FAT and SAT.

For factories, FAT is important means to ensure product quality and production safety. Through professional testing, factories can discover problems and hidden dangers in the machine’s production process, and take timely measures to improve production efficiency and machine’s quality. In addition, FAT can also help factories comply with legal and regulatory requirements, avoiding fines and legal liabilities caused by illegal operations.

For customers, SAT is also an important way of ensuring product quality. User conduct site acceptance testing of the equipment to ensure that its performance and functionality meet expectations in actual usage environments. This step ensures that the system can work stably and reliably under actual operating conditions, and meet the needs of users.

4.What are the Benefits of FAT and SAT?

Why we need conduct FAT and SAT? These two stages play a crucial role in the delivery, installation, and commissioning of equipment. Through these two stages of acceptance procedures, it can be ensured that the equipment can operate smoothly and meet the needs of users. Are you curious about their detailed benefits?

(1)Meeting customers’ requirement

Meeting Customers’ Requirement - Sourced: protoplastics.com

Satisfying the customer’s need is the ultimate objective of product. FAT and SAT can check that the machine whether meet the customer’s requirements. Once the equipment passes the inspection, it can proceed to the next step.

(2)Safeguarding the quality of the equipment

Through professional testing of FAT and SAT, problems with the equipment can be identified and timely adjustments and repairs can be made to ensure the quality of the final product, and ensure that system components and overall performance meet industry standards..

(3)Saving time and cost

Saving Time and Cost - Sourced: Applied Performance

By conducting FAT and SAT, machine problems can be detected and reported to relevant departments for timely repair, thereby avoiding rework and maintenance costs caused by final product quality issues.

(4)Reducing risk

Reducing Risk - Sourced: 54 Collective

These two testing methods can avoid certain risks. By testing the system in a controlled environment, potential issues can be identified and fixed, reducing the risk of failure after on-site installation.

5.What are the Similarities between FAT and SAT?

We have learned that FAT is conducted at the manufacturing plant before shipment, and SAT is the on-site testing of installation after shipment to the user. As two acceptance testing, FAT and SAT testing methods have some similarities, mainly including:

(1)Quality and safety assurance

Quality Assurance - Sourced: Wise IT

The main purpose of FAT and SAT is to test the quality and safety of products and meet customers’ need before they are put into use.

(2)Requiring documentation

During the process of FAT and SAT, the test date and corrective behaviors need to be documented and a final FAT/SAT report need to be written.

(3)Comply with regulatory standards

Regulatory Standards - Sourced: The FAIR Institute

Both FAT and SAT need to be tested according to industry regulations and standards, which are set by agencies such as FDA and EMA.

6.What are the Differences between FAT and SAT?

Although FAT and SAT both belong to acceptance testing and have some similarities, there are also some differences between these two acceptance methods, mainly reflected in the testing site, environmental conditions, and other aspects.

(1)Testing site

Testing Site - Sourced: AIST Global

The biggest difference between FAT and SAT lies in the detection site. FAT is tested at the manufacturer’s location. SAT conducts testing at the customer’s location. After the equipment is successfully delivered to the user’s site, the user representative will conduct SAT to ensure that the performance and functionality of the equipment meet expectations in the actual usage environment.

(2)Environmental conditions

Because they conduct in different sites, the environmental conditions of the testing sites where FAT and SAT conduct are diversified, mainly displaying in compressed air or steam, temperature and humidity.

(3)Documentation

Documentation - Sourced: Zamann Pharma Support

FAT and SAT need documentation, and they are differed in the level of detail of the content. The information in the FAT documentation is more abundant than SAT documentation. FAT needs to undergo more functional and safety testing, with more specific and diverse testing content, in order to guarantee the quality of the product when it leaves the factory.

(4)Time

FAT and SAT are at different time stages in the completion of equipment. FAT conducts before delivering the machine to the customer, and SAT conducts after the installation of the machine.

7.What are the Procedures of FAT and SAT?

Due to the similarities and differences between FAT and SAT, their procedures also have similarities and differences. Well, let’s learn about their detailed process together.

(1)FAT procedure

The common FAT procedure goes through 6 stages, as follows:

| Procedures | Description |

| 1.Planning and preparation | Before acceptance, the staff need to develop a detailed acceptance plan, including the equipment to be accepted, the acceptance personnel, the acceptance time, and standards. |

| 2.Visual testing | Checking the appearance of the equipment, mainly including components, labels, joint and painting. It is also necessary to check whether the instruments and accessories are consistent with the contract.

In addition, it is necessary to check the wiring of the power supply unit, the input voltage of the power supply, and whether the nameplate is correct. |

| 3.Functional testing | Conducting functional testing on the equipment, including charging and discharging cycles, adjusting parameters, etc. |

| 4.Stability test | When conducting stability tests on the machine, continuous operation for 72 hours is required. Mechanical, electrical, or software adjustments cannot be made without the buyer’s permission. |

| 5.Safety testing | Testing the safety of the equipment, including alarm function, to ensure compliance with safety standards and enable safety protection measures under fault conditions. |

| 6.Documentation | Recording the results of the test and any issues that arise. |

(2)SAT procedure

The common SAT procedure goes through 5 stages, as follows:

| Procedures | Description |

| 1.Preparation and installation | Before conducting SAT acceptance, it is necessary to make sufficient preparations for the equipment, including installation, debugging, calibration, etc.

Preparing for equipment installation and debugging, and reading the FAT documentation. Installing the equipment by technical personnel from the manufacturer at the customer’s location. |

| 2.Visual testing | Check for any damage or issues with the equipment during transportation. |

| 3.Functional testing | Connecting the equipment to other devices and conducting functional testing on the equipment. For control systems, loop verification is a necessary step. |

| 4.Inspection of User Requirement Specifications | Check the user requirements specifications to ensure that the design and functionality of the equipment meet the user’s needs. |

| 5.Documentation | Record the results of the test and any issues that arise. |

Overall, the processes of FAT and SAT can be repetitive, both the customer and manufacturer need to send engineers to participate in FAT and SAT, but SAT can detect issues that FAT cannot detect in actual environments.

8.What Items are Included on the FAT and SAT Checklists?

The Factory Acceptance Testing and Site Acceptance Testing Checklist is a comprehensive document that lists the standards, procedures, and requirements for evaluating and verifying the quality and functionality of machine and systems. All FAT and SAT checklists are not exactly the same, but they basically include the following points.

FAT and SAT Checklists - Sourced: Psychology Today

List of testing machines: This mainly records the names and models of the machines that need to be tested.

The reference specification list: It includes a series of related files involved in the FAT and SAT processes, such as dimensions, materials, and performance parameters.

Equipment calibration certificates: A calibration certificate for testing equipment is a document that proves that a specific device has been inspected, tested, and adjusted to meet specific accuracy and precision requirements.

Test data: After conducting functional, performance, and security tests, the operators record test results, including any issues identified during testing.

9.Why Is SAT Conducted After FAT?

One major difference between FAT and SAT is that they are in different time periods, and SAT needs to be conducted after FAT. Do you know the reason behind it?

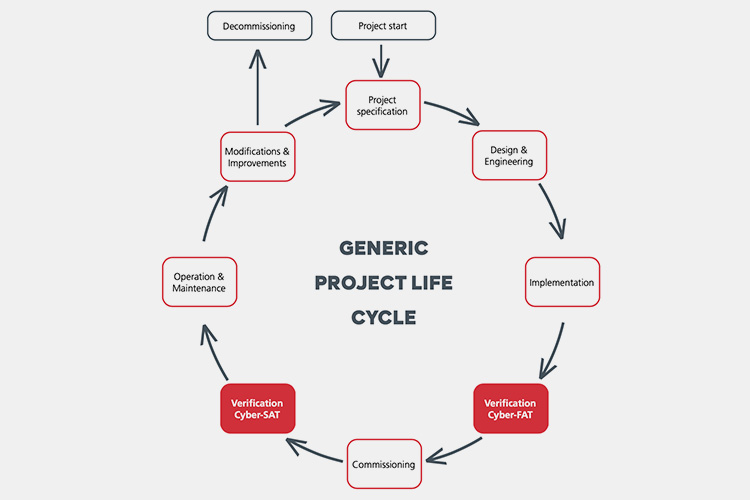

Generic Project Life Cycle - Sourced: Secura

The picture above shows the generic project life cycle. When the equipment completes FAT, it can ensure the quality of the equipment before leaving the factory. During the transportation of equipment to customers, damage may occur. SAT can further detect quality issues and, when operated in actual environments, can detect problems that were not detected in the factory.

FAT mainly focuses on the manufacturing quality and performance of equipment, while SAT pays more attention to the reliability and stability of equipment in actual use environments. Therefore, site acceptance testing must be conducted after factory acceptance testing.

10.What Should be Considered When Conducting FAT and SAT?

In order to obtain accurate results, we need to consider multiple factors when conducting FAT and SAT.

(1)Using proper materials

Different Materials - Sourced: PixelSquid

Each machine uses different materials, including liquids, solids, and particles. Different materials can affect the testing results, and in severe cases, even the performance of the machine. Therefore, it is necessary to choose suitable materials according to the machine’s user manual.

(2)Training operators and technicians

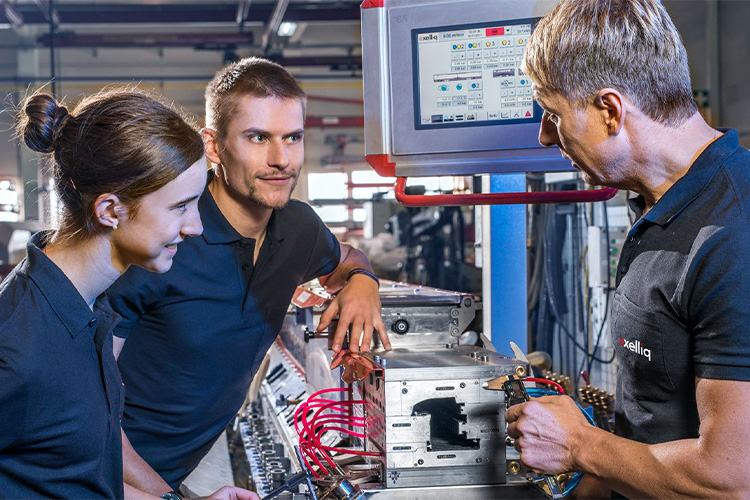

Training Operators And Technicians - Sourced: Exelliq

It is necessary to enhance employees’ professional knowledge and skills, strengthen their knowledge of equipment testing, verification, and compliance. Technical personnel are required for guidance and installation during FAT and SAT. Operators need to constantly observe the operating status of the machine, identify problems and defects of the machine.

(3)Understanding user requirements specification

User Requirements Specification - Sourced: Post en Dekker blog

During the initiation phase of the project, users provide their expected usage requirements for the production equipment. This instruction needs to be combined with practical factors such as usage purpose, usage environment, and purpose.

Based on sufficient information collected, the equipment requirements should be provided as comprehensively as possible, and these requirements should be verifiable. The descriptions used in the URS should be clear, accurate, and measurable. These requirements include: Product and process requirements, regulatory compliance requirements, operational, maintenance, and technical requirements.

(3)Effective cooperation and communication

Effective Cooperation And Communication - Sourced: GenSight

Effective communication plays an important role in greatly improving work efficiency. Manufacturers and customers need strengthen cooperation and communication. During the FAT and SAT processes, effective communication is necessary to promptly adjust and resolve any issues that arise with the machinery and equipment.

Conclusion

FAT and SAT serve as a significant role in the acceptance progress of machines, which should be taken seriously to ensure the smooth delivery and use of equipment. Have you gained a better understanding of FAT and SAT after reading this article? If you have any further questions about acceptance testing, feel free to contact Allpack at any time.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide