Everything You Need to Know About Tube Filling Machine Parts

In the realm of production and packing, speed and accuracy are critical parameters. Tube-filling machines are crucial in multiple industries, including pharmaceuticals and cosmetics. They are responsible for precisely filling and sealing several items in their packages/tubes.

Understanding the fundamental parts and the working protocols of a tube filling machine is essential for workers, maintenance staff, and managers to maximize efficiency, solve problems, and uphold strict manufacturing standards.

This blog post will cover all the details you need to know about the tube filling machine to get the best one for your business.

1.Tube Filling Machine and its Different Types

A tube filling machine is a specialized device engineered for precisely filling and sealing several products in plastic or metallic packaging tubes. It is an indispensable constituent of several sectors, such as pharmaceuticals, food, and cosmetics.

Various models of tube filling machines specifically developed for varying production needs are marketed. These models are categorized based on automation level and are described below:

Manual Tube Filling Machine

Manual Tube Filling Machine

As the name indicates, such tube filling machines require human involvement throughout the working process. It is made up of high-grade stainless steel. It is a hand-operated device comprised of a lever mechanism. The tubes are manually placed under the spout and the lever is pulled to dispense the product into the tube.

After filling, the tail end is folded and sealed through pressure contact using another lever system. It has less production capacity, entirely dependent on the operator’s skills. It is a suitable device for small-scale businesses with minimal production needs.

Semi-automatic Tube Filling Machine

Allpack Semi-automatic Tube Filling Machine

The partially automatic version of the tube filling machine is slightly more advanced than manual ones but less efficient than fully automated versions. This device combines manual and automated actions. Some processing steps are performed manually while the device handles the rest of the process through self-activated mechanisms.

The basic components in the device include the hopper, filler, sensor, and sealer. Loading of tubes and material plus discharging of finished tubes are performed manually.

Automatic Tube Filling Machine

Allpack Automatic Tube Filling Machine

The automatic tube filling machine is an advanced equipment with the latest technology. The device is equipped with sophisticated components, effectively carrying out the whole packaging process with minimal to no operator intervention.

It is an ideal element for large-scale industries as it can process large quantities of products in a limited time with profound accuracy and efficiency.

2.Everything You Need to Know About Tube Filling Machine Parts

Although various varieties of tube filling machines are available, they all have the same essential components. With a better understanding of these fundamental components and their functions, you will be able to get the most out of your device and maintain it in better condition. Here is a detailed description of everything you need to know about the tube filling machine’s essential parts:

Body

Body/Frame – Picture Courtesy: iPharmachine

The body is the support system of the entire device, holding the components together. It is usually made up of high-grade corrosion-resistant stainless steel. It is the external part of the device and all the components are covered by it.

Hopper

Hopper

It is an important part of the tube filling machine. It is located at the top of the device and is responsible for temporarily housing a bulk quantity of empty tubes. It feeds the tubes to the device’s rotary table at a steady rate to optimize the process. Its size and shape vary with different models.

Filler

Filling Spouts

It is another critical component of the tube filling machine and is responsible for filling the tubes precisely and efficiently. It consists of filling nozzles that dispense the product into the tubes directly. It can be customized based on the shapes and sizes of the tubes.

Sealer

Sealer

The sealer is responsible for sealing the tail ends of the tubes after filling. It prevents product leakage and unwanted spills.

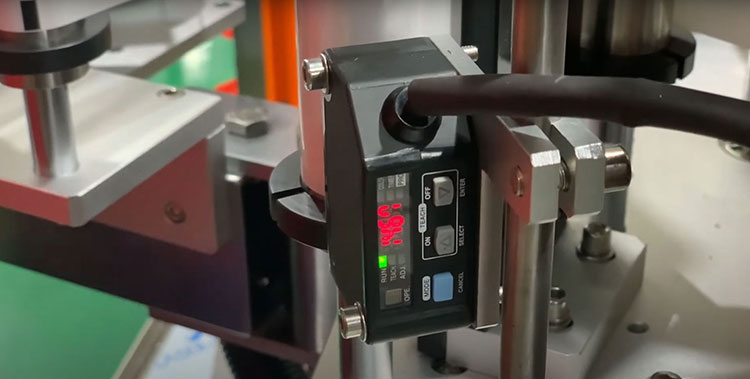

Sensor

Sensor

The sensor is responsible for detecting errors in the filing process. It aids in recognizing inaccurately filled tubes and minimizes operational errors.

Cutter

Cutter – Picture Courtesy: Sainty Tec

After sealing, the cutter trims the ends of the tubes to make them look elegant.

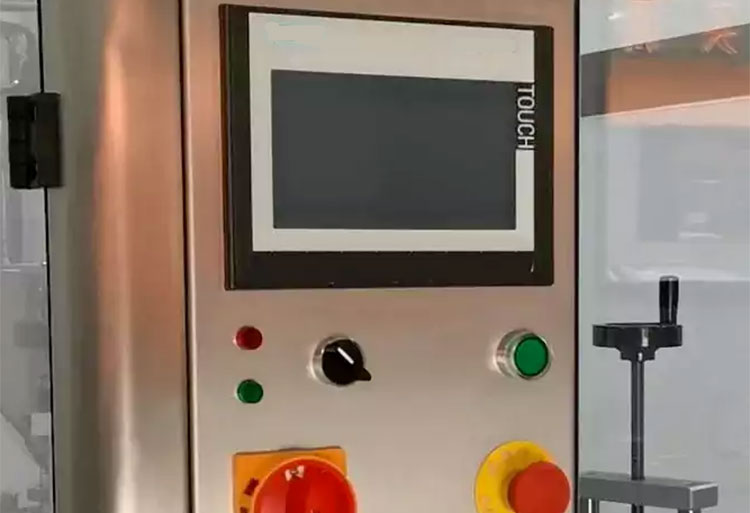

Control Panel

Control Panel

The control panel is a digitalized touch screen, allowing operators to monitor the tube filling process and regulate it accordingly.

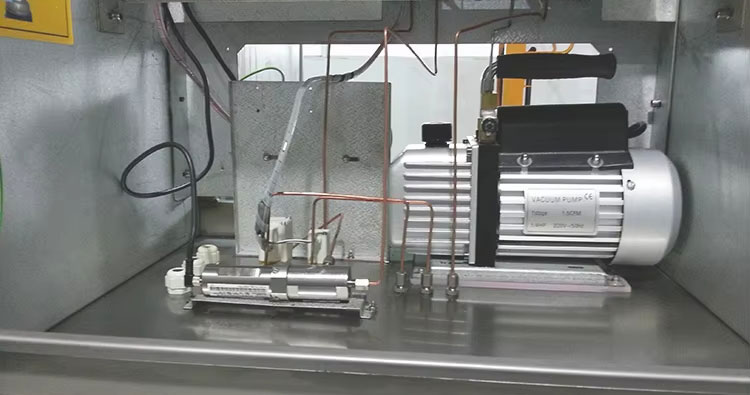

Electric Motor

Electric Motor

The electric motor provides the necessary power supply to run the machine smoothly.

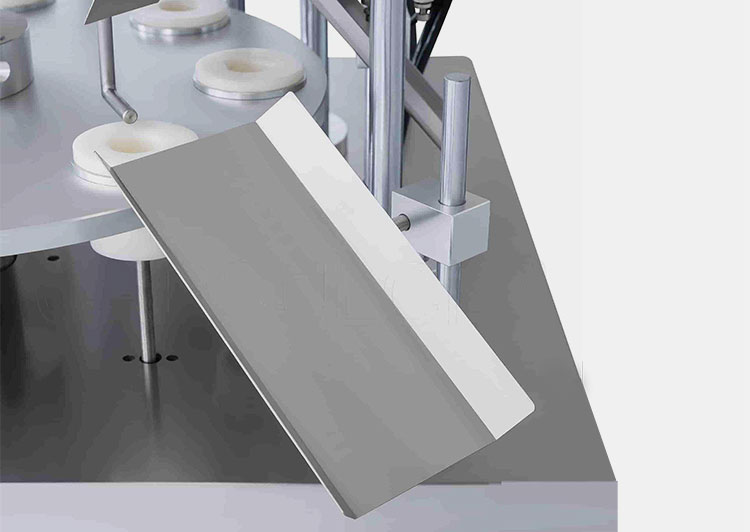

Discharge Unit

Discharge Unit

The discharge unit has the typical shape of an inclined flat surface. It collects the finished tubes (filled and sealed) and expels them from the device for further processing.

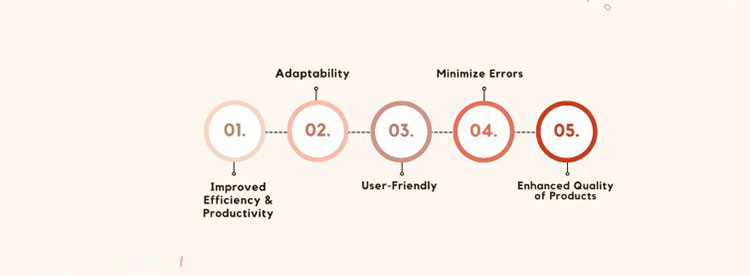

3.Benefits of Tube Filling Machine

The tube filling machine is a tremendous innovation in the packaging industry. It offers numerous benefits across several industries. Here are some major benefits a tube filling machine provides to your business:

Improved Efficiency and Productivity

Improved Efficiency and Productivity

The device automates the packaging process and minimizes human intervention, resulting in efficient processing and increased production output. The hopper feeds the empty tubes and directs them to the rotary table which in turn guides them in an orderly manner toward the filling and sealing section. The entire process is performed by the device automatically.

Adaptability

Adaptability – Picture Courtesy: VKPAK

The tube filling machine is a versatile tool. The filling nozzles can be adjusted as per the product’s nature and tube dimensions.

User-Friendly

User-Friendly

The control panel screen of the device offers a user-friendly experience. The device can be operated quite easily using the touch screen and regulating the process parameters.

Minimize Errors

Minimizing Filling & Sealing Errors

The tube filling machine provides precision in filling, minimizing errors. The sensors detect the tube alignment as well as the filling gauge, resulting in accurately filled tubes.

Enhanced Quality of Products

Enhanced Quality of Products

Automated mechanisms prevent cross-contamination during the process. It improves the product’s hygiene and overall quality.

4.What are the Products of Tube Filling Machines in Various Industries?

The tube filling machine is a sophisticated and versatile piece of equipment. It is utilized across various industries to package several products in tubes. Some of the notable materials packaged in tubes using a tube filling machine are:

Cosmetic Products

Cosmetic Products

Several cosmetic goods are packaged in tubes using a tube filling machine. The efficient sealing maintains the safety, freshness, and purity of these personal care items. These items include:

- Shampoos

- Tooth gel

- Moisturizing lotions

- Face creams

- Shower gels

- Face serums

Medical Care Products

Medical Care Products

In the medical care industry, the tube filling machine is utilized to contain several medicinal items in various tubes. It maintains the product’s integrity for the desired amount of time. Some common items are:

- Skin ointments

- Creams

- Lotions

- Topical pastes

Food Items

Food Items

The tube filling machine is also a popular equipment in the food sector. Several food items are filled by this device, keeping them fresh and pure. These items include:

- Ketchup

- All types of sauces

- Chicken Spread

- Puddings

Veterinary Products

Veterinary Products

Several veterinary items come in tubes. The tube filling machine efficiently fills these products. Some common items are:

- Pet food

- Veterinary medical creams

- Nutrition products

Stationery Items

Stationery Items

The tube filling machine also fills various stationery goods in tubes. These include:

- Paints

- Adhesives

- Liquid colors

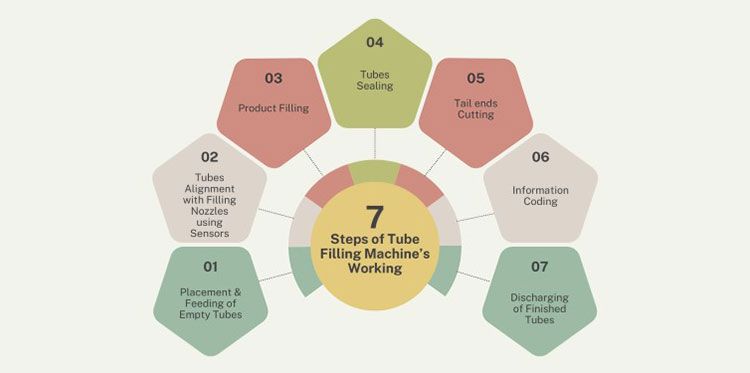

5.Working Principle

As you have understood the role and function of the crucial tube filling machine parts, you might think about how this machine operates. So, let’s find it out!

Step 1: At the beginning, the empty tubes are placed in the hopper, which feeds them to the device where they move toward the rotary table.

Step 2: As the tubes pass the filling section, their alignment is detected by the sensor. If the tubes are not aligned with the nozzles, they are adjusted automatically. It helps in product spillage and ensures precise filling.

Step 3: Subsequently, the filling spout is advanced to enter the tube and dispense the predetermined amount of product. In piston tube filling machines, the spouts are activated by the cylinder.

Step 4: After filling, the tubes are directed toward the sealing segment where the sealing clamps seal the ends.

Step 5: After sealing, the sealed end of the tube is precisely cut and refolded to enhance its durability.

Step 6: Once the tubes are finalized, crucial information about the product is coded onto it. It is an optional step in the process.

Step 7: After proceeding through all the sections, the finished tubes are expelled from the machine through the discharge unit.

6.Heat Sealing vs Ultrasonic Sealing

The tubes are passed through the sealing section after being filled, where they are efficiently sealed to prevent leaks. There are 2 common mechanisms used for sealing tubes:

Heat sealingis an efficient and common method of sealing tubes. It utilizes excess temperature to melt and seal the tubes.

Ultrasonic sealinguses ultrasonic rays for sealing. It is a more efficient and fast approach to sealing. It is a beneficial method for heat-sensitive products.

7.Maintenance

The tube filling machine requires a significant amount of investment. Regular maintenance and cleaning are needed to keep it in optimum condition and ensure its extended lifetime. Some of the necessary measures that should be taken are described below:

Regularly wipe out the whole device after each working batch.

Conduct a deep cleaning operation of the device to prevent accumulation and left-over residues. Disassemble the device and thoroughly wash every component with water or any other suitable cleanser using a soft fabric, particularly the hopper and sealer.

Check the filling spouts for blockage. Clean them to clear the clogging.

Lubricate the dynamic elements of the device to reduce friction and ensure uninterrupted operation.

Regularly check the sensor for accuracy to abstain from inconsistency.

Periodically examine all the parts for damages and tears, especially sealer, cutter, and nozzles. Replace or fix the damaged parts immediately to avoid costly breakdowns.

Regularly update the software to the latest version to gain access to the newest features.

Conclusion

Finally, a tube filling machine is a must-have for any production line given its numerous benefits and value addition to businesses. It is a handy and versatile equipment for a variety of sectors. After understanding its different parts and their functions, you will certainly realize what a beneficial tool it can be for your business. It can be overwhelming to look at the diverse range of models of the tube filling machine, so choosing the best one for your products can be challenging. If you need assistance in this regard, please contact Allpack, a reputed manufacturer and service provider. You will surely be guided in a better way!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide