Cooking Oil Bottling Line: The Complete Buying Guide In 2025

Are you tired of using semi-automatic machines for bottling cooking oil? Or do you want to increase the efficiency and accuracy of your cooking oil packaging? In any case, you need to reduce your manual intervention and look towards automating the process which is only possible with a Cooking Oil Bottling Line.

Dealing with large volume of cooking oil, which is a routine necessity of every home, it is significant to take care of the hygiene, product quality, as well as take measures to meet the production targets. In such a case, Cooking Oil Bottling Line offers convenience, safety, and resilience to deal with free flowing sticky cooking oil. To explore more about it, take start and give this review a thorough read!

1.Define Cooking Oil Bottling Line?

Cooking Oil Bottling Line- Picture Courtesy: VKPAK

The production of cooking oil at any level is so giant that its packaging cannot be carried out manually or else it will lead to inconsistencies. That's why, to deal with the bottling of various cooking oil such as sunflower oil, olive oil, and peanut oil, a full fledged production line is employed which is known as cooking oil bottling line.

This line is a complete bottling solution that consists of a bottle unscrambler, liquid filling machine, bottle capping machine, inkjet printer and labeling machine. It is fully automatic in technology and has a robust structure to deal with all kinds of containers and liquids beyond cooking oil. Moreover, it provides safe environment for the processing of cooking oil while retaining their quality and enhancing productivity.

2.Enlist The Advantages Of A Cooking Oil Bottling Line?

Cooking oil bottling line is best known for its advantages which can be attained by its use. So, let's explore the features of a cooking oil bottling line and the associated benefits!

Independent Operation

Independent operation of cooking oil bottling line- Picture Courtesy: GFT Group

The most paramount aspect which every manufacturer looks for is the least dependency of machine on operator as it is useful for enhancing precision and reducing labor. So, a cooking oil bottling line offers independent operation with each step being administered by the bottling line itself.

Maintain Consistency

Consistently finished cooking oil bottles- Picture Courtesy: Freepik

By taking guidance from the settled parameters, and sensors which are located at every entry and exit of machine, cooking oil bottling line make sure to maintain consistency in all the steps. Hence, each finished cooking oil bottle will have same amount of material as well as label and printing.

Enhance Productivity

Cooking oil bottling line is fully automatic in its performance due to which the time spent due to manual intervention is skipped. Similarly, its system to detect presence of bottle and allow cooking oil filling to reduce the waste of material. Resultantly, it increases the productivity ratio to greater extent.

Versatility

Cooking oil in different types of containers- Picture Courtesy: kahaninternational.com

Another advantage of having a cooking oil bottling line is that you can utilize it for containers with irregular shapes and different sizes. In addition to it, this solution is applicable to liquids other than cooking oil such as sauces, drinks, and syrups etc.

Robust Construction

Robust construction of cooking oil bottling line- Picture Courtesy: edibleoilfillingmachine.com

The structure of cooking oil bottling line is compact and precise with different machines being connected together. Each machine is built with 304 stainless steel body to resist bacterial growth, corrosion, and other environmental effects. Moreover, it has safety system as well in form of alarm indicator and emergency stop to avoid damage of the product and machines.

3.What Type Of Containers Are Supported By A Cooking Oil Bottling Line?

A cooking oil bottling line is able to deal with containers of different specifications and for that, it only needs a little structural adjustment and nothing more. So, let's know the types of containers which it can support in a bit detail!

Bottles

Bottle is the most common and widely used container for almost every kind of material especially liquids like cooking oil. It is characterized by its narrow neck and a cap over it for convenient opening and closing. A cooking oil bottling line can process underlying mentioned bottles type:

| No | Type | Picture |

| 1 | Plastic Bottles

Plastic bottles are popularly used for delivering low volume of cooking oil as they are flexible and cost-effective compared to other types of bottles. |

Cooking oil plastic bottles |

| 2 | Glass Bottles

Glass bottles are highly hygienic and free from bacteria. Although, they are expensive but good for the preservation of olive oil and other cooking oil. Similarly, you can process them through a cooking oil bottling line. |

Cooking oil glass bottles- Picture Courtesy: cooktopcove.com |

| 3 | Square Shape Bottles

Cooking oil bottling line can easily fill and pack beautiful square shape bottles of different cooking oil. |

Square shape cooking oil bottle- Picture Courtesy: Crate & Barrel |

| 4 | Round Shape Bottles

Round Shape bottles are commonly used for cooking oil bottling. They are easily stackable and therefore, processed by a cooking oil bottling line. |

Round corn oil bottle- Picture Courtesy: elburgglobal.nl |

| 5 | Irregular Shape Bottles

Most of the cooking oil manufacturers new in the field try to grasp consumer attention and thereby using charming and unique design irregular shape bottles for cooking oil. In this way, no need to worry about their processing as this bottling line is fit for them. |

Irregular shape cooking oil bottle |

Jerrycans

Cooking oil jerrycan- Picture Courtesy: Wary International PTE LTD

Another type of container processed by a cooking oil bottling line is jerrycan. Jerrycans are medium size containers made from rigid plastic. They have a handle for easy carrying and therefore hold the capacity of storing up to 5 liter of cooking oil.

Buckets

Cooking oil bucket- Picture Courtesy: Kalahari Deals Namibia

Small buckets with an attached handle are also suitable for cooking oil storing. As the structure of cooking oil bottling line is adjustable, so, you can undergo these buckets through it.

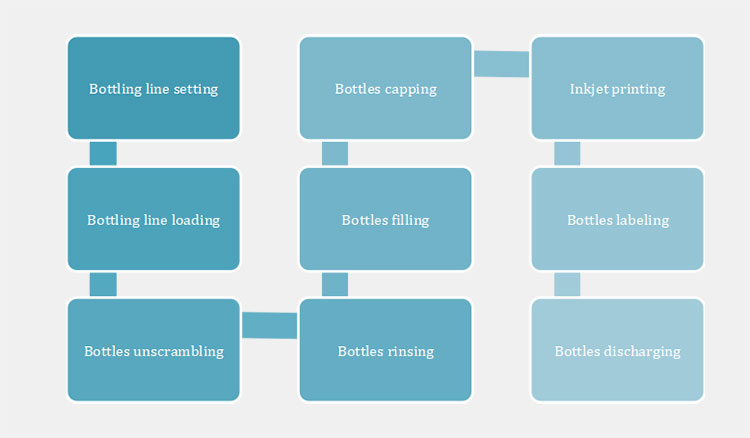

4.Explain The Working Process Of A Cooking Oil Bottling Line?

The working process of a cooking oil bottling line is straight forward by following predetermined steps. Every machine of the line is responsible to perform its task and ultimately their timely response leads to the completion of cooking oil bottling. These steps are explained below:

Bottling Line Setting

Before starting operation, it is necessary to set the machine. For this, you need to adjust its structure in accordance with bottles size and shape. In addition to it, set the parameters of the bottling line's different units via control panel such as the volume of cooking oil to be filled in each container, the capping pressure, printing data, and labeling etc.

Bottling Line Loading

Bottles caps loading- Picture Courtesy: GFT Group

After setting the cooking oil bottling line, the next step is to supply it with essential materials. This process include feeding bulk volume of cooking oil into the hopper, loading sufficient number of empty bottles or containers in a bottle unscrambler, supplying the tank of capping machine with bottles' caps, and placing the labeling roll in associated machine.

Bottles Unscrambling

Bottles unscrambling- Picture Courtesy: GFT Group

Once the bottling line is set and loaded with material, it is ready to be started. Similarly, upon starting it will begin unscrambling the bottles. During this stage, the randomly positioned bottles in form of stock is aligned into synchronized manner through unscrambling technique and these bottles are supplied to the bottle rinsing unit for washing.

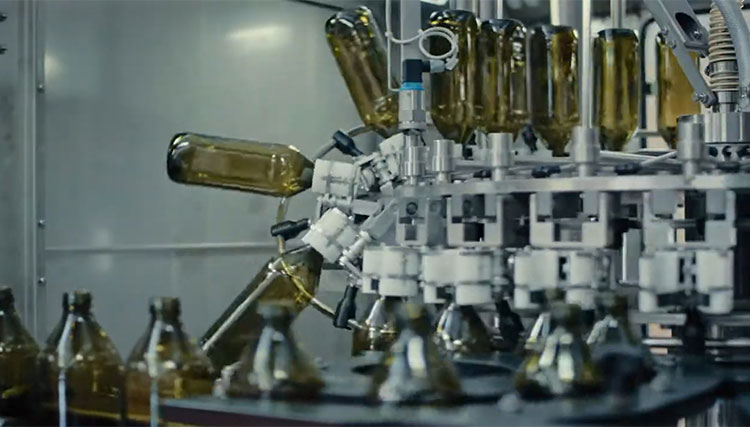

Bottles Rinsing

Bottles rinsing- Picture Courtesy: GFT Group

Now, the unscrambled bottles are conveyed through conveyor. At this point, these empty bottles are accurately rinsed with water one by one. After rinsing, they are moved ahead for filling.

Bottles Filling

Oil filling- Picture Courtesy: GFT Group

Moving forward, these bottles are conveyed for oil filling. As, they reach under the filling nozzles, the conveyor get stopped and the oil filling machine start dispensing the weighed volume of oil into these bottles. When fixed volume of oil is filled into bottles, the filling nozzles are sealed and oil filling get stopped. Hence, these oil filled bottles are ready to be taken for other steps.

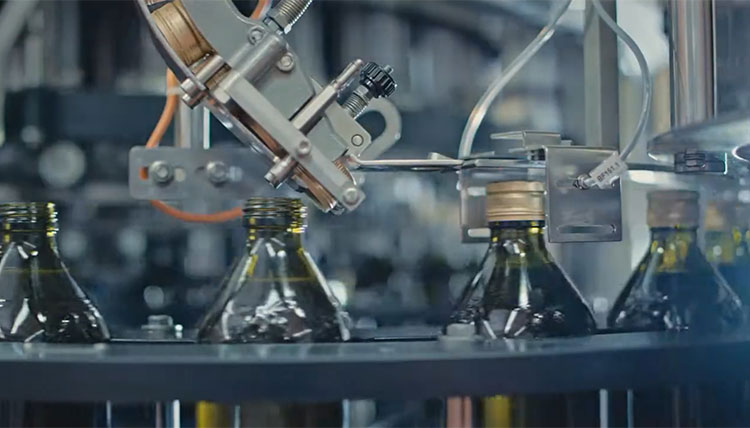

Bottles Capping

Bottles capping- Picture Courtesy: GFT Group

Once bottles are filled with oil, they are mobilized through conveyor towards a capping machine. Here, as the bottles are passing under the cap delivery chute, they pick up cap on their mouth. Similarly, these caps are tightly screwed or crimped around their opening to create strong sealing.

Inkjet Printing

Upon bottles capping, the next step is their inkjet printing. During this phase, capped oil bottles are passed through the inkjet printer which throw data in form of spray towards these bottles. This data gets imprinted over the bottles which include batch no, price information, and expiration date etc.

Bottles Labeling

Bottles labeling- Picture Courtesy: GFT Group

At this point, processed oil bottles are brought for labeling. Now, the labeling type depends upon what type of machine is being used. For instance, if shrink sleeve machine is used in the cooking oil bottling line, so, a sleeve film will be provided around bottles which will be then heated to create shrink labeling. On the other hand, if sticker labeling machine is used, so, an adhesive label will be applied to the labels.

Bottles Discharging

Bottles discharging- GFT Group

At last, all the finished cooking oil bottles will be ejected out of the cooking oil bottling line from its last unit through a conveyor. These bottles may be now further processed for secondary packaging.

5.What Machines Make Up The Structure Of A Cooking Oil Bottling Line?

Cooking oil bottling line is a long body that is made up of several machines. Each of the machine is itself possessing numerous components and is assigned with a particular task. Therefore, in upcoming paragraphs, you will be shown these machines in detail:

Bottle Unscrambler

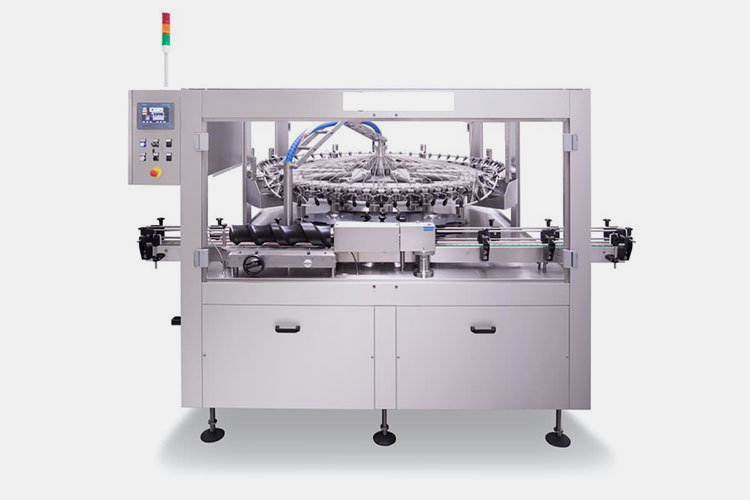

Allpack- APC-A160 Bottle Unscrambler

A bottle unscrambler is a specialized equipment designed to sort and orient the disorganized bottles loaded into it. This machine constitute the first unit of a cooking oil bottling line. It is made up of a rotary plate, conveyor, glass protector, stainless steel body, and control system etc.

It works by processing the scrambled bottles in a rotary disc. Similarly, with the help of sensors and tools, it orients the bottles and supply it to bottling line. The machine is able to process bottles of different sizes and shapes.

Bottle Rinsing Machine

60 Pincer Bottle Rinser- Picture Courtesy: IC Filling Systems

Bottle rinsing machine is another important unit of a cooking oil bottling line. Its function is to clean the bottles from inside by washing. It has a heavy-duty structure which is composed of several parts such as a conveyor, bottles holders, rinsing system, water tank, working area and other essential parts. It simply works by taking the bottles from conveyor and tightly holding them in grippers. Afterwards, these bottles are rinsed with water and moved ahead.

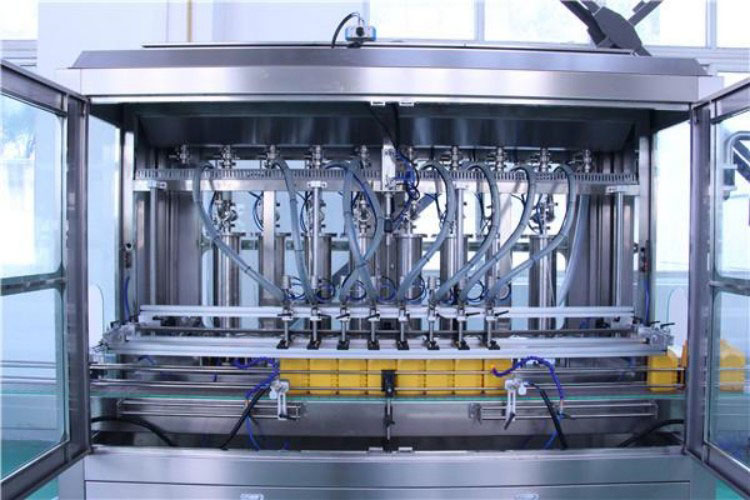

Bottle Filling Machine

FL-101 Automatic Filling Machine- Picture Courtesy: packleader.com

Bottle filling machine is another significant machine which is part of a cooking oil bottling line. It is a liquid filling machine which is responsible to dispense the accurate volume of liquid oil into bottles. The machine has a robust structure with several components including a liquid tank, conveyor, control system, filling heads, and particular filling system. It functions by measuring the desired volume of cooking oil as set up by the operator and then discharge it into the bottles.

Bottle Capping Machine

Allpack- APC-D902 Capping Screwing machine

Cooking oil bottling line has another important machine which is termed as bottle capping machine. This equipment is specialized in supplying caps to the bottles and also apply them tightly over bottles mouth. It has a simple and safe structure which is mainly consisted of a cap elevator, cap infeed chute, chuck, cap pressing part, cap screwing device, and main frame etc.

Inkjet Printer

Allpack- Fastjet A400-60Si standard inkjet printer

Inkjet printer is another crucial part of a cooking oil bottling line. It has precise body and is comprised of few components such as a digital control panel, sensor, printing head and main body. It follows simple operational procedure where the data is set by operator and the machine then store it and apply it to passing bottles in form of spray.

Labeling Machine

Allpack- APC-T2 Multi-function labeler

The labeling machine constitute the last section of a cooking oil bottling line. It is responsible for applying labels to the finished bottles. The machine is made up of a stainless steel body, control cabinet, label roll, fur brush, label cutter, electric eye, and conveyor etc. It starts unwinding label from roll when bottles are fed into it through conveyor. Similarly, these labels are applied to the bottles after which they are discharged from the machine.

6.Write Down The Applications Of A Cooking Oil Bottling Line?

Bottling liquids like cooking oil is one of the difficult tasks if done manually. Same is the case with all other liquids in food and non-food sectors. That's why, every such industry is in need of a cooking oil bottling line. In this question, we have highlighted some of the prominent applications of a cooking oil bottling line:

Cooking Oil Industry

Sunflower oil- Picture Courtesy: stylecraze

Cooking oil industry is constantly engaged in the manufacturing and processing of different types of cooking oil. As the production sphere of this industry is so vast, it requires a cooking oil bottling line which can easily handle all the essential steps of packing cooking oil into bottles.

Beverage Industry

Various juice bottles- Picture Courtesy: designerpeople.com

Another application of a cooking oil bottling line is beverage industry. This sector is also involved in the production of beverages like juices, soft drinks, mineral water, and milkshake etc. Hence, the most suitable and comprehensive option to deal with these liquids is the one and only cooking oil bottling line.

Seasoning Industry

Various liquid seasoning bottles

Most of the seasoning industries have now switched their seasoning delivery mode from powder to liquid. Similarly, sauces and other dressings were already sold in liquid form. That's why, now seasoning industry want a safe and efficient solution to pack these essentials in bottles for which a cooking oil bottling line is perfect choice.

Lubrication Industry

Lubricants jerrycans- Picture Courtesy: F&L Asia

Lubricants keep the world moving! This notion is better explaining the importance of lubrication oil and greases in our daily life such as they are used for locomotion, machines, and other things. Therefore, their production and processing is also very extensive for which only a cooking oil bottling line can be a best option.

Healthcare Industry

Cough syrup packaging

Healthcare industry has a priority for hygiene and safety of their goods. Since, a cooking oil bottling line is made up of food grade materials, it provides a better option for healthcare industry to process their liquid syrups, ointments, and other stuff.

Chemical Industry

Laundry detergent bottle- Picture Courtesy: wbm.com.pk

Last but not least, cooking oil bottling line can also be used in chemical industry where the manufacturing and processing of cleaning agents and chemicals is a routine practice.

7.How To Check The Quality Of A Cooking Oil Bottling Line?

It is significant to check the quality of a cooking oil bottling line as it is going to deal with your edible cooking oil. In this way, you only need to check whether it is adhering the guidelines of certain quality standards or not and that can be checked by looking into the bottling line's certification. So, let's have a look what these certifications are!

Quality standards icon- Picture Courtesy: datixinc.com

ISO:International Organization for Standardization is an international organization that establishes standards which are applicable to the goods and equipment produced worldwide. So, your cooking oil bottling line should be certified by it.

UL:If you are concerned about your bottling line's electric system safety which is very important, then you must look for UL certification as it ensures the safety of equipment against electric

CE:For all the manufacturers who are from European Union countries, CE mark is of prime importance. It stands for Conformate European and represent the safety policies for machines and goods which are meant to be used there.

GMP:Good Manufacturing Practices is another wide range quality standards which deals with the structural safety of cooking oil bottling line.

8.What Are The Cleaning And Maintenance Requirements Of A Cooking Oil Bottling Line?

Sanitizing your machine is the assurance of its safe and hygienic working, while as, keeping it maintained assure its long working life. It simply means, that cleaning and maintenance are two very critical aspects of dealing with your cooking oil bottling line. In this way, we have provided you some valuable guidelines which will definitely help you in this way. So, make sure to understand these all!

Man maintaining the machine- Picture Courtesy: eMaint

Cleaning:You should begin with regular cleaning of your cooking oil bottling line. As this equipment is large enough due to constituting different machines, it is your responsibility to clean each unit separately. However, few steps are common to all of them which are the disassembling of parts like hopper, filling heads, and label applicator etc. Similarly, they should be washed while using recommended detergent and for the rest of parts, it is better to use dry cloth.

Lubrication:This bottling line has many parts which are in constant state of moving like conveyor, belts, and feeding unit. So, you need to keep them lubricated all the time to avoid friction and damaging of parts.

Parts Changeover:While operating your cooking oil bottling line, it is a matter of fact that any part of it may get defected or stop functioning. It simply means that the specific part is out of order and needs to be replaced. Hence, you should change it timely to avoid further parts damage.

Inspection:Regular inspection of each unit of the bottling line is very crucial as it will let you know about the abnormal behavior of machine. Moreover, when you use containers of different specifications, then make sure to first adjust the body of machine in accordance with these containers.

9.Explain The Troubleshooting Of A Cooking Oil Bottling Line?

A cooking oil bottling line may have spontaneous problems which can be tackled easily by understanding the causes and taking right actions. In the below paragraphs, we have explained the troubleshooting of common errors occured while operating a cooking oil bottling line:

| Bottle Unscrambler

Highlighted bottle unscrambling- Picture Courtesy: bellatrx.com |

||

| Issue:

Bottles breakage |

Cause:

The error in sensor leads to the constant working of machine due to which bottles get overlapped and may get defected or broken. |

Solution:

Check the sensor and reinstall it for properly detecting the start and end of each cycle. |

| Issue:

Jamming of bottles |

Cause:

The rotary disc may stop moving when bottle get stuck into the mold. |

Solution:

Check the rotary disc and remove out stuck bottle from the mold. |

| Bottle Filling Machine

Encircled bottle filling head- Picture Courtesy: packrusa.com |

||

| Issue:

The filling head is blocked |

Cause:

There may be any foreign object which is stuck in the filling nozzles. The filling head may be contaminated. |

Solution:

Check the filling heads and remove the foreign particle. Disassemble the filling heads and clean them properly. |

| Issue:

Filling inconsistencies |

Cause:

The setting is not proper. Machine may be tilted due to uneven surface. The nozzles may have accumulated dirt. |

Solution:

Reset the machine setting through control panel. Place the machine on flat even floor. Clean the filling heads. |

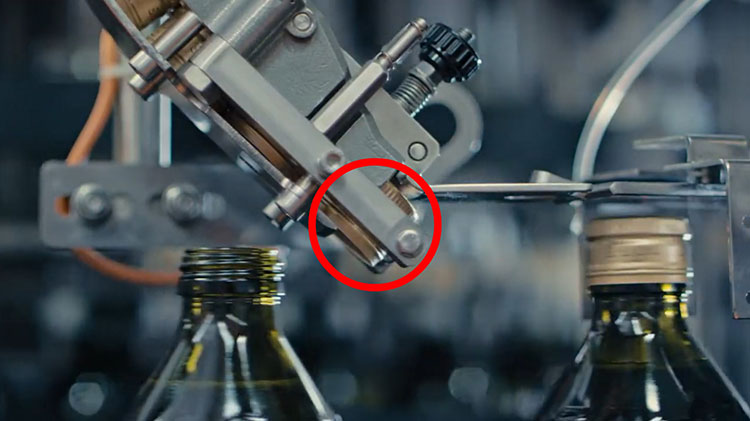

| Bottle Capping Machine

Highlight capper head- Picture Courtesy: GFT Group |

||

| Issue:

Missing caps |

Cause:

The capper head is located at height and is not touching the bottle mouth. The spindle may lacking caps supply. |

Solution:

Locate the capper head in accordance with the height of bottles. Supply the caps to cap elevator. |

| Issue:

Caps damage or breakage |

Cause:

The torque pressure is excessive leading caps to get deformed. |

Solution:

Reduce the torque pressure to avoid this problem. |

| Inkjet Printer

Highlighted inkjet printing machine- Picture Courtesy: linxglobal.com |

||

| Issue:

Zigzag printing |

Cause:

There is setting issue of the printer. The drivers are outdated. |

Solution:

Set the machine from step one by using its digital control panel. Install the updated drivers. |

| Issue:

Improper working |

Cause:

Poor connection to power. Any part of it is damaged. |

Solution:

Supply adequate power. Check and replace the damaged part. |

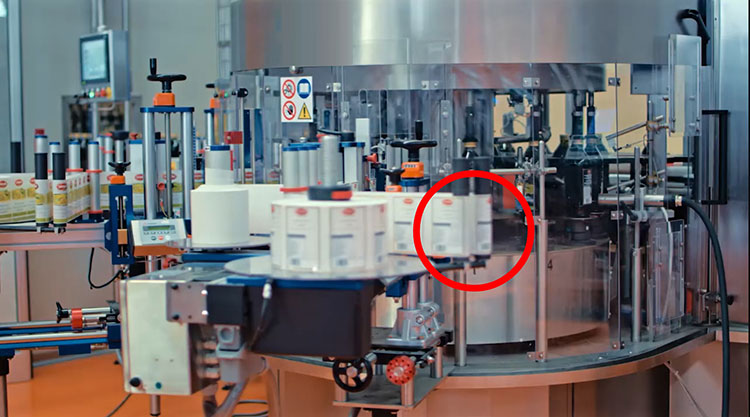

| Labeling Machine

Highlighted labeling rollers- Picture Courtesy: GFT Group |

||

| Issue:

Label material is not moving on substrate |

Cause:

Label pulling rollers are loose. Drive belt is loose. One of the pulleys is skipped. |

Solution:

Tight the label pulling rollers. Check and adjust the drive belt. Make sure to pass label from all the intermittently located pulleys. |

| Issue:

Label is poorly adhered to the bottle |

Cause:

Bottle has dust or dirt over it. Label is poorly pressed around the bottle. |

Solution:

Use tidy bottles and operate the machine in clean environment. Adjust the fur brush for uniform label pressing. |

10.What Should Be Considered When Buying A Cooking Oil Bottling Line?

If you are intending to buy a cooking oil bottling line then don't forget to pay heed to some of the important considerations which are as follows:

Productivity

Large number of cooking oil bottles

First of all, ask your vendor to inform you about the production speed of a cooking oil bottling line. It is important because there are different kinds of bottling line available in market. Similarly, depending upon your production needs, you can opt for the one by checking the productivity ratio of the bottling line that suits your daily requirement.

Scalability

Cooking oil bottling line is a comprehensive solution which can transform your production by its efficient performance. However, due to the rapid changes in customer demands and preferences, you may want to upgrade your cooking oil bottling line. In this case, it is eminent to confirm that whether the bottling line will be able to accommodate customization.

Expenditure

Expenditure icon- Picture Courtesy: nationalbusinessmirror.com

Estimating the overall cost of your cooking oil bottling line is another crucial factor to be considered. For this, you can simply examine your budget and then opt for the reliable solution whose original price and operational cost are easily bearable to you.

Quality Assurance

Quality assurance icon- Picture Courtesy: vecteezy.com

Ask your supplier for the quality assurance of bottling line in form of customer service, warranty, and certification of the machine. It is essential because the cooking oil bottling line you are about to purchase is going to be your life time partner.

Conclusion

To summarize, Cooking Oil Bottling Line is a one-step solution to your extensive cooking oil processing business. It can aid you in the most critical phase of cooking oil handling which is its safe and perfect bottling. Not only is it beneficial in terms of accuracy but it also increases your existing productivity. You just need to understand its structure and operate it on right principles which are all explained above. Apart from it, the cooking oil bottling line require little maintenance and can run for decades. So, don't miss the opportunity to become a valuable supplier of Allpack for having a top-notch cooking oil bottling line! Stay in contact with us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide