Different Types Of Liquid Filling Machine You Should Know

All day long, we use liquids in different forms to make our survival better. From the oral intake of water, beverages, and syrups to the use of detergent, shampoo, and pesticides we cannot skip the consumption of liquids. Similarly, their production and processing is carried out on large scale by utilizing various equipment. Among them, Different Types Of Liquid Filling Machine are of prime importance.

Are you also among one of the producers of liquids but getting confused in choosing between different types of liquid filling machines? If yes! Then welcome to this blogpost. It holds all the relevant information about Different Types Of Liquid Filling Machine You Should Know. After reading it thoroughly you will be able to distinguish between them and opt for the best compatible one. So, just start delving deeper into it and make it happen!

1.What Do You Know About Different Types Of Liquids?

Liquids flowing on a hand

Liquid can be defined as a state of matter with a specific volume but no fixed shape. It can be distinguished from all other matters on its characteristic to flow. Liquids can be categorized as free flowing, non free flowing, viscous, and thick liquids due to their resistance to flow. Similarly, liquids are considered flexible substances due to their ability to adapt any shape in when they are placed.

As liquids are of different types, their handling and packaging is carried out by keeping their distinct specifications. In this way, one of the most critical tasks is the accurate filling of different types of liquids for which the packaging equipment manufacturers have pioneered range of liquid filling machines which you will be knowing in the upcoming questions.

Some of the common liquids include:

- Water

- Beverages

- Sauces

- Lubricants

- Chemicals

- Cream

- Shampoo

- Syrups

2.Different Types Of Liquid Filling Machine- Filling Measurement Method?

Depending upon the nature of liquids, different types of liquid filling machines are designed to better deal with their filling. Similarly, the most important categorization made is the different types of liquid filling machines according to their measurement method. It simply explains the multiple methods being employed for filling liquids precisely. These are as follows:

Liquid Level Filling Machine

52-ROF Biner Ellison Rotary Overflow Filler- Picture Courtesy: accutekpackaging.com

Liquid level filling machine is also known as overflow filling machine. It is the popular type of machine which fill liquids into containers to a fixed level. Mostly, it uses a diving nozzle which dive into container and dispense the liquid into it. The nozzle retract when predetermined level is achieved and in case of over filling, excess liquid is sent back to reservoir.

Benefits

- It helps in reducing material waste by employing overfilling technique.

- The possible creation of foam during filling is eliminated with the use of diving nozzles.

- The machine is suitable for all types of containers by employing level based filling.

Limitations

- Processing highly valuable liquids by liquid level filling machine may cause economic losses due to the variations in product volume.

- It is undesirable for liquids which needs strict administration of filling exact dosage.

Application

Liquid level filling or overflow filling machine is best suitable for liquids of medium to low level viscosity such as edible oil, pesticides, bleach, and liquid detergent etc.

Volumetric Liquid Filling Machine

Volumetric liquid filling machine is another type of liquid filling machine that fills containers with a predetermined quantity of liquid, measured by the volume displaced rather than checking the net weight or level of the filled container. It is best suitable for precise volume filling, however, due to the variations of liquids, volumetric liquid filling machine can be further divided into three types:

Piston Filling Machine

Allpack- PPF-50/250/500/1000/2000/5000 Semi-automatic Pneumatic Piston Filler For Liquids

Piston filling machine is one of the popular types of volumetric filling machine which measure and dispense liquids by using a piston cylinder. The desired volume of liquid is drawn into a cylinder which is then pushed to discharge the liquid into container via nozzle. The volume of liquid can be simply increased or decreased by modifying the length of piston's stroke.

Piston filling machine uses two types of filling mechanism naming check valve piston filling and rotary valve piston filling. The former is suitable for liquids without any particles, while as, the later support thick liquids with small to large particulates.

Benefits

- Maintain high filling accuracy.

- It is safe for all kinds of food grade liquids.

- Precise structure with small footprint and easy handling.

Limitations

It can only accommodate limited volume of liquid at one type.

Application

Piston filling machine is best applicable for thick and viscous liquids which can be flat or with particulates. The common examples include ketchup, mayonnaise, pickles, sauces, jam, and cream etc.

Gravity Filling Machine

Gravity Filling Machine- Picture Courtesy: apacks.com

As the name indicates, gravity filling machine works on the principal of gravitational force. It has a large reservoir or tank placed on the top of machine which has a connection with filling heads. Similarly, the containers are filled when valves of the nozzles are removed from nozzles and liquid start flowing downward into awaiting bottles. Fill volume is determined by the timers which regulate the closing and opening of valves, therefore, it is also called time-based filling machine.

Benefits

- Good for delivering exact volume.

- It can work pretty well for filling liquids with identical characteristics.

- It is cost-effective by using simple filling method of gravity, thereby, ending need for special measuring systems.

Limitations

- Unsuitable for thick and viscous liquids.

- It requires complete rebalancing if user want to process different liquids which is both time taking and expensive.

Application

Gravity filling machine is a good choice for the filling of free flowing liquids and liquids with low level of viscosity that do not change with ambient temperature such as chemicals, milk, coffee, beverages, and paint etc.

iii. Pump Filling Machine

Allpack- YT180-2 Single Head Small Volume Magnetic Gear Pump CNC Liquid Filling Machine

Pump filling machine is yet another type of volumetric liquid filling machine. It employs pump mechanism for the measuring and dispensing of liquids. The machine is independent in its performance by taking liquid from hopper, weighing it properly, and transferring it into the underlying containers through single or multiple filling heads.

The pump mechanism include peristaltic pump, gear pump, and rotary pump. Each type is used for enhancing the filling efficiency and fill volume accuracy.

Benefits

- High filling accuracy.

- Pump filling machine is a versatile equipment that does not require parts changeover for eclectic filling requirements.

- It can deal with small to large fill volume.

- Wide range of models to suit various industries.

Limitations

For filling foamy liquids, the speed of pump filler is supposed to be reduced which in turn will reduce the efficiency of filling.

The machine may have higher initial cost due to its special pump system.

Application

Pump filling machine is the most flexible and resilient machine that can better deal with liquids of all kinds encompassing thin liquids like water to thick and viscous fluids like shampoo, honey, lubricants and lotions etc.

Net Weigh Liquid Filling Machine

Net weight filling machine- Picture Courtesy: kwt-auto.com

Net weight liquid filling machine is a unique machine that differ from other types on its characteristic to utilize weight-based filling. The machine is proficient in controlling the weight of product being filled into containers in order to ensure filling precision. For this purpose, it has a special feature of weight scale which remain alert during and after filling of liquid for checking the weight.

Benefits

- It supports all kinds of small to large containers regardless of their shapes and sizes.

- The machine is good for large filling volume ranging from 5L to 30L.

- Good for businesses that are concerned with the weight of product rather than volume.

Limitations

- It does not focus on the volume of material being discharged into the container.

- The machine is not applicable to low volume of liquids.

Application

Net weight filling machine is a perfect choice for filling the large volume of different types of liquids ranging from oil, sauces, and petrol to pesticides and paint etc.

3.Different Types Of Liquid Filling Machine- Degree Of Filling Automation?

Liquid filling machines can also be categorized into different types according to their degree of filling automation. It mainly consists of three types which are explained below:

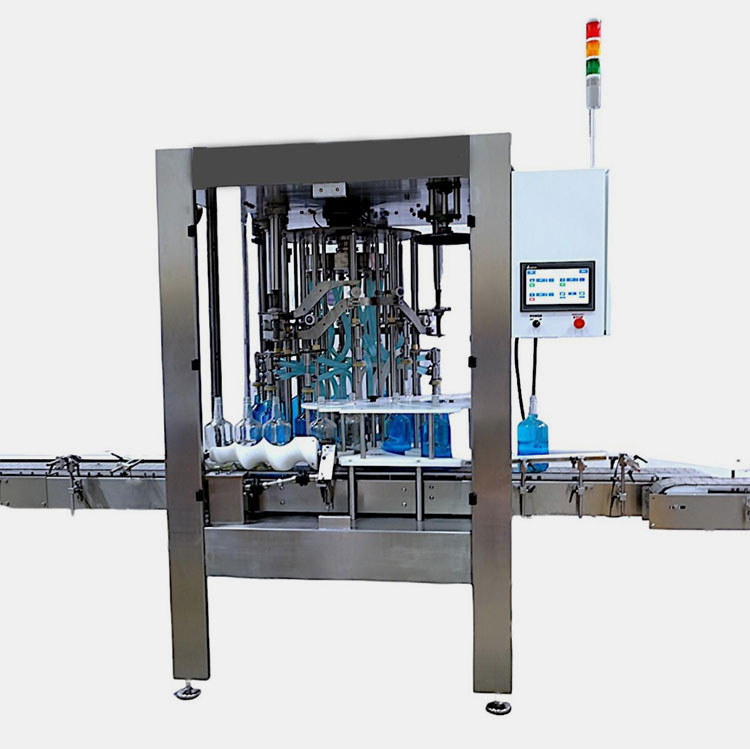

Fully Automatic Liquid Filling Machine

Allpack- Automatic Liquid Soap Filling Machine

Fully automatic liquid filling machine is the sophisticated machine with advanced technology to automatically carry out its function of filling liquids. The machine has complex structure with its ability to be integrated with other machines like liquid supply tank and bottle feeding machine etc. It works independently once parameters are set and the operation is continued until the desired number of containers are filled. Conveyor is used to mobilize the empty containers for filling and their final discharge.

Benefits

- It gives high production efficiency and accuracy with sensors.

- Automatic parts changeover and safety alerting system.

Limitations

The machine has high operational and maintenance cost.

It occupies more space and require well trained operator to understand its mechanism and conduct troubleshooting.

Application

This machine is a highly valuable equipment to be employed fo large to extra large production facilities such as beverage industry, cosmetic industry, medical industry, and chemical industry etc.

Semi-Automatic Liquid Filling Machine

allpack- PPF-50T/250T/500T/1000T/2000T/5000T semi-automatic gas-filling piston filler for pastes

Semi-automatic liquid filling machine combine together the automatic and manual operation. With small footprint and automatic technology, the machine can be easily operated, however, user is required to intervene in the process for loading and unloading of containers. The machine is available in different designs and configurations in accordance with varying liquids and containers.

Benefits

- The machine is less expensive than fully automatic liquid filling machine with low power consumption and tools required.

- Offers flexibility to be adjusted for filling different types of liquids and containers.

Limitations

Less efficient as loading and unloading of containers is carried out by operator.

There may be risk of product contamination due to manual intervention

Application

Such type of precise equipment is good for low to medium scale production in food, medical, and beauty care sectors.

Manual Liquid Filling Machine

Allpack- A03 Manual paste liquid filling machine

Manual liquid filling machine is hand operated small size machine. Its design is simple with few components comprising a hopper, handle, filling nozzle, and liquid controlling tools etc. However, in some cases, the design of machine may be a bit complex for example the piston filling machine has complicated structure than that of a bottle filling machine with valve.

Its operation is pretty easy with material loading in hopper and placing container under the filling nozzle. Similarly, the liquid is dispensed into bottle by pushing the handle manually.

Benefits

- It is a cost-effective solution for low volume liquids.

- Well-suited for substances with sensitivity to heat and shearing.

Limitations

The process is time-consuming.

It is labor intensive with entire dependence upon user for operation.

Application

Manual liquid filling machine is useful for low volume of liquid substances being processed in home based businesses, laboratories, and research centers.

4.Different Types Of Liquid Filling Machine- Filling Direction?

The rapid advancements in technology has also addressed the manufacturers' concerns regarding the expected efficiency and space covered by the different types of liquid filling machine. Now, you can choose between linear liquid filling machine and rotary liquid filling machine keeping in view their compatibility to your existing conditions. So, let's know a bit more about these two types!

Linear Liquid Filling Machine

Linear type vacuum liquid filling machine- Picture Courtesy: gloex.net

Linear liquid filling machine is a classical type of automatic equipment with a linear design that processes bottles and containers in a straight line. It utilizes a conveyor that mobilizes containers to pass through filling station and carry out their discharging for further packaging. It requires other machines such as capping machine and labeling for the additional necessary processing of bottles.

Benefits

- It has simple structure which makes it easy to use.

- The machine is an economical solution with little maintenance and operation cost.

Limitations

It covers more space and process limited number of containers at the same time

Application

The machine is ideal for startup businesses in beverage, food, and daily chemical industry.

Rotary Liquid Filling Machine

Rotary capping and filling machine- Picture Courtesy: pmrpackaging.com

Rotary liquid filling machine is a sophisticated machine with complex structure and working mechanism. It is quite effective to deal with multiple bottles at the same time. The design of machine is rotary as suggested by the title, therefore, most of the models do have a capping system as well. In this way, it is a better option for the filling of different liquids in large number of containers.

Benefits

- It meets intense production throughput and maintain high filling accuracy.

- The machine cover less space and perform dual function of filling and capping as a single entity.

Limitations

Complicated structure with heavy-duty machinery requiring stable energy source.

Expensive with high initial cost and maintenance requirements.

Application

This machine is perfectly suitable for the extra large production facilities with high demand for efficiency as well as liquid filling precision.

5.Different Types Of Liquid Filling Machine- Filling Container Type?

If you are using special containers for liquids with specific size and shape then wide variety of machines are available there in market. You may be wondering how! But we have brought them for your clear understanding which you will explore in the underlying explanation:

Bottle Liquid Filling Machine

FL-101 Automatic Bottle Filling Machine- Picture Courtesy: packleader.com

Bottle liquid filling machine is one of the most popular machines specialized in filling bottles of different sizes and shapes. It can fill round bottles, square bottles, oval bottles, and irregular shape bottles with precise amount of liquids. The machine can be integrated with labeling and capping machine to make a production line and enhance the automation level. Most of the bottle filling machines are used for filling juice, water, syrups, and personal care liquids.

Jar Liquid Filling Machine

Jar filling machine- Picture Courtesy: tenco.it

Jar liquid filling machine is another type of equipment designed to meet the requirements for filling jars. These jars are often made up of glass to better preserve the liquids against corrosion and bacteria. Similarly, the machine is capable of handling these sterile jars effectively and deliver an accurate volume of liquid into these jars. Mostly, such machines are employed for the filling of honey, sauces, marmalades, and pickles in various sizes jars.

Can Liquid Filling Machine

Can liquid filling machine- Picture Courtesy: asgmachinery.com

A can liquid filling machine is another type of machine that is tailored with advanced features to accurately fill liquids into tin cans. It is often employed for the filling of beverages and carbonated drinks such as sodas, wine, and soft drinks etc., into cans. For the reason that cans are distinct from other types of containers in their packaging, it can be integrated with can sealer and labeling machine to undertake its specific needs and enhance the automation level.

Bag Liquid Filling Machine

Allpack- APKRL200-Y Rotary Liquid Premade Pouch Filling Machine

As liquids like ketchup, mayonnaise, and even drinks can now be packed in flexible pouches like doypacks, bag liquid filling machine is there to fullfil this task. The machine is available in form, fill, and seal design where it can finish the liquid filling from the formation of bag till its filling and sealing. While as, for premade pouch filling, machine is also there to reduce packaging time and fill the precise volume of liquids and pastes into bags.

Jerrycan Liquid Filling Machine

Jerrycan filling machine- Picture Courtesy: pestopack.com

Jerrycan liquid filling machine is a type of equipment utilized for the filling of liquids into jerrycans. It can handle various sizes and shapes of jerrycans in different industries. Most of the jerrycan liquid filling machines are used for the filling of edible oil, pesticides, lubricants, and liquid home cleaner. The machine has automatic system to accomplish its prime function of jerrycans filling and may be customized to meet specific material needs.

Barrel Liquid Filling Machine

Allpack- Drum/ Barrel Liquid Filling Machine

Barrel liquid filling machine is another form of machine that is specifically tailored to fill large size plastic and metal barrels and drums with precise liquid volume. The machine is also workable for buckets and it can work along with other machines to automate the production line. In addition to it, barrel liquid filling machine is fully automatic and suitable for the processing of large volume of corrosive, non-corrosive, free flowing and viscous liquids.

6.How To Determine The Right Type Of Liquid Filling Machine For You?

After going through the long lasting list of different types of liquid filling machine, you might be able to distinguish between each type and know how they are suitable or unsuitable for your business. Despite that, we want to make it more easy for you to choose between them the best one. So, consider the underlying factors and we assure you that buying the right machine will seem like a piece of cake!

Material Nature

Liquids with different flow properties

First and foremost thing to always look for is the characteristics of the material you are processing. It simply means to know the nature of your liquids. For example, whether the liquid is free flowing like water, viscous like honey, or thick like toothpaste and cream. Once, you have determined this factor, it is going to be very easy to secure the liquid filling machine of right category for your business.

Production Volume

Another paramount factor for selecting the effective liquid filling machine is to examine your current production volume and expected growth in near future. For instance, if you are a beginner in the field with ordinary production volume then going for semi-automatic model will be a safe choice.

In contrast, if you are on the ground for a long period of time and looking for efficient equipment then fully automatic machine is no other than a good option.

Container Type

Different types of containers

As mentioned above, containers are of different types and each container require specific machine to meet its requirements. Similarly, you should be clear whether you are using bottles, cans, jerrycans, or tubes. Once known, you will be ready to figure out the suitable machine for you.

Space

Edible oil filled bottles processing- Picture Courtesy: Freepik

The available space in your working area matters a lot in choosing the right liquid filling machine. Suppose, with small working area, you have chosen for a heavy-duty machine then what will be the result? A congested working environment! So, make sure not to overlook this factor.

Quality

Quality assurance elements- Picture Courtesy: Open Library

Your another essential concern should be the quality of liquid filling machine. After all, it is going to be your life time partner in business. For this, you need to check the vendor reputation and experience in relevant field. In addition to it, considering the warranty policy and quality certifications accredited to the machine play a key role in determining the quality of machine.

In this way, FDA, ISO, GMP, and CE are some of the important quality standards which your liquid filling machine should meet with.

Conclusion

So, are you ready for landing? Well, you must be! As we hope that this article has enabled you to explore The Different Types Of Liquid Filling Machine You Should Know. From now onwards, there is no need to rush if you encounter variety of liquid filling machines. It is always important to understand that each machine has its own specifications, benefits, and limitations. These attributes are what making them excel the liquid filling on every level and raise your business to the heights of glory. So, if you are interested in purchasing a liquid filling machine then Allpack is the best supplier to be considered. Just leave a message and we will contact you ASAP!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide