Coffee Pouch Machine: The Complete FAQ Guide In 2025

Coffee Pouch Machine: The Complete FAQ Guide In 2025

Coffee has now become a very popular drink that can be seen everywhere in people's lives. In addition to the irresistible taste of coffee itself, the packaging of coffee is also very important. Have you ever known what machines are currently on the market that can be used to pack coffee in pouches? Do you know the different features and functions of these coffee pouch machines? Do you know how to choose a suitable coffee pouch machine according to your needs?

This coffee pouch machine FAQ guide can explain to you the construction and features of different coffee pouch machine, as well as other frequently asked questions. Hope you will keep reading!

1. What Is A Coffee Pouch Machine?

Coffee Pouch Machine -photo credits: xhteapack

The coffee pouch machine refers to machines that can automatically fill and pack the coffee into different pouches. The coffee includes coffee beans, coffee granules, and coffee powders. The coffee pouch machines have now become an important part of the coffee packaging industry.

In addition to the bag packaging that can provide you with coffee. The coffee pouch machine can also provide multi-functional packaging solutions for various products. From food to personal care products, pharmaceuticals, etc., coffee pouch machines can provide you with a variety of packaging solutions.

2. What Are The Applications Of The Coffee Pouch Machine?

Coffee pouch machines can be widely used in various industries with the multifunctional design:

Food and Beverage

Coffee pouch machines are extensively used in the food and beverage industry for packaging products such as coffee, tea, snacks, nuts, chips, biscuits, bread, water, juice, etc. It can be applied to solid packaging as well as liquid packaging.

Pharmaceuticals

Coffee pouch machines are applied in the pharmaceutical industry for packaging products such as capsules, tablets, protein powders, supplements, and nutrients.

Personal Care

Coffee pouch machines are used in the personal care industry for packaging products such as shampoo, lotions, creams, sanitizers, conditioners, makeup, detergents, hand soap, etc.

Pet Food

Coffee pouch machines can also be used in the pet food industry for packaging products such as cat litter, pet biscuits, pet meats, pet teething sticks, etc.

Agriculture

Coffee pouch machines can be used in agriculture for packaging products such as plant fertilizer, seeds, insecticide, ripening agent, etc.

Electronics

Coffee pouch machines can be widely applied in the electronics industry for packaging products such as headsets, chargers, phone cards, charging cables, mice, etc.

3. What Are Mostly Packed By The Coffee Pouch Machine?

A coffee pouch machine is mainly used to package coffee and coffee peripheral products. At the same time, coffee pouch machine is also widely used in the packaging of other products:

Coffee

The coffee here refers to coffee beans, coffee granules and coffee powders. They are all suitable for filling and packed in pouches with different shapes and sizes. The pouch packaging of coffee beans and coffee granules can preserve the freshness of coffee to a greater extent. Generally, coffee powder is more suitable for sachet and stick-pack packaging.

Nuts

Nuts, like coffee beans, are granular products. They are all suitable for pouch packaging. Especially the packaging of premade and stand-up pouches. This is beneficial for users to take and store at any time.

Pills And Tablets

In addition to blister board and aluminum-plastic packaging, capsules and tablets can also be applied in the pouch packaging with the coffee pouch machine. Its advantage is that it can provide you with all the capsules, tablets, supplements and nutritional supplements you need for a day or a week at one time.

Shampoo

The shampoo pouch packages are more environmentally friendly and portable. When you are traveling, it is easier to store the shampoo in the pouch than the shampoo in the bottle.

Pet Biscuits

Pet foods including the biscuits are easy to be packed with the coffee pouch machine with high capacity and high efficiency.

Seeds

Seeds can be filled and packed into pouches with the coffee pouch machine for higher speed and high accuracy.

4. What Are The Bag Styles And Packaging Materials For The Coffee Pouch Machine?

The Bag Styles For The Coffee Pouch Machine:

Pillow Pouches

The pillow pouches, also called back-sealed pouches, are the most common bag styles for flexible packaging. The pillow pouches formed and filled like a pillow. This bag style can be applied to most packaging machines.

Gusset Pouches

The gusseted pouches are the best options for the standup pouches. By opening the two gussets at the bottom of the bag, it can add more space to the bag and save you more packing materials.

Flat Bottom Pouches

Flat bottom pouches, also called standup pouches, are five-sided sealed and can do free-standing with a rectangular base. It is suitable for most of food and snack packaging with kraft paper, aluminum, or LDPE materials.

Spout Pouches

The spout pouches can be customizable and versatile and designed with your needs. The spout pouches are flat-bottom designed with the spout on top of the pouch for easy sucking or pouring. It is suitable for liquid, and paste packaging.

Valve Pouch

The valve pouch is specially designed for packaging the coffee beans that are applied with a degassing valve on the top of the bags. The main function of the degassing valve is to help the coffee packages maintain their shape by allowing the gases to escape.

Bag-In-Bag Pouches

The bag-in-bag pouches refer to the coffee drinks or coffee powders in the stick packs or sachets and then packed into the bigger pouches. This packaging bag style can facilitate consumers' consumption and storage.

Packaging Materials For The Coffee Pouch Machine:

Kraft Paper

The kraft paper is a porous kraft paper with high elasticity and high tear resistance. It is often used in food packaging. This packaging material brings good qualities of strength and durability to coffee beans.

Plastic Films

Plastic films are widely used in the packaging of items in various industries. It is thin, durable, healthy, and safe. It can bring good closure and security to the packaging of coffee. This kind of packaging can preserve the freshness of coffee very well.

Aluminum Foil

The aluminum foil is very flexible and can wrap items easily. This material is strong. Durable and insulated. It can bring the supreme packaging experience to the packaging of coffee. At the same time, the disadvantage of this packaging method is that the cost will be slightly higher.

5. What Are The Benefits Of Using The Coffee Pouch Machine?

If you are a coffee producer, what benefits do you need from your coffee pouch machine?

Benefits Of Using The Coffee Pouch Machine:

Packaging Waste Reduced

Before using the coffee pouch machine, you may need to manually weigh, pack, pack, seal the coffee, etc. This series of manual operations has many uncertain factors and will cause a lot of waste of materials. Through the automatic weighing, filling, packaging, sealing, etc. of the coffee pouch machine, you can precisely control every process.

Coffee Protection And Freshness

Different coffees have different characteristics and flavors. In order to maintain the unique freshness and flavor of coffee, some coffee pouches will be flushed with nitrogen during the packaging process. And coffee pouch machine can provide you with good airtight sealing to keep them from getting wet.

Packaging Efficiency

By using a fully automatic coffee pouch machine, there is no need for workers to intervene in the entire packaging process except for opening, supervision, and later maintenance which can greatly improve your efficiency and bring you greater economic benefits.

Versatility

In addition to the functions of weighing, filling, packaging, and sealing, some coffee pouch machines can provide you with the functions of counting, printing, reporting errors, automatic maintenance, and cleaning. This is very convenient for your use.

6. What Are The Types Of Coffee Pouch Machines?

There are many kinds of coffee pouch machines, and we will just briefly introduce all the types. If you want to know the differences and details between various machines, you can refer to our website:

VFFS Coffee Pouch Machines

VFFS Coffee Pouch Machines -photo credits: bojupacking

VFFS coffee pouch machines refer to the vertical form fill seal coffee pouch machines. It is characterized by the vertical design of the machine, and the entire coffee-filling process is from top to bottom. VFFS coffee pouch machines are mainly used in the packaging of free-flowing products, including cereals, powders, and liquids.

HFFS Coffee Pouch Machines

HFFS coffee pouch machines refer to the horizontal form fill seal coffee pouch machines that can complete the whole coffee packaging process horizontally. Its advantage is that this horizontal packaging design can better facilitate the bag-making direction and product handling. HFFS coffee pouch machines are able to handle various irregular shapes or larger products.

Doypack Coffee Pouch Machines

The doypack coffee pouch machines can automatically complete the whole process of pouch stand-up, doypack bag forming, material filling, sealing, date printing, etc. Designed with the advanced photoelectric sensor tracking system and servo motor puller, all machines here can ensure the precise bag width and position of film.

Horizontal Premade Coffee Pouch Machines

The horizontal premade coffee pouch machines are specially designed to fill and seal premade pouches with different materials, especially coffee beans. All the premade coffee pouch machines are fully automatically controlled and operated with high efficiency and capacity.

Weighing Coffee Pouch Machines

The weighing coffee pouch machines utilize a variety of weight-sensing mechanisms to accurately weigh the coffee beans with high accuracy and package them into pouches. They are suitable for weighing and packing granules or irregular shape products.

Rotary Coffee Pouch Machines

Rotary Coffee Pouch Machine -photo credits: smartweighpack

The rotary coffee pouch machines are specially designed for filling the coffee into the premade pouches. It can meet the requirements of different enterprises for different pouch sizes. The rotary coffee pouch machines are the perfect packaging solution for coffee-premade pouches.

7. What Are The Working Principles Of Coffee Pouch Machines?

Different models of coffee pouch machines work differently:

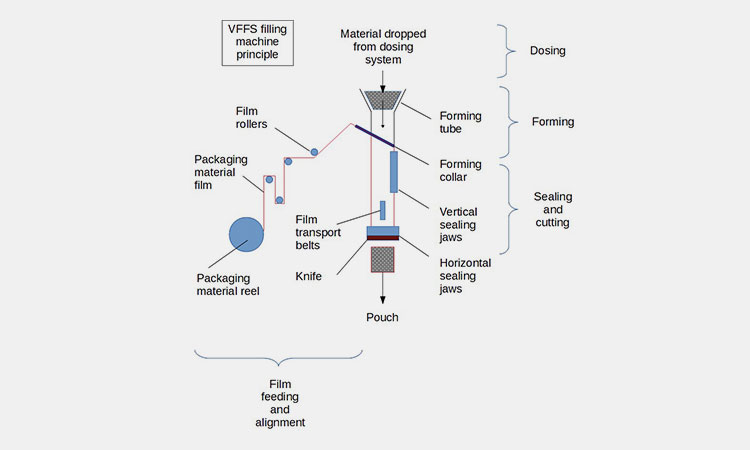

Working Principle of VFFS Coffee Pouch Machines

After the coffee beans have been uploaded into the feeding hopper and dropped from the dosing system, the films will be automatically fed in a flat and rolled forming like a tube. After being back-sealed with the vertical sealing jaws, the coffee beans will be filled into the pouches. Once the coffee beans are filled into the back-sealed pouch according to the set parameters, the pouch will be end-seal by the horizontal sealing jaws and discharged.

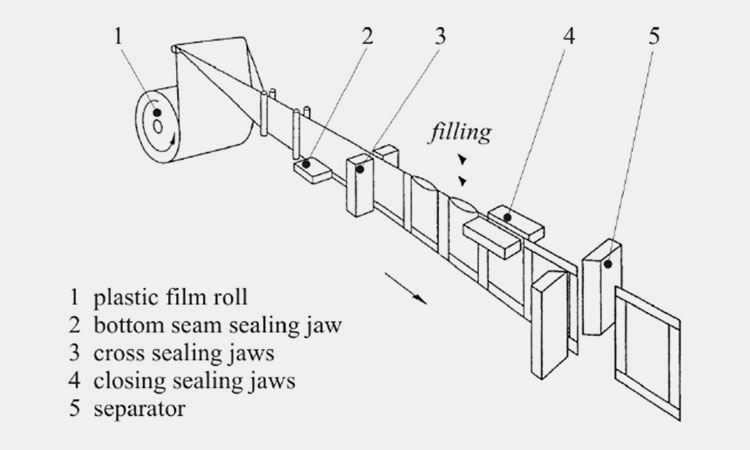

Working Principle of HFFS Coffee Pouch Machines

Working Principle of HFFS packaging machine -photo credits: researchgate

The wrapping films will be stretched horizontally from the plastic film roll and then pulled together to form a tube shape. After being sealed by the bottom seam sealing jaw, the pouch will be filled with the coffee beans with the set amount in advance. Once the pouch is full then it will be sealed by the closing sealing jaws. The separator will cut the pouches one by one and be discharged.

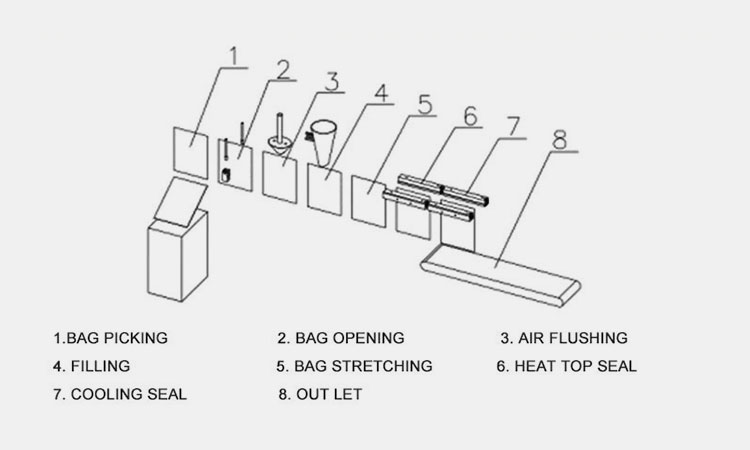

Working Principle of Doypack Coffee Pouch Machines

Working Principle of Doypack Coffee Pouch Machines -photo credits: grepack

After the bags have been picked, they will be opened immediately and flushed with air or nitrogen as required. Once the pouches have been flushed, the coffee beans will be dropped and filled into the pouches in the required amounts. Once filled up, the pouches will be stretched up and top-sealed by the heat. After being cooling-sealed, the pouches will be discharged.

Working Principle of Premade Coffee Pouch Machines

Horizontal Premade Coffee Pouch Machines -photo credits: grepack

After bags have been picked by the grip, they will be opened and flushed with the nitrogen. The coffee beans will be filled into the pouches with the bag stretching system. The heat top seal will be applied. After being cooled by the cooling seal, the finished pouches will be discharged.

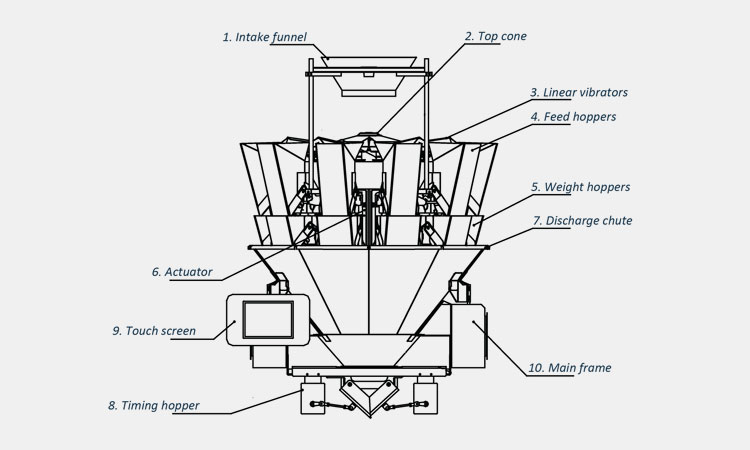

Working Principle of Weighing Coffee Pouch Machines

Working Principle of Weighing Coffee Pouch Machines -photo credits: yamatoscale

Uploading the coffee beans into the intake funnel. The coffee beans will be transferred into the linear vibrators. After being dropped from the feed hoppers, the coffee beans will be weighed by the weight hoppers. There are actuators inside the weight hoppers. When the coffee beans are weighed according to the set parameters, they will automatically be dropped into the packaging system below. The packaging system packs and heat-seals the coffee in the same grams.

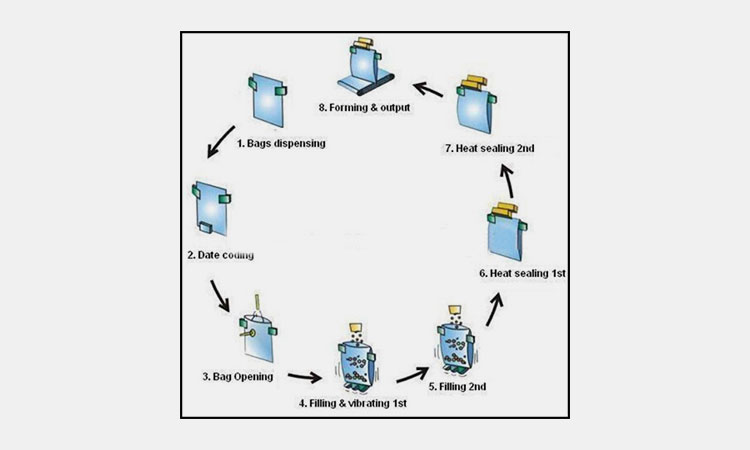

Working Principle of Rotary Coffee Pouch Machines

Working Principle of Rotary Coffee Pouch Machines -photo credits: fenbopackaging

The rotary coffee pouch machine is equipped with a fixed number of grips in a rotary round. After the pouches have been uploaded into the magazine, the data coding will print the data. After that, the grip will open it one by one, and coffee beans will be filled into the pouches two times. Once the pouches are filled with the set amount, the pouches will be sealed and discharged.

8. What Are The Main Components In The Coffee Pouch Machine?

Main Components In The Coffee Pouch Machine -photo credits: afpakmachine

There are five main parts in the coffee pouch machine:

Z Type Coffee Beans Feed Tunnel

The Z-type coffee beans feed tunnel, also called as Z model lifter feeding machine, is specially designed for loading the coffee beans into the head weighers. The feeding machine uses a hopper to load materials to avoid scattering and polluting.

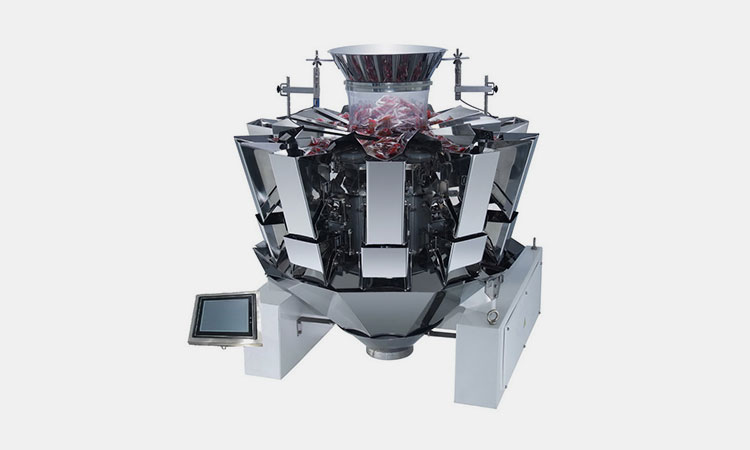

10 Heads Weigher For Coffee Beans

The head weighers are equipped with a vibrating plate and the weighing sensor for the coffee beans evenly weighed and dispensed. After coffee beans have been distributed from the heads and weighed evenly, they will be loaded into the vertical packaging machine below.

Platform To Load Weigher

The platform to load the weigher is a flat bracket to hold the head weighers and connect the head weighers with the vertical packaging machines below. It is equipped with handrail stairs for labors to check and inspect the machine's working process easily.

Four-side Sealing Pouch Forming and Sealing Machine

The four-side sealing pouch forming and sealing machine, also called a vertical packaging machine or vertical form fill seal machine, is applied for packaging the coffee beans in the pouches. After the coffee beans have been distributed from the head weigher, the films will be formed into a pouch. The pouch will be sealed and printed after being filled with the coffee beans.

Finished Products Output Conveyor

All the filled and sealed coffee bean pouches will be discharged into the output conveyor. The finished product's output conveyor can be connected with the lines or the carton machine.

9. What Are The Related Machine In Different Coffee Pouch Machines?

There are some optional devices that can be applied for improving your packaging efficiency and speed:

Multi-heads Weigher

The multi-head weigher is suitable for working with the VFFS coffee pouch machines for coffee bean weighing and distributing. It is a material dosing and auxiliary device. You do not need to equip this machine if you are using a counting device instead of a weighing device.

Linear Weigher

Linear Weigher -photo credits: technopackcorp

The linear weigher is also a material dosing device that measures and dispenses products with great accuracy and speed. It is capable of weighing and dispensing a wide variety of product types. Designed with a four-head weighing system, it is suitable for quicker filling times.

Z Type Feeding Machine

Z Type Feeding Machine -photo credits: conveyorproducer

It is a Z-type elevator feeding machine that conveys the coffee beans into the feeding hopper automatically. It is an optional device that can speed up your packaging speed.

10. Coffee Pouch Machine VS Coffee Stick Packing Machine

Coffee pouch machine refers to machines that fill and pack coffee beans, coffee granules, or coffee powders into different pouches.

Coffee stick-packing machines refer to the machines that fill and pack coffee powders into stick packs.

Bag Styles

The coffee pouch machines mainly use pouch styles including quad pouch, flat pouch, gusset pouch, valve pouch, etc. The pouch design is to be able to pack more materials, saving space and reducing costs.

The coffee stick packing machines mainly use stick packs for coffee powder packaging. The stick pack design is to avoid the waste of materials and make it more convenient for consumers to drink.

Machine Design

The coffee pouch machines include many different kinds of machines, which includes VFFS coffee pouch machines, HFFS coffee pouch machines, doypack coffee pouch machines, horizontal premade coffee pouch machines, weighing coffee pouch machines, rotary coffee pouch machines, etc.

The coffee stick-packing machines mainly include one type, which is the stick-packing machine.

11. Coffee Pouch Machine VS Coffee Sachet Machine

The coffee sachet machines refer to the machine that fills and pack the coffee powders into the sachets. In addition to packaging coffee powder, this machine can also fill all powder and liquid materials. It is widely used in various industries, including food, chemical, pharmaceutical, agricultural, and so on.

Bag Styles

The coffee pouch machines mainly use pouch styles including quad pouch, flat pouch, gusset pouch, valve pouch, etc. The pouch design is to be able to pack more materials, saving space and reducing costs.

The coffee sachet machines mainly use the sachet styles for filling and packing coffee powders. The sachet design can reduce material waste, and improve the utilization of packaging materials such as films.

Coffee Sachet Machine Design

The coffee sachet machines include the horizontal type and the vertical type. The horizontal type is more efficient and energy-saving with four-side sealing. The vertical type is more convenient for you to control and inspect.

12. How Does Coffee Pouch Machine Work To Keep The Freshness Of The Coffee Beans?

One of the important tips to keep the freshness of the coffee beans during the packaging process is to keep the residual oxygen level low. All coffee beans are sterilized and roasted before packaging. When the roasted coffee beans are in the package, if the oxygen content in the bag is reduced, the freshness of the coffee beans will be greatly improved.

How To Reduce The Oxygen Level Low In The Pouches?

After research, the most effective way to maintain the freshness of coffee beans is to use modified atmospheric packaging or nitrogen gas flushing. This packaging method mainly replaces the remaining oxygen by filling the belt with a sufficient amount of nitrogen during the packaging process of coffee beans.

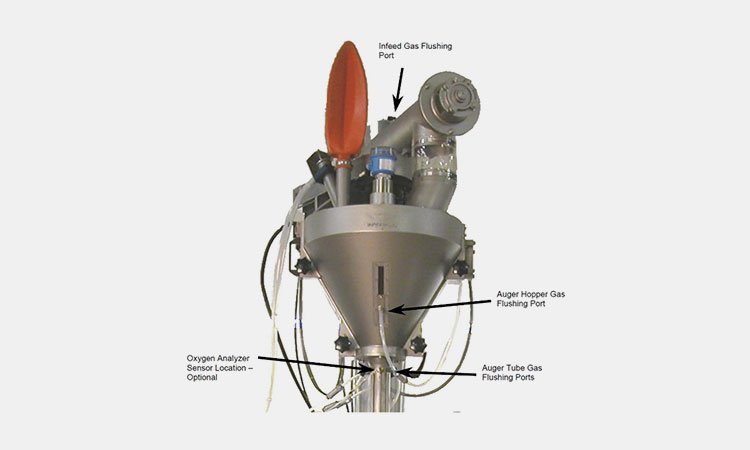

What Is The Nitrogen Gas Flushing System For The Coffee Pouch Machine?

Nitrogen Gas Flushing System -photo credits: rovema

The nitrogen gas flushing system can be widely applied in horizontal and vertical coffee pouch machines. It is an optional device that can be set above the feeding hopper. The nitrogen gas flushing system features inlet and control valves to flush nitrogen into the screw hopper, forming tube, and optional horizontal cross-feeder.

13. How To Choose The Best Coffee Pouch Machine For Your Business?

If you are a coffee producer and are looking for the right coffee pouch machines for your business, the following points are very helpful for you:

Coffee Powder Or Coffee Beans

Some machines can only be used for powder filling, and some machines can be used for both powder filling and granule filling. You need to consider clearly whether you need to fill powder products or granular products according to your product positioning.

Space

The size and footprint of the machine should also be taken into consideration. Some multifunctional machines are designed to be very large, so they occupy a large area. Vertical machines have a smaller footprint than horizontally designed machines. But horizontal machines work more efficiently.

Machine Manufacturer Reputation

A reputable machine manufacturer, then their machine quality will be high. In the process of choosing a machine, it is also a matter of choosing a good after-sales service and partner. If you choose a high-quality partner, your machine will be used more smoothly.

Conclusion:

By fully understanding the details of all aspects of coffee pouch machines, you may have a general understanding of this machine. However, the design and application of machines is a complex and practical problem. If you have more questions, welcome to consult our customer service or browse our website: https://www.allpackchina.com/. Thanks for reading!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply to you ASAP within 24 hours

Coffee Pouch Machine: The Complete FAQ Guide In 2025 Read More »