Dry Granulation Process: The Ultimate Guide In 2025

Do you know granulation is gaining traction in the manufacturing industry? With granulation, you can turn fine powder into compact granules within a short time. Two processes are most common in the granulation technique, one being the dry granulation process.

It is a straightforward and cost-effective process, needing less equipment to create a system. A dry granulation process is employed for the manufacturing of moisture and heat-sensitive drugs. It is an efficient process that increases the stability of drug components.

Now this blog “Dry Granulation Process: The Ultimate Guide In 2024” will answer all your questions about the dry granulation process. So, sit tight and read this guide.

1.What is Meant by the Dry Granulation Process?

Dry Granulation Process

The granulation process is particle transformation and enlargement. It is the process by which fine powders are changed into spherical masses called granules. The dry granulation process is a subtype of the granulation process. It is the process in which granules are created without the help of any granulating fluid or binder.

The dry granulation process is typically used for powders that are sensitive to heat and water content. It generates dust-free and free-flowing granules. There is no change in the chemical composition of granules in the dry granulation process because a binder is not added during granulation. This process takes dry raw materials and compacts them in larger granules to lock in the ingredients proportion. It is the most widely used technique for forming oral solid dosage because it densifies powders.

2.Why Do You Need a Dry Granulation Process?

The dry granulation process is needed for different purposes because it decreases the surface area of sensitive ingredients, making them easier to transport and handle. It improves the homogeneity of ingredients and their flowability. Some of the reasons why dry granulation is a preferred technique are as follows:

Formation of Heat-Sensitive Drugs

Formation of Heat-Sensitive Drugs- Picture Courtesy: PharmTech

Some drugs deteriorate at high temperatures; therefore, the dry granulation process is a suitable solution to deal with this issue. It does not involve drying at elevated temperatures so, it formulates thermos-sensitive drugs easily.

Reduction in Moisture-Related Issues

Reduction in Moisture Related Issues

Moisture content in pharmaceutical formulation could leads to detrimental effects like promotion of microbial growth, change in physical properties, and increase in drug degradation. However, with dry granulation process, these problems are easily resolved, because there is no liquid addition during dry granulation steps.

Efficient Processing

Efficient Processing

Dry granulation process has integral role in efficient and smooth processing, as it increases the powder flowability. Powder clumping has serious consequences like bridging, arching, and segregation. These issues are prevented with dry granulation process.

Rapid Production

Rapid Production

There are a smaller number of steps in the dry granulation process, especially it bypasses the drying step, which decreases the production time leading to increased production efficiency. It decreases the granulation time and streamline the production performance.

Cost-effective Process

Cost-effective Process

The dry granulation process is a very cost-effective process because it has lower overhead cost. It does not require binder that saves the purchasing cost of binder. Moreover, there are fewer equipment involved in dry granulation process, resulting in lower operational expenses.

Increased Compressibility

Increased Compressibility- Picture Courtesy: Signos

Compressibility is important in tablet formation and dry granulation process create granules that are easier to compress. This results in sturdy and homogenous tablets.

High Stability

High Stability- Picture Courtesy: Good Housekeeping

The dry granulation process is essential in preserving the chemical stability of powder components. Due to zero use of binder or solvents, there is no loss of potency, hence it ascertains that drugs retain their therapeutic potential over the course of their life.

3.What are the Types of Dry Granulation Process?

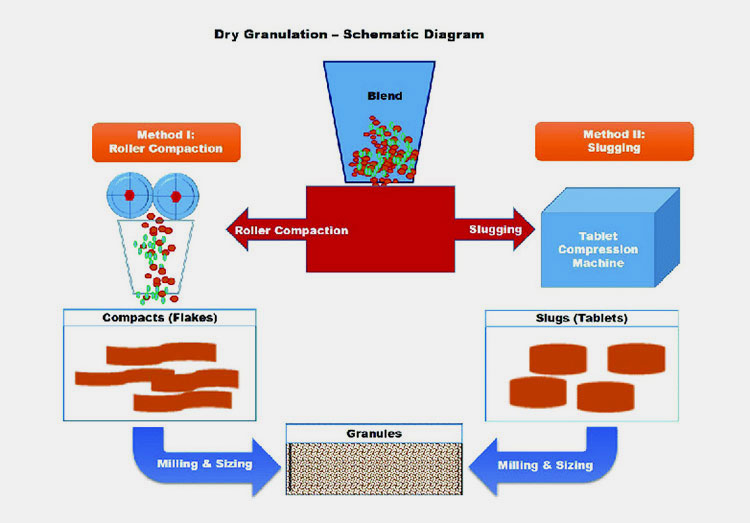

There are two types of dry granulation processes, which are discussed below:

Slugging

Slugging- Picture Courtesy: Packaging Strategies

It is the earliest form of dry granulation process. slugging is the also referred to as precompression or double compression. In this process, the powders are uniformly mixed and then compacted into slugs (large tablets) using standard tablet press. After using mills, these slugs are converted into granules.

Process of Slugging- Picture Courtesy: Gerteis

The weight of the slugs differ in the slugging process as small particles do not flow efficiently in the tablet press die cavity. Hence, slugs formed as a result of slugging have non-uniform characteristics and cannot be effectively milled. Therefore, slugging is not frequently used in the dry granulation process.

Roller Compaction

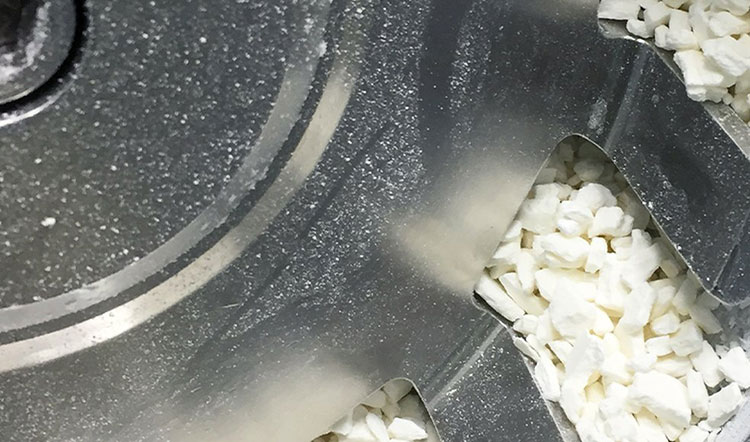

Roller Compaction

It is one of the most commonly used methods in dry granulation. It is alterative method to slugging dry granulation process. This process is dependent upon the intermolecular bonding between particles. This bonding is created by the particle arrangement, deformation, and fragmentation during the roller compaction dry granulation process.

It produces a solid mass called ribbon, flakes or sheets by the compaction of powders. These ribbons are broken down into granules of smaller sizes using mills. In this way, powders agglomerate together to produce granules.

Roller Compaction- Picture Courtesy: Pharmaceutical Technology

In roller compaction dry granulation method, the powder mixture is compressed via high pressure forces to augment the size of granules. The powder blend is transported to the counter-rotating rollers that compact or squeeze the powder to generate the sheets. These sheets are breakable and split into flakes. These flakes are milled into granules after careful treatment.

The gap between roller is responsible for homogeneity and bulk density of the final granules.

4.Enumerate Industrial Applications of the Dry Granulation Process?

Due to the diverse uses of dry granulation process, it is executed in different industries to produce different types of products. Some of its applications are included below:

Pharmaceutical Industry

Dry Granulation Process in Pharmaceutical Industry- Picture Courtesy: diaTribe

First and foremost, dry granulation process is utilized in the pharmaceutical industry for producing the desired-sized particles because it boosts material flow. This process has improved robustness; thus, it manufactures tablets and capsules having unvarying weight and acceptable strength. It also has contributed in the formation of controlled release pills.

Nutraceutical Industry

Dry Granulation Process in Nutraceutical Industry- Picture Courtesy: ET HealthWorld

It is another important industry in which dry granulation process is used for creating different nutraceutical oral dosage form like vitamin and mineral supplement pills. Dry granulation process results in uniform distribution of drug ingredients. Nutraceutical granules have better processibility improving the manufacturing practices.

Food Industry

Dry Granulation Process in Food Industry

Yes, dry granulation process is a suitable method for forming different kinds of instant mixes, flavoring agents, and other important food particles. This procedure also produces different instant beverages and drinks like soups and juices. Dry granulation process also boosts the uniformity of spice blends and herb mixes.

Chemical Industry

Dry Granulation Process in Chemical Industry- Picture Courtesy: The STOCKMEIER Group

The dry granulation process also has a pivotal place in the chemical industry, as it increases the handling and storage characteristics making it the perfect approach for creating non-clump anticaking agents, food additives, fillers, and catalysts. It also improves the cleaning action of detergent powders.

Agriculture Industry

Dry Granulation Process in Agriculture Industry

In the agriculture industry, fertilizers, pesticides, and other insecticides powders are routinely processed. So, dry granulation process is a common practice in the agriculture industry. It also boosts the attributes of agriculture powders and decreases the quality deviations.

5.What are the Steps in Dry Granulation Process?

There are different steps involved in subtypes of dry granulation process. These steps are penned below:

Steps in Slugging Dry Granulation Process

Steps in Slugging Dry Granulation Process- Picture Courtesy: iPharmachine

First, the powder mixture is introduced in the tablet press machine for slugging.

Afterward, slugs are formed by compression powders using flat-faced punches in the die cavity. These slugs have a diameter of about 25 mm and a thickness of about 10-15 mm.

The screening or sieving of slugs is performed both before and after compression.

After screening, the slugs are divided into intended size particles using mills or oscillating granulators.

Finally, reduced particles are sieved to attain final granules.

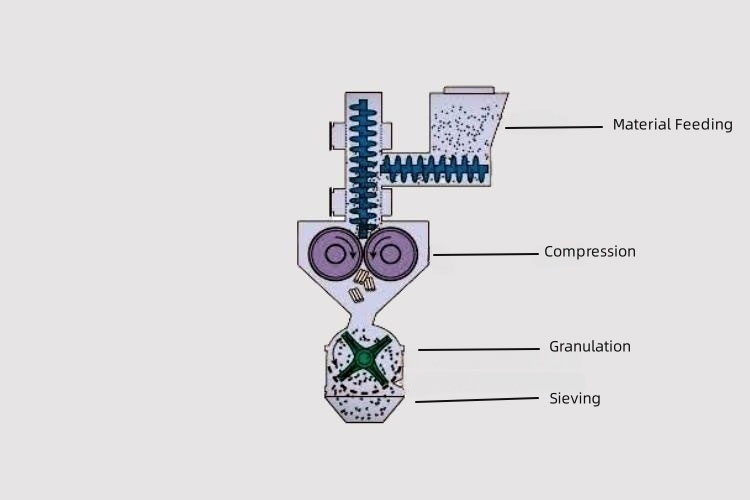

Steps in the Roller Compaction Dry Granulation Process

Steps in Roller Compaction- Picture Courtesy: Pilotech

In this process, first raw material is loaded in the funnel that is equipped with agitator, feed auger, and tamp auger. These components transfer powder material to the rotating rollers.

When the powders reach the gap between counter-rotating rollers, a force is exerted on the powder for compression.

High compression force on the powders transforms them into ribbon-shaped mass.

These ribbons are transported to the sieve to separate out desired-sized particles.

Afterward, these particles are moved toward the mills to obtain required sized particles.

Fine granules having size less than required and sent back to the granulating funnel for second cycle of dry granulation.

6.What Equipment are Employed in Dry Granulation Process?

There are two main types of machines in the dry granulation process, for instance:

Slugger

Slugger Machine- Picture Courtesy: Yinda Machinery

It is one of the oldest machines for granulation. It is a standard tablet machine for rotary press that is used for the compaction of powders. It employs mechanical force to convert powders into granules of even shapes and sizes and creates bolus or slugs. This machine forms large tablets and compacts powders that have lower flowability.

Working Principle

Working Principle of Slugging- Picture Courtesy: giexpre

It has two different die cavities that provide mechanical force for the compression of powders without the need for any solvent or heat. The powder is subjected into a feeding hopper and the auger helps in facilitating the compressing die. The powder is milled to form a slug known as pre-compression. The main compression is followed by exerting pressure on it with the help of an upper punch. Now, the lower die punch rises to eject the material.

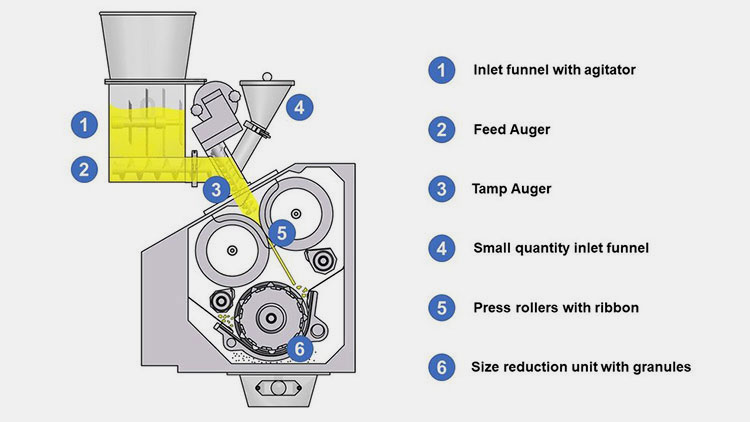

Compaction Roller

Pharmaceutical Compaction Roller- Picture Courtesy: Fitzpatrick Company

Nowadays, the slugger machine for dry granulation is largely replaced by the roller compaction machine. This machine is the core part of the dry granulation line for solid dosage form. It has two pressure rollers with which a mixture of powders is transformed into a ribbon, sheet, or flake. It delicately compresses the powder blend without breaking it.

It has a hopper, feeding part, and compaction part. The roller compression pressure is adjusted using a hydraulic control system to create granules with unvarying crushing strength. It creates uniform and consistent-sized granules. The compaction roller is a cost-effective machine because it does not require wet massing and drying stages, saving energy and operational costs.

Working Principle

Working Principle of Compaction Roller- Picture Courtesy: L.B. BOHLE Coating

The bulk powder for compaction is transferred to the hopper via a powder handling system. The hopper is equipped with a screw feeder that moves the powders in space between pressure rollers. The counter-rotation of rollers brings the powders to the central area between rollers, which exerts pressure on the powders for compression. Then, the rotation of rollers pushes the enlarged mass outward of the machine.

7.What are Problems Associated with the Dry Granulation Process?

Although the dry granulation process is an advantageous technique, bringing several benefits to the production, still there are some problems arise occasionally in this method. These problems are discussed below:

Particle Hardness

Particle Hardness- Picture Courtesy: Syntegon

Cause

High compression pressure results in hard granules, creating problems in subsequent processes like milling and tablet compression.

Solution

This problem can be resolved using lower-pressure forces during roller compaction and slugging. Also, gently mill the granules to decrease their hardness.

Dust Generation

Dust Generation- Picture Courtesy: Multistation

Cause

Open systems and ineffective ventilation lead to high dust generation. Rough powder handling and manufacturing steps cause dust generation.

Solution

This issue is solved using enclosed systems and processing stages to reduce dust exposure. Also, setup, appropriate ventilation systems to manage dust levels.

Segregation of Particles

Segregation of Particles- Picture Courtesy: BulkInside

Cause

This could happen because of over mixing or diversity in the particle sizes. Similarly, density differences in the final blend results in segregation of particles.

Solution

To prevent this issue, optimize mixing time and limit the range of particle sizes. Decreasing density differences in the final blend resolves this issue.

Fines in Granules or Slugs

Fines in Granules or Slugs- Picture Courtesy: Industry Plaza

Cause

The utilization of unsuitable sieving mesh and high speed of mills could be the reason of fines in the final product.

Solution

Using right sized mesh screen and lowering the speed of dry mill prevent this defect.

Non-Uniformity in the Particle Size

Non-Uniformity in the Particle Size- Picture Courtesy: Justdial

Cause

It is due to inadequate mixing time and inadequate speed of the roller compaction.

Solution

It is recommended to improve the mixing time and alter the speed of roller compaction.

8.What are the Recent Advances in the Dry Granulation Process?

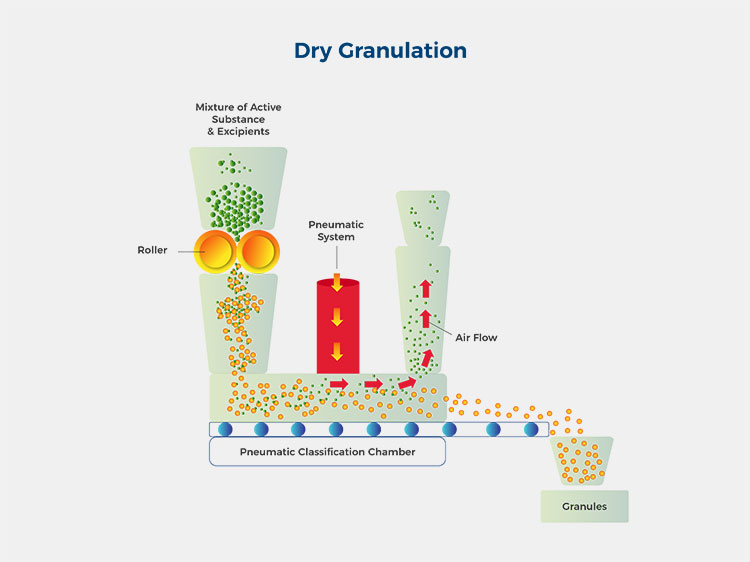

Pneumatic Dry Granulation Process- Picture Courtesy: Sudeep Nutrition

Recent advances in the dry granulation process include the pneumatic dry granulation process. It is a combination of roller compaction and proprietary air classification (pneumatic system). In this process, the first granules are created from fine powders employing mild compression force in the roller compaction. Then, smaller particles are separated from the required-sized granules in a classification chamber using a gas stream.

Entrained smaller particles are transported to the cyclone device and are either moved back to the roller compaction for reprocessing or stored in a container for later regranulation.

It can process higher drug loads and create good-flowing granules. Moreover, it rapidly processes materials, has lower operational costs, decreases material wastage, and lowers dust generation because it is a closed system.

Conclusion

The dry granulation process is a simple and cost-cutting technique, requiring little to less materials and equipment. It is a resourceful technique to manufacture heat and moisture-sensitive drugs. Moreover, the absence of granulating fluid in the dry granulation process simplifies the formulation and preserves the potency of drugs, reducing their drug degradation. Slugging and roller compaction are the main techniques in the dry granulation process while recent advances in this process include the pneumatic dry granulation process. Now, if you have more queries about the steps and equipment of the dry granulation process, you can contact the Allpack team now!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide