Sauce Packaging: The Complete FAQ Guide In 2025

Sauces are semi-solid, liquid foods or creams which are used in other food to enhance their taste and bring out their best flavor. Over the past few decades, the food industry has dived into making various kinds of sauces by experimenting with lots of different ingredients. The use of sauces has taken the world by storm and can be found in every part of the world, whether it is a restaurant, street food or someone’s kitchen, sauces are universally loved by everyone for its addictive taste and appetizing look!

These sauces come in various textures and need to be packaged so that they can be safely transported from their manufacturing place to their final destination. For this purpose, sauce packaging is used to pack these sauces for their easy and safe transport. They come in different shapes, sizes, color and designs to make them more appealing to the customers.

Let us discuss in detail about sauce packaging and see which one is the most suitable for your industry.

1.What is sauce packaging?

It is a procedure of packaging sauces into containers like glass, plastic, cans, jars etc. to preserve it for longer time and also to secure it from contamination and other spoiling agents. Otherwise the contents, the sauces, could turn hazardous that could lead to a high risk of a foodborne illness to consumers, when exposed to atmosphere or any other potential contaminants.

2.What are the common types of sauces in sauce packaging?

Sauce packaging machine can be used for several different types of sauces. These sauces can be of any colour and texture. Let us discuss the different types of sauces these machines can package.

a)Hot sauce

Hot sauce is a seasoning made up of chilli peppers, vinegar, citrus fruits and salt. This sauce is widely used all around the world due to its hot and tangy flavour.

b)Soy sauce

Soy sauce is a brown, salty liquid most popularly used in Asian countries in their food items to enhance their flavour. It can be used virtually in all of Asian cuisines since its umami flavour made from fermented soybean adds flavour to any dish.

c)Pasta sauce

Pasta sauce is primarily used in dishes like noodles and pasta which gives them the main flavour. It acts as the main liquid medium for the dish, enhancing its flavour since it is made up of ginger garlic, onions and olive oil.

d)Tomato sauce

Tomato sauce is the main ingredient for many famous dishes like pizza and pasta. Its acidity, sweetness and umami flavour provides excellent taste to Mexican salsas and Italian pasta dishes.

3.What is the history of sauce packaging?

For one instance, the packaging seems a pretty basic technique and therefore we hardly give it a thought in daily life and we might take it for granted on a major part but in actual it is the result of many centuries and evolution that led us the way we do preserve it in this era and not only the way we preserve it but also the methods we use to transport it and keep it safe and fresh to eat.

The history of preserving food dates back to many years when our ancestors, the hunter gatherers, for say, around 10,000 years ago, used to preserve food in natural materials like banana leaves.

One of the oldest preserving material is ceramic pottery that dates back to around 20,000 years ago. Among many of the archeological findings, the samples of food, wine, honey and beer are found well preserved in clay pots and urns.

The other popular materials for food preservation are metal and glass that dates back to 1200bc.

Others popular but not so ancient materials include plastic, tin etc.

The use of plastics for sauce packaging and also for other products was done in early 1900s.

Plastic turned out to be very convenient material for usage because of its few characteristics like being lightweight which reduced the shipping costs, it could easily be made airtight and also it is waterproof that would assist in prevention from moisture.

4.What are the benefits of sauce packaging?

The sauces are the flavor enhancers which are found approximately at every point of world and in every kitchen possible. One’s meal might not be completed with any of the sauces, therefore its preservation and quality has to be best in every way possible when it reaches to consumer. People use many options for packing of sauces such as pouches, plastic bottles and glass bottles. Let us discuss the benefits of using sauce packaging below.

a)Provides protection

The main reason why sauce packaging is used primarily is to provide protection to the sauce inside. It serves as the medium to transfer the sauce from its site of production to its site of use without getting damaged. Thus maintaining its flavor and texture.

b)Increases shelf life

Sauce packaging increases the shelf life of product. This increase in life assists the producers by providing more time for export to more far areas. It also gives more time for potential sale and higher customer satisfaction. This results in cost saving at production end by preventing the losses associated by early expiry and also at consumer end since the products life has increased.

c)Ability to market brand name:

Human tends to get attracted to those things that are premium finished. Using sachets, plastic and glass bottles provide the companies with an opportunity to market their brands name, thus boosting their sales and increasing their profit margin.

The glass bottles are used for long time even the product has finished. It is used for other storing purposes like oil and other syrups. And so the constant use and looking at the same bottle everyday keeps them reminded to buy the same product next time they go shopping. This enhances the chances of consumer retention and loyalty.

5.Which containers can be used in sauce packaging?

In order to choose which packaging style is the most suitable for your sauce, there are several packaging styles available in the market. These packaging styles have their own unique features. Let us take a look at each of them below.

a)Spouted pouches ( stand up pouches )

These type of pouches are one of the most popular ones out there to package sauces like ketchup, hot sauce etc. its attractive features include its convenience and easy to use ability. Its user friendly design is provided with a cap at one end.

When compared to plastic (PET) bottles or glass jar, stand up pouches are easier to transport and more convenient to keep at the grocery shelves.

b)Four side seal pouches ( flat pouches )

This sachet type pouch is made of two films which covers all the sides of the pouch except for one side which is used to fill the sauces. It is one of the economical type of pouches out there and is primarily used to fill ketchup or chilli garlic sauce.

c)Glass jar sauce containers

Storing sauces in a glass jar is one of the wisest decision since it is the most protective type of sauce packaging available. Its strong, durable material prevents any kind of interaction between the sauce and dust, moisture or air. Thus it increases the shelf life of the sauce which makes it safer to use it for longer period of time.

d)Plastic ( PET ) sauce bottles

These types of bottles are cheaper and more user friendly than the other types. It protects the sauces from external factors. Unlike glass jars, it will not break if it falls down. It is leak proof and can be used again to fill the sauces.

e)Cans

These high strength cans are an excellent option to fill any kind of sauce. They provide strong protection and prevent the sauce from getting degraded by any external factors. Thus they increase the shelf life of the sauces which can be shipped to any part of the world, enabling wider access for its consumption.

6.What is the process of sauce packaging?

There are a few stages which need to be considered when considering sauce packaging. These steps are.

a)Filling

The first and foremost step of sauce packaging is to fill them with sauce. This is done by filling the sachets or glass bottle with the help of nozzles. These nozzles are operated automatically with the help of a control panel.

b)Sealing

After the package has been filled, it needs a hermetic seal to prevent the contents inside from getting damaged. This is done by applying sealing machines to the sauce containers by using impulse sealers or heat gun. These equipment use high temperature to seal them off.

c)Printing and labeling

After sealing sauce package, the next step is to print and label the bottle. This is an extremely important step since the aesthetic of the product packaging would be the key feature to attract customers into buying your product. So you need to decide which design layout would be the most attractive to promote your brand and increase its sales.

7.Which kinds of machines are used in the process of sauce packaging?

There are several types of sauce packaging machine which have their own features and qualities. You can choose any type of machine, depending on your requirements. Let us take a look at each of these type below.

a)Manual sauce filling machine

This machine, as the name suggests is used manually to fill the bottles. Its body is made of stainless steel, it consists of hopper,handle,filling nozzles and base. The worker adds the sauce into the hopper, adjust the filling volume according to the requirements and finally press the handle to fill the sauce into the packet.

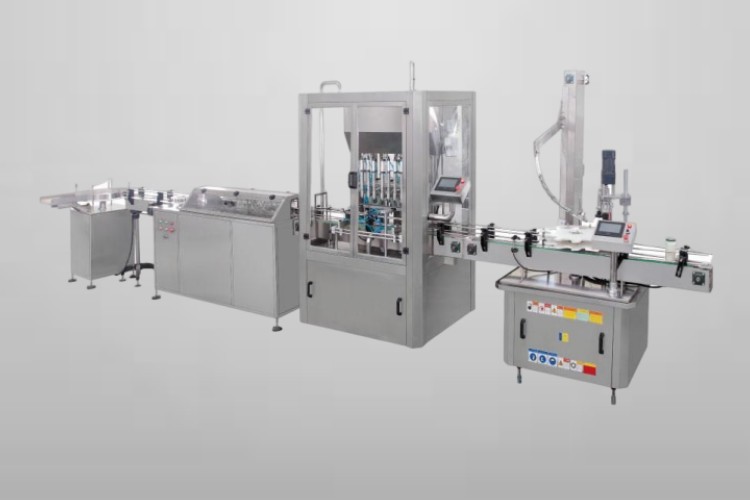

b)Automatic sauce filling machine

This machine works on its own without any human interference. The bottles or the pouches needed to fill are arranged on a conveyor belt in an orderly manner and sent to that part of the machine which contains filling nozzles. After that, the machine fills them with sauce automatically and seals them with the specific lid.

This machine is excellent to use for large scale production since it has the capability to automatically package thousands of bottles or packets in a single day. The worker only has to monitor the process by using the control panel.

c)Semi- automatic sauce filling machine

The process of semi-automatic sauce filling machine is almost exactly like the automatic sauce filling machine. The only exception is that it requires a worker who will arrange the bottles or packets on the conveyor belt in an orderly fashion.

After the machine is done with filling and sealing the bottles, the worker has to pick them up and send it for final packaging. This machine is much cheaper than automatic sauce filling machine too.

d)Piston filler sauce filling machine

This machine is based on the principle of volumetric filling. It consists of nozzles which direct a specific quantity of sauce into the bottles or packets. The piston moves in and out of the cylinder using the hydraulic system.

The volume of sauce being filled can be adjusted using the stroke length of the piston. This ensures high accuracy every time the bottles are filled with sauce.

e)Pneumatic sauce filling machine

This machine uses compressed air to fill the bottles with the sauce. It eliminates the need of electricity needed for the filling process. This greatly reduces the possibility of a short circuit or any possible damage to the machine and the people working around it since it doesn’t contain the electrical components.

f)Tube sauce filling machine

Many sauces are filled in certain packages which are in the form of tube since they are convenient to use. This machine consists of the main frame made of stainless steel, a tank which contains the sauce and the filling nozzles which fill the tubes with the desired sauce.

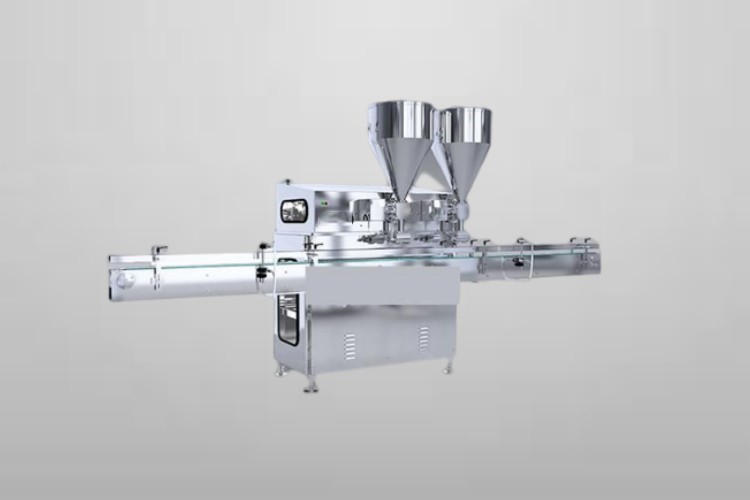

g)Double head sauce filling machine

This machine contains two nozzles which direct the sauce into the bottles. Since there are two nozzles, it increases the overall production and efficiency of the machine. Thus, they are ideal for use in large scale production which require a machine which would have the ability to package sauce into hundreds of bottles each day.

h)Sauce container filling machine

This type of machine contains different number of nozzles. The bottles or the sauce container are placed on the machine according to the number of nozzles it contains. This machine comes in two forms, automatic and semi-automatic.

In automatic sauce container filling machine, the machine fills the container through the nozzles and transports it to the other part of the machine through the conveyor belt. The machine does this completely on its own. After filling a batch of bottles, it moves it to the other part and picks up a new batch automatically. The process only has to be monitored with the help of a control panel.

In semi-automatic sauce container filling machine, the worker has to place the empty bottles on the machine after which the fills them with sauce and transports it to the other part through the conveyor belt. After that, the worker has to pick up the filled bottles and replace them with the new empty bottles to begin the process again.

i)Sauce pouch filling machine

In this type, the sauce is filled in a pouch or a sachet. The pouch is picked up by a robotic arm which places it on a conveyor belt which then transports it to the hopper. The lid of the pouch is opened and is then filled with the sauce. The amount of sauce filled depends on the parameters set. The pouch is sealed by high temperature, cooled off and finally replaced by the empty pouches to begin the filling process again.

j)High viscosity piston filler sauce machine

This type of machine is ideal for filling liquid of different viscosities, especially sauces which are thick in nature.The machine fills the containers with predetermined quantity of the sauce. This ensures that each container or bottle is being accurately filled.

This machine too comes in two forms, the automatic high viscosity piston filler sauce machine does the whole process on its own and the other one, the tabletop piston filler sauce machine requires a worker to operate certain phases of the process.

k)Can sealing machine

The working principle of this machine is dependent on the concept of pressure and force. After the can is filled with the sauce, force is applied to the body of the can which is then sent to the seamer base plate. This base plate then orients the lid over the body of the can after which the seaming rollers apply force on it, forming an airtight seal.

l)Sauce capping machine

Sauce capping machine, as the name suggests is used to place the caps on the bottles. These caps come in different shapes and sizes according to the design of the bottle. The different type of sauce capping machine are

- Snap cappingmachine

- Chuck capping machine

- Bottle cork machine

- Screw-on cappingmachine

- Spindle capping machine

m)Sauce labeling machine

This machine is used to print and place label on the container or bottle. The bottles are placed on the conveyor belt after which the printed label is attached to the container. Thus it helps the company to promote its brand and increase their sales.

8.Factors To Consider Before Opting For Sauce Packaging.

a)Authenticity of the product supplier

Before buying a particular sauce packaging from a product supplier, check whether he is reliable and has authentic documents which prove that his company is approved by the government and he has all the machine certificates to support his claim.

b)Level of Expertise

Another important factor to consider is the manufacturer’s level of expertise and experience in the industry. Ideally, you should choose a manufacturer that has a team of highly skilled and knowledgeable engineers and technicians who are well-versed in the design, construction, and maintenance of sauce packaging machines.

c)Versatility of sauce packaging

Often times, a single factory is capable of producing different kinds of sauces, each having different texture, viscosity and colour. Choosing a packaging style which would be able to handle all these sauces would be the best option since the customer wouldn’t have to buy different sauce packaging for different sauces.

d)After-Sales Service

It’s also important to choose a machine from manufacturer that has a good after-sales service. This means that the manufacturer should be able to provide you with technical support and assistance in case of any problem or issues.

e)Customizability

Another thing you should consider is the customizability of the sauce packaging machines, some manufacturers offer a wide range of customization options for their machines, which can help you to tailor the machine to meet the specific needs of your business.

9.How To Store Sauces To Maintain Their Freshness?

In order to maintain the freshness of the sauces, there are a few ways which can ensure that they can be used for longer period of time without getting spoiled. These are.

- Refrigerate your sauce as soon as you open its packaging. This will increase its shelf life and you would be able to use it for longer period of time.

- Avoid its interaction with direct sunlight since it has the ability to chemically degrade the sauce and make it inedible.

- Place them in glass jar to provide it strong protection from any dust or other air pollutants.

- Make sure the sauce does not come into contact with moisture or water since this can initiate breeding grounds for fungal growth.

- Make sure that the lid of the jar or bottle is properly sealed to avoid the sauce from spilling or from getting contaminated.

- Before opening a new sauce bottle, try to finish the older one first to prevent it from getting stale and unusable.

10.What Kind Of Information Should Be Given On Sauce Packaging?

Whenever the sauces are packaged in bottles, jars or pouches, they are provided with labels which include all the information needed to educate the consumer what kind of product they would intake. This information includes

- The contents of the sauces which include all the ingredients used to make it. This is important since the consumer would know whether the ingredients being used are healthy or not.

- The company logo and the brand name. This is important not just for the consumer but for the industry as well since it gives them a great opportunity to market themselves and gain more customers.

- Attractive designs and colours to attract more customers.

- The weight of the product.

- The name of colouring agents or preservatives used.

- The expiry date and manufacturing date so that the consumer uses it before the sauce gets inedible.

- Health and safety guidelines.

11.How To Choose a Proper Sauce Packaging Machine?

When choosing a sauce packaging machine, there are several factors that you should consider ensuring that you select the best manufacturer for your business.

Verify Proven Track Record

First and foremost, you should look for a manufacturer that has a proven track record of producing high-quality machines. This can be determined by researching the manufacturer’s reputation and customer feedback, as well as looking at the design, construction, and performance of the sauce packaging machines they produce.

Determine Cost of The Sauce Packaging

Evaluating your budget and deciding which sauce packaging is the most suitable for your company is one of the most crucial step when setting up your business. Check which type of sauce packaging would be the most suitable for your company and cater to all your requirements.

Determine Production Capacity

It is necessary to determine your production capacity; then look for type of machine such as manual, semi-automatic or automatic.

Determine Area Specification of Your Lab

For choosing proper sauce packaging machine, you must know area specification for installation the equipment, such as length, width. It is helpful to decide whether machine can be best fit for allotted portion and allows ease of working.

Conclusion

After discussing all the points above, you would be well aware now that sauce packaging has many types of styles which can be used to fill various kinds of sauces. Our company has a wide range of sauce packaging options available for you at an affordable price. So don’t forget to check them out!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide