Dissolution Autosampler: The Complete Buying Guide In 2025

Are you ready to know about the dissolution autosampler? If you are unfamiliar with it then this blog is ideal to explore the equipment. In pharma, quality control testing critically requires a dissolution autosampler to keep recording the essential data related to your medicine profile. Nevertheless, it must be uniform and consistent in every batch.

By utilizing a dissolution autosampler, you can estimate the releasing behavior of medicine when it enters the body, so you can’t ignore this essential device for manufacturing and testing the pharmaceutical ingredients. To know more about it! Please have a look at our blog, we promise, you will find it worth reading.

1.What is a dissolution autosampler?

Allpack Dissolution Autosampler

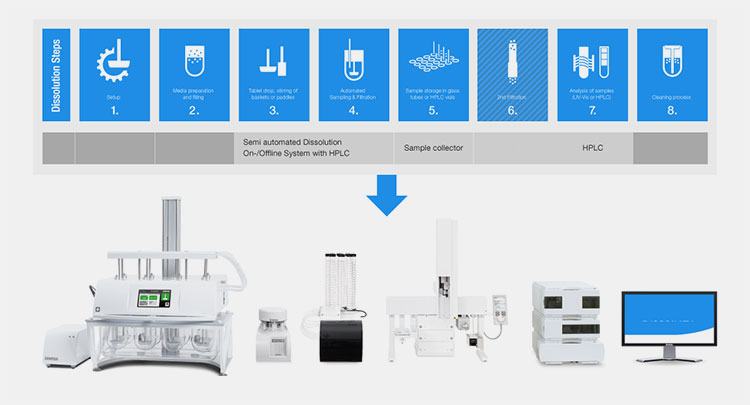

Dissolution testing is a fundamental assaying technique in pharmaceutical development for determining the release timings of active medicinal components from their source dosage. It is a time-dependent evaluation process that should be automated with the use of a dissolution autosampler to save valuable seconds and decrease variances in the sampling protocol.

A dissolution autosampler has special worth in designing pharmaceuticals because it mechanically extracts test samples from the dissolution apparatus at any given time. It has versatile functions- from filtering fluidic medium and withdrawing samples to collecting these aliquots in vials for next-in-line HPLC and UV processes.

It centralizes dissolution testing through its speedy and effective sampling, which is integral in the consistent inspection of the dissolution process without considering hectic manual sampling.

2.What is the purpose of a dissolution autosampler?

A dissolution autosampler is an automated device that has revolutionized techniques of sampling. Due to this machine, manufacturers attain the reliability of test estimations. Let’s learn about the important pros of a dissolution autosampler.

High Efficiency

High Efficiency- Picture Courtesy: Agilent

In the dissolution testing, multiple formulations are evaluated in particular time intervals. So, the need for automated sampling is fulfilled by a dissolution autosampler. It boosts efficiency by a greater margin with its potential to extract multitudes of samples over an extended duration. It does not require consistent manual interference, which improves the throughput of dissolution analysis. It also stores data protocols and saves time for setting up the machine.

High Sampling Time Points

High Sampling Time Points- Picture Courtesy: SOTAX

It is dictated in US Pharmacopeia (USP) that sampling and filtration of the dissolution medium must be performed within ± 2% of the desired time point. Manual sampling is grounded on the researcher watching a stopwatch or being notified by an alarm. Hence, protocols with the smallest intervals between time points are hectic to handle physically.

However, a dissolution autosampler easily starts the sampling sequence within short intervals by keeping cannulas in the dissolution vessel for the entire duration of the test.

More Consistent Data

More Consistent Data- Picture Courtesy: Agilent

The slip-ups in extracting samples from incorrect and non-uniform positions within the vessel remain unnoticed in a post-run evaluation, challenging the consistency of the dissolution profile.

By utilizing a dissolution autosampler, analysts and developers gain precise control over important factors, for instance, sampling volume, time, location, and sampling depth, which results in the generation of consistent, repeatable, and accurate data and lowers the degree of variance in dissolution outcomes.

Upholding Sample Integrity

Upholding Sample Integrity- Picture Courtesy: Agilent

A dissolution autosampler is responsible for collecting, purifying, and transferring data without even a minor change in sample integrity. It is comprised of clean sampling probes and tubes that avert contamination possibility. Moreover, it reduces the exposure to environmental factors that comprise the stability of the sampling aliquot.

Role in Real-Time Investigations

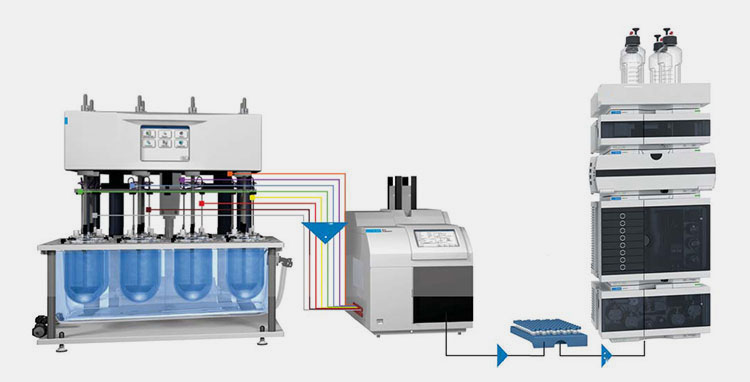

A dissolution autosampler can be integrated into advanced analytical systems, for instance, UV spectrophotometers or HPLC systems to assess the release rate of formulations in real-time. These investigations into dissolution profiles aid in rapid data collection, lower the waiting time for result collection, and boost decision-making capabilities for better quality control.

3.Where a dissolution autosampler is needed?

A dissolution autosampler goes hand in hand with the dissolution testing apparatus. It is needed in every field where dissolution tester is utilized for kinetic release studies. We are penning some fundamental sectors, where you are more likely to see a dissolution autosampler.

Pharmaceutical Sector

Pharmaceutical Manufacturing- Picture Courtesy: Supply Chain Digital

A dissolution autosampler is invented to speed up the development and testing of pharmaceuticals. With the aid of this machine, developers can easily test numerous drug prototypes simultaneously. It also allows researchers to quickly compare bioequivalence parameters of generic and branded therapeutics. Moreover, this device facilitates the assessment of the dissolution behavior of novel drugs during preclinical trials.

Biopharmaceutical and Biologics Manufacturing

Biopharmaceutical Manufacturing- Picture Courtesy: BioSpectrum Asia

Nowadays, biopharmaceuticals including vaccines, clotting factors, antibodies, and many more are frequently manufactured to cater the human therapeutic needs. Therefore, a dissolution tester with a dissolution autosampler is normally utilized in this sector to study and determine the release characteristics of various biologics and biopharmaceuticals.

Nutraceutical Sector

Nutraceutical Manufacturing- Picture Courtesy: ACG

With the increase in health fitness trends, there is a high need for vitamin, mineral, and herbal dietary supplements. Consequently, there is substantial demand for a dissolution autosampler in the nutraceutical sector to automate the dissolution evaluation practices for nutraceutical formulation. This equipment streamlines analysis procedures by its efficient and steadfast testing of various sample batches.

Veterinary Pharmaceuticals

Veterinary Pharmaceuticals- Picture Courtesy: Croda Pharma

Veterinary medications are also analysed at every formulation step to make sure they have a preferred dissolution profile and absorption rate. Hence, a dissolution autosampler is a pivotal instrument for determining the safety and potency of veterinary care drugs.

Biotech Research

Biotech Research- Picture Courtesy: Croda Pharma

A dissolution autosampler has a crucial role in studying the pharmacokinetics profile of novel drug delivery technologies, for example, nanoparticles, liposomes, or microspheres. It measures the intended duration at which these systems release their core drug ingredients.

Agrochemical Sector

Agrochemical Sector

Dissolution testing is also implemented in the agriculture field to investigate and determine the dissolution, absorption, and bioavailability of pesticides, herbicides, and fungicides solid formulations. Therefore, a dissolution autosampler is a key instrument to gauge the effectiveness, safety, and environmental risk of different agrochemicals.

4.What are the components of a dissolution autosampler?

Various parts in a dissolution autosampler collaborate to attain work efficiency. These components automate the complete cycle of sample drawing, filtering, and relocating. A detailed list of various parts and their function in a dissolution autosampler is written below:

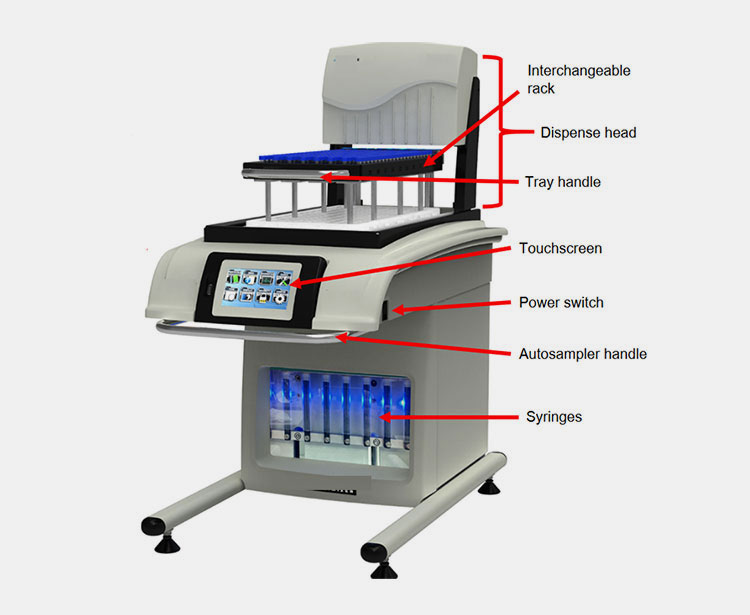

Parts of Dissolution Autosampler- Picture Courtesy: teledynelabs

| Interchangeable Rack | This part is located at the topmost area of the dissolution autosampler. It can accommodate various sizes and kinds of vials types- containing filtered medium- for various testing needs. It boosts the adaptability and vial format handling of the dissolution autosampler and aids operators in easily changing sampling parameters. |

| Dispense Head | It transfers the sample fluid into suitable vials or other container types with the help of sampling tubes or pumps. It features several channels for quick and precise dispensing of sample aliquots to execute real-time dissolution assessment. |

| Tray Handle | It is a mechanical component found in the dissolution autosampler to take out the sample collection tray or interchangeable rack from the machine. The tray handle is a vital component that imparts ease and safety to operators when they switch or collect sample vials. |

| Touch Screen | It is an interface through which users can interact with the dissolution autosampler. In modern types of machines, this display screen is used for programming and adjusting devices for new testing operations. The operators control the settings of sampling volume, sampling intervals, and filtration options through this panel. It usually has features for real-time visualization and self-troubleshooting. |

| Power Switch | It is typically found at the back or side panel of a dissolution autosampler and regulates the flow of electric current to core components. The machine performs its sampling tasks when this switch is set on. |

| Autosampler Handle | This component acts as a portability support and facilitates operators in relocating or repositioning the machine. The Autosampler handler is installed in the compact model of the dissolution autosampler. |

| Syringes or Peristaltic Pump | Syringes are core parts of the machine and are integral in pulling out and relocating required volumes of dissolution fluid from the dissolution vessel. Their movements are controlled and directed by the motor units. Peristaltic pumps are also found in some types of dissolution autosamplers and they utilize rollers for exerting pressure on elastic tubes and extracting the aliquot liquid. |

5.How does a dissolution autosampler work?

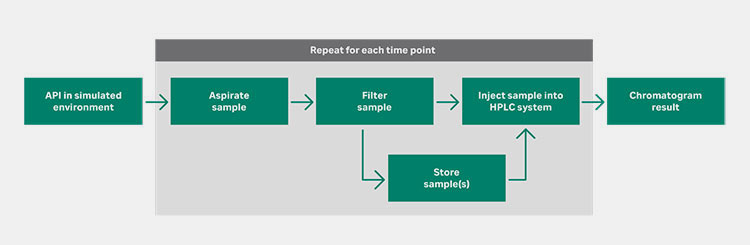

A dissolution autosampler operates together with a dissolution tester. It can pull out samples from several vessels in one cycle, consequently increasing processing speed. A sequential order of working steps in the dissolution autosampler is described below:

Dissolution Autosampler Protocol- Picture Courtesy: cytiva

Preparation

Preparation

At the start, operators diligently configure programming options, for example, sampling time interval, sample extraction volume, and number of vessels from which samples are withdrawn.

Sampling

Sampling- Picture Courtesy: Agilent

On starting the machine, it begins processing operational parameters and sets off the sampling system at a designated instant, which in turn instigates the dropping of sampling probes or cannulas into dissolution vessels. For consistency in sample extraction, the cannulas go at a fixed depth (halfway between the top point of the paddle or basket and the surface of the fluid).

After lowering, the sampling is carried out through a peristaltic or syringe pump that maintains sampling volume precision, and after dispensing aliquots in vials, the leftover media in the sampling line is transferred back to the vessel.

Filtration

Filtration Plates

The filter system- located at the junction of the sampling cannulas and sampling loop or before the start of the analytical system- filters out the undissolved residues while the dissolved drug is retained from analysis or storage.

Sampling Transfer

Sample Transfer- Picture Courtesy: Agilent

Finally, the dissolved drug sample is loaded into vials present on the sample collection tray or interchangeable rack. UV spectrometers or HPLC are integrated with some types of dissolution tester systems for instantaneous investigation, which reduces manual intervention and is time-efficient.

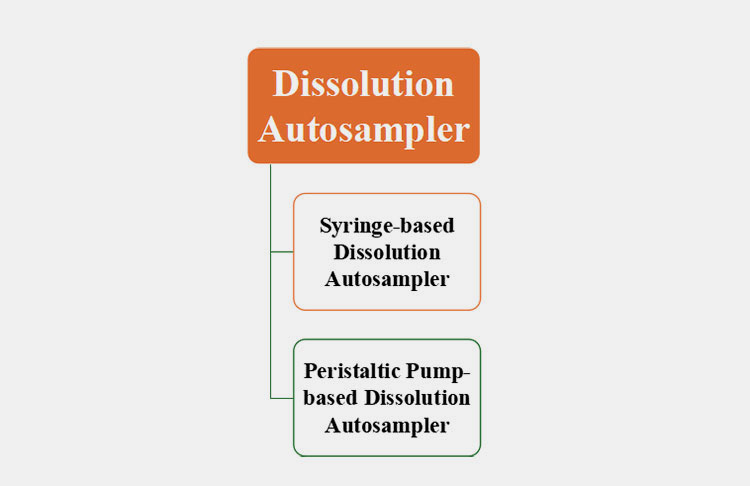

6.What are the classifications of dissolution autosampler?

There is a wide array of models of a dissolution autosampler, but for simplicity, this machine is categorized into two primary subtypes, which are:

Syringe-based Dissolution Autosampler

Syringe-based Dissolution Autosampler- Picture Courtesy: Electrolab

It is a typical dissolution autosampler, equipped with extremely precise syringe pumps to extract even a minute quantities of dissolution fluid from the vessel at a precise and consistent rate. This type of dissolution autosampler has a multitude of pumps with its motor-driven syringe that pull out the liquid through its ascending and descending motion.

Syringe-based dissolution autosampler is popular among manufacturers due to its aptitude to draw volumes at a controlled rate, providing reproducibility in test estimations. It is found in small labs because it only pulls small amounts of liquids. There is no contamination during sampling owing to minimal interaction between the outside environment and the sampling medium.

Peristaltic Pump-based Dissolution Autosampler

Peristaltic Pump-based Dissolution Autosampler- Picture Courtesy: Labindia Analytical

This category of dissolution autosampler is ideal for large pharmaceutical setups because of its continuous sampling ability and versatility in extracting both small and large quantities of dissolution fluid. It can conduct testing of typical immediate-release medications and can be employed to sample more intricate extended-release prototypes.

Peristaltic pump-based dissolution autosampler is extremely useful in pulling sensitive and delicate media, as it gently handles the liquids without exerting shear pressures that could affect the integrity of delicate samples and change their dissolution profile. It is fairly easy to maintain because it needs tube replacement and could be used for longer periods without going for challenging and costly repairs.

7.What are the sampling system parameters of the dissolution autosampler?

Parameters of Dissolution Autosampler- Picture Courtesy: Erweka

Proper operational control and exactitude in testing methods in the dissolution autosampler depends on the proper programming of sampling system parameters. Let’s discuss some basic sampling system parameters:

| Sampling Volume | The volume of dissolution aliquot collected from the dissolution vessel during each cycle is called sampling volume. About 1-10 ml of sampling volume is pulled during the sampling sequence. The amount of sampling volume should match the analysis method and estimate of the analyte. |

| Sampling Intervals | They are pre-determined time intervals during which an aliquot sample is extracted from the dissolution media and examined for the quantity of dissolved drug. It is calculated by considering the dissolution time of the sample and the required level of understanding needed from the dissolution study. Samples should be drawn at the selected time within a 2%-time window. |

| Sampling Location | It is a precise area in the dissolution vessel where the sampling probe is lowered. This location should be one cm away from the vessel wall to ascertain the fluidity of the media. The actual sampling position is dependent on the total test volume. Deviations in sampling location likely produce erroneous readings because the concentration of dissolved product is inconsistent in the entire dissolution vessel. |

| Sampling Flow Rate | It is the rate at which aliquots are taken out using a cannula or probe. Consistency in the sampling flow rate is necessary for minimizing the turbulence of medium or inaccurate sampling. |

| Temperature | A uniform temperature of 37°C is sustained throughout the dissolution autosampler to prevent a shift in the solubility of the drug. |

8.How to clean the parts of the dissolution autosampler?

Cleaning of Dissolution Autosampler- Picture Courtesy: SOTAX

The dissolution autosampler must be cleaned between the batches to eliminate the likelihood of contamination and ensure sampling meticulousness. So, here are some basic learning tips to increase the productivity of your system.

Disassembly of System

First, you must turn off the device and disengage its power source to avoid accident risk. Next, unload sampling trays or racks from the machine. Gently and gradually disassemble parts, for example, sampling probes, lines, and pump heads.

Cleaning

Use a soft-hair brush and light cleaning agent to clean sticky particles or solid substances both from the interior and exterior of the sampling probe. Use a suitable solvent or water for completely flushing the interior of the syringes to expel the dissolution liquid.

Inline filter mechanisms must be replaced after every batch to avoid the buildup of contaminants. Pump heads and sample loops must be sanitized with an appropriate cleaning agent.

Rinsing and Drying

Rinse sampling trays, tubing, and collection vials with water or other cleaning solvent. Reassemble the components after thoroughly air drying them.

9.How to fix the common dissolution autosampler issues?

Unexpected problems in a dissolution autosampler are due to certain reasons and addressing those reasons is key to resolving these problems. However, they should be rectified on time, as otherwise, it would result in serious downtime. Here are some main and frequent issues and their solutions in a dissolution autosampler:

Poor Performance of Pumps

Poor Performance of Pumps- Picture Courtesy: SOTAX

The syringe or peristaltic pumps are unable to pull or transfer the sampling medium. It is because of continuous abrasion on pumps, syringe components are not correctly installed or aligned, or pump lines in peristaltic pumps are old or incorrectly positioned.

Solution

To overcome this issue, you should replace old and defective pumps. Check the installation and alignment of syringes in syringe-based dissolution autosampler and reinstall or readjust their alignment. For the peristaltic pump-based dissolution autosampler, you must replace or reposition the pump tubing if it’s worn out or wrongly placed.

Trapped Air in Sampling Probe

Trapped Air in Sampling Probe

This issue can disrupt the precision of sample retrieval and lead to capricious data findings. There is a variety of causes of this issue including, inadequate degassing of dissolution fluid, fissures in tubes or unsecured lines, and high aspiration speed.

Solution

It is advised to remove the trapped air by degassing the dissolution fluid before initiating test protocols. Change old or faulty tubes and tightly secure any loose lines. Decrease the aspiration speed to lower the frequency of air bubble formation.

Inconsistency in Extraction Volumes

Inconsistency in Extraction Volumes

Sometimes, there is variability in volumes pulled out of the dissolution vessel, contributing to erroneous testing calculations. This is the result of several factors, such as air bubbles in the sampling probes, failure in properly maintaining the syringe or peristaltic pump, hindrances in sampling tubes, and leakage in sampling lines.

Solution

To solve this issue, you must purge the sampling probes and cannulas to eliminate entrapped air bubbles. Secondly, properly schedule calibration cycles to attain consistency in sampling volume. Checking and cleaning sampling pathways remove the clogging and blockage in lines. Frequently test sampling lines for leakage and switch defective lines.

Sampling Interruptions

Sampling Interruptions- Picture Courtesy: Agilent

It happens in some cases that the machine cannot withdraw samples at exact time points, affecting accuracy in dissolution computations. There are errors in inputting sampling timings, causing sampling collection inaccuracies. Furthermore, sampling lagging is also because of software errors or mechanical calibration issues.

Solution

To address this challenge, recheck and re-enter correct inputs on the control panel for seamless sampling withdrawal. Look for software updates to settle timing problems or bugs. Last but not least, recalibrate your systems to attain synchronization between the dissolution autosampler and dissolution apparatus.

Conclusion

A dissolution autosampler offers improvements in test precision over human-based sampling, because various parameters such as, timing interval, and filtration facets are regulated and implemented without discrepancies from the operator. It pulls sampling fluid precisely at the right time points and locations. It ensures sampling and filtration timing accuracy and enhanced throughput. Investing in the dissolution autosampler is the answer to all your problems of variable sampling and anomalous data outcomes. To buy a top-notch and cutting-edge dissolution autosampler, you are requested to contact our sales representatives. Allpack is committed to offering unparalleled service and support and is well-experienced in fulfilling the unique needs of your businesses.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide