Convenient Prefabricated Food Counting Machine: The Complete Buying Guide in 2025

Greetings to all those who love the food industry! Are you ready to take your production line to the next level? Well, get ready for the start of the revolution in innovation and progression. As the year 2024 comes to an end, so does the packaging of ready-made tasty food with the introduction of convenient prefabricated food counting machines. These technologies now hold the potential to revolutionize the process of food manufacturing and deliver unprecedented precision, totality, and efficiency.

Now, worry not, because it is possible to grow through this new transformative world without much difficulty. This ultimate guide on 'Convenient Prefabricated Food Counting Machine' would enabling you to gain all the needed information with so much ease. Welcome to this new step in your journey. Now let's have a look.

1.What Does Mean A Convenient Prefabricated Food Counting Machine?

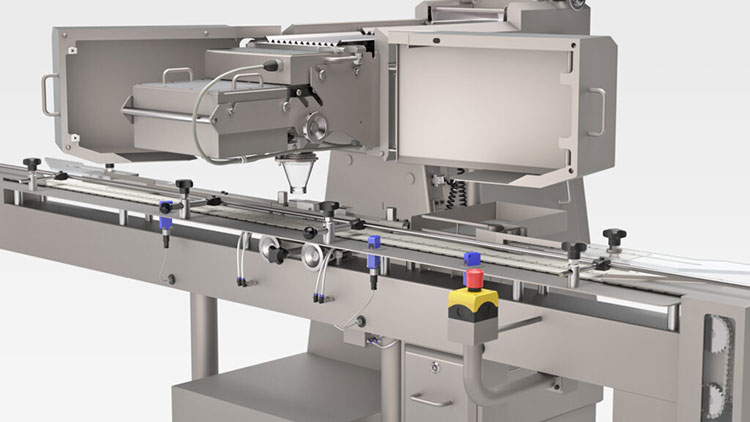

A convenient prefabricated food counting machine - Picture courtesy: cremer.com

A convenient prefabricated food counting machine is an automatic and user-friendly machine which saves time. This machine is widely used in counting various food products including biscuits, candies, frozen foods, pet food, nuts, snacks, and many more to make food more versatile.

Due to the convenient use of this machine, it enhances the reliability, efficiency, hygiene, and accuracy of the food product. It also removes food products from contamination and can handle the shapes and sizes of the food items.

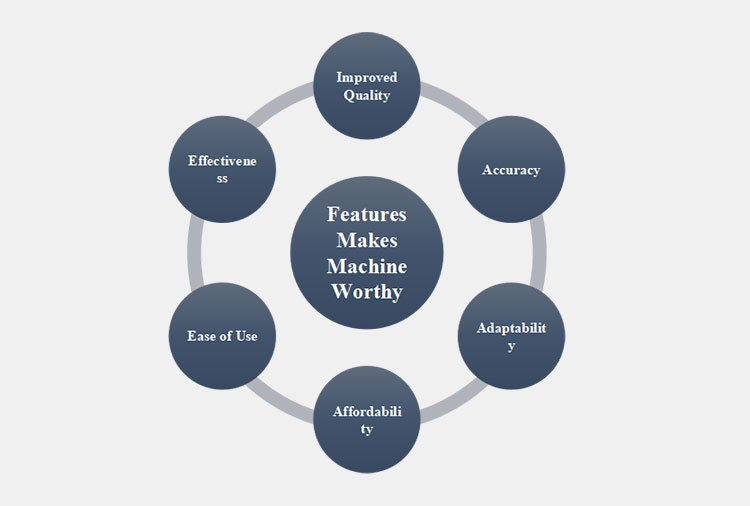

2.What Are The Features That Make The Convenient Prefabricated Food Counting Machine A Worthy Investment?

Features of the convenient prefabricated food counting machine - Picture courtesy: made-in-china.com

Before the advanced technology, manual food counting was the popular choice in various food sectors. Now since the technology is very vast so why we don’t get benefits from it? Using the convenient prefabricated food counting machine to count the food items, makes this machine worthier. Here, are some features that make this machine worthier is discussed below.

Accuracy:

This machine has innovative sensors that make this machine demandable. This sensor is used for counting purposes. Due to this sensor, the accuracy and precision of the food counting remain maintained. It eliminates various errors and adjusts the quality consistently.

Adaptability:

This machine is highly adaptable. Among food items, it can count various other products such as nuts, candies, pills, pellets, and many more other items. This flexibility increases the utility demand of this machine.

Affordability:

The convenient prefabricated food counting machine is less expensive but still shows high production. The automation of these machines reduces labor costs. Which ultimately reduces operational costs and makes it affordable.

Ease of use:

The convenient prefabricated food counting machine has an appropriate system. This makes it user-friendly as a result it has simple working protocols. Due to this automatic process, this machine does not require extensive training. So, makes simple protocols for proper functioning that make this machine demandable.

Effectiveness:

It can perform all the functions more conveniently which enhances the effectiveness of this machine. Due to the machine’s effectiveness, it can count food items and other related products well and quickly. Therefore, eliminates the labor cost, and also reduces the performance time of the machine.

Improved quality:

It maintains consistency in the counting of the food products. This consistency increases the satisfaction of the customer. Due to its convenient operational procedure, the chances of contamination become negligible. Thus leading to enhanced quality of the food product.

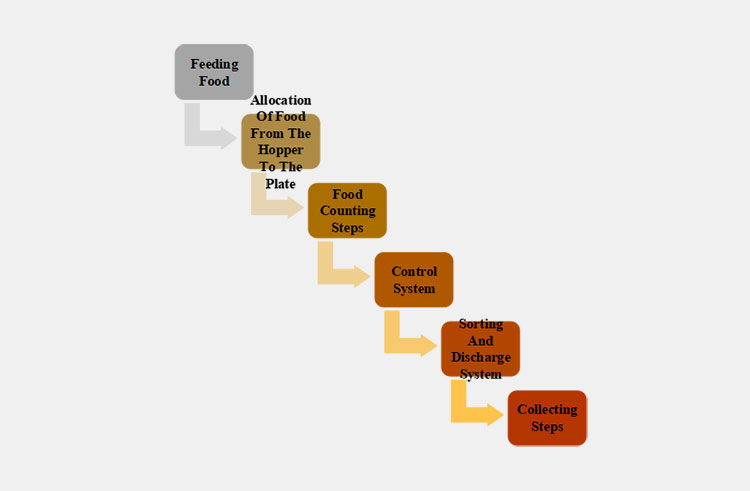

3.What Are The Functioning Mechanisms Of The Convenient Prefabricated Food Counting Machine?

The counting of food or other related items is an essential step in any industrial sector. The counting steps maintain the efficiency and reliability of the product. Before packaging food items or products, the counting step must be required and go through proper stages. The working principle of the convenient prefabricated food counting machine has several steps. These steps are associated with the different chambers of the machine, that are interlinked to each other.

The steps used for the proper functioning mechanism of the convenient prefabricated food counting machine include;

Steps Of Food Counting By A Convenient Prefabricated Food Counting Machine

Feeding food

Before counting the food, it is essential to load it into the machine. The component in which food is loaded is the hopper. This step could be done automatically or manually, depending on the type of machine. During feeding the food to the hopper, its quantity takes matter because overloading may cause problems. These problems could be the wastage of food reducing the reliability of the product.

Allocation of food from the hopper to the plates

Once, the food is added to the hopper. The next step requires moving food from the hopper to the plates of the machine. These plates work in a vibrating environment. Due to this vibration in the plates, the food becomes spread and brought into line for counting.

Food counting steps

The next step is the main step of the machine, which is counting the food. The food moves from the plates to the counting tray. Here again, the vibration makes consistency and the alignment of the food for counting. The detection sensor that is adjusted in the machine, is used for counting the food due to its photoelectric effects. The detection sensor makes the machine convenient and easy to use.

Control system

The control system of the convenient prefabricated food counting machine performs the main role. This system is the main power of the machine as it controls each step. The number of food collection is possible to be controlled by this control system of the machine. It adjusts the quantity of the food that aims to collect.

Sorting and Discharge System

Once, the food counting steps are completed, then it moves forward towards the sorting steps. This step is essential for packaging the correct quantity of the food. After counting food comes at the head of the machine for discharging. In this step, the monitoring of the accuracy of the food counting is carried out.

Collecting Steps

After the discharging of the food from the machine, the next is the collection of the food. The sorting and required quantity of the food must be collected. The collection could be possible in the box, pouches, or in othe packaging materials.

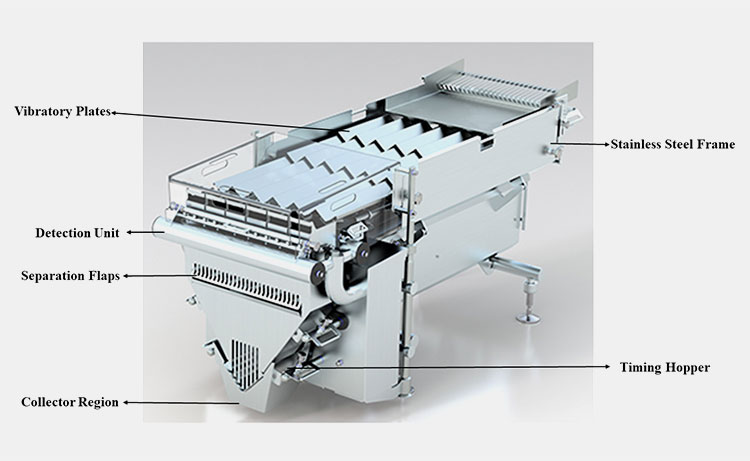

4.What Are The Components Of The Convenient Prefabricated Food Counting Machine?

Components of the machine - Picture courtesy: cremer.com

A convenient prefabricated food counting machine is an essential machine. It is used to count food and maintain consistency. It is widely used in many industries. This machine has many components that are used for its proper functioning. Let us discuss each part of the machine and also explore the role of each.

Vibration Plates

A vibrating plate is the main component of the convenient prefabricated food counting machine. It is used for the transportation and separation of the food items. Due to its vibration condition, these plates maintain consistency on the food products. Food moves from the hopper towards the next chamber in a regular way by these plates.

Detection Units

Detection units are also an essential part of the convenient prefabricated food counting machine. It detects food products based on the quantity required. It has a sensor that has the ability to detect the exact quantity of the food items. It is that component of this machine that maintains and adjusts 100% accuracy on the counting of the food.

Separation Flaps

Separation flaps separates the counts foods items in an accurate way. Once, the count of the food is detected, then it is separated due to the separation flaps of the machine.

Timing Hopper

It is those chambers of the machine that are used for discharging the food-counted product. It discharges the specific quantity of the food product from the separation flap of the machine to the collector region.

Collector Region

The collector region of the convenient prefabricated food counting machine is used to collect the counted food items. For collection of the food items, either bags, plates, pouches or any other materials could be used.

Stainless Steel Frames

The whole body of the convenient prefabricated food counting machine is made up of stainless steel frames. The steel is used to make the frames of the machine to avoid the machine from corrosion. Due to the stainless steel frames, the reliability of the food items remains maintained.

5.What Industries Have The Most To Gain From A Convenient Prefabricated Food Cutting Machine?

A convenient prefabricated food counting machine has tremendous applications. It is not only used on the food industries. However, it is widely applicable in many other industries for counting products other than food. Due to its numerous advantages, it can be used in food industry, pharmaceutical industry, dried fruit industry, cosmetic industry, nutraceutical industry, veterinary industry, hardware industry, chemical and agriculture industry. Now let’s have a look to check how it is applicable in many other industries!!!

| Food Industry | |

|

Since the main purpose of this machine is to count. In the food industry, it is widely applicable for counting food products including, candies, gums, beans, chocolate balls, fried foods, and many other food items. |

| Pharmaceutical Industry | |

|

A convenient prefabricated food counting machine is also used in the pharmaceutical industry. It is used for counting tablets, capsules, pills, and other pharmaceutical products efficiently. |

| Cosmetic Industry | |

|

Among food industries, this machine is also used in the cosmetic industry. This machine is used to count various hygiene and personal care of the cosmetics. |

| Nutraceutical Industry | |

|

The convenient prefabricated food counting machine is also widely applicable in the nutraceutical industry. In these industries, it is used for counting supplementary materials such as pills, vitamins, and so on. |

| Veterinary Industry | |

|

The convenient prefabricated food counting machine is also used in the veterinary industry for counting feed, pellets, pills, etc. |

| Hardware Industry | |

|

It is also essential to count small hardware, which is also possible due to the convenient prefabricated food counting machine. This machine is used in the hardware industry to count bolts, nuts, screws, and many more hardware items. |

| Chemical And Agriculture Industry | |

|

Due to the numerous applications of this machine, it is also used in various chemical and agriculture industries. In these industries, this machine is used to count various products including fertilizers, naphthalene balls, pesticide balls, etc. This machine accurately counts each item in both industries. |

6.What Other Machines Can Work With The Convenient Prefabricated Food Counting Machine?

The convenient prefabricated food counting machine is a convenient tool for counting and sorting of food items. However, there are other machines that can be used together with the food counting machine that is specifically designed for this purpose.

| Machine | Purpose |

| Labeling Machine

|

A labeling machine can be employed to put on labels on the packaged food items that contain information like the name of the product, its weight, the expiring date, and nutritional value. This can help in enhancing the appearance and recognition of the food products. |

| Barcode Scanner

|

A barcode scanner may be used to scan the food items’ barcodes before the counts are taken. This can be useful in automating the process of identifying the food items and keep track of the count and sort them accordingly. |

| Quality Control Machine

|

It is possible to use a quality control machine to scan the food items to ensure that they do not contain any defects or contaminants. This can assist in making sure that only quality and safe food products are the ones that will be counted and packed. |

7.What Should Be Done To Keep The Convenient Prefabricated Food Counting Device In A Proper Manner?

To preserve the convenient prefabricated food counting machine appropriately, some practices may be followed. The above-mentioned steps will help ensure that the machine is operational, accurate and safe for use at all times. Here are some recommendations:

| Regular Cleaning and Maintenance | Calibration |

| Make sure that the machine is clean in a way that eliminates food particles that may stick on the surface of the machine. Rinse the machine gently only with warm water and diluted mild detergent only and do not scrape or apply anything that may damage the machine.

Conveyors or any other rotating part – check these parts and ensure that there is no debris that could slow down the efficiency of the machine. Before using the machine, check whether it has some defects like loose screws or some of the parts are damaged. In case problems are identified, it is advisable to consult the manufacturer or a professional technician for services. |

It should be noted that counting should be adjusted from time to time in order to increase the accuracy on the machine.

It can be done based on the recommendations of the manufacturer which may require the use of calibration weights or even the change of some values. It is suggested to record the calibration dates as well as the results in order to evaluate how the machine is working. This will help in identifying any changes or differences that may be observed in counting accuracy. |

8.What Problem Could Be Associated With The Convenient Prefabricated Food Counting Machine? And That Are The Trouble Shooting To Solve This Problem?

The convenient prefabricated food counting machine is a highly useful machine in the food industry that accurately tallies the food and other items. It is convenient and easy to use. Nevertheless, it is susceptible to the development of complications that could potentially impair its functionality, as is the case with another machine.

Counting of the food by convenient prefabricated food counting machine - Picture courtesy: sedpharma.com

Counting error:Inaccurate counting is yet a prevalent issue that may arise with certain counting’s. This is the reason why the identification of objects is crucial: an incorrect evaluation can result in monetary damages and inaccurate stock control.

Verify the testing: It is also necessary to configure the machine to recognize the type of food item being calculated. It is suggested to adjust the machine in a periodical way to confirm accurateness and the usage of high-quality materials during installation process.

Clean the machines: As the sensors have sensitive functioning and may get dirty, they can affect the counted figure. So, servicing procedures are recommended including the frequent cleansing of the sensors.

Conduct a mechanical evaluation: Make sure that machine doesn’t have any issues like broken wires or damaged or rusted parts. For further queries, the customer should contact the manufacturer to either replace the machine or get the essential replacement parts.

Jamming or blockages:This is another crucial issue observed about jamming or blockages within the machine. This has the potential to disrupt the counting process and potentially cause damage to the machine. To address this problem, you can:

Eliminate any hindrances: Thoroughly clear away any food items or debris that could be causing the jam or blockage. Adhere to the manufacturer's instructions to ensure a safe removal process.

Greasing: Ensure that any moving parts on the machine are sufficiently greased so as to avoid friction and potential jamming. Ensure that you utilize lubricants that are specifically recommended by the manufacturer.

Software issues:At certain times, issues in the machine arise due to the software or programming. It can lead to incorrect counting. To resolve this problem, you can:

Keep the latest software: Update your software or buy the latest versions which are important for the machine. This can resolve frequent programming issues and will enhance performance.

Reset the machine: If the issues are arising continuously, reset the machine to its original settings. You can also reprogram it by following the manufacturer’s instructions.

Connection of the components of the machine to each other - Picture courtesy: foodanddrinktechnology.com

9.What Points Should You Consider Before Buying A Convenient Prefabricated Food Counting Machine?

Picture courtesy: cremer.com

There are several things one should consider while deciding on a simple, convenient prefabricated food counting machine purchase. Food stock counting and tracking depend on this tool, so it is crucial to choose the one that will fit a company enough.

Reliability and Time: A convenient prefabricated food counting machine has to mostly count in an exact and quick way. Think about a device that can quickly and accurately count a large number of things. Since the procedures will be more homogeneous, this will help to eliminate operational hitches and mistakes.

Capacity: One of the factors to take into account is the countable capacity of the convenient prefabricated food counting machine. That is the count of several objects concurrently. It is crucial since you might require a larger machine to meet your needs based on the size and quantity of food items you manage in your company.

Convenient and User-friendly: It should be easily operated and should not possess any sub-systems, that can be operated only by a professional. Controls must be within reach and if there is a screen, then it must be conspicuous if the equipment has this feature. This will enable you and your staff to observe how it works and some ways which you can be able to put it to optimum use fully. It is also necessary to establish whether the machine has other qualities like an auto feeder or separator to the line. If available, this will make the level of convenience even higher.

Stability and Service: A convenient prefabricated food counting food machine is costly. Therefore, it is acceptable to select one that is well-built. Make certain that the machine is constructed from a high-quality material that is reasonably durable and can withstand the harsh conditions of a commercial kitchen. Additionally, it is imperative to consider factors such as the availability of spare parts and the maintenance required for the specific machine to operate properly.

Conclusion

Nowadays packed food is more demandable and consistency of the food items in the packed remains challenging. In the modern era, the convenient prefabricated food counting machine is the trustworthy choice as it eliminates the manual food counting process. This machine offers accuracy, reliability, and consistency in counting the food material. If you want to buy a new convenient prefabricated food packing machine and want any assistance. You may contact Allpack. You will be guided in a good way.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours