Collagen Protein Powder Stick Packing Machine: The Complete Buying Guide In 2025

Today health-conscious individuals demand collagen protein powder because of their numerous health benefits. These increase muscle mass, improve bone health, relieve joint pain, and promote heart efficiency. Seems relatable. Yes!

Nowadays, collagen protein powders are packed in small stick packs by the collagen protein powder stick packing machine. This machine improves automation, efficiency, and accuracy as well as has a role in product branding and marketing.

Now are you looking for a solution to increase your protein efficiency? Are different machine options overwhelming you? Then you are at the right place.

Read this comprehensive buying guide to understand every minute detail about the collagen protein powder stick packing machine like its uses, pros, categories, and many more.

1.How To Explain Collagen Protein Powder Stick Packing Machine?

Allpack Collagen Protein Powder Stick Packing Machine

A collagen powder stick packing machine is a specially design machine for forming, filling, and sealing collagen powders into stick packaging style. This machine takes a forming film, cuts it into smaller strips, folds it around the forming tube and transforms them into captivating stick packs.

This machine is an innovation in packaging technology, where the function of every part is coordinated through the control panel. The control panel of the collagen protein powder stick packing machine provides an easy way to adjust program options by showing essential display selections.

Furthermore, the collagen protein powder stick packing machine is extremely flexible in terms of producing different packaging stick packs.

2.Why Collagen Protein Powder Stick Packing Machine is Popular in Industries?

The collagen protein powder stick packing machine provides various significant advantages to businesses because of its cutting-edge technology. It is hugely popular in the industry because it takes businesses towards a new level of success and expansion. Some of the advantages, this machine offers to businesses are:

Increased Level of Production

Increased Level of Production

Manual labour can be very slow, decreasing production efficiency. That is why manufacturers are switching over to automatic collagen protein powder stick packing machines because of their great production capacity. High-tech and sophisticated technology boosts production efficiency far beyond than possible with manual packaging.

Efficient Sealing

Efficient Sealing

Preservation of the freshness of collagen protein powders is a critical aspect in achieving the required nutrition benefits. This protection is all because of effective and airtight sealing produced by the collagen protein powder stick packing machine. It offers strong sealing that protects inner sealed contents from air and moisture.

Accuracy in Every Filled Stick Pack

Accuracy in Every Filled Stick Pack

Over and underfilling is very detrimental to the production, often causing wastage of expensive collagen powder protein and loss of customer’s trust in brand production. Thus, the collagen protein powder stick packing machine is routinely seen in the powder filling industries because it offers accuracy of powder fill in every stick pack. With precise loading systems, there is no chance of fill variation.

Cost Cutting Benefits

Cost Cutting Benefits

Due to precise filling and forming systems, the collagen protein powder stick packing machine does not waste product and packaging materials, saving the need to purchase powders and packaging film again and again. This saves the operational cost.

User-friendly Operation

User-Friendly Operation

The collagen protein powder stick packing machine has user-friendly technology like HMI touch screens and PLC systems. These systems are easier to understand and command, needing little to less skill. This saves valuable time for the operator.

Versatility

Versatility of Collagen Protein Powder Stick Packing Machine

Are you thinking that the collagen protein powder stick packing machine makes simple stick packs? Well, this is not the case, since it is a versatile machine equipped with different kinds of forming, sealing, and cutting components with which it produces diverse shaped stick packs. it also forms stick packs varying in seal and cut pattern.

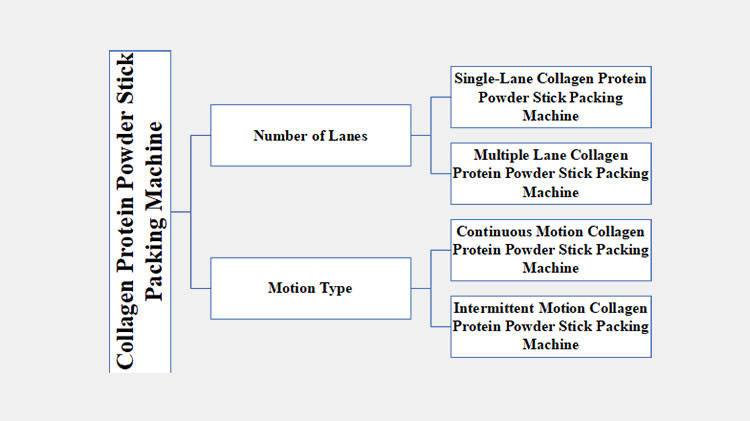

3.What are the Categories of Collagen Protein Powder Stick Packing Machine?

The collagen powder stick packing machine is classified into different types based on the number of lanes and operation type. These types are penned below for your ease of selection.

According to the Number of Lanes

Single-Lane Collagen Protein Powder Stick Packing Machine

Allpack Single-Lane Collagen Protein Powder Stick Packing Machine

A single-lane collagen protein powder stick packing machine is defined as a small machine having a compact construction and is easily operatable. It is portable meaning it is easily moved around via rotary wheels and because of its lightweight feature.

It is a cost-effective unit for small and medium-sized production and it is capable of producing 60 packs per minute. It is used in home-based businesses and laboratories.

Multiple Lane Collagen Protein Powder Stick Packing Machine

Allpack Multiple Lane Collagen Protein Powder Stick Packing Machine

This type of collagen protein powder stick packing machine is a huge-sized machine due to the presence of multiple lanes. About 4-12 lanes are present in the multiple-lane collagen protein powder stick packing machine. These lanes assist in producing several stick packs in one cycle.

It is usually found in large production plants that need a higher output rate. It can output more than 400 stick packs per minute.

It is not portable due to its heavy-duty build.

According to Motion Type

Continuous Motion Collagen Protein Powder Stick Packing Machine

Continuous Motion Collagen Protein Powder Stick Packing Machine

It is an advanced innovation in the collagen protein powder stick packing machine. It has a continuous forming, filing, and sealing technology, thus operating continuously without pausing. Its output rate is far above that of its intermittent motion collagen protein powder stick packing machine counterpart. It is an efficient and automated machine

Intermittent Motion Collagen Protein Powder Stick Packing Machine

Intermittent Motion Collagen Protein Powder Stick Packing Machine

In contrast to the continuous motion collagen protein powder stick packing machine, this type of collagen protein powder stick packing machine is slow and has less production rate as it pauses between every step of forming, filling, and sealing. However, this machine is more flexible and has more accuracy.

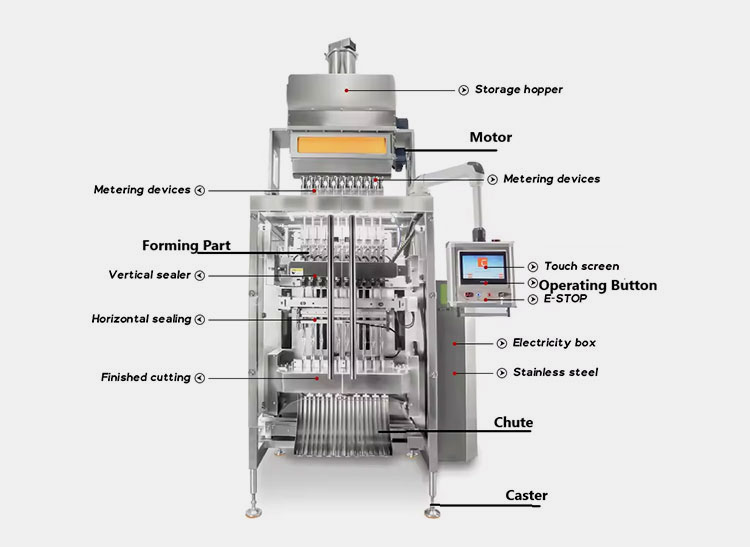

4.Enlist Parts of the Collagen Protein Powder Stick Packing Machine.

Parts of Collagen Protein Powder Stick Packing Machine

| Storage Hopper | It is the bulk-sized hollow part that houses a large supply of collagen protein powders for an uninterpreted flow of operation. It supplies a gradual amount of protein powders to the filling devices. |

| Metering Device | The metering device is fixed on the top of the machine. It is a weight-measuring devices that dispense a precise amount of collagen protein powders from the hopper to the filling devices. |

| Motor | The motor part is crucial in powering up the machine. It is a transformative unit that converts the electric energy to mechanical energy and supplies it to other components. |

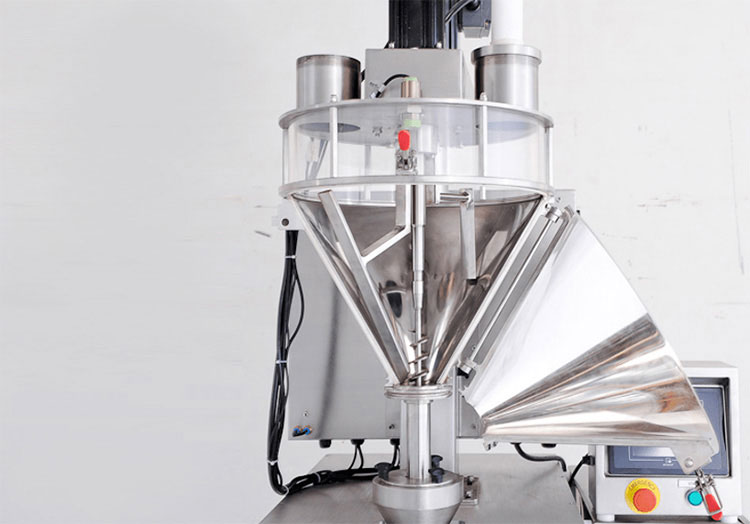

| Forming Part | It is a conical hollow tube located at the upper side of the collagen protein powder stick packing machine. it is essential in doubling and shaping the strips of packaging film into the stick packs. |

| Vertical Sealer | These are the sealers present at the side of the forming tube and join together two longitudinal seams of the packaging film. |

| Touch Screen | Different options regarding the machine's function are displayed on the touchscreen interface. It allows the users to easily supervise and adjust the machine functions. |

| Operating Button | It is also called the start button. This button is the main button that turns on the machine. |

| E-Stop Button | It is an emergency stop button. The users immediately press this button in case of machine failure. By pressing this button, the machine instantly shuts down. |

| Horizontal Sealing | It is the core sealing part of the machine due to its role in sealing the top and bottom edges of the packaging film. Horizontal sealing jaws along with vertical sealing jaws are responsible for airtight sealing of the collagen protein powder stick packing. |

| Cutting | It is integrated towards the lower end of the machine and has a role in separating two stick packs from each other. |

| Electricity Box | It is the core electric powerhouse of the machine because it contains different switches, breakers, relays, cables, and wires for powering up the equipment. |

| Stainless Steel Frame | It is the external body of the collagen protein powder stick packing machine and is made of hygienic stainless steel that is quite easy to clean. |

| Chute | It is an integrated component and finished stick packs are led to discharge in the chute |

| Caster | It is the round base that provides balance to the machine. It allows the machine to remain upright. |

5.What is the Working Mechanism of a Collagen Protein Powder Stick Packing Machine?

With just only a few steps, the working mechanism of the collagen protein powder stick packing machine is quick and efficient. The detail of the working mechanism is listed below:

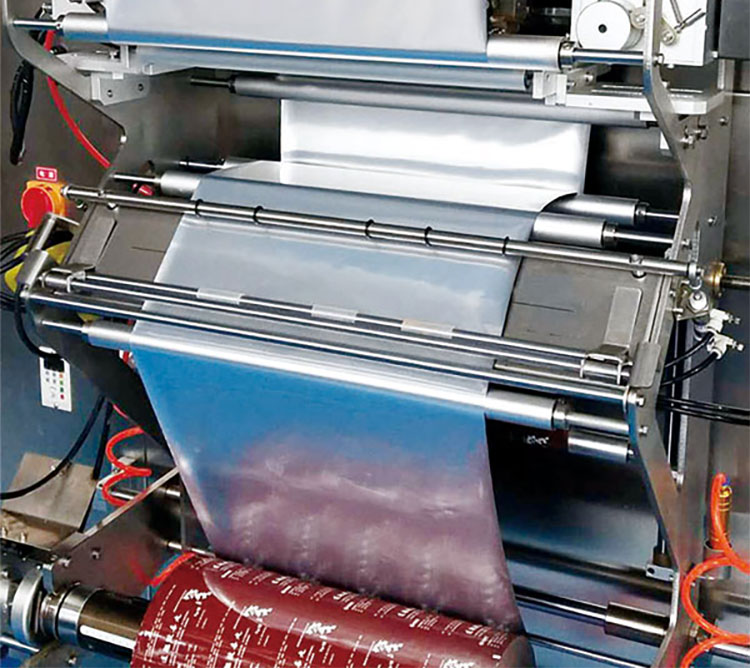

Film and Collagen Protein Powder Loading

Film Loading

Before turning on the machine, the operator put a heavy-duty packaging film roll over the unwinding disk. At the same time, bulk volumes of collagen protein powders are placed in the large-size hopper.

Machine Settings

Machine Settings

Different programming parameters are adjusted and set on the HMI interface of the machine. By the programming of HMI, different inputs like powder weight, stick pack length, and sealing temperature are assigned for faster processing. Afterwards, the machine is turned on.

With the power supply, the motor powers up different components of the machine like metering devices, film rollers, and vertical and horizontal sealing jaws.

Stick Pack Formation

Stick Pack Formation

After getting the energy from the motor, the unwinding rollers begin to rotate and by the constant movement of these rollers and film unwinds and travels towards the forming tube. Before reaching the forming tubes, integrated cuts strip the film into individual pieces. The number of these formed pieces is dependent upon the number of lanes.

Now each film strip reaches its respective conical shape forming tube. In this station, the film strips will be doubled and wrapped around hollow former and converted into stick packs by heated vertical and horizontal sealers.

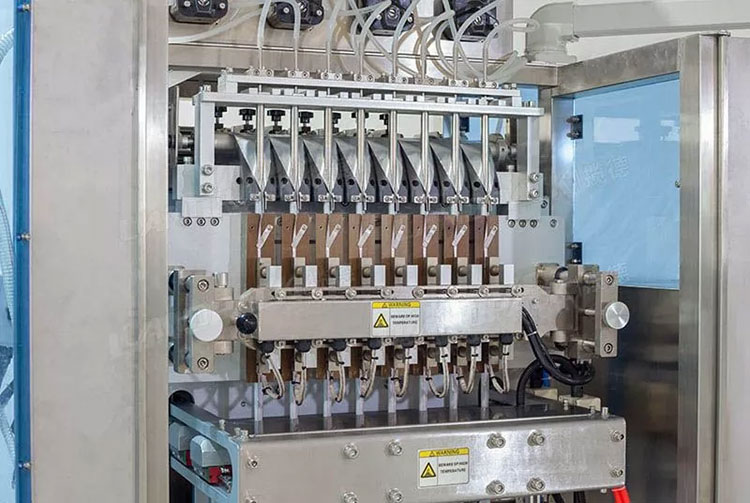

Filling

Filling

Upon stick pack formation, now it's time for stick pack filling with the collagen protein powder. For this job, this powder is initially measured through the metering devices. When the preprogrammed weight of collagen protein powder is measured then it is dispensed inside the stick packs.

Sealing and Cutting

Sealing and Cutting

After filling, the sealing step occurs at the sealing station. Here a pair of horizontal sealing jaws are applied to the top part of the collagen protein powder stick packs and these jaws forcefully seal the two ends. Later, the separation of stick packs is carried out by the sharp cutters. Next, finished stick packs are passed down the chute.

6.What are the Uses of a Collagen Protein Powder Stick Packing Machine?

The uses of a collagen powder stick packing machine are infinite because it is easily customized to fill different kinds of powders varying in flowability and particle size. However, we have highlighted some significant industrial sectors for your ease of understanding:

Protein Powder Industry

Application of Collagen Protein Powder Machine in Protein Powder Industry

There are many different kinds of protein powder present in the market nowadays. Each has a specific use due to its health benefits. These powders are packed in stick packs via a handy device called a collagen protein powder stick packing machine. It packs a wide range of protein powders like whey protein powder, casein protein powder, soy protein powder, and many more in the stick pack.

Medical and Nutritional Industry

Application of Collagen Protein Powder Machine in Medical and Nutritional Industry

Due to its flexibility and adaptability, collagen protein powder stick packing machine is used in the medical industry. This machine is tailored to make a stick pack, enclosing different medical and nutritional powders like supplement powders, electrolyte mixtures, mineral powders like calcium and magnesium, etc.

Food Industry

Application of Collagen Protein Powder Machine in the Food Industry

Since the collagen protein powder stick packing machine is efficient and advanced, it is routinely utilized in the food industry. It is utilized to pack sugar, salts, spices, milk powders, cocoas, vegetable powders, curry powders, herbs, etc in the individual-sized stick packing machine. Food stick packs are very popular nowadays.

Beverage Industry

Application of Collagen Protein Powder Machine in the Beverage Industry

Yes, collagen protein powder stick packing machine is also typically seen in the beverage industry for packaging different kinds of beverage powders like juice mixes, coffee powders, tea powders, energy booster powders, hydration powders, etc in beautiful stick packs. This machine has the latest technology and it speedily packs beverage powders.

Agriculture Industry

Application of Collagen Protein Powder Machine in the Agriculture Industry

The use of a collagen protein powder stick packing machine is not limited to the medical and nutrition sectors. Because this robust machine has found its application in the agriculture sector as well. It is utilized for packing small amounts of fertilizers, pesticides, insecticides, and organic manure in portion-control stick packs.

7.What is the Production Volume of a Collagen Protein Powder Stick Packing Machine?

Production Volume of Collagen Protein Powder Stick Packing Machine

The production volume of the collagen protein powder stick packing machine varies from model to model of the machine. Generally, it is dependent upon several factors such as:

| Number of Lanes | Different types of collagen protein powder stick packing machines have different numbers of lanes. These range from single lanes to multiple lanes (2, 4, 6, 8, 12). The higher the number of lanes higher the production volume of the machine. |

| Speed | It is measured in cycles per minute (CPM). It denotes how many forming, filling, and sealing steps are carried out in one minute. If the collagen protein powder stick packing machine has more CPM, it in turn leads to more production volume. |

| Product Nature | The density, particle size, and flowability of the product can affect the production volume. Production volume with free-flowing particles will be more than non-free-flowing powders. |

8.What is the Preventive Maintenance of Collagen Protein Powder Stick Packaging Machine?

Preventive Maintenance

Preventive maintenance is a kind of regular procedure passed out to prevent breakdowns in a machine. Its essential aim is to recognize and address minute flaws before they become greater problems.

Here are some maintenance tips:

| 1. Prevention Schedule For Collagen Protein Powder Stick Packaging Machines | The most significant step of effective packing machine maintenance is preventive maintenance, which gives a long life to the unit. As with a car, a packaging machine needs to be serviced in a regular and timely manner to maximize its output. Once the packing machine has been installed, it will be necessary to develop and carry out a preventative maintenance policy. The maintenance program tries to prevent both major and minor problems through the minimization of unplanned stoppage. |

| 2. Automation of Routine Tasks To boost efficiency | We suggest making packing machine maintenance assignments that include both complex assignments and simpler, routine tasks that workers conduct regularly. To accomplish the autonomous maintenance tasks, provide the operators with the packaging machine maintenance checklist and then assign them to complete certain tasks on a daily, weekly, monthly, quarterly, and biannual basis. |

| 3. Work with Responsive Packaging OEMs | Work with responsive OEM packaging companies for such scenarios. If a packaging machine fails, time is of the essence. Before the purchase of a packing machine, you should do a thorough investigation of an original equipment manufacturer (OEM) to find out about their technical support team, service accessibility, and spare parts inventory. Instead, it is beneficial to make purchases from a provider who offers multiple end-user services such as remote access and debugging for the most common problems. |

| 4. Learn your spare parts list | When you purchase a packaging machine, the OEM should provide you with a necessary spare parts list. This list should be sorted into groups depending on machine wear, from high to low so that you can plan inventory accordingly for high, medium, and low wear parts. It is generally recommended to keep high-wear components on hand to lessen the possibility of having to wait for a delivery to arrive during production's highest periods. |

| 5. Plan for Repairs and Obsolescence | Naturally, packing equipment and software will require adjustments. Some may just become obsolete as technology develops. Maintain an ongoing connection with the collagen protein powder stick packaging machine manufacturer to learn about any upgrades or recommendations that will help you stay on track and ahead of the curve. |

9.How Can You Troubleshoot Collagen Protein Powder Stick Packing Machine?

When we talk about the collagen protein powder stick packaging machines that are used in the pharmaceutical industry due to the high automation and efficiency of the process. This machine operates on the principle of combining different components and processes to obtain the smallest packages. Despite that these systems are mostly dependable and simple to operate, they may develop some problems which need troubleshooting. These problems and their solutions could be:

| Problems Due To | Solutions | |

| Power Supply |

Power Supply |

Make sure the equipment is getting an adequate power source |

| Material Supply |

Material Supply |

Make sure that there is enough collagen protein powder for the packaging.

Inspect the hopper or feeder for clogs or inhomogeneity in the material flow. |

| Soiled/ Unclean Machine Component |

Unclean Machine Components |

To avoid machine improper functionality, it should be ensured that all the components such as the hopper, feeding tubes, sealing bars, and sensors are clean. |

| Sensor Problem |

Sensor Problems |

The calibration of the sensor must be up to date. |

| Worn-out Belt |

Worn-out Belts |

In the case of worn belts, they should be replaced immediately to eliminate operational problems and let the packaging processes flow smoothly.

Adjusting at regular intervals belt condition and tension can aid in preventing early wear and prolonging the maintenance time. |

| Machine Setting |

Machine Setting |

Regularly examining the machine's settings such as temperature, speed, and sealing pressure must be used to avoid maintenance problems.

Adjust the machine settings according to the manufacturer's recommendation on the collagen protein powder stick packing machine. |

10.How to Buy Best Collagen Protein Powder Stick Packing Machine?

When it comes to making a critical decision for your firm, a variety of challenges occur, one of which is selecting the best collagen protein powder stick packaging machine. Does it feel relatable? So, why not go with some simple factors? Let's mark the important ones!

Speed

Speed of Collagen Protein Powder Stick Packing Machine

When choosing a protein powder stick packing machine, inquire about the equipment's speed to meet set production targets. It will help you determine both the machine's speed and your productivity level.

Filling system

Auger Filler

Another key aspect is the sort of filling system offered by the machine. For example, is it an auger or volumetric cup or screw filler? Is it suitable for your current powder nature? Answering these questions will undoubtedly benefit you

Customization

Customization of Collagen Protein Powder Stick Packs

People no longer associate themselves with the same old things. The emerging styles are separate, with new and unique design packages that catch the eye differently. So, try the machine's modification and adaptability to manufacture a variety of stick packs.

Cost

Costs

When you are on the brink of revolutionizing your packaging mode, it is always suitable to pay attention to the expenditure, this purchase will cause in both the short and long term. It simply means to estimate the collective cost of the machine which will include the original price of a machine, the cost of packaging material, installation, and parts changeover etc.

Conclusion

This buying guide about the collagen protein powder stick packing machine aims to examine the importance of this machine in the modern world of economics and technology. By adding this machine to your productions, you can bring positive changes to your businesses and add value to your production. Before adding this machine to production, first consult machinery experts like Allpack because we are committed to providing valuable machines and services, So, do not forget to contact our customer care. Happy Shopping!!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide