Confectionery Packaging The Complete FAQ Guide in 2025

Did you know the confectionery packaging is expected to rise tremendously by 4.3% annually till 2025?

Confectionery packaging is a highly diverse and versatile field of business with excellent trends followed for gifts, celebrations, and other items like birthdays, etc. The key growth behind its high-driving success is improved aesthetics presentation which compels consumers to grab them on store shelves.

Whether you’re a newbie or high business enterprise, selecting the right confectionery packaging for your product is always involved with increased market growth. So read this blog and find significant parameters, equipment, and relevant points to confectionery packaging.

1.What Is Confectionery Packaging?

Confectionery Packaging Design- Picture courtesy: Dieline

Confectionery packaging encloses sweet items such as jellies, chocolates, chewing gums, sugar candies, and hard or soft gummies in such an appropriate packaging material that enables protection against environmental degradation and preserves the food during storage and transportation.

High-grade plastic, aluminum, recyclable paper and even metal containers are used for this process. Different packaging formats are used to provide retail and bulk quantities of confectionery products.

Whether your product needs to be displayed to convince consumers at impulsive buy or simply to maintain craftsmanship of your brand, along with delivering of quality packaging, our packaging solutions support your cause.

2.Why Do You Need Confectionery Packaging? Why it is so popular?

Eating Confectionery Candies- Picture courtesy : Very well Mind

Of course, in order to preserve freshness and premium quality of any of your eatables, you need its sturdy and flexible packaging.

Now if you ask why confectioneries are so popular, let us outline some reasons for you.

Various Confectionery Candies

Confectioneries are loved for being soft for mastication, enhancing consumers mood and needing them to want some more as they are known to relieve stress and reduce depression as these sugary treats serve to be a good dopamine rush.

These delicious candies can be enjoyed because of it’s ability to be molded into hundreds of unique shapes, each having it’s own specificity and fun, thereby can be added to events to make it more amazing.

Gummies compared with other sweets hold less calories and have zero fat which makes them desirable for anyone. Chocolates on the other hand are innovatively manufactured nowadays in more healthier options such as vegan options, reduced sugar content or in dark chocolate form which proves beneficial for health.

Health supplements and beauty products manufacturers have combined their formula nutrients inside some of the confectionery items such as gummies offering good range of multivitamin supplements and some medicinal ingredients like tinctures have been infused into candies. The addition of citrus flavors and nuts to chocolates and other types of confectionery increases their nutritional value.

3.What should you know about confectionery packaging's significance?

The confectionery packaging is designed to provide the following benefits to the manufacturer as well as consumer.

An Advanced Packaging Way

Excellent Confectionery Packaging- Picture Courtesy: Opera Food

The confectionery packaging is the solution for various textures, shapes, and coating of the confectionery items to store to make them easy to handle and adaptable.

Ensuring 100% selling

Confectionery Packaging with More Profitability

A good and presentable confectionery packaging offers you 100% selling assurance hence you can get back your double investment in the form of profitability.

Offering Customized Packaging with Bespoke Material

The confectionery Packaging- Picture Courtesy: Mekitec

The confectionery packaging is specifically designed with tailored requirements hence it offering you customized features and designs for your product.

Extended Shelf life and High Hygiene

A confectionery Packaging offers Extended Shelf life and High Hygiene

If your candies are soft or hard, the confectionery packaging offers its protection for stable shape and quality. Moreover, the packaging keeps external factor away from your product so you can provide high quality hygienic product to your customers.

Easy Transportation

Ease of transportation Picture Courtesy: Ixtenso

The confectionery packaging is promising method of keeping confectionery intact and stable from manufacturing company till end user no matter which corner of the world you belong in.

4.Is Confectionery Packaging Different from Other Food Packaging Types?

The confectionery packaging is certainly similar to other food packaging and other various packaging products. There are commonly used confectionery packaging materials and styles are helpful in the packaging the commonly used packaging pattern and types of confectionery packaging are discussed below where you can find similarities with other food packaging items. Some of them are:

Pouch

This is the most popular and commonly used confectionery packaging in today’s world. The pouches are of various different categories as well. It is up to your choice, what you’re planning to add for your products.

| Stand Up Pouch

These are aesthetically pleasant as well as stable form of packaging with broad space for your candies or other confectionery items as it has broader bottom which helps you in keeping them intact on market’s shelves. This is mostly designed with resealable closures such as zip lock, slider, or zippers. |

Stand up pouches- Picture courtesy: 48hours |

| Quad-Seal Pouch

This is similar to stand up with four intact and prominent corners offering a wider options to store confectionery items. The qual seal pouches are easy to stand in an upright position with stable leveling for standing on shelves. The pouches are available to store 125 grams to 1kg of confectionery items perfectly. |

Quad seal Pouch- Picture Courtesy: Foster Packaging |

| Flat Bottom Pouch

This is look like a box and known as block bottom pouches. It has ability to store more confectionery items as it has broader bottom space with side gussets offering beautiful and sophisticated packaging designs. |

Flat Bottom Pouch- Picture Courtesy: Confectionery Product |

| Flat Pouch

This is also known as flat-lay pouches are simpler than above described options. The flat pouch has Unstable base that can lay on the back without no side gussets. It is mostly designed with 3 sides seals can be used as a single serving pack. |

Flat Pouch |

Jar/Container

Jars/Container- Picture Courtesy: Swag

The confectionery packaging is also done in various available jars or containers with different sizes, and formats. This is a conventional method of packaging which is also replaced with pouches, sachets, and other modes. The jars and containers are still preferred for high safety, quality, and integrity offerings to your products as well as promising market options.

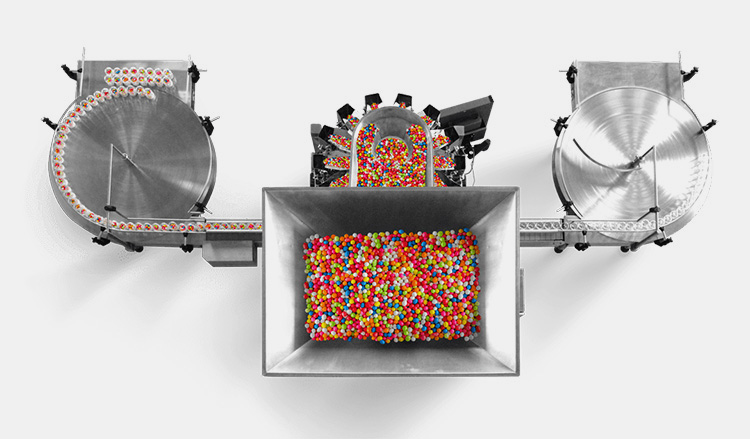

5.What Are The Types Of Confectionery Packaging Machines?

There are various types of confectionery packaging machines, some of them are discussed below:

Flow Wrapping Confectionery Packaging Machine

Flow Wrapping Confectionery Packaging Machine

This is the most just a lot more affordable confectionery packaging solution which is compact, reliable and sturdy flow wrapping considered as a great equipment for confectionery candies or candies around the world best known for fulfilling confectionery packaging needs. The working of this machine entirely taken place in a horizontal manner that’s why it is also known as HFFS machine.

WORKING

This is highly ideal machine to pack sticky, soft, and multipack confectionery packaging where manual film is fed to the machine which is securely able to handle the formation of bag, sealing and intricate cutting once product is presented inside the bag. The machine is made up quality standard material where touchscreen, automatic sensing, presence of sealing jaws, and cutters allow the procedure highly programmable and accurate.

Vertical Form-Fill-Seal (VFFS) Confectionery Packaging Machine

Vertical Form-Fill-Seal (VFFS) Confectionery Packaging Machine

A VFFS confectionery packaging machine, a best engineered that is featured in a compact size which can be install in various measurements of labs. The machine is commonly used in small, moderate, and large production industries for confectionery packaging as it gives you tremendous working capacity. From the unwinding of film roll till the packaging procedure, the entire working takes place in a vertical fashion. That’s why it is known as VFFS machines.

WORKING

The machine works when a flat sheet of film roll is unwounded itself around the collar or dancer arm present at the top part of the machine. you can load the film roll manually and put in feed information on PLC. Once the films roll around the narrow tube and forms a shape of cylinder the heat sealer joins its edges around it leaving one side opened where hopper drops the confectionery product. Once the product is positioned the heat sealer joins the left section of the pack and seal the bag.

Sachet Confectionery Packaging Machine

Sachet Confectionery Packaging Machine

The high speed sachet confectionery packaging machine is featured in various automation assisting confectionery packaging in a small and single serving packaging of confectionery items. The sachet packaging machine is cost-economical and commonly used equipment in various industries.

WORKING

The working of sachet confectionery packaging is taken place via auger, volumetric, or net weighing units to fill the sachet formed by the machine itself by following the VFFS working principle such as formation of the sachet from a single sheet of film roll, filling of products and sealing of the sachet respectively. The sachet are used as a single serving confectionery packaging.

Stick Confectionery Packaging Machine

Stick Confectionery Packaging Machine- Picture Courtesy: Mentpack

You have seen wafer, biscuits, lollipops, marshmallow etc,. packed in a stick packaging. This is done by this machine which is indeed small, sturdy and compact solution to bring this job effectively. This machine is suitable for the various categories of industries as it is quick forming and loading solutions with high sensors unit that avoid error occurring during the production process.

WORKING

The working of stick confectionery packaging is very much similar as VFFS machines where the roll of film is opened via rotation of dancer arm to form number of stick packs by help of forming tube, sealers, cutters, to create several stick packs as a result. The filling of product takes place by the help of volumetric fillers, or auger filler to get a correct amount of the items then final sealing taken place followed by discreet cutting of edges to obtain a final product individually.

Pre-Made Pouch Confectionery Packaging Machine

Pre-Made Pouch Confectionery Packaging Machine

The pre-made pouch confectionery packaging machine is perfect for fast and high production houses of confectionery items where machine is responsible for automatic working without consuming time on the making or creating pouches, rather it picks an already formed pouch for positioning confections.

WORKING

This is also known as a bagger machine that offers an easy handling and operability by griping the stack of premade bags manually loaded in the magazine of the machine. by the help of air inflator the lips of the bags are opened widely. The fillers such as volumetric, auger, or multi-weighers, are used to filled the pouch respectively. The machine is responsible for sealing the bag either by zipper closing, heat sealing, sliding or clipping them. The machine is also featured with bag shaker which is used to level the filled product dropped inside.

Container or Jars Confectionery Packaging Machine

Container or Jars Confectionery Packaging Machine

The containers or jars confectionery packaging machine is used in the broad industrial sector that is assisting you not only in the packaging of the confectionery items but various other products as well such as pharmaceuticals, nutraceuticals, and other. The machine is robust and highly reliable in giving you results as you want. This machine is striking with excellent features and product safety against external hazards.

WORKING

This machine mostly features with an integration of bottle or jars unscrambler which helps you in offering a uniforming supplying of correct jars or containers. Once the number of jars/containers reaches the filling nozzle of the machine; it senses it by sharp detectors. The machine drops an assigned number of confectionery items into each individual bottle/container/jar and stops the supply once they’re acquired with it. The filled containers leave the machine and moves toward the further procedure such as capping or induction sealing, and so on.

Vacuum Packaging Machine

Vacuum Packaging Machine- Picture Courtesy: Auger Enterprises

Vacuum confectionery packaging is the commonly used methodology for filling confectionery items to extend their shelf life and product quality for a longer time. The presence of air inside the packaging is undesirable which is entirely removed by using vacuum pressure. This feature is now commonly employed in various machines to attain the desirable outcomes for confectionery packaging.

WORKING

The vacuum confectionery packaging machine is used displace air with vacuum environment inside the packaging material simply by sucking the presence of oxygen from the packaging material and leaves no trace elements inside it. The filling nozzles or filling station first drops the item inside the packaging then machine creates a low-pressure environment. The vacuum presence is the prime reason to ensure high lifetime of the confectionery products.

ACCORDING TO THE ORIENTATION OF PACKAGING MATERIAL

The confectionery packaging machines are also following different movement orientations of packaging products. For example:

Inline Confectionery Packaging Machine

Inline Confectionery Packaging Machine

The inline confectionery packaging machine is highly precise and flexible machine where input and output of the filling material follows a linear pathway to enter and leave the machine for packaging items. This is conventional and commonly used machine in various production processes due to its ease of handling and precision.

WORKING

The machine follows easy working principles where product become subjected to filler nozzle to get free-flowing confectionery items under a controlled and compact unit where low chances of contamination is there. Once the product is filled it leaves the unit. The easy and common example of this working is a flow-wrapping or jar filling machine which use a linear pattern of packaging.

Rotary Confectionery Packaging Machine

Rotary Confectionery Packaging Machine

If you’re looking to achieve high confectionery product packaging output, then rotary confectionery packaging machine is absolutely ideal for you. The machine is ideal for facilities where installation area is limited but you’re aiming to meet high production capacity, because the machine is compact and compatible with integrating various other units of the packaging line.

WORKING

The machine follows packaging procedure using a rotary pathway such as, the empty packaging material are subjected to enter the machine, filled, sealed, and discharge following the rotational fashion. In this way thousands of containers or packaging material ins and outs the machine in a short time.

ACCORDING TO DIFFERENT FILLING HEADS

The confectionery packaging machine is also featured with different filling head types such as:

Single Head Confectionery Packaging Machine

Single Head Confectionery Packaging Machine- Picture Courtesy: TAM

This is the simple machine which is preferred for running the small and medium production industries for filling and packaging of the confectionery items. The machine is featured with single filling head that can fill hundred to thousands of packaging material per hour effectively.

Double Head Confectionery Packaging Machine

Double Head Confectionery Packaging Machine

This is an advanced machine that is preferred to run medium to large production batches which is designed with double filling heads used to fill fast and accurate filling of confectionery items.

Multiple Heads Confectionery Packaging Machine

Multiple Heads Confectionery Packaging Machine- Picture Courtesy: Samfull Packing

This is the giant solution for dealing large production industries where machine is featured with multiple filling heads that can carries fast, accurate, and precise working of confectionery packaging in no time. The machine is able to run day and night without worrying about any quality error or trouble. Users just need to click the process and rest of the operating system can manage itself.

6.What Products Suggests Confectionery Packaging?

The confectionery packaging is suitable for broad range of broads with various packaging options that we already have discussed above. You can select confectionery packaging perfectly if you’re associated about the following list of products.

Fudge

Fudge- Picture Courtesy: TOM

This is the most lovable and mouth watering confectionery preferred by a huge group range of people that is packed with jars, sachet, or pouches to prevent the interaction of air or moisture content with it and ultimately preserve the quality and freshness of these item efficiently.

Gummy Bears

Gummy Bears- Picture Courtesy:Miss gourmet

Everyone love gummies that are formed in the various shapes, colors, sizes, tastes, flavors and much more. Similarly, the packaging of gummies are also striking with broad range of confectionery packaging options such as sachet, stick packs, jars, pouches, flow-wraps etc.,

Marshmallows

Marshmallows- Picture Courtesy: Eroma

This is the most enticing treat which is much popular among youngsters and children. The confectionery packaging is typically offered in plastic jars, stick packs, and pouches to store marshmallows and protect them against dryness.

Chocolates

Chocolates- Picture Courtesy: AAK

Whether chocolate sticks or bars, these confectioneries are widely packed in flow-wrap, boxes, jars, and pouches to maintain their integrity, quality and taste for a longer time.

Toffee

Toffees- Picture Courtesy: Lolli-Shop

These are commonly packed in pre-made pouches where bulk quantities of toffees are easily stored and dispensed whenever you need them. Their packaging is quite essential in order to keep its integrity and freshness for extended periods as it becomes sticky with time.

Candy

Candies- picture Courtesy: The original Lolly Shop

The candies are also an important confectionery product which is mostly packed in bags, pouches, pillow pouches, or sachets or even in bulk bags that are mostly presented with highly aesthetic display as an eye-catching product.

7.What Kind of Confectionery Packaging Suitable for Your Products?

The various confectionery items have several packaging options. Check to asses which one is best fit for your production process would help you in selecting the right pattern and right machine.

Sugar Confectioneries

Sugar Confectionery- Picture Courtesy: Asia Pacific Food

The sugar confectionery basically includes nuts, fruity products, chewing gums, gummy bear candies, lollipops, jellies, chewy and stretchy candies.

They are mostly packed with packaging material lined with metalized layer which is useful in the protection against stickiness of product with each other as well as with the packaging material.

Pouch packaging is considered ideal to enhance more enticing appearance of your brand and product as well and it performs good barrier properties. These materials are mostly recyclable, with reduced moisture barrier and light barrier properties, hence better for storing sugar confectioneries.

Chocolate Confectionery

Chocolate Confectionery- picture Courtesy: Healthline

These include chocolate bars, cremes, truffles, and related items that are packed in plastic pouches with or without a metalized line. The pouches with such layers are helpful in protecting cross or entrance of air inside the pack hence extending product’s shelf life and enhance ideal packaging that keep product fresh and intact for a longer time.

Baker’s Confectionery

Baker’s Confectionery- Picture Courtesy: Sammic

The Baker's Confectionery are included with cakes, pastries, cookies bars that are mostly packed in air tight pouches, pillow sachet, and stick pack. The sealing of these products are accompanied by zippers, and sliders, where consumers can reuse the products. Moreover, bakery confectionery is commonly packed with stand up pouches with kraft paper where products can get more space to stay intact inside.

8.How Does The Metallised Layer Preserve The Freshness Of Your Confectionery Items?

The High-Quality Confectionery Packaging- Picture Courtesy: KN Packaging

The metalized layer of confectionery packaging is a good shielding barrier against the entrance of air, moisture, light, and physical and chemical entities.

This layer acts as a high barrier which creates obstructions against these agents via a thin coating of a vacuum layer of aluminum foil as well as polyester which cumulatively displays effects of an insulator for confectionery products.

These metalized layers packaging is helpful in extending product life as well as preventing the invasion of microbes or contaminants. By considering the above all factors will collectively preserve the freshness and aroma of confectionery products with quality and shelf life of the packaging content.

Conclusion

Confectionery is now a vital part of markets and consumer's hearts. It is essential to not only preserve its taste and quality but also maintain attractiveness. For this reason, manufacturers of the confectionery industry pay extreme attention for packaging of their products. And because Allpack bespoke confectionery packaging equipment is easy to use, economical, quick, and efficient, then why not give it a try? We’re here to assure you that you won’t be disappointed! Please contact us now for more information and purchasing the right machine for your confectionery items.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide