Your Best Deblistering Machine Suppiler

- Electrical Brake Switch and Lock Switch

- Particle Rubber Plate Sequential Connection

- Unique Retractable Automatic Cutting Device

Deblistering Machine

Allpack deblister machine is an automatic tablet picking (stripping) machine for recovering drugs from the packaging board of aluminum plastic foam covered with defects. It is composed of a 304-grade stainless steel shell, micro motor, primary reducer, roller combination, guide plate combination particle rubber plate sequential connection, equipped with an electrical brake switch and lock switch. The micro motor and the primary reducer drive a set of rollers simulating the action of manual stripping tablets to peel off the aluminum plastic bubble cover plate of the whole plate from the defective packaging plate and collect the particles and the packaging separately through the guide plate and the particle baffle plate. A deblistering machine is a specialized piece of equipment used to separate solid dosage forms from their packaging.

Deblistering Machine

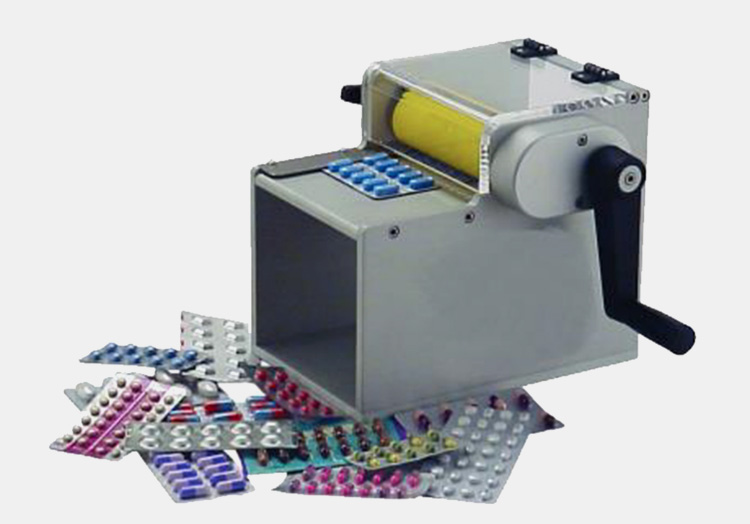

PY-120 Automatic Tablet Deblister Machine Capsule Deblistering Machine for Pill Tablets

Allpack PY-120 Alu-PVC or Alu-Alu deblister machine is an automatic tablet picking (stripping) machine for recovering drugs from the packaging board of aluminum plastic foam cover with defects. It is composed of 304-grade stainless steel shell, micro motor, primary reducer, roller combination, guide plate combination particle rubber plate sequential connection, equipped with an electrical brake switch and lock switch.

Good in appearance& simple and generous

Easy to clean&humanized in design

Easy to use and safe

PY-120A Type Aluminum-plastic Medicine Deblistering Machine

Allpack PY-120A deblister machine has high precision and good effect. The capsules and tablets are extracted completely from the aluminum board, and the capsules and tablets will not be squeezed out.With reasonable design, and pay attention to details, the whole design process is based on the need of the actual users. It is safe to operate, easy to move, different in sizes, easy to adjust the arrangement of the medicine board, and there is no need to replace the mold. It is able to be meet the actual needs of the workshop to the largest extent.

Small in size and flexible

Convenient and practical

High precision and good effect

PY-130 High Speed Drug Deblistering Machine

Allpack PY-130 deblister machine is an automatic tablet picking (stripping) machine for recovering drugs from the packaging board of aluminum plastic foam cover with defects. It is composed of 304 grade stainless steel shell, micro motor, primary reducer, roller combination, guide plate combination particle rubber plate sequential connection, equipped with electrical brake switch and lock switch. The micro motor and the primary reducer drive a set of rollers simulating the action of manual stripping tablets to peel off the aluminum plastic bubble cover plate of the whole plate from the defective packaging plate.

Good in appearance, simple and generous

High precision and good effect

Lower cost in power

PY-160 doubel channel Deblistering Machine

Allpack PY-160 double channel deblister machine is applied for eliminating and recycling capsules or tablets from blisters. It helps to reduce labor and improve working efficiency, make the whole recycling process more standard, and and simplified, greatly improve production efficiency. The machine is made of stainless steel. It has high efficiency and reliable operation, and the speed is adjustable, infinite speed.

Unique retractable automatic cutting device

Well separation of waste capsules

Easy operation

PY-80 Type Aluminum-plastic Medicine Deblistering Machine

Allpack PY-80 deblister machine can help you solve your company waste aluminum-plastic plate recovery problem, reduce the large labor force to improve work efficiency, so that the entire recovery process more standardized, simple, greatly improve the production efficiency.It is easy to operate, maintain and repair, lower cost in power ,lighter in weight ,smaller in size and weaker in noise .It is the best substitute for squeezing out the tablets and pills from aluminum covered plastic films by hand. It is suitable to all kinds of aluminum covered plastic film wrapping machines.

Easy to adjust the arrangement of the medicine board

No need to replace the mold

High performance

The Buyer's Guide

Deblistering Machine: The Complete Buying Guide In 2025

When it comes to the pharmaceutical industry, one of the major concerns is ensuring that medication gets to patients quickly and safely. To optimize efficiency in packaging and delivery, many companies now use a blistering machine to remove tablets from blister packs with surgical precision precisely.

The innovative design of these machines allows for precise loading at high speeds, meaning pharmacies receive medications faster than ever before, providing an efficient way for healthcare professionals to get medication into the hands of those who need it most.

This blog post will explore how these unique machines work, their advantages over manual methods, and what industries can benefit from them. Let’s get started!

1. What Is A Deblistering Machine?

A deblistering machine is a specialized piece of equipment used to separate solid dosage forms from their packaging. It works by cutting, separating, and collecting tablets, capsules, or other solid objects from the blister packs they are stored in.

Deblistering machines are commonly used in pharmaceutical production lines to speed up repackaging and reduce manual labor. These machines come in various sizes and can be used in semi-automatic and fully-automated production environments. They can also process many blister packs, including cards, strips, and trays.

Deblistering process is important in ensuring that drugs are safely repackaged, and the correct dosage is maintained. deblistering machines are designed to provide a quick, efficient and safe process for separating tablets from their packaging.

2.What Are The Components Of A Deblistering Machine?

Deblistering Station

This is the main component of a deblistering machine and is responsible for removing blisters from their packaging. The deblistering station cuts the plastic or foil card and extracts the product intact, ready for further processing or dispatch.

Feeding System

This component of the deblistering machine is responsible for feeding the blister packs into the deblistering Station. The Feeding system can be manually operated, semi-automated, or automated, depending on the size and complexity of the deblistering machine.

Blister Pack Sorter

This component is used to sort the blister packs based on size and shape. The Sorter helps deblistering machine to identify the product from its packaging and can also be used for quality control of the deblistering process.

Product Separating System

This component is important to the deblistering machine as it separates products after deblistering. The Separating System can be manually operated or automated and helps deblistering machine to separate the products from their packaging.

Product Tray

This component collects the deblistered products and can hold hundreds of deblistered packages. It is also possible to use multiple trays in deblistering machine to increase its capacity of the deblistering machine.

Rejection System

The Rejection system helps deblistering machine to identify any faulty packages which are not suitable for further processing. This component is essential for quality control and assurance of the deblistering process as it can help the deblistering machine identify faulty packages.

Control System

This component controls the deblistering process and can be either manually operated or automated, depending on the deblistering machine type. The Control system helps deblistering machine carry out its functions effectively and efficiently.

3.What Are The Advantages Of Using A Deblistering Machine?

Deblistering machines offer a variety of advantages. They include;

Increased Efficiency

Deblistering machines are designed to quickly and efficiently process many pills in a short period, making them ideal for high-volume production lines.

Improved Quality

Deblistering machines ensure consistent quality and accuracy with each batch, helping to reduce waste and optimize efficiency.

Reduced Labor & Cost

Deblistering machines offer fast, automated deblistering processes, eliminating the need for manual labor and reducing production costs.

Enhanced Safety

Deblistering machines help minimize contact with medications, ensuring that operators remain safe from potentially hazardous materials when handling pills. This also helps to minimize the risk of contamination.

Versatile

Deblistering machines are highly versatile and can be used to process a variety of different pill types, from tablets and capsules to soft gels and multi-particulate products. This makes them ideal for use in many different production lines. Also, these machines can also be easily adjusted to accommodate specific packaging requirements.

4.What Are The Applications Of A Deblistering Machine?

Deblistering machines are increasingly becoming popular in many industries. They include:

Pharmaceutical Industries

Deblistering machines can be used in pharmaceutical industries to open the blister packs and separate tablets, capsules, or soft gels from their packaging. This process helps improve safety and efficiency in drug production systems.

Medical Industries

Deblistering machines are also used in medical establishments such as hospitals, clinics, and pharmacies to remove tablets or capsules from their packaging. This process helps improve safety and accuracy when preparing medication doses for patients.

5.How Does A Deblistering Machine Work?

Deblistering machines use high-speed rotary cutters that cut through the plastic blister package, separating and sorting the individual doses. It typically consists of two main parts: an unwinder, which unrolls the blister card and feeds it into the Machine, and a cutting unit, where the tablets are cut out of the blister pack.

Also, the deblistering machine uses several different tools, such as blades or punches, to cut through the foil and paper layers of the blister pack. The tablets then drop down into a collection tray or bag below while the waste material is discharged separately. Deblistering machines offer an efficient way to quickly separate medication from its packaging to repackage them for different applications.

Additionally, deblistering machines can break down large quantities of tablets for counting or sorting and repackage them into smaller containers. These devices are commonly found in pharmaceutical and healthcare industries, where the accuracy and safety of the medication are paramount.

6.What Are The Different Types Of Deblistering Machines?

There are different types of deblistering machines on the market. They include:

a)Manual deblistering machines

Manual deblistering machines are typically used for small batch sizes or when high accuracy is required. These deblistering machines tend to be slow but reliable operations; however, they require skilled operators who understand how to effectively deblister products.

b) Fully automatic deblistering machines

Automated deblistering machines are much faster and can handle larger production volumes with fewer errors than manual Deblistering. Also, these machines are much more efficient in terms of labor and cost savings, as they can complete more batches in less time.

c)Semi-automatic deblistering machine

Semi-automatic deblister machines are normally used for low to medium scale production. These types of machines are smaller and lighter than full-automatic machines. They require operators to manually feed the blisters into the Machine and monitor the process during operation.

d)Rotary deblistering machine

Rotary deblistering machines are designed to process large volumes of blisters at high speed. This deblistering machine typically has multiple stations where the blister cards or trays are automatically separated from the backing material and inspected for defects.

e) Robotic deblistering machine

Robotic deblistering machines are automated systems that use robotic arms and grippers to deblister products from their backing materials efficiently and reliably.

This type of deblistering machine can be tailored to fit different production lines, thus providing an automated solution for deblistering products with minimal operator intervention.

7.What Is The Difference Between Manual And Automatic Deblistering Machines?

Manual deblistering machine

Automatic deblistering machine

Manual deblistering machines use a cutting blade to mechanically cut the blister pack open and extract the individual pills or tablets from the packaging. This process is relatively quick but requires significant manual labor as each pill must be placed into a tray by hand. Manual deblistering machines can also be prone to mistakes if operators fail to correctly identify each pill type before placing them in their respective trays.

On the other hand, automatic deblistering machines work similarly to manual deblistering machines in that they use a cutting blade to separate pills from their packaging. However, these machines are automated and use high-tech sensors and cameras to detect the type of pill or tablet before it is placed into a tray. This reduces the possibility of mistakes while significantly speeding up the deblistering process.

Automatic deblistering machines can also be programmed to handle different blister packs, making them much more versatile than manual deblistering machines.

8.What Type Of Products Can Be Removed From Their Blister Packs Using A Deblistering Machine?

The deblistering machine can deblister a wide range of products such as:

Capsules

Capsules packaged in blister packs can be deblistered using a deblistering machine. The deblistering process separates the capsules from their packaging, allowing for easier and more efficient handling of the medications.

Tablets

Tablets come in blister packs and can be deblistered with a deblistering machine. The deblistering process separates the tablets from their packaging, allowing easier and more efficient handling of these medications.

9.What Type Of Blister Packs Can Be Processed Using A Deblistering Machine?

Deblistering machines can process different types of blister pack materials, such as:

Plastic Paper

Plastic paper blister packs are the most commonly deblistered packages. These packs have a combination of plastic and paper materials that can be deblistered quickly and efficiently. Also, most machines on the market apply this type of packaging.

Plastic plastic

Plastic blister packs are deliverable but require specialized deblistering machines. These packages typically have two layers of plastics that need to be separated before deblistering can occur.

Aluminum plastic

These packages typically have two layers of plastics and one layer of aluminum that need to be separated before deblistering can occur. Just like plastic paper, aluminum plastic packaging can heat the PVC sheet for placing product but is sealed with aluminum foil instead of paper.

Aluminum-Aluminum

Manufacturers do not commonly use this blister packaging because its cost is much higher than other materials. However, due to its opaque nature, it is very suitable for packaging medications that are light sensitive, thus protecting them from light.

10.How Can You Increase Efficiency And Productivity By Using A Deblistering Machine?

By utilizing deblistering machines, your company can benefit from increased efficiency, productivity, and accuracy in blister removal. The deblistering process is done with minimal human intervention, ensuring consistent quality output and a low risk of product damage during the deblistering process.

Furthermore, deblistering machines allow for increased flexibility in processing various sizes of blisters. deblistering machines can also be linked to other automated systems, further improving the levels of automation and efficiency in your production process.

11.What Safety Measures Should Be Taken While Using A Deblistering Machine.

Certain safety measures must be taken when using a deblistering machine to ensure the safety of the user and those around them.

- Always wear safety goggles and protective clothing when operating a deblistering machine.

- Always ensure that all moving parts on the deblistering machine are properly lubricated and operating correctly.

- Operators should inspect the Machine before use to ensure that all bolts, nuts, and screws are tightened securely. This will help reduce the risk of accidents caused by loose parts.

- Ensure that all deblistering machines are operated by trained and certified personnel who know how to use them safely and efficiently.

- 5.Put in place procedures to ensure deblistering machines are regularly cleaned and maintained, including cleaning the deblistering area after each use.

- Perform a risk assessment for each deblistering operation before starting work to identify any potential hazards or risks that may arise during the operation of the Machine.

- Regularly check deblistering machines for any signs of wear or damage before starting work to ensure they are in proper working order with all safety guards securely attached.

- Ensure deblistering machine components and parts stay locked into place while operating the Machine to reduce the risk of injury caused by loose or falling components.

- Make sure that deblistering machines are kept away from areas with an increased risk of dust or debris buildup, such as near storage devices and other machinery.

- Provide additional training and supervision to deblistering machine operators if they are unfamiliar with the deblistering process.

- Make sure deblistering machines are always unplugged when not in use to reduce potential risks of electric shocks and other hazards.

12.What Problems Are Associated With Using A Deblistering Machine And Their Possible Solution?

While deblistering machines can be efficient and cost-effective, some risks are still associated with using them. Below are some:

Cross Contamination of Drugs

This problem can result from the presence of dust particles in the machine. Debris from other pills or capsules can mix with those being processed, leading to incorrect dosages for patients if not managed properly.

Solution

To prevent this contamination, it is important to ensure that all parts of a deblistering machine are kept clean and free from dust and debris.

Damage to Medication

Deblistering machines can cause tablets to break or capsules to be crushed, which can lead to a decrease in the efficacy of the medication.

Solution

Operators of these machines should follow safety protocols and adjust the settings accordingly for each type of pill or capsule being blistered.

Jamming

Debris or dust buildup on moving parts can cause the machine to malfunction, resulting in costly downtime and possible production delays.

Solution

Regular maintenance should be done on all parts of a deblistering machine to ensure it functions correctly and efficiently.

Noise Pollution

Deblistering machines may produce noise levels that can be disruptive and annoying

Solution

Use deblistering machines with sound dampening features or locate them in rooms specifically designed for deblistering processes, to keep the noise at minimum levels.

13.What Are The Maintenance Procedures Of A Deblistering Machine?

Specific maintenance procedures must be followed to ensure that deblistering machines run smoothly and safely. These include:

Checking for Any Wear or Damage

Inspecting deblistering machines for any wear or damage should also be part of the maintenance procedures.

This involves examining parts such as rollers, blades, and belts for signs of rust or corrosion. If any signs of wear or damage are noticed, they should be addressed immediately to prevent further damage.

Cleaning and Replacing Parts

Cleaning the deblistering machine is essential for keeping it running properly. This includes both exterior and interior components of the deblistering machine. Exterior components such as rollers must be wiped down with a soft cloth or brush to remove any dirt or dust buildup.

The interior components must also be cleaned using specialized cleaning solutions specifically designed for deblistering machines. Special care should be taken to avoid damaging these sensitive components.

Adjusting Settings According to The Manufacturer’s Instructions

Adjusting deblistering machines is important to ensure they operate at optimal levels. This includes ensuring the blade settings are adjusted correctly; these settings can vary depending on the model and manufacturer of the deblistering machine being used.

Additionally, it is important to periodically check all other deblistering machine settings according to the instructions given by the manufacturer.

Lubricate All Moving Parts

Regular lubrication of all moving parts helps prevent corrosion and ensures that the deblistering machine runs smoothly. It’s important to check the manual for recommendations on which type of lubricant should be used with your deblistering machine model.

Check and Adjust Deblistering Speed

A deblistering machine should be checked regularly to ensure it runs at its recommended speed. Adjust the deblistering speed accordingly to ensure maximum efficiency and accuracy.

Perform Regular Maintenance Checks

It’s important to perform regular maintenance checks on your deblistering machine to keep it running at peak performance levels. This may involve checking all components of the deblistering machine, testing the deblistering speed, and adjusting any necessary settings.

14.What Factors Should Be Considered Before Purchasing A Deblistering Machine?

Cost-Effectiveness

Deblistering machines are expensive, so it is essential to factor in the total cost of ownership before making a purchase decision. Compare prices from different suppliers to make sure you get value for money.

Reputation of Manufacturer

The manufacturer’s or supplier’s reputation is important when buying a deblistering machine. Look for companies with a good track record in customer service and product quality.

Reliability

Deblistering machines must be reliable to ensure a consistently high level of productivity. Consider the quality and reputation of suppliers and any customer reviews or testimonials you can find.

Versatility

If you plan on using your deblistering machine for multiple applications, make sure it is suitable for all of them before you purchase it. Look for machines that are versatile and flexible enough to handle various tasks with ease.

Maintenance Requirements

Deblistering machines require regular maintenance to operate optimally and last longer. Consider the costs associated with such maintenance requirements when deciding which machine to buy.

Deblistering Machine Specifications

Before purchasing a deblistering machine, it is important to consider the specific specifications of the machine, such as its size and capacity. This will help ensure that the machine can meet your needs.

Warranty

Deblistering machines are a long-term investment, so it is important to consider the warranty offered by suppliers. Ensure the Machine is covered for any parts and labor required in case of damage or malfunction.

Post-Purchase Support

Manufacturers offer post-purchase support services such as installation, training, and technical assistance. Make sure these services are available before you make your purchase decision.

Delivery Time

Deblistering machines are typically made to order, so it is important to factor in delivery time when considering potential suppliers. Try to find out how long the manufacturer will take to deliver your order before committing to a purchase.

CONCLUSION

A deblistering machine is an important tool in various industries, improving efficiency and effectiveness in many operations. Deblistering machines open blister packs and separate their contents for various purposes – recycling, inspection, repackaging, and more. If you are in the market looking for a reliable and efficient way to remove the adhesive from blister packs, Allpack company is your best solution.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586