Dry Animal Food Packaging: The Complete FAQ Guide in 2025

In today’s world, due to increasing trend of keeping luxury pet, the demand of safe dry animal food packaging got high in market. Now animal lovers look for food which packed with considering safety and also sustainability. We also see shoppers show interest in paying more for more sustainable and convenient features like easy in handling and zipper seals for keeping food fresh till last scoop.

Now you are curious to know how your animal dry food packed and sealed? What are cutting edge technology, equipment and procedures are used in dry animal food packaging? How your pet or animal food makes their way to market shelves?

Either you are looking for suitable dry animal food packing or either you are animal lover you have many questions in mind related to suitable packaging? which material is suitable for animal dry food packaging. We got you, without any further delay let’s begin this topic.

1.What is Dry Animal Food Packaging?

Dry Animal Food Packaging- Picture Courtesy: Pet Food Processing

Dry animal food packaging is an effective way to enclosed animal food like biscuit, kibble and other food item in a protective layer to enhances food nutritional value or quality, extend its shelf life and taste. Animal food packaging act as barrier which protects food from external factors like moisture, air and light that may compromises food freshness and nutritional value of food.

Dry animal food refers to the product in which moisture content is reduced. Most of the dry animal food contains only 6-10% of moisture and rest of the food is dry matter. Due to low moisture content, it helps in prevention of fungal and bacterial contamination.

2.Why Do You Need Dry Animal Food Packaging?

In today world, consumer prefer easy to go packaging of animal food which is handy to use with maintaining high quality and freshness of food. In this manner, dry animal food packaging has become staple for all animal lovers and keeper. In this topic, you will learn how dry animal food packaging is benefitting consumers as well as manufacturers.

Maintaining safety and quality of food

Maintaining Safety and Quality of Food – Picture Courtesy: Ouma Flexible Packaging

These animal dry food packaging comes in different zipper, slider and resealable bag which maintain the quality and safety of food. These packaging prevent any contamination and damage ensuring quality and safe product for consumers. Dry food packaging with resealable option enhances customer trust on brand.

Extending shelf life of food

Extending Shelf Life of Food- Picture Courtesy: Pooch & Mutt

Dry animal food packaging kept food fresh for longer period which extend the shelf life of animal food. Most of the dry animal food contain mineral and fats which are vulnerable to oxidation, if not packed properly. So these dry food packaging creates a barrier from external environment like moisture and light, reducing spoilage and enhancing shelf life.

Improving brand representation

Improving Brand Representation

It is noticed that dry animal food packaging is the key for customer attention. Designing and color combination plays an important role in brand representation and creating customer memory. Dry animal food packaging with exceptional brand designing make the product stand out in crowd.

Communicating product information

Communicating Product Information

Animal food packaging also helps to communicate product information to consumer. Nowadays people are more concerned about what type of food, they are buying for animal and from where dry animal food is sourced. These animal food packaging label help buyer in selecting right product on basis their demand and nutritional value needed for their animal.

Sustainability and eco-friendly

Sustainability and Eco-friendly- Picture Courtesy: ProAmpac

In today’s world, people are looking for sustainable and ecofriendly products. So different manufacturer comes with sustainable and ecofriendly option for dry animal food packaging like in paper bag and recyclable plastic which are easily degradable and environment friendly.

Ease of handling and storage

Ease of Handling and Storage- Picture Courtesy: Packaging Europe

Dry animal food packaging comes in different sizes and specification. They also come with handle which ease the handling for consumer as well they are easily stackable and can be stored easily.

3.How Different Industries Incorporating Dry Animal Food Packaging In Their Practices?

Dry animal food packaging has vast implementation in other industries. Other industries also adapted this packaging due its durability to with stand moisture and preventing damage to the product. Here you will see some major industries which are incorporating dry animal food packaging.

Food industry

Food Industry- Picture Credit: Food Engineering

In food industry, dry animal food packaging vastly use to store different food items like cereals, snacks, baking supplies like flour and sugar etc. This food packaging kept the food fresh and improves shelf life of food. Cereals, chips and nuts are also kept in resealable packaging which is similar to dry animal food packaging.

Agriculture industry

Agriculture Industry

We have seen an increasing demand of dry animal food packaging in agricultural industry because it will keep fertilizers and seed fresh and enhances performance of fertilizers. It protects product from moisture and contamination.

Nutraceutical and herbal industry

Nutraceutical and Herbal Industry- Picture Courtesy: Stab Branding

Due to evolving industries, there is huge application of dry animal food packaging in herbal and nutraceutical products. Some herbal powder products are moisture sensitive and form clumps when come in contact with moisture. This packaging is great way to enhance stability and quality of herbal product.

Similarly, they also come with resealable option like in animal food packaging, which makes it convenient to reuse and keeping product quality same throughout the bag.

Chemical industry

Chemical Industry- Picture Credit: CarePac

In chemical industry, many cleaning agents like detergent are pack in same packaging like dry animal food packaging. Detergents are packed in these packaging to prevent moisture contact and product damage.

Construction industry

Construction industry- Picture Courtesy: Construction Kenya

In construction industry, dry animal food packaging is vastly used to pack cement, plaster and building materials. These reinforced packaging prevent moisture contact and hence preventing construction material as most of the building material are solidifies if nor packed and sealed properly.

4.What are Step by Step Process Involved in Dry Animal Food Packaging?

The process of dry animal food packaging involve series of step by step process which ensure accuracy and quality of packaging. In this topic, you will learn how your animal food are packed with high efficiency and accuracy.

For bags and pouches packaging

Selecting and preparing packaging material

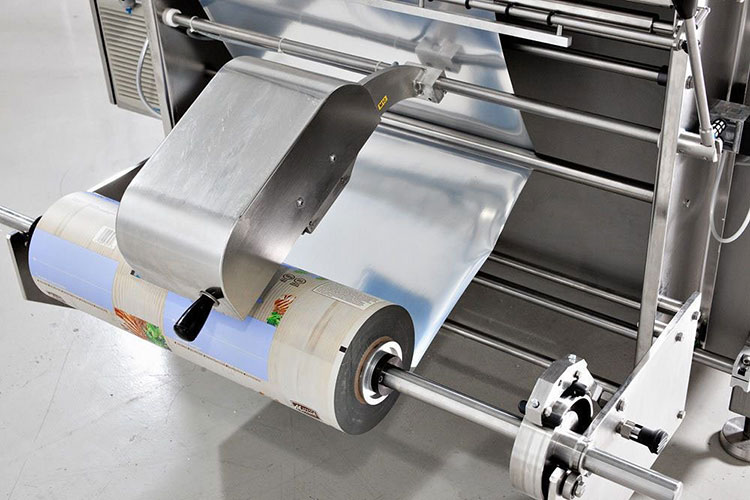

Selecting and Preparing Packaging Material- Picture Courtesy: Viking Masek

First step is to select packaging material for dry animal food packaging which best fit with your requirement. Many option are available like paper, plastic or even jars. After selecting material, you need to prepare or aligned material with your packaging machine.

If you select plastic or paper, it comes in big film roll. You need to unwind the film roll with the help of unwinding device and places in packaging machine for further packaging process.

Printing information

Printing Information

In second step of animal food packaging, film is passed through printing machine which print desired information or specification which installed in machine. It includes product name, company logo, nutritional table value, weight and other specification. Printing on film is done by thermal or ink-jet type printer.

Pouches or bag formation

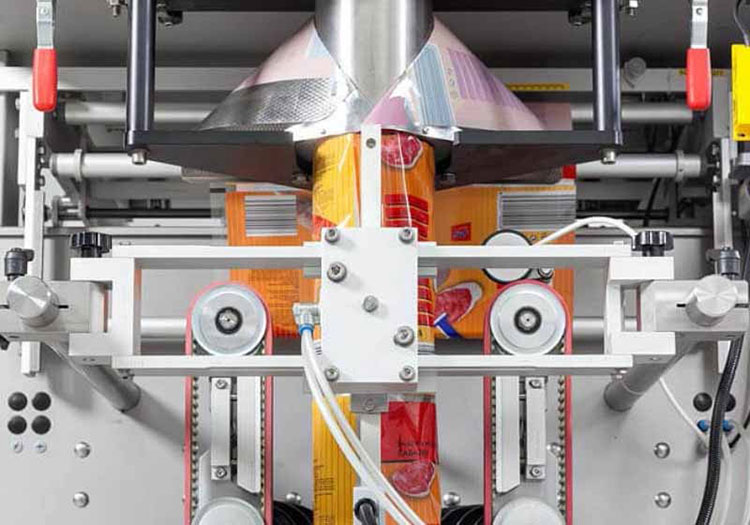

Pouches or Bag Formation- Picture Credit: Viking Masek

In third step, film is roll around vertical or horizontal tubes which take the shape of bag and the sides or bottom of bag is sealed by sealing machine. Now pouches are ready for filling of animal food.

Filling of bags and sealing

Filling of Bag and Sealing

In this step, bag is precisely filled animal food during animal food packaging. This is an automated process which ensure accurate amount of animal food is filled in each bag as well maintaining quality of food.

After bags are filled sealing machine sealed the opening of bag ensuring bag is complete air tight close so that dry animal food is not contaminated or spoil during storage.

Discharging of bags or pouches

Discharging of Bags or Pouches- Picture Courtesy: Viking Masek

After bag are filled and sealed, a sharp jaw cutting blade in sealing machine comes forward and cut the bag. When the sealing machine jaw open bag drop on conveyer belt from where it is transported to distribution unit.

For jars and glass containers packaging

Feeding and positioning jar

Feeding and positioning Jars- Picture Courtesy: C-Trak Conveyors

Clean jars are placed manually on conveyer belt or placed by automated machine which pick jar and placed on conveyer belt. The jar filling machine makes sure that jars are accurately positioned and accurately placed filling nozzle.

Product feeding in hopper

Product Feeding in Hopper- Picture Courtesy: Agf.nl

At feeding station, hoppers or storage bin are loaded with dry animal food like biscuits or kibbles. After that jars are moved below vibratory feeder which regulate easy dry animal food flow without clogging. It also weighed the ingredient and make sure each jar receives accurate quantity.

Automatic filling of jars

Automatic Filling of Jars- Picture Courtesy: Landpack Packaging Machinery

At this stage, set amount of dry animal food is precisely dispensed in each jar with the help of nozzles which ensure accurate filling. Some machine installed vibration movement in conveyer belt which reduce air gap and settle food.

Sealing and capping

Sealing and Capping of Jars- Picture Courtesy: CWM Automation

This the last step in dry animal food packaging in jars. First caps are sorted and placed on filled jars. Caps are either screwed tightly or pressed on place depending on the jars opening. Some jars are sealed with aluminum foil and then capped.

Labeling and Distribution

At final stage, after capping jars are moved to labelling station. Jars are label with installed specification depending on manufacturing requirement.

5.What Kind of Equipment Used in Dry Animal Food Packaging?

Dry animal food packaging involve number of equipment which efficiently packed food with greater production outcome. Let’s discuss few of important equipment which are involved in process.

Premade pouch packaging machine

Premade Pouch Packaging Machine

This machine is a best choice for packing animal food in pouches of any texture and consistency. These machines are capable of filling pouches of different sizes and shapes. This machine can fill 60-100 pouches in a minute with great accuracy.

Premade pouch packaging machine is also capable to fill pouches with resealable options which is convenient to open and use.

Working principle

In this instrument, premade pouches are loaded in bag magazine from where gripper picked pouches one by one. Then they are moved to filling station where they first open by inflating air. Now these inflated pouches are filled with animal food through volumetric filler which precisely fill accurate amount in each bag. Sealing station sealed opening of pouches.

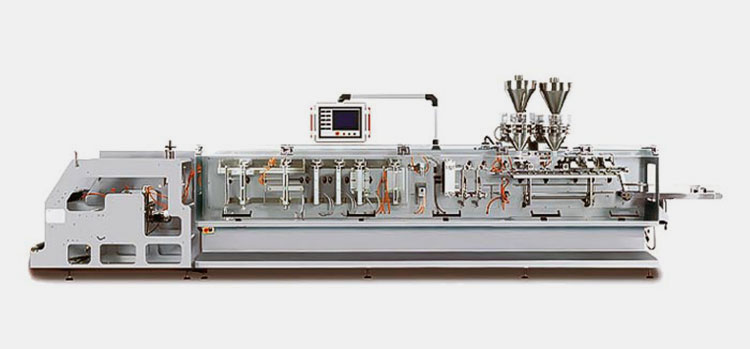

Horizontal form fill and seal machine (HFFS)

Horizontal Form Fill and Seal Machine- Picture Courtesy: Lenis Machine Inc.

Horizontal form fill and seal machine is a versatile equipment used to pack dry animal food. It works in horizontal direction and suitable for heavier animal food packaging which may damage by vertical filling. This equipment also helps in cost cutting which was spend on premade pouches.

Working principle

This equipment work by unwinding packaging film and then fold it. Then this film is loaded on folding belt from where it moves to forming station. At forming station, it takes shape of bag and animal food is filled through conveyer belt at filling station.

When bags are filled, they are moved to sealing station where sides of bags are fused together to create air tight dry animal food packaging.

Vertical Form Fill and Seal Machine (VFFS)

Vertical Form Fill and Seal Machine

Vertical form fill and seal machine is most commonly used equipment in animal food packaging. It is a versatile equipment and can work with wide range of animal food whether it is dry treat, curries for animal or seeds for exotic birds. It is equipped advance technology and efficient sensors for quick packaging.

Working principle

In vertical form film machine, film roll is unwounded and loaded on film conveyer belt from where it reaches forming station. At forming station, film is wrap around vertical forming tubes creating shape of bag. Vertical sealing jaws closed sides and bottom layer of package.

Then filling station fill the animal feed in bags and sealed the opening. At the end stage, cutter cut the edges of two bags.

Flow wrapping machine

Flow Wrapping Machine

This machine designed with compaction and high tech sensor which precisely accelerate product on conveyer belt result accurate packaging. Flow wrapping machine is economical and durable option. It is used for packaging large animal food like cereal bars, candies and biscuits.

Working principle

Its process start by placing film roll in unwinding device which unwind film, after unwinding film roll is moved to form tubes. The product is placed on conveyer at consecutive distance. The gripper place product on film which then fold around the product and edges are sealed by sealing machine.

Jar filling and sealing machine

Aipak Jar Filling and Sealing Machine- Picture Courtesy: Aipak

Jar filling and sealing machine is a highly automated which can efficiently fill animal dry food in jars like animal snack, candies and animal sweet treats. It can efficiently fill, cap and label variety of products in jar.

Working principle

The process start with aligning jars on conveyer belt which is then carried to filling station. On filling station, jars placed below filling hoppers which precisely fill jars with accurate amount. Then jars are moved to sealing and capping station. Now jars are closed with cap and tightly sealed to ensure freshness and quality of animal food.

6.What Is the Shelf Life of Dry Animal Food Packaging?

Shelf Life of Dry Animal Food Packaging- Picture Courtesy: All About Feed

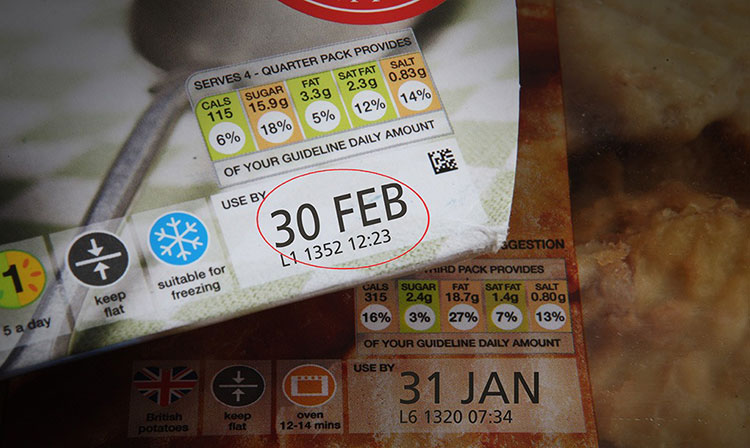

Shelf life is an assurance of product by manufacturer that within the define period, the packaging will keep the dry animal food safe from microbial contamination and external factor like moisture, and pest contamination.

Shelf life of dry animal food packaging depend on many factors like materials used in dry animal food packaging, contamination from environmental factor, storage condition, type of closure option used and expiry mentioned on the product etc.

Shelf life of dry animal food packaging is same as mentioned expiry date on animal food package. The usual expiry of dry animal food is 1-2 years, when packed. After opening the packaging, the animal food should be consumed with in 1 and half a month to avoid loss of quality.

7.What Kind Packaging Material Is Suitable for Dry Animal Food Packaging?

Packaging material for dry animal food packaging plays crucial role in effective packaging outcome. Nowadays with evolving technology a lot packaging material are available but few common packaging materials are discussed below.

Plastics

Plastic-Picture Courtesy Best Suppliers

Plastic is widely use material in animal dry food packaging because it can protect animal food from moisture, oxidation and keep the food fresh for longer period. These plastic bags come with resealable zipper option which extent the freshness till last scoop.

Most commonly used plastic material are propylene (PE), polyethylene (PP) and polyethylene terephthalate (PET). It can use to make pouches, bags and tray and can be molded in desired shape and design.

Paper

Paper Material –Picture Courtesy: BowePack

Paper material for food packing is more economical as compare with other packaging material. Dry animal food is usually packed in paper and it is also great eco-friendly option. Animal lovers who are looking for sustainable option in dry animal food packaging, paper is preferable choice for them.

Integrated material

Integrated Material- Picture Courtesy: Pet Food Processing

Integrated material is a combination of different substance include paper, plastic and metal layer due to this combination it is the most superior material and also environmental friendly as its biodegradable.

It is designed to provide maximum protection against moisture, heat and air. On the other hand, these materials are lightweight and cost effective in transportation.

Glass

Glass Containers- Picture Courtesy: TechBullion

Nowadays people love to keep luxury pet. So, the manufacturer also comes up with luxury packaging in glass containers and it gives packaging a fancy touch. These glass jar also airtight so an effective way in keeping freshness of dry animal food packaging for longer period.

8.Which Information is Provided Over Dry Animal Food Packaging?

Information Provided Over Dry Animal Food Packaging - Picture Courtesy: Otosection

Information provided on the dry animal food packaging vary from manufacturer to manufacturer. But, these are the most common specification which are mention on almost all animal food packaging.

Product name is most important in dry animal food packaging and manufacturer uses catchy names so they can stand out in crowd.

Brand name and logo is crucial for consumer because most of the time customer may forget the name of product but they remember logo or brand of packaging.

Ingredient list is important for animal lover because customers are keen to know what is added in their animal food and from where raw material is sourced in their animal food. A clean ingredient list is a win-win situation for manufacturer.

Nutritional value table is important for consumer to select product depending on requirement of their animal. Like vitamin and mineral and growth stimulating factors and their quantities will help consumer to select their desired product.

Mentioning shelf life make product safe for consumer. So they know in how much their animal can consume this food.

Storage condition is crucial for maintaining quality and safety animal food.

It is mandatory to mention allergen warning on packaging. So animal lover know which product is safe for their animal.

9.What are Common Problems Encounter During Dry Animal Food Packaging and Their Possible Solutions?

We know animal food packaging industry is growing faster but few problems still encountered by manufacturers. Let’s discuss common problem and their expert solution.

Oxidation of dry animal food

Oxidation of Dry Animal Food –Picture Courtesy: Dogster

Dry animal food is high in fat content so they are prone to oxidation leading to change in color and taste of animal food. It may lead losing efficacy of animal food or mold formation.

Solution

To overcome this problem, manufacturer must select oxygen-barrier material with multi-layer packaging, vacuum condition is used to ensure air tight packaging is done to protect dry animal food from oxidation.

Labelling Error

Labelling Error – Picture Courtesy: OAL

Improper labelling like missing ingredient, nutritional value or expiry date is not clear will lead to regulation issues and brand will lose customer satisfaction.

Solution

Manufacturer must use automated labeling machine which eliminate human error. Other than that you must quality check label before package. To build customer satisfaction or over regulatory issues make sure transparency in listing ingredient and possible allergens warning.

Packaging equipment malfunction

Packaging equipment malfunction- Picture Courtesy: Native Pet

These automated packaging equipment working continuously encounter malfunction which result in delays and errors.

Solution

Equipment require timely inspection and regular maintenance for efficient performance. Identifying problem before it escalates, will save from major problem and delays. You should invest in reliable and quality packaging equipment to ensure good and dry animal food packaging.

Spoilage from moisture content

Spoilage from Moisture Content-Picture Courtesy: Kohepet

Moisture exposure in dry animal food packaging is major challenge for manufacturer. Moisture can cause mold formation, spoilage and alteration of taste of dry animal food. It may hinder with the shelf life and nutritional value of animal food.

Solution

This problem can be easily overcome by using multi-layer packaging or moisture barrier packaging. You can also reduce this problem by using desiccant like silica gel, which can absorb moisture content and prevent spoilage of dry animal food.

Conclusion

Dry animal food packaging ensure quality and safe food for animals. It also plays crucial role in providing information related to ingredients and nutritional value of animal food, which is beneficial for consumer to select right dry animal food depending on their animal needs. In This article, you learned about benefit of dry animal food packaging, material used or different equipment used for dry animal food packaging. Still you are confused about dry animal food packaging material, you are encouraged to contact our AIPAK team any time.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide