Equipment For Making Cosmetics: The Complete FAQ Guide In 2025

It seems like you are a cosmetics manufacturer and looking forward for relevant equipment. Isn't it? Probably yes! Well, cosmetic industry is on rise due to its global demand which is why spending on its manufacturing for quality production can potentially generate high profit. In this way, one of the primary requirements is to have Equipment For Making Cosmetics.

Did you have any idea about the equipment needed? Or are you new in the field and finding it difficult? In any case, there is no need to worry as we are here to provide you with a detailed FAQ guide which is going to end all of your queries. So, stay tuned and know about the list, uses, features, and handling requirements of equipment for making cosmetics!

1.What Are The Equipment For Making Cosmetics?

Various lipsticks- Picture Courtesy: gienicos.com

The use of cosmetics is no exception in our daily life! Starting from cleaning to beautification of hair, face, and nails, we continuously use beauty care products. These products vary from liquid shampoo to semi-solid creams, gaseous perfumes and solid soap bars.

As the physical properties and essence of these cosmetics vary from one another, different machines are used for their production. These equipment undertake all the steps from preparing raw material till their transformation into finished products.

In this way, the common equipment used for making cosmetics include crushing machine, emulsifying mixers, moulding tools, compression machine, and filling machine. You will know these equipment in detail in the upcoming questions.

2.Why Equipment For Making Cosmetics Are Important?

Cosmetic filling into jar- Picture Courtesy: unilogo.com.pl

As we know, that cosmetics are used on regular basis in form of moisturizer, oil, and lip balm etc., they are in direct contact with our skin and hair which are very sensitive. In this way, it is very important that high quality and safe equipment are used which preserve the originality and delicacy of the produced products.

Similarly, cosmetics are usually available in powder, liquid, or semi-solid form. These structural forms needs to be well processed under required condition and time period. Thus, it is only possible when necessary equipment like emulsifiers, mixers, and compaction machines for cosmetics are durable and automated.

3.Enlist Some Of The Major Equipment For Making Cosmetics?

There are multiple equipment used for making cosmetics. Some of the frequently used apparatuses include:

Vacuum Emulsifying Mixer

Allpack APKZRJ Bottom Homogenizer Vacuum Emulsifying Mixer

Vacuum emulsifying mixer is one of the important equipment used for making cosmetics. It is suitable for the emulsification of various semi-solid cosmetic products such as lotion, ointment, sunscreen, toothpaste, and gel etc. The machine is made up of a water tank, oil tank, main tank, and main frame. It works on the principle of mixing together solid content with gradual inclusion of water and oil. During the process, agitator keep mixing the formula which result in the creation of a homogeneous emulsion.

High Shear Mixing Granulator

Allpack HLSG Series High Speed Wet Mixing Granulator

High shear mixing granulator is another equipment necessary for making cosmetics. The machine is highly durable made with stainless steel body which is corrosion resistant. It is primarily used to make granules from powder by mixing powders with liquid solvent. It functions by adding the liquid solution into filled pot during operation. The continuous movement of agitator and and blade produce uniform shape granules. It is perfect for solid cosmetics including face powder, glitters, shimmer, and highlighter.

Fluid Bed Dryer

Allpack FG-60 fluid bed drier

Fluid bed dryer is an efficacious machine used for the drying of powders and granules. It has precise body with simple operation based on the principle of fluidization where a hot air passed through the material filled perforated bed. The particles flow into air like fluid inside the chamber. Consequently, drying of the substances occur. This equipment is highly effective and required for the drying of various cosmetic products such as loose powder, compact powder, makeup dyes, and bleach powder etc.

Bin Mixer

Allpack Model CH-VI Forced-Type Mixer

Bin mixer refers to an extremely intelligent machine designed to mix or blend powdery or granules type materials. It consists of a revolving bin attached to the main frame with other parts comprising control panel, electric cabinet, and universal wheels. It supports the mixing of two or more types of substances by revolving the bin. The continuous back and forth movement of particles in the bin lead to the formation of uniform particles distribution. Hence, it is best suitable for the mixing of dry cosmetic powders like eyeshadow, glitters, and blush etc.

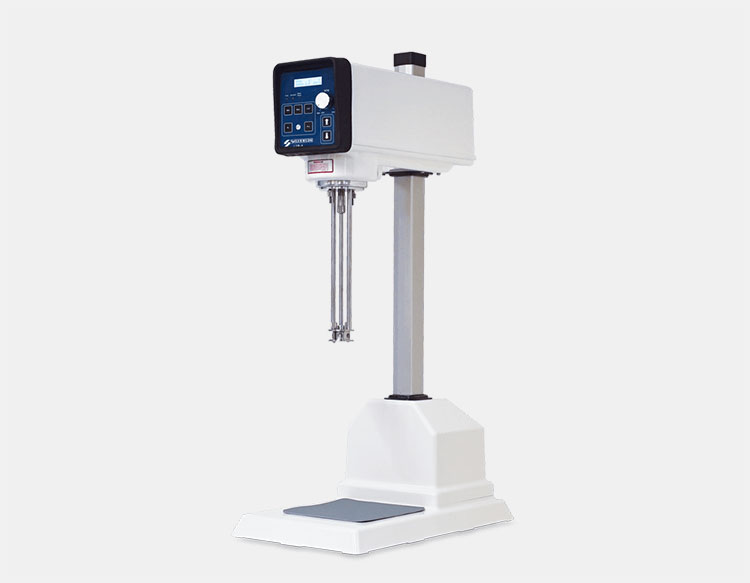

Laboratory Mixer

Laboratory mixer- Picture Courtesy: silverson.com

Laboratory mixer is another advanced equipment included in the list of equipment for making cosmetics. It is a compact solution employed for the mixing and dispersion of various liquid solutions along with solid material which are immiscible. It uses high pressure force and special design agitator and stirrer to mix the materials. It is ideal for making oil based solutions, raw material extraction for cosmetics, and glycerin etc.

Cooking Kettle

Cooking kettle Metos Viking- Picture Courtesy: metos.com

Cosmetics such as soaps, nail polish, creams, and lotions require proper temperature for making. In this way, cooking kettle which is made from quality stainless steel provide the required temperature and ensure uniform mixing with the help of turbo mixers and agitators. The kettle is tailored to match specific requirements regarding temperature and automation making it widely applicable to numerous products.

Storage Tank

Industrial storage tanks- Picture Courtesy: aske.in

Storage tank is designed to facilitate the storage of liquid cosmetics at suitable temperature condition. As there is high chance of corrosion which may degrade the quality of products, storage tank is constructed with 304 and 316 stainless steel. The capacity of storage tank vary from 500L to 30,000L. Similarly, the specifications such as stirring, jacket system, and insulation mechanism make it more rigorous for maintaining optimal temperature.

Lipstick Molding Machine

CRLA20 Lipstick molding machine with silicon molds (20 ppm)- Picture Courtesy: citus-kalix.fr

Lipstick molding machine is another excellent equipment used for making cosmetics such as lipstick, lip balm, highlighter stick, and foundation stick etc. The machine is highly advanced in its construction with automatic technology to safely carry out the molding of lipstick in silicone molds. It easily changes the parts with changing format and have simple cleaning requirements.

Cosmetic Powder Press Machine

5HP Semi-Auto Cosmetic Compact Eyeshadow Foundation Powder Press Machine- Picture Courtesy: gienicos.com

Cosmetic powder press machine is another most significant equipment developed to press face powder, blush powder, and eyeshadows in compact form. It is made up of several components comprising main frame, hopper, pan loading system, control panel, pressing device, and electric cabinet etc. It works by unloading the pan and placing it under filling head from where precise amount of powder is poured into pan and then compressed with pressure.

Universal Crusher

Allpack B Series Universal Crusher

Universal crusher is used for crushing material into powder and granules. In cosmetics manufacturing, it plays crucial role by breaking down the large pieces of dyes and other objects into powder. It has simple construction with easy working principles where objects are loaded in the hopper, passed through the crusher, and discharged from the outlet. This machine can also be used for foodstuff, chemical, and pharmaceutical manufacturing.

Vibrating Sifter Machine

Allpack ZS Series Vibrating Rectangular Screening Machine

Vibrating sifter machine is another valuable machine to be included in the equipment for making cosmetics. It is an advanced solution to replace the traditional method of sieving powders and liquids. As for as cosmetics are concerned, so, most of the time particles are dense or viscous making their further processing a difficult task. Thus, a vibrating sifter machine can perfectly sift the material and end their lumps. It is best suitable for eyeshadow and face powder.

Spray Filling Machine Production Line

AIPAK Spray Filling Machine Production Line

Spray filling machine production line is high automation equipment designed to safely fill spray and perfumes into containers. It consists of a bottle unscrambler, bottle feeder, spray filling machine, and bottle capping machine. The operation is carried out in a synchronized way where bottles are unscrambled, fed to the filling machine, spray is filled into bottles, and then the filled bottles are capped. Hence, the enclosed spray filling is achieved with no danger from environment.

Mascara & Lip Gloss Filling Machine

KM503 Mascara and lip-gloss filling machine (40 ppm)- Picture Courtesy: citus-kalix.fr

Mascara and lip gloss filling machine is a specialized machine in filling mascara and lip gloss. It is well qualified to deal with various viscosities and cosmetics such as concealer, liquid lipstick, and skin corrector etc. The machine come in various capacities for loading material and support different types of containers with varying sizes and shapes. It simply works by taking material from hopper into the filling nozzles, accurately weighing it, and precisely depositing into the bottles. The machine then cap the filled bottles tightly.

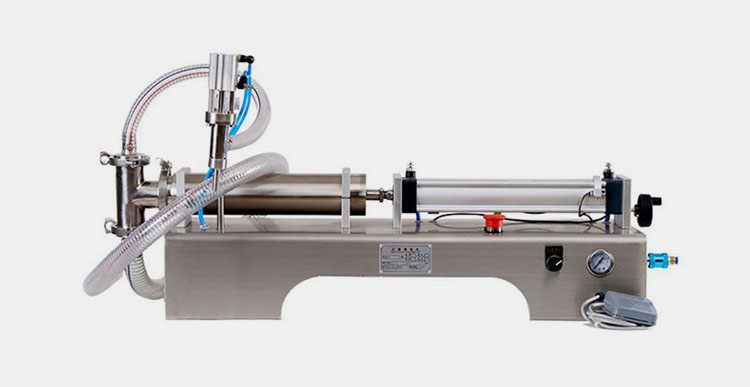

Cosmetics Filling Machine

Allpack Pneumatic Filling machine Cosmetics

Cosmetic filling machine is used for the filling of liquid and semi-solid cosmetics such as creams, lotion, and shampoo etc., in bottles and jars. The machine effectively measure the exact volume to be filled and dispense it into bottles. It uses pneumatic technology for filling cosmetics. It is available in semi-automatic and automatic system to fulfill your diverse needs.

Cosmetic Tube Filling Machine

Allpack NF-80 Automatic Al Aluminum/Plastic Soft Tube Filling and Sealing Machine Lotion

Cosmetic tube filling machine is other such significant equipment used for the filling of ointment, facial cream, face mask, moisturizer, and hair gel etc. It is characterized by durable structure made up of stainless steel body, material hopper, working chamber, and control system. It undertakes the process in a single run with tube unloading from magazine, its placement over mold, material filling, tube sealing, embossing and trimming etc.

4.What Are The Key Features Of Equipment For Making Cosmetics?

Equipment for making cosmetics have essential features. These are shared by almost all these machines in common which are explained below:

Compact Design

Allpack compact design WLDH- Horizontal ribbon Mixer

From vacuum emulsifying mixer to vibrating sifter machine and spray filling machine, every equipment for making cosmetics has compact structure. They are robust and at the same time easy to mobilize and place anywhere needed.

High Automation

Cosmetic Filling Machines Filling Closing groninger- Picture Courtesy: wfoqfashion.shop

Automation is the key for high production and effective performance of machines which is present in almost all of the equipment for making cosmetics. They are standalone machines that function smoothly and automatically once started. Similarly, they fulfill the production output aims of manufacturers.

Convenient Operation

Operator placing lid over emulsifying mixer- Picture Courtesy: yekeey.com

For every machine used for manufacturing, the convenience in operation means a lot. The same concept apply to equipment for making cosmetics. They come up with attached devices for controlling and operation such as touch screen and control panel. Thus, less human intervention is recorded while operating the machine.

Quality Compliance

Quality icon- Picture Courtesy: Adobe Stock

The quality of heavy-duty machines like equipment for making cosmetics is necessary which is why you will find these machines with compliance to important quality standards like ISO,GMP, and FDA. They are made while using recommended 304 and 316 stainless steel along with other quality parts.

Versatility

As mentioned above, equipment for making cosmetics are highly automatic and meant for carrying out heavy-duty work. In this way, each machine offers flexibility and is versatile enough to be upgraded and integrated with other machines.

5.What Are The Uses Of Equipment For Making Cosmetics?

When it comes to discuss the uses of equipment for making cosmetics, there are multiple fields where we found these machines being used. Some of these applications are enumerated below:

Beauty Care Industry

Various beauty care products- Picture Courtesy: wfoqfashion.shop

Well, beauty care industry is on the top of the list where equipment for making cosmetics are needed. They are used for making face powder, eyeshadow, lipstick, and shampoo etc. The common examples include pulverizer, filling machine, powder compression machine, and emulsifier machine.

Food Industry

Ketchup & mayonnaise in bowl- Picture Courtesy: menshealth.com

Another major application of equipment for making cosmetics is food industry. These machines are used for producing products like ketchup, sauces, coffee powder, beverages, and pet food etc.

Pharmaceutical Industry

Ointment releasing from tube- Picture Courtesy: making.com

Pharmaceutical industry has a key concern for the production of medicines, ointments, and syrups etc., which is the safe and hygienic environment. Now, this enclosed environment is better provided by equipment for making cosmetics such as stainless steel high shear mixer, vibrating sifter machine, and filling machine etc.

Daily Chemical Industry

Various forms of detergent- Picture Courtesy: oakvalleyappliance.com

These equipment are also useful in daily chemical industry for the production and processing of detergent powder, liquid cleaning agent, and chlorine tablets. They are safe and protected against pollution, corrosion, and environmental moisture.

Lubrication Industry

Lubrication oil bottles- Picture Courtesy: motulindia.com

Equipment for making cosmetics are also useful in lubrication industry. They are utilized for making lubrication oil, greases, and lubricant spray etc.

6.Explain The Cleaning And Handling Requirements Of Equipment For Making Cosmetics?

Cleaning of the equipment for making cosmetics is so necessary as all the associated products are in direct contact with human skin. In this way, it is very important to disinfect your machines on regular basis and also conduct their proper maintenance. The below mentioned guidelines will help you:

Operator maintaining machine- Picture Courtesy: orchidlifesciences.com

Cleaning

Once the machine is done with working task, power it off and disassemble the removable parts like hopper, filling nozzles, sifting tray, and mixing bowl etc.

Use a clean cloth to remove out all the dirt and residues which is left on machine parts.

Now, you may use different cleaning methods such as immersion cleaning, jet cleaning, brushing, or ultrasonic cleaning etc.

Always remember to use recommended detergent agents whether powder or liquid form.

Maintenance

- Conduct visual inspection of your equipment for making cosmetics by checking their different parts for wear and tear. Pay special attention to seals and gaskets due to their proclivity to corrosion.

- Carry out functionality test during operation and examine if the various parts are working effectively.

- Lubricate the moving parts of machines with right type of lubrication oil or grease otherwise it can damage the parts.

- Keep updating the software of machines and calibrate them with right tools and instruments required.

7.Factors To Consider When Buying Equipment For Making Cosmetics?

When buying equipment for making cosmetics, it is essential to consider some of the important factors which are as follows:

Production Level

Operator making a checklist- Picture Courtesy: pharmafranchisecompanies.com

First and foremost thing you need to look for is your production level. Determine where you are standing. Are you new to the field with requirement of medium scale production? Or are you intending to purchase full fledged automatic equipment for large scale industry? Answering these questions will simply let you know to take a wise decision.

Overall Cost

Cost presentation idea- Picture Courtesy: mckenzielake.com

Estimate the cost of equipment for making cosmetics which you need. For this, make sure to look into the exact price of the machine as well as their operation and maintenance cost. Once done, compare it with your budget, so, you will be able to pick for the machine under your budget.

Supplier Reputation

Supplier association icon- Picture Courtesy: datawiz.io

Supplier reputation is significant for every buyer of cosmetics making equipment. It is because you are going to purchase many machines which needs to be installed, operated, and modified with time. In this way, the supplier should be experienced, certified by international quality standards, and must provide warranty and after-sale service.

Customization

With rapidly changing world as a result of technology, it is inevitable that machines are becoming more advanced with new features and specifications. However, this doesn't mean that previous machines are totally replaced rather they can be modified to work efficiently. Therefore, when choosing equipment for cosmetics, check if they can be customized.

Conclusion

To wrap up this FAQ guide on Equipment For Making Cosmetics, it is pertinent to remind the importance of these machines. They are highly advanced and made from quality material which are fully safe to process beauty care products. Each equipment has convenient operation making it easier to operate. They can also be integrated with other machines to make production line. Thus, the production process become more handy. If you are interested in purchasing equipment for cosmetics, Allpack is a reputable supplier working for over 13 years and offering efficacious machines along with one year of warranty. You can contact us through our link!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide