Foil Sealing Machine: The Complete Buying Guide In 2025

Foil Sealing Machine: The Complete Buying Guide In 2025

In the world of modern products packaging, foil sealing machines are indispensable solutions for multiple industries. They allow companies to package and protect their products from extraneous dirt and moisture as well as aid in product preservation.

At its core, this machine is employed to hermetically seal containers by forming an airtight bond between the lid material and container neck enabling certain breathability while maintaining ideal levels of humidity that preserve your product’s longevity.

In this blog post we’ll dive into the various types of foil sealing machines available, how they function and why they’re so beneficial to businesses across multiple industries worldwide. Let’s get started!

1.What Is A Foil Sealing Machine?

A foil sealing machine is a device used to hermetically seal containers with foil lids. It applies foil seals or lidding on the top of a container, forming an air-tight barrier to extend the shelf life and protect the contents. These machines are commonly used in industries such as food, pharmaceuticals, chemicals, and cosmetics.

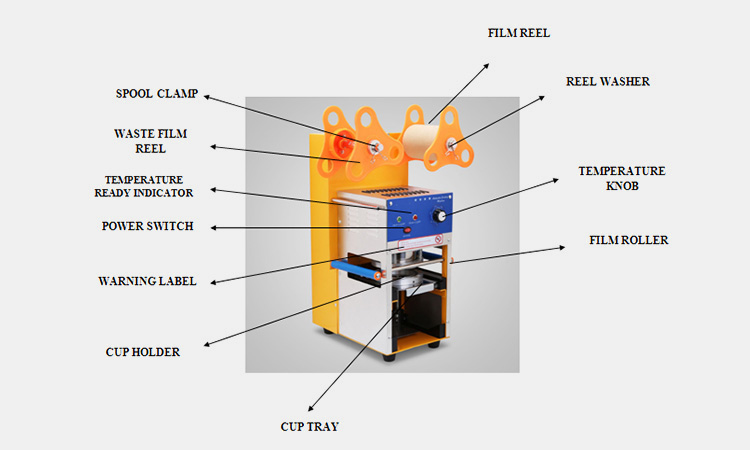

2.What Are The Components Of A Foil Sealing Machine

A foil sealing machine typically consists of five key components: the foil feeder, foil sealer, foil cutter, foil seal applicator head and conveyor.

The Foil Feeder.

It is used to supply a continuous strip of foil to the foil sealer. The foil sealer ensures that each length of foil has precise dimensions and is cut to size, ready for foil sealing.

The Foil Seal Applicator Head.

This head is responsible for applying the foil seal onto the product or packaging and is designed to achieve a secure and consistent foil seal each time.

The Foil Cutter.

This component separates each foil sealed package from the foil strip.

The Conveyor.

This element moves packages along its length for foil sealing, with additional conveyors available to remove foil sealed packages as required.

3.What Are The Applications Of A Foil Sealing Machine?

Medicine And Pharmaceutical Production.

They are used to seal medicine and pharmaceutical products, such as tablets, capsules, syrups, injectables, liquids etc., in foil bags or plastic containers. This ensures that the contents remain sterile and safe for consumption.

Cosmetic Packaging.

These devices are also used to seal cosmetics such as creams, lotions and other beauty products. This ensures that the product remains safe and free from contamination while in transit or on display.

Food Packaging.

In the food industry they are used to package food items like chips, candies, snacks etc., This not only helps keep the food items fresh but also prevents moisture, air and other contaminants from entering the product.

Chemical Packaging.

Chemicals such as paints, adhesives and many more can also be packaged by this essential tool. This helps to prevent leakage of hazardous materials during transport or storage.

4.What Are The Working Principles Of A Foil Sealing Machine?

A foil sealing machine works by using heat to create an air-tight seal between a foil lid and the container it is placed on. The foil lid is attached to the container and heated with either a heating element or induction coil.

Once heated, the foil will form an airtight bond with the container or the packaging material being sealed, providing a secure seal that can be used to protect contents from contamination and other environmental factors. Therefore, the foil creates a barrier between the container and its contents helping to keep the product fresh or secure for long.

5.What Are The Different Types Of Foil Sealing Machines?

There are a variety of foil sealing machines available for different purposes.

In Form Of Automation:

Manual Foil Sealing Machines.

These are the simplest form of foil sealing machines and require manual operation. This requires users to manually place foil over a container, press down onto the foil using a handle lever, and then pull the foil away. This process is repeated multiple times with each container in order to achieve an airtight seal.

Semi-Automatic Foil Sealing Machines.

They use a combination of manual and automated processes. With this type, users still need to manually place foil over a container but the foil is then automatically pressed down and pulled away. This makes it easier to achieve an airtight seal as there is less human error compared to manual foil sealing machines.

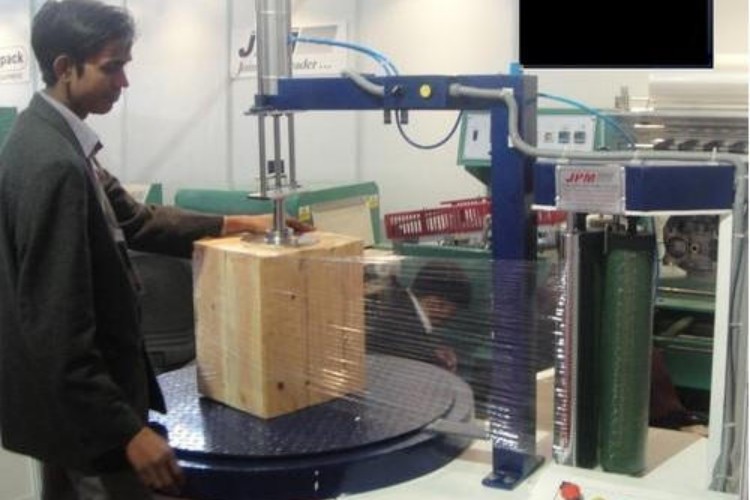

Automatic Foil Sealing Machines.

These machines are the most efficient type of foil sealing machines and require minimal user input. This type is typically used in high-volume production lines and uses a conveyor belt system to feed foil over each container. The foil is then automatically pressed down and pulled away, creating an airtight seal with every cycle. Compared to manual or semi-automatic foil sealing machines, automatic foil sealing machines are faster and require less labor.

This equipment are an essential tool for companies that need to package their products in airtight foil seals. Depending on the needs of your business, you can choose the type that best suits your production line requirements.

In Form Of Packaging Process:

Induction Foil Sealing Machines.

Induction foil sealing machines use electromagnetic induction to heat and seal foil material onto the tops of containers. This process begins with an induction foil sealer, which uses a high frequency alternating current passing through a coil that is wrapped around the container’s opening.

The resulting magnetic field produced by this coil causes an electric current to flow in the foil material. This current passing through the foil material creates resistance, which produces heat and seals the foil to the container’s neck. The foil sealer then cools down quickly after the foil is sealed onto the container’s neck. This process is efficient, reliable, and ensures a secure seal for products being packaged

Heat Induction Foil Sealing Machines.

These types of devices are used to seal foil packaging with a secure and tight seal. The foil sealing machine uses induction heat that is generated from a coil surrounding the foil area, which creates an electromagnetic field. This causes eddy currents in the foil which in turn generates heat.

This heat then melts or softens the foil which forms a bond with the container material, creating an airtight and leak-proof seal. The foil sealing machine is designed to apply uniform heat throughout the area of foil being sealed and ensures that each foil package has a reliable seal.

The foil sealing machine creates reliable seals that are up to industry standards, allowing you to trust in the quality of your foil packaging

6.What Are The Different Material Types That Best Work With A Foil Sealing Machine?

A foil sealing machine is an easy-to-use tool that can be used to seal materials of various types. The most common materials sealed with foil sealing machines are:

- PET (polyethylene terephthalate)

- HDPE (high-density polyethylene)

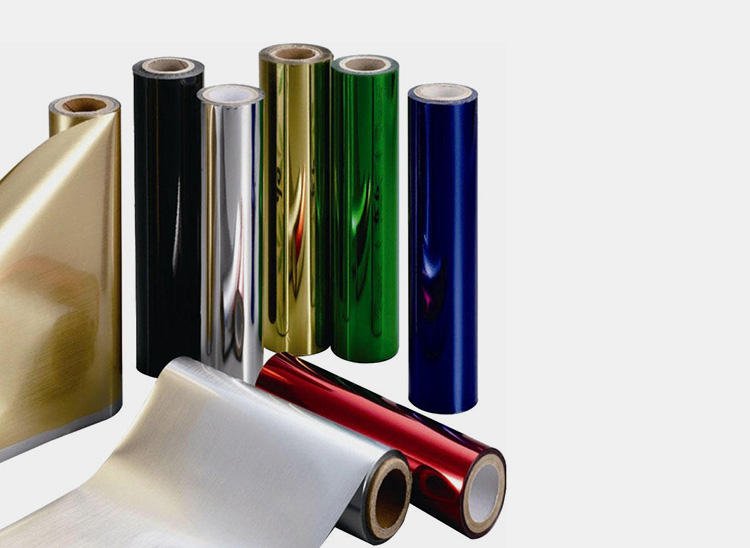

- Metal foil

PET

Is one of the most widely used plastic materials and is known for its durability, clarity and strength. This type of foil sealing is ideal for food-grade packaging and can provide a secure seal that prevents leakage or contamination from occurring.

HDPE

This type of foil is a durable, lightweight plastic material used in many applications including packaging, bags, containers and bottles. Foil sealing with HDPE is often used in the medical and pharmaceutical industries, as it provides a superior seal that won’t easily be breached.

Metal foil

These foils are highly resistant to punctures and tears, making foil sealing with metal foil an ideal choice for packaging products that require extra protection. This type of foil sealing is also great for product branding, as metallic foil can provide an eye-catching foil finish that’s sure to stand out on shelves.

PVC Foil

Also, this foil is another popular foil choice for foil sealing machines as it offers excellent flexibility and is resistant to many chemicals. It can also create an airtight seal, making it suitable for products that need to be kept fresh or free from contamination.

These machines are versatile and can be used with a variety of foil materials depending on the product that needs to be sealed. With the right foil material choice, businesses can ensure that their products remain protected during storage and transport.

7.What Type Of Packages That Can Be Sealed By A Foil Sealing Machine?

A foil sealing machine is a versatile tool that can seal a wide variety of packages. Some of the most common items that can be sealed by foil include:

Bottles

These machines can quickly and efficiently seal bottles with foil or plastic materials, creating an air-tight and water-resistant bond.

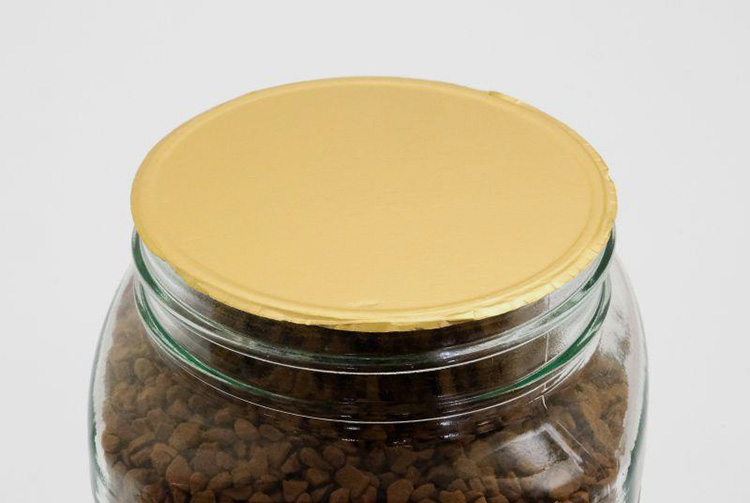

Jars

They can also be used to seal jars with foil, creating a secure seal that maintains its freshness for an extended period of time.

Pouches

They are also often used in the food and beverage industry to quickly and efficiently seal foil pouches filled with dry ingredients or liquids.

Cartons

Foil sealing machines can seal cardboard cartons and boxes, providing an extra layer of protection to the contents inside.

Bags

They are also used to quickly create a reliable and secure foil seal on paper bags, plastic bags, and other materials.

Trays

These machines are ideal for sealing foil trays that contain food products, helping to maintain the freshness of the contents inside.

Cups

They are also used to quickly create foil seals on cups and other containers, providing an effective barrier against moisture and other contaminants.

Lids

They are the ideal tools to quickly and efficiently seal foil lids on various containers, providing a secure closure that can keep contents fresh for an extended period of time.

8.What Is The Importance Of Sealing Your Products With A Foil Using A Foil Sealing Machine?

Using a foil sealing machine to seal your products with foil has several advantages.

Protection

Foil provides an effective barrier against moisture, oxygen, and other elements that may damage the quality of your product or make it unfit for consumption therefore it ensures that your products reach customers in ideal condition.

Aesthetics

Appearance of your product is always very crucial, giving it a professional and attractive look will make your products more appealing on the shelves and attract customers’ attention.

Security

Tamper-evident foil seals are a great way to secure your products in transit. Foil seals will always help you ensure that no one opened the package before it reached its destination and that the product is still safe and intact.

Retaining Fragrance

Foil sealing helps to retain the fragrance of products. This is particularly important in food and beverage packaging, where foil seals can help to maintain the freshness and aroma of your product for longer.

Increasing The Shelf Life

Your products are kept in good condition for a longer period of time thus helping you avoid wastage and ensuring that your products are always fresh and ready for customers.

Increasing Productivity

They quickly create a strong seal that is more durable than other methods of sealing, reducing downtime in many packaging operations. With foil sealed packages, the need for manual labor is reduced and productivity is increased.

Cost Savings

They are a cost-effective way to package products in that foil is inexpensive compared to other packaging materials. They also require minimal maintenance and can be used for long periods of time without needing to be replaced and also foil seals reduce the amount of foil needed to package each item, helping to further reduce costs.

Eco-Friendly

The foil they use is 100% recyclable and can be reused many times. This helps to with the reduction of waste, making foil sealing a more sustainable option when compared to other packaging methods.

9.How Can You Increase Efficiency Of A Foil Sealing Machine?

These are a few steps you can pick to increase the efficiency of a foil sealing machine:

Firstly, you should make sure that your machine is well maintained and running at optimal performance. Regularly check that all components are functioning properly, such as the foil feed mechanism and the roller or stamping head. You should also ensure that you are using the right foil material for your application—not too stiff and not too soft.

Secondly, adjust the machine’s settings to ensure maximum efficiency. Determine the ideal foil seal temperature that works best for your product and adjust accordingly. You should also make sure that there is a consistent seal pressure throughout each cycle and that you are getting an even foil seal.

Thirdly, keep your machine clean and free of debris. Make sure to check that any foil scraps or residue is removed regularly in order to avoid clogging up the feed system and causing unexpected downtime.

Ensure also that you are using the correct foil roll size for your application. A foil roll that is too small can cause foil waste and a foil roll that is too large can lead to excess foil being used.

10.What Maintenance Requirements Are There For A Foil Sealing Machine?

The foil sealing machine is a versatile and efficient tool for food, medical and other packaging needs. However, to ensure the long-term durability of the device, it is important to perform regular maintenance tasks on it.

Do regular checking of the signs of wear and tear is one of the most important maintenance requirements. This includes inspection of the foil sealing rollers, motor, electrical connections, and other components for any signs of damage or wear. Check also for any loose bolts that could affect the performance of the machine.

You can as well clean foil sealing machines each and every time. This ensures that dirt and debris do not accumulate in the foil sealing rollers or other parts of machine and interfere with its performance.

This machine’s lubrication also needs to be consistent, check to ensure that all components are moving smoothly and efficiently and also filling the oil reservoir. It is also important to lubricate the foil sealing rollers to ensure a smooth finish for each job.

Finally, it is important to verify whether settings are correct and up-to-date. This includes checking the foil heating temperature, foil delivery speed, motor voltage, current draw, and other settings.

By performing these basic maintenance requirements regularly, you can help ensure that your foil sealing machine is able to provide reliable and efficient results for years come.

11.What Kind Of Considerations Do You Take When Purchasing A Foil Sealing Machine?

When purchasing a foil sealing machine, there are several factors to take into account.

Size of foil roll.

you should consider the size of foil rolls that you need to use with the foil sealer. Some machines may be limited in this regard and unable to accommodate large foil rolls which can limit your production capacity.

Features.

Secondly, look for foil sealing machines that have features that can help you streamline your production process. For example, some foil sealers have an automatic foil cutting and loading system which reduces the time it takes to get your foil sealed containers ready for sale.

Speed.

Consider the sealing speed of the foil sealing machine as this will determine how quickly you can wrap products for shipment or storage.

Durability.

Make sure that the foil sealing machine is made from durable materials and has a warranty in case something goes wrong.

Buying a foil sealing machine with these considerations can help ensure that it’s an effective addition to your production line thus investing in the right foil sealing machine can help improve the efficiency of your production process and make sure that you are providing a quality product for your customers.

Conclusion

The ultimate goal of a foil sealing machine is to help you better protect and preserve your products, so it’s important to find one that fits your needs. With its versatility, expertise, and ability to keep up with the changing market trends, Allpack is your premier supplier for all your needs in foil sealing machines. From stand-alone solutions to fully automated systems, they offer tailored solutions based on the scale of your production and desired end results. Allpack is committed to providing customers with high-end equipment and seamless services that surpass their expectations. Put your trust in them when it comes to purchasing a quality machine at an affordable price.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Foil Sealing Machine: The Complete Buying Guide In 2025 Read More »