Desiccant Inserting Machine: The Complete Buying Guide in 2025

Desiccant Inserting Machine: The Complete Buying Guide in 2025

Is it possible to put desiccant manually in hundred bottles each minute? Certainly not!

A desiccant inserting machine is a superb technology that emerged through mechanical engineering that controls thousands of bottles for the fastest desiccant insertion each hour. Therefore, your product can be safe against humidity for a longer time. This machine is not only responsible for safeguarding delicate formulation but offering you high efficiency and profitability. Do you know how it works? What important components are responsible for its integrity and excellent functionality? How can it help to improve your production line? Please read this guideline carefully prepared to answer your all questions. Let’s get started it!

1.What Is Desiccant Inserting Machine?

This is an advanced machine designed to place a desiccant inside the packaging material that ensures the packaging product is intact and fresh against moisture. Because desiccant is responsible to trap moisture inside packaging container and protects the progression of degradation. By this way, you can retain potency and efficacy of your active product during transportation or storage for a longer time.

Previously, manual method was used to keep desiccant inside natural products like sugar, salts, Over time industries brought revolutionary way by using automatic desiccant inserting machine that has emerged in modern industrial sector as the most robust and time saving option.

With the help of sensors, conveyor, and touchscreen mechanism; it can ensure hundreds of desiccant placements with low chances of human error as well contamination.

2.What Is the Industrial Purpose of Desiccant Inserting Machine?

The industrial applications of a desiccant inserting machine are broad and diverse. This is because moisture absorbents play important role products safety. Some of major industrial uses are as followed:

Pharmaceutical Industry

Picture Courtesy-Abrifete

The significance of a desiccant inserting machine cannot be overlooked when it comes to storing and transporting medicines. The presence of desiccants is involved in maintaining the potency, quality, and safety of sensitive pharmaceutical products against degradation. For example, gelatin capsules, tablets, effervescent tablets, etc.,

Food Industry

Epicurious

When it comes to preserve the freshness and taste of food products; a desiccant inserting machine play a significant role to maintain product’s shelf life by preventing microbial growth or preserving the nutritional values. For example, dried fruits, ready to use chapatis, spices, cereals, grains, etc.,

Chemical Industry

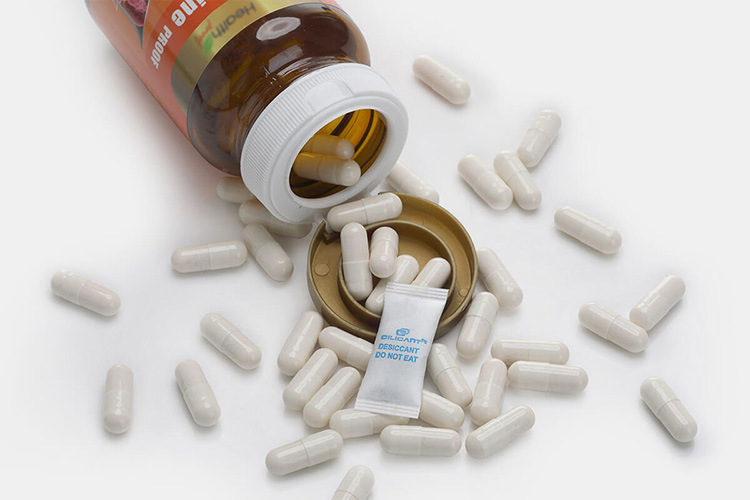

Nutraceutical Industry

The nutritional supplements are the sensitive category of oral dosage forms that are composed of essential and non-essential vitamins, proteins, trace elements, minerals, probiotics, and other important compound that can boost well-being. Indeed, moisture can deteriorate integral elements of these supplements; a desiccant inserting machine is of prime important in this industry as it offers you an easy and fast solution of placement desiccant in each packaging respectively.

Cosmetic Industry

The manufacturing of face serum gelatin capsules, face powders, eye powders, and hair products, are always prone to degradation in the presence of moisture content. A desiccant inserting machine is a useful equipment for inserting desiccant bags to protect these products against moisture.

Electronic Industry

Picture Courtesy- Aquauk

This industry deals with a broad spectrum of electrical components made up of steel, iron, nickel, etc to make tools like switches, circuit extension boards, nuts, etc. Inside their packaging pouches, a desiccant inserting machine is worth buying the machine in this sector as a moisture absorber can avoid humidity to save the product from corrosion.

Agricultural Industry

Picture courtesy- Amazon

A desiccant inserting machine is used in the agricultural industry for the packaging of seeds, grains, dried flowers, pollens, etc., these substances are used for germination procedures to progress the development of the crop. So, a desiccator inside is recommended to avoid moisture content and improve the ideal condition.

Optic Industry

A desiccant inserting machine is used to put desiccant in the packaging bags of contact lenses, glasses (sun glass, vision glass) to avoid moisture content and protect against moisture content that affects the surface of the glass or induce lenses stickiness.

Pet Food Industry

This industry is a large manufacturing sector for producing pet food to maintain health by offering good nutritional values. These products include nuts, beans, cereals, grains, vitamins, and minerals that must be moisture-free. A desiccant inserting machine is highly recommended and used during the packaging procedure of these products.

3.What Are the Benefits of a Desiccant Inserting Machine?

A desiccant inserting machine is a popular and useful machinery that has rapidly replaced manual handling of inserting desiccant as it offers unlimited benefits to your business. Some of them are discussed below:

Offering High Speed and Quick Operation

A desiccant inserting machine has solved the hectic methodology of manually inserting each strip inside each individual pack. A high speed and quick operation ensure catering to high production capacity in no time that leading to improve productivity and profit.

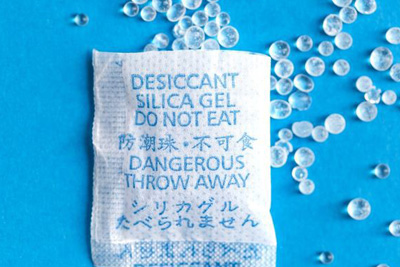

No Chance of Product Damage or Leaked Desiccant Strip

The machine can accurately cut every ending of the strip so it can perfectly place inside without any chances of desiccant leakage or entrance silica gel beads in your product.

Stainless steel Body Structure

The machine makeup is entirely based on stainless steel which ensures super hygiene with no chances of cross-contamination or microbial growth.

No Laborious Work

An automatic system for long term processes can reduce labor costs and continuous supervision or handling. This machine can ultimately save costs in all aspects.

Perfect Integration with Other Machines

The machine can seamlessly integrate with other machines of the production line without any replacement or modification of the facility setup.

4.What Is Working of The Desiccant Inserting Machine?

The working principle of a desiccant inserting machine is super-easy. Please follow our step by step working principle with easy illustrations.

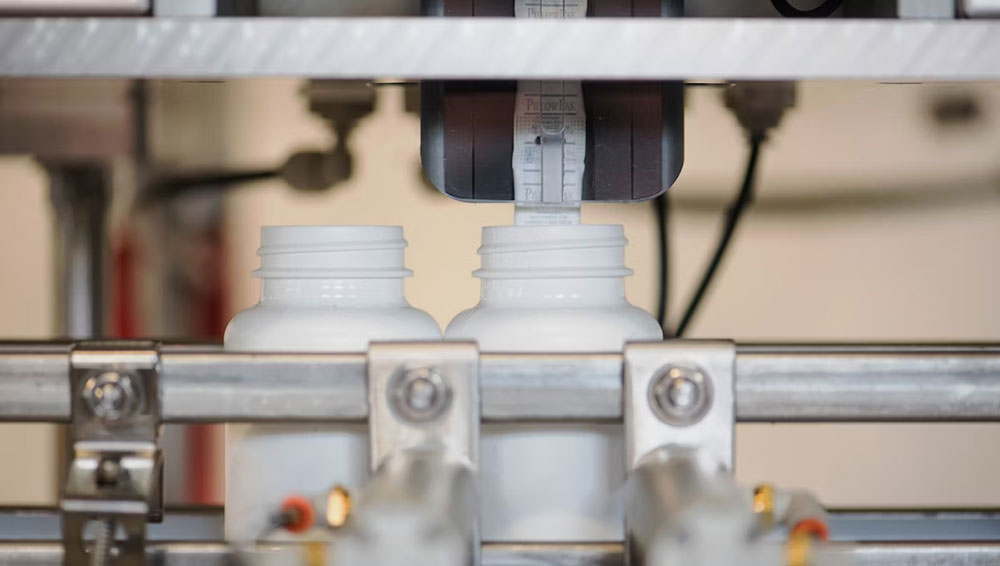

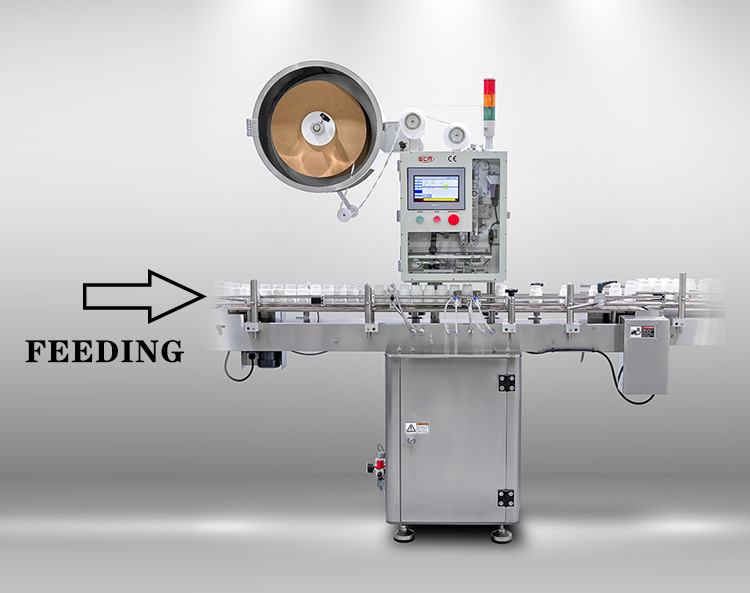

STEP 1- Feeding

At this stage, whether a container, bottle, jar, or pouch, comes inside the machine with the help of a conveyor that loads them in one go. This pathway helps in positioning the packaging material towards its exact position where a desiccant has to be loaded.

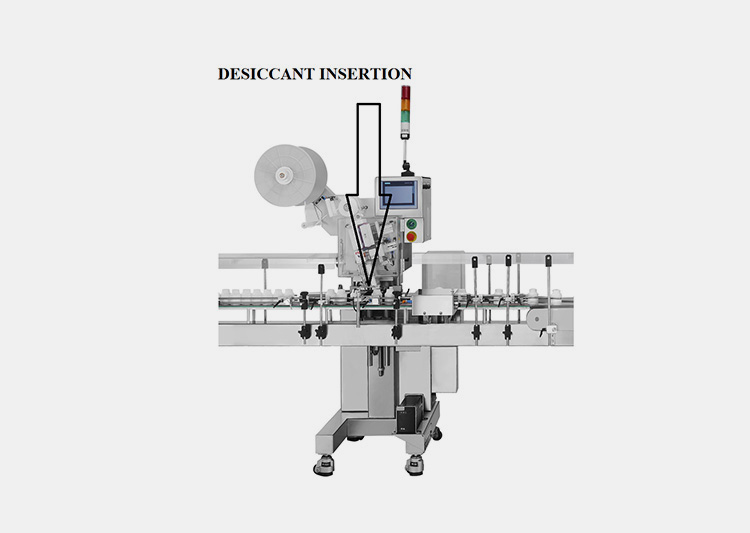

This is another major step where a loaded desiccant is ready to supply into the packaging with the help of a rotating desiccant supply unit. These desiccants are designed in such a way that each packet goes directly into individual products respectively.

A desiccant inserting machine is equipped with shear knives for the purpose of separating each desiccant strip from the series of loaded sheets or films. When an object faces the desiccant inserting zone, the sensor detects the presence and cuts the strip automatically cut them.

This is an important step which is closely similar to the cutting step. Upon subjecting the bottle right to the desiccant zone; the machine senses the presence and positions each unit of desiccant into it. ., The following step assures you have put desiccant which is ready for insertion without any damage or leakage.

This is the step that allows corrected bottles with desiccant inside to be ready to leave the machine and can continue to enter along the production line for the final procedure. Upon the type of packaging material, it can pass through a series of steps such as sealing machine, labeling, etc.,

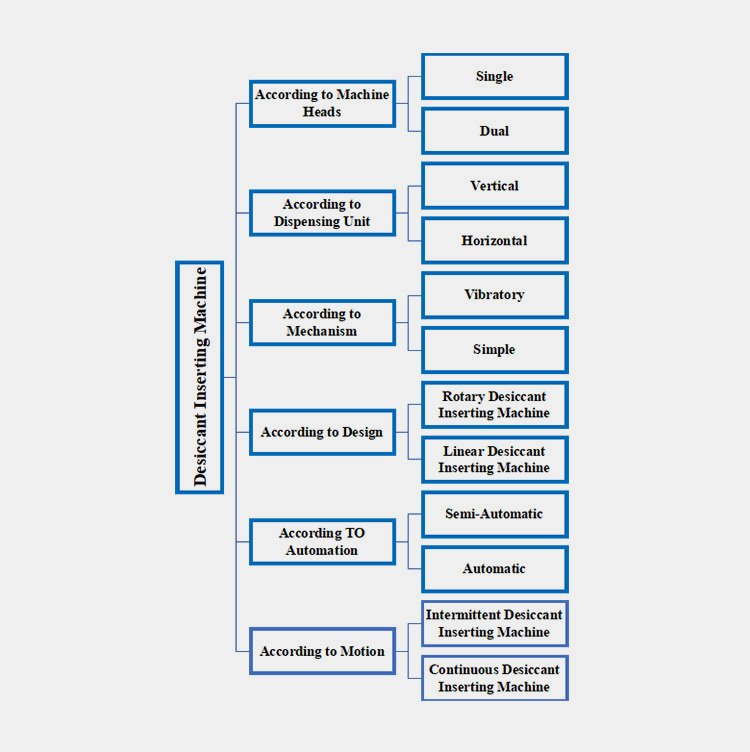

5.How To Classify a Desiccant Inserting Machine?

A desiccant inserting machine presents the following classification:

ACCORDING TO MACHINE HEADS

Single Head Desiccant Inserting Machine

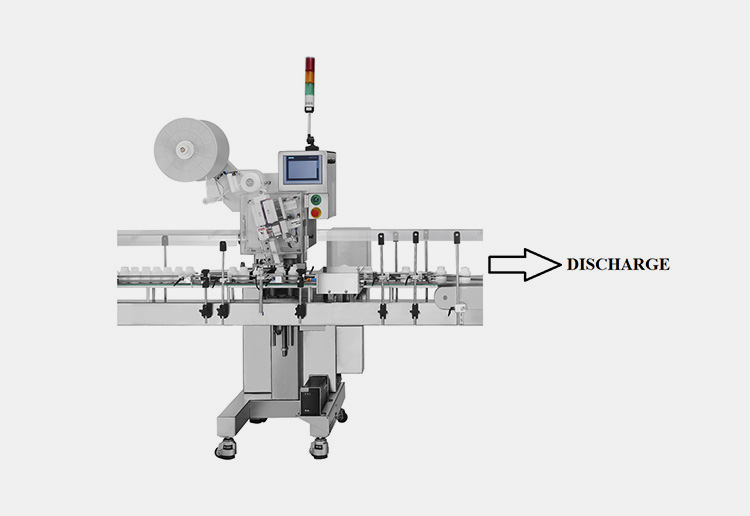

Picture Courtesy: countec

A single head desiccant inserting machine is a specialized design used for inserting unit desiccants into packaging material such as sachets, bottles. This is the compact and cost-economical option to approach modern way of packaging. This is a robust machine that utilize the single head for desiccant film roll suitable for small to moderate capacity production facilities.

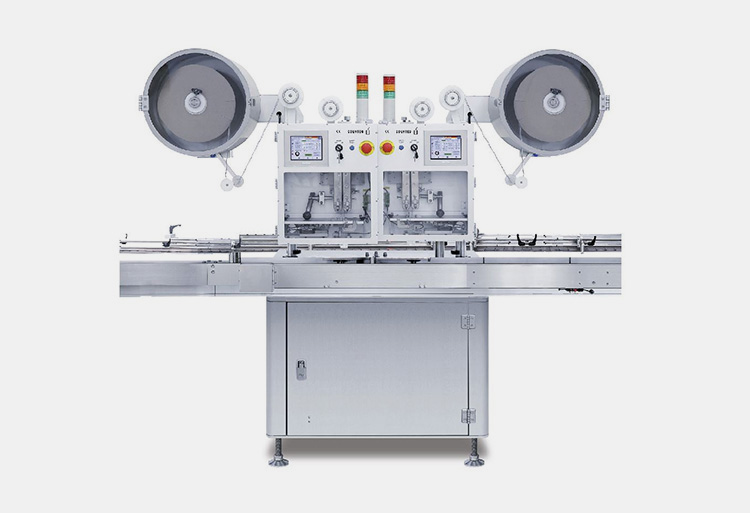

Dual Head Desiccant Inserting Machine

Picture Courtesy: countec

A dual head desiccant inserting machine is an excellent machine used to cater to large production capacities. This machine is equipped with dual unwinding desiccant heads with dual cutting knives and features more extensive options that can simultaneously perform the best and fast operation in a short time. This machine can deal with hundreds of bottles per minute with 100% accuracy. A sensor ensures the entire procedure is perfectly run through exactness and transported product is correct for further steps.

ACCORDING TO DISPENSING UNIT

Vertical Desiccant Inserting Machine

Picture Courtesy: Made in China

This machine is ideally designed for overwrapping film pouches, or film form sealing machines where the hopper dispenses the desiccant unit vertically. This structure works when containers or pouches are subjected to an upright position where their primary facing orientation is straight or vertical. This machine is commonly used in the food pouch packaging industry.

Horizontal Desiccant Inserting Machine

Picture Courtesy: Made in China

A horizontal desiccant inserting machine is designed to insert desiccant units into containers. The following machine works on a continuous pattern to offer seamless operation with high accuracy.

ACCORDING TO MECHANISM

Vibratory Trays Desiccant Inserting Machine

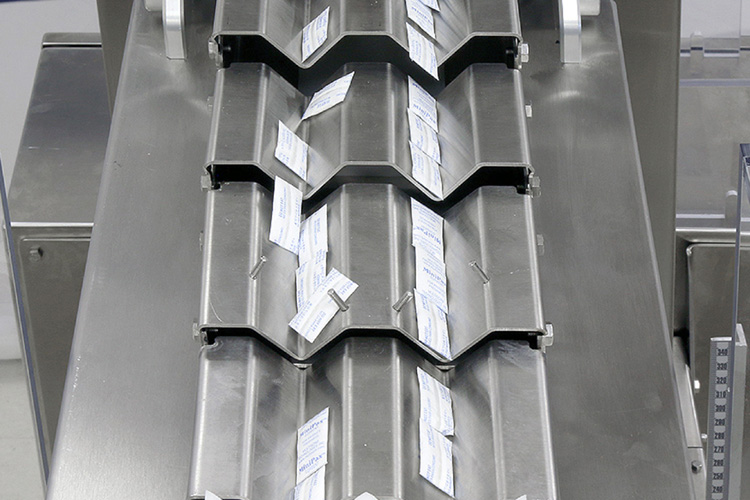

Picture Courtesy: Bellatrex

This machine inserts desiccants inside the packaging material with the help of vibratory trays that are designed with multiple channels that assist the way toward the container, bottle, pouch, etc., These trays vibrate in a gentle way to align the desiccants and ensure the control over the procedure.

Simple Desiccant Inserting Machine

Picture Courtesy- Youtube

This machine is commonly used standard way of desiccant insertions into each packaging material. This machine follows a straightforward procedure that works by directly cutting of strips and their insertion into each packaging material without any steps or complicated mechanisms.

ACCORDING TO DESIGN

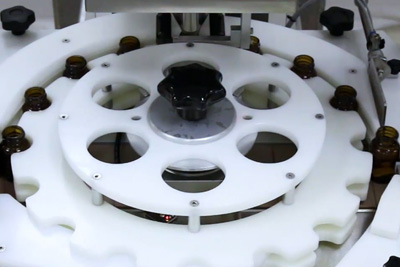

Rotary Desiccant Inserting Machine

In the rotary desiccant inserting machine, bottles move seamlessly around the desiccant inserting zone via a circulatory turret or carousel. The empty bottles rotate where desiccants are entered and leave the system along the rotary pathway. This machine is used for fast and high-speed production processes that give you high output.

Linear Desiccant Inserting Machine

In this machine, all the packaging material comes in contact with the desiccant insertion zone in a linear fashion. This follows semi-automatic or automatic functioning where the process is taken place gently throughout the pathway which is a suitable option for medium to large production batches.

ACCORDING TO AUTOMATION

Semi Automatic Desiccant Inserting Machine

semi-automatic desiccant inserting machine- Picture Courtesy CVC

A semi-automatic desiccant inserting machine requires the involvement of the operator in running some steps such as loading empty containers for desiccant insertion, whereas once they’re fed onto the conveyor it combines the automatic running via insertion of desiccant inside. After placement of the desiccant, the machine delivers the container via a conveyor which is removed manually. This machine is suitable for medium production systems where hundreds of bottles can be treated each hour.

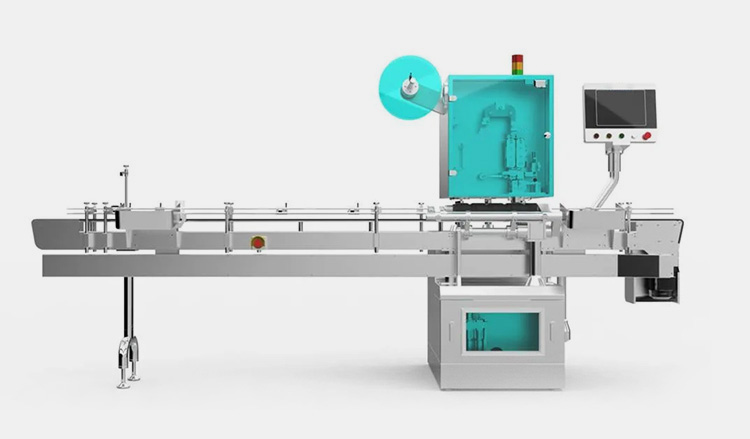

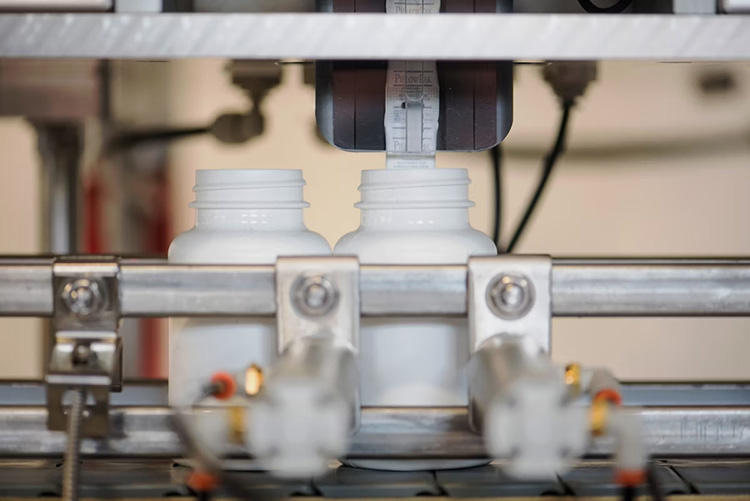

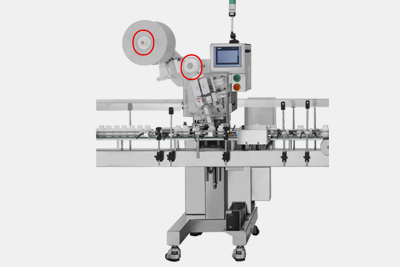

Automatic Desiccant Inserting Machine

Picture Courtesy- Alibaba

This machine works fully automatically where a set of containers comes in contact with desiccant placement and leaves itself without the requirement of manual handling. An automatic desiccant inserting machine is an ideal machine for a production area running a huge capacity of containers. Because this machine offers a consistent work throughput with gentle placement of desiccants under high speed.

ACCORDING TO MOTION

Intermittent Desiccant Inserting Machine

This machine is designed with a special feature in which the desiccant inserting machine places the desiccant bag or strip inside the container in Start-Stop motion or following intermittent motion. This machine is an economical device that can ideally cater to small to medium production lines.

Continuous Desiccant Inserting Machine

Here, the mechanism of the desiccant inserting machine follows a continuous motion with no Start-Stop working principle ultimately ensuring a seamless movement of the production procedure.

6.What Is the Mechanical Structure of a Desiccant Inserting Machine?

Desiccants are available in two types i.e. pre-cut pouches and canisters. Some desiccant-inserting machine work with single types while other models can be used to insert both types. Some important parts of the desiccant inserting machine are given below however, one should always consult the machine manual for an accurate description and working of the machine.

| Part | Description | Picture |

| Roller | Some desiccant inserting machines have rollers instead of hopper where rolls of uncut desiccant are hung up. As the rollers move the desiccants are conveyed into the machine. |  |

| Shearing knife | Before delivering the desiccant to the counter a highly precise knife cuts at the edge without damaging the desiccant. The desiccant then moves toward the counter via a vibratory tray. |  |

| Hopper | This is the unit where pre-cut pouches or canisters are held. Machine equipped with hoppers do not required shearing knife or rollers. Many manufacturers offer models that accommodate either orientation. |  |

| Vibratory tray | From hopper individual desiccant are moved towards the counter via vibratory tray. The movement and separation of the desiccants is due to continuous and vibratory motions. |  |

| Counter | Most automatic machines have infrared sensory counters that detects desiccants and releases single desiccant in the bottle below the chute. |  |

| Chute | Chute delivers desiccant inside the bottles. |  |

| Rotary wheel | A rotary wheel orientation is most commonly desired when high production capacity is required. A rotary wheel simultaneously deliver number of bottles below the chute for release of product. |  |

| Conveyer | Conveyer system is usually consisting of infeed, outfeed conveyer, pulleys, belt etc. Conveyer system is controlled by a three phase motor and can be operated via control panel. |  |

| Control panel | Control panels in most automatic units have a touch screen display through which the entire operation is carried out. From machine parameters to machine function, all are operated and displayed on the screen. |  |

| Detection system | The desiccant inserting machine is equipped with top notch infrared sensors that not only detect and release desiccant into the bottles but also remove unfilled, inverted, and dropped bottles from the conveyor. |  |

| Removal mechanism | The system detects and removes any unfilled bottle from the assembly by simply changing the path of the bottle. Once the bottle is removed the diversion is automatically cleared and the outfeed is continued. |  |

7.What Types of Products Are Supported by A Desiccant Inserting Machine?

Desiccant inserting machines can support multiple products in terms of packaging. These products are enlisted below:

| Bottles | Desiccant inserting machine is ideal for processing all types of plastic and glass bottles with ranging size. These bottles may contain medicines, candies, bubble or gummies etc. |  |

| Jars | Jars made up of glass or pottery can also be processed by this machine. They are mostly used for storing food like biscuits, snacks and other types of dry food to prevent moisture. |  |

| Pouches | Pouches are moisture resistant storage packages made with plastic and a thin layer of aluminum foil to resist ultraviolet light. However, most of the pouches still contain silica gels for additional care. Therefore, a desiccant inserting machine is used to carry out this task. |  |

| Sachet | Similar to pouches, sachets are also made from plastic, but they are small in size and having little space for storage. A desiccant inserting machine is capable of doing the same task for sachets too. |  |

| Cans | Cans are rigid and compact storage containers derived from metal. Most of the susceptible and sterile goods are stored in cans to give extra protection, hence, they are filled with desiccant by this machine. |  |

| Tubes | You may have an experience using effervescent tablets which are packed in large narrow tubes made of flexible plastic having a silica bag inside it. This excellent experience is indeed the result of desiccant inserting machine which processes it responsibly. |  |

| Cartons | Cartons are small corrugated boxes made from paperboard. These cartons are used for a variety of purposes such as packing food items, jewelry, home accessories or glass, etc. Therefore, reputable industries used to process supply their customers with the best products unaffected by moisture, for which they use a desiccant inserting machine. |  |

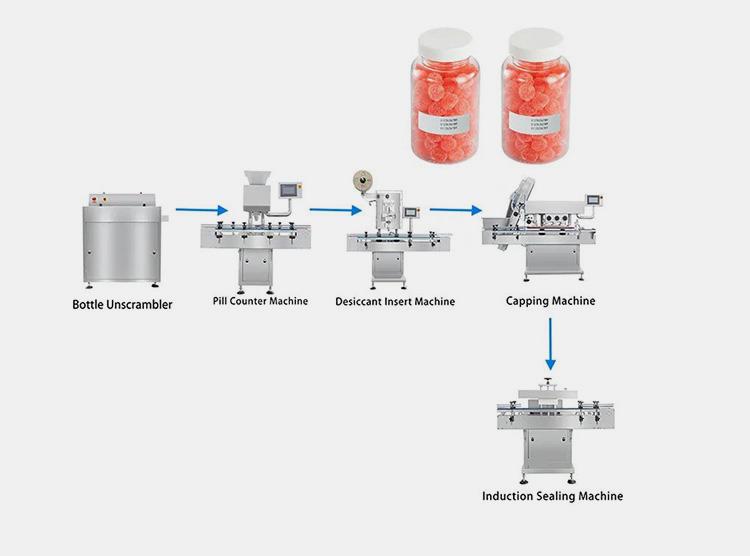

8.What Production line does a Desiccant Inserting Machine Support?

The Production Line of Desiccant Inserting Machine Support

| Bottle Unscrambler | In the first step, this machine is mainly responsible to arrange empty bottles in a proper alignment in order to correct orientation. This can help to maintain a smooth flow in the production line, particularly at the upright position. |

| Pill/Tablet/Capsule Counter Machine | As the name suggests, this machine is efficient in counting pills/tablets and dispensing in the bottles accurately with surety to product uniformity and a correct number of pills.

|

| Desiccant Inserting Machine | This is the focal point of the production line, which is highly important for product safety by inserting moisture-repellent pouches in each bottle accurately. |

| Capping Machine | After completion of product fillings, these bottles are properly secured with caps or lids. The capping machines are highly automatic with tightening of the caps for safety particularly in storage and transportation. |

| Induction Sealing Machines | These machines tend to provide airtight seals by generation of heat with an extra layer for the protection of the bottles from tampering and maintenance of the product freshness. It reflects the quality of the product. |

9.How to Maintain the Desiccant Inserting Machine?

Picture Courtesy- Made in China

This is essential to take care of your machine on a regular basis to ensure it gives a good performance and extended shelf life. There are some maintenance points you must follow to achieve better results.

| Maintenance | Description |

| Daily | A visual must be done regularly after the operation to determine loose components or abnormalities.

Using compressed air, a dry cloth, and a brush can help you in proper cleaning of debris or dust around every corner of the machine. |

| Weekly | All moveable components of the machine should be treated with lubrication to avoid friction. For example, conveyor belt, cutting knives, rotary desiccant dispensers., etc.

Check and replace worn out parts of the machine. |

| Periodically | Reset the setting of the machine using PLC. Delete old file for fast response of the touchscreen system.

Check the interior electrical component of the machine and replace wiring, damaged parts if needed. Lubricate the movable joints for smooth functionality. |

10.What are the Technical Problems and Solutions of Desiccant Inserting Machine?

While using desiccant inserting machine, you may face some challenges which can lead you to bigger problems. To enable you to solve these issues, the table below will be helpful:

| No | Problems | Causes | Solution | Picture |

| 1 | Instead of cutting the edge, the blade cuts middle of desiccant | It is due to inaccurate setting of distance between each desiccant bag | Adjust the length for each desiccant bag by using touch screen panel |  |

| 2 | The problem of inaccurate desiccant cutting remains after setting of distance | If you are using marking based sensor cutting then there may be double mark on desiccant bag | Make sure to use blank bags for desiccant. In case of printed bags, keep the color of targeted area distinguish |  |

| 3 | Rollers show resistance while pulling desiccant | It occurs when rollers are too much dry, thus, result in friction | Keep the rollers and wheels lubricated to prevent surface resistance |  |

| 4 | The edges of desiccant bags are roughly knives | It may be due to untidy or blurred cutting blade | Clean the blade by removing residues and replace it with new one if blunt |  |

11.What Points to be Considered Before Purchasing a Desiccant Inserting Machine?

Discussed below are the points one must keep in mind when purchasing a machine.

Size and Packaging Type

Do you run a packaging line with large sizes? You must see if the selected machine offers to insert desiccant strips with various sizes and can accommodate fully different containers.

Production Capacity

Are you Planning to Run Faster Production? You must determine your planning goals such as expected production capacity as well as the number of desiccant insertions in each cycle. This would help you to choose whether you need a small, medium, or large machine.

Automation

Picture Courtesy- Alibaba

Are you affiliated with limited production? For that buying an automatic desiccant inserting machine is not a wise decision. You can determine what production output per hour you need and what automation is suitable for your purpose. If you have limited labor resources then go for automatic, if you have a limited budget go for semi-automatic.

Flexible Integration

Picture Courtesy: Lenis Machine

You must know future machines can seamlessly be compliant with other existing machine and allow flexible integration with them.

Installation Area

Picture Courtesy: Bellatrex

You must determine production flooring and facility area specification in order to adjust your machine perfectly. Larger machines in congested areas cannot be accommodated and may affect its efficiency later.

Conclusion

In conclusion, a desiccant inserting machine plays a significant role in maintaining product stability, freshness and shelf life. By placing a desiccant inside the packaging containers can effectively enhance the protection and minimize the chances of developing moisture content. That’s why machine is preferred in contributing high role in various industries. Planning to Purchase? Contact us now for more guidance and details.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Desiccant Inserting Machine: The Complete Buying Guide in 2025 Read More »