Coffee Packaging Machine: The Complete Buying Guide In 2025

A cup of coffee is the daily wake-me-up of almost 1 billion people around the world. This coffee must undergo the farming, harvesting, washing, roasting, and ultimately packaging stage. However, coffee packaging is the most significant activity, which if not practiced responsibly, can ruin the hard work. This is a conundrum most of the manufacturers are grappling with. But solution is simple- a Coffee Packaging Machine!

Coffee Packaging Machine is an equipment that help you get through the difficult phase of coffee packaging. You may have question sounding how! Then let us introduce you with this buying guide which is broad enough to cover the coffee packaging machine from every angle including its benefits, types, applications and beyond. So, just start reading and go through it!

1.Define Coffee Packaging Machine?

High-speed coffee drip bag packing machine- Allpack

Coffee packaging machine is an advanced intelligent equipment employed to pack different types of coffee powder, granules, and drinks in packages. These packages are durable enough to protect the coffee from harsh external environment and adds into its longevity and retaining freshness.

2.What Are The Advantages Of A Coffee Packaging Machine?

Coffee packaging machine is beneficial for your coffee preservation as well as your business. It can astonishingly generate profitable revenue for your industry due to effective and efficient packaging. Let’s explore few more!

Production Efficiency

Coffee stick packaging presentation idea- Picture Courtesy: Behance

Production efficiency is what associated with coffee packaging machine. It is tailored with ultrafast technology and its automatic components such as film guiding, forming, and material weighing greatly contribute to reach to the highest possible production target.

Safety Compliant

Having been made from corrosion resistant stainless steel with anti-bacterial properties, coffee packaging machine is complying GMPs regulations. Hence, your coffee will be processed in entirely hygienic and safe environment leading to an increased recognition around the globe.

Marketing

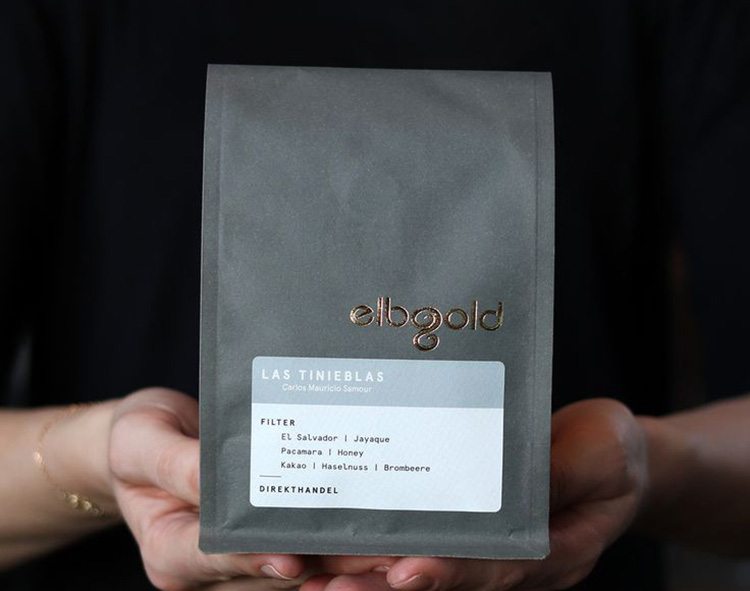

Woman holding branded coffee bag in hands- Picture Courtesy: elbgoldshop.com

After all it is the packaging that represents your brand and coffee in your absence. That's why, coffee packaging machine is now one-step solution to provide your customers errorless and perfectly packed coffee packages.

Promote Handling Convenience

Consumer handling coffee beans pouch- Picture Courtesy: coffeeshopstartups.com

Coffee packaging machine is a means to promote handling convenience. For instance, you can use it for employing different seals as well as single-serving coffee, twin bag packaging, or bulk coffee delivering.

Quality Retention

Coffee quality retention idea- Picture Courtesy: Behance

Packaging reduces the coffee waste caused by spoilage, leakage, and quality degradation. In this way, a coffee packaging machine can provide perfect sealing to retain the freshness, taste, and aroma of coffee throughout its shelf life.

3.Enumerate The Various Types Of Coffee To Be Packed By A Coffee Packaging Machine?

Coffee is available in distinct forms depending upon their processing such as coffee beans, instant coffee, and coffee drinks. These all can be precisely packed by a coffee packaging machine. Below is the concise description of these all:

Coffee Beans

Coffee beans in spoon- Picture Courtesy: mewe.com

Coffee beans refer to the unprocessed coffee which only undergo washing and roasting step before its packaging. Therefore, coffee beans are frequently packed in large bags and containers through coffee packaging machine.

Instant Coffee

Woman pouring instant coffee in cup- Picture Courtesy: Imbibe

Instant coffee can be defined as processed coffee extract obtained from coffee beans to facilitate quick preparation. This already brewed coffee powder can be simply add into hot water or milk for consumption. Hence, you will often find instant coffee in small stick packs or bottles.

Coffee Drink

Coffee drinks containers- Picture Courtesy: hejstudio.at

All types of hot, iced, and cold coffee come under the category of coffee drinks. They are already made with various liquids especially milk to provide users with ready to drink coffee. Ergo, packaging adopted for coffee drinks is different from that of other types of coffee and done by liquid coffee packaging machine.

4.What Packaging Styles Can Be Processed By A Coffee Packaging Machine?

You will find plethora of packaging styles and formats available for coffee packaging. Moreover, each of them can be securely packed while using relevant coffee packaging machine. Underlying packaging formats are popularly processed by coffee packaging machine:

Bottles

Coffee glass bottle presentation idea- Picture Courtesy: Behance

Bottles are commonly used packaging containers for storing all types of coffee including powdered coffee, coffee beans, and coffee drinks. They are easy to open with a cap and best suitable for coffee till last dosage as bottles can be tightly capped after multiple times opening.

Cans

Various coffee cans- Picture Courtesy: wanabeverage.com

Cans are metal based packages made from tin, steel, or aluminum. Mostly, iced coffee, cold coffee, and other types of liquid coffee are delivered in cans, however, cans with lids may be used for solid coffee as well. Using cans for coffee packaging will greatly assist in preventing access of moisture, light, and oxygen to inside material.

Cups

Coffee cups- Picture Courtesy: Behance

For packaging liquid and creamy coffee, plastic or paper cups may be used. These cups are durable, handy, and promote convenient coffee drinking via straw. Hence, you will find cups as mostly used in restaurants and markets where coffee packaging machine is employed to undertake the task.

Bag-in-Box

Consumer filling glass from coffee bag-in-box- Picture Courtesy: foodbev.com

Bag-in-box is an innovative packaging style where a strong plastic bag is used to hold the coffee and seated in a corrugated box. The plastic bag has a fitment through which coffee can be dispensed into a glass or cup. Hence, bag-in-box is ideal for making large volume of prepared coffee accessible to consumers.

Sacks

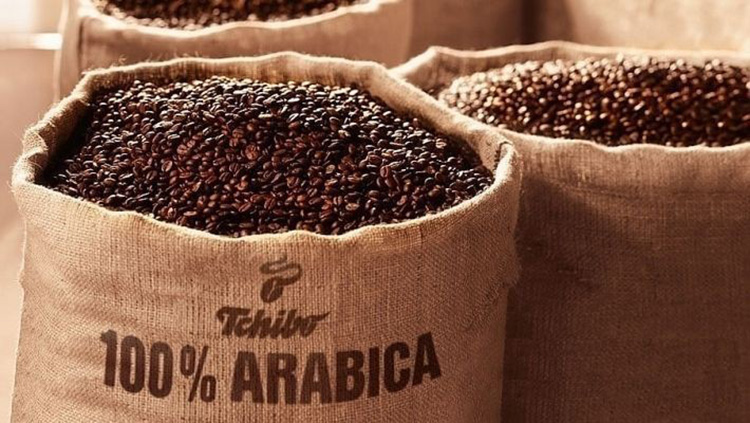

Coffee filled sacks

Sacks are large bags made from burlap or thick plastic which are meant for storing and shipping bulk materials. Likewise, unprocessed coffee beans can be packed in sacks while using coffee packaging machine.

Gusseted Bags

Gusseted coffee beans bag- Picture Courtesy: Nusantara Kopi

Gusseted bags are counted as the form of flexible packaging which are made from paper, plastic, and aluminum, or mixture of these materials. Due to the additional gusset added to the bag sides and sometimes bottom, gusseted bags provide more space for holding bulk coffee beans as well as powder.

Standup Pouch

Standup coffee pouch display- Picture Courtesy: mockupden.com

Standup pouch, doypack, or retort pouch are the names of similar packaging bags having the ability to stand up-right. Such type of pouches are desirable for preserving both solid coffee and coffee drinks with different sealing of zippers and spouts respectively.

Stick Packs

Multiple coffee stick packs- Picture Courtesy: My Coffee Stix

Stick packs are characterized by their small, narrow, and long body which perfectly holds the single serving of coffee blend. Hence, coffee packaging machine can be employed to pack the consumers' everyday need of coffee in stick packs for handling convenience.

Sachets

Coffee sachet with cup- Picture Courtesy: Behance

Another kind of coffee bag which a coffee packaging machine is capable of processing is sachet. Similar to stick packs, sachets are too useful for single coffee serving, but its shape is square, and the size may slightly differ.

Pillow Bags

Coffee pillow bag

Pillow bags are the common packages processed by a coffee packaging machine. They are made from cheap plastic, thus, reducing packaging cost as well as ensuring high protection to coffee against microorganisms and humidity.

Drip Coffee Bag

Consumer filling water in coffee drip bag- Picture Courtesy: feindcoffe.com

Drip coffee bag is a sort of filter bag in which ground coffee is filled to let the coffee lovers enjoy it anytime. This bag is made from mostly cloth, paper, or porcelain and is placed in Nitrogen gas filled sachet to maintain the freshness of coffee.

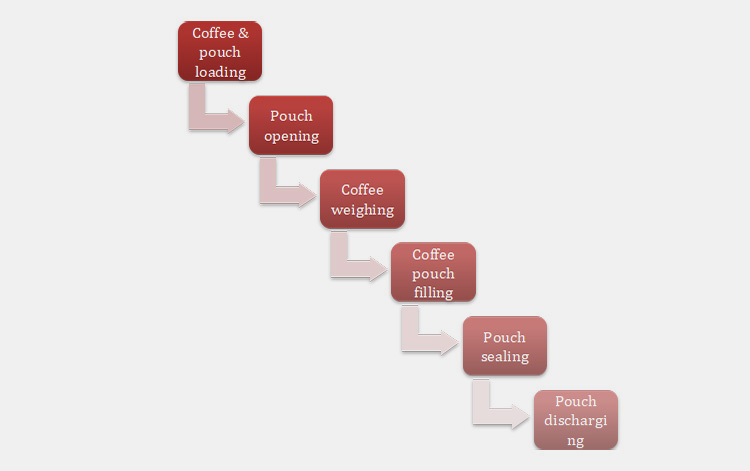

5.Explain The Working Principles Of A Coffee Packaging Machine?

It is important to know the working procedure of coffee packaging machine before bringing it into operation. However, it must be noted that each type of coffee packaging machine has distinct working principles which you will know in next question. Below will be discussed the principles of premade pouch filling machine:

Coffee & Pouch Loading

Bulk coffee powder- Picture Courtesy: Destination Bio

The first step will require the operator to load machine hopper with bulk quantity. Along with that, supply bag magazine with premade empty pouches. At this stage, operator will set basic parameters in machine such as the volume of coffee to be filled in each pouch, temperature of sealing jaws, and coding instructions.

Pouch Opening

Pouch opening- Picture Courtesy: JDA Progress

When the machine is started, a robotic arm will grab empty pouch from magazine and open it with the help of clamps. At this point, nitrogen flushing can be done to eliminate the presence of oxygen, however, this step is optional.

Coffee Weighing

Coffee Weighing in machine

Third and most crucial step is the weighing of coffee powder. Here, the powder will undergo multiple vibratory stages in order to make uniform dosage. Moreover, auger filler and vibratory filling mechanism may be used for accurate measuring depending upon the coffee flow.

Coffee Pouch Filling

Coffee Pouch Filling- Picture Courtesy: JDA Progress

Once coffee is collected in a bin attached to the vibratory weighing chamber, the coffee will fall into an opened pouch.

Pouch Sealing

Pouch Sealing- Picture Courtesy: JDA Progress

Upon coffee filling into pouch, the pouch will get sealed with the help of heated sealing jaws. However, in case of zipper sealing, only the pressing of opposite sides will create stringent sealing. At this point, coding over pouch takes place which includes the manufacturing and expiration date and batch no.

Pouch Discharging

Finished pouch discharging- Picture Courtesy: JDA Progress

In the last step, coffee filled and sealed pouches are being fallen by the main machine over conveyor which takes the pouches to collection container for further packaging.

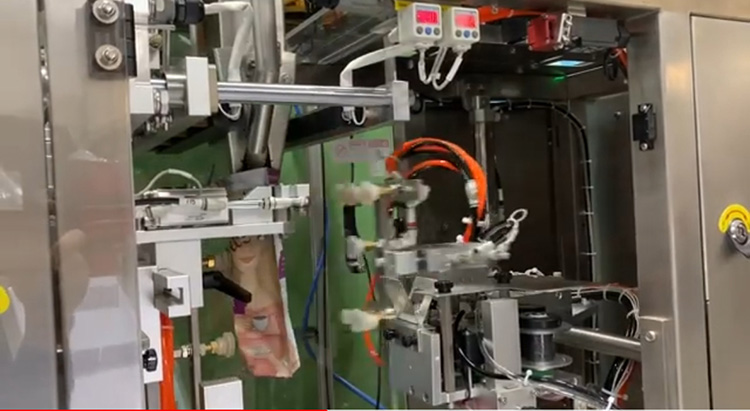

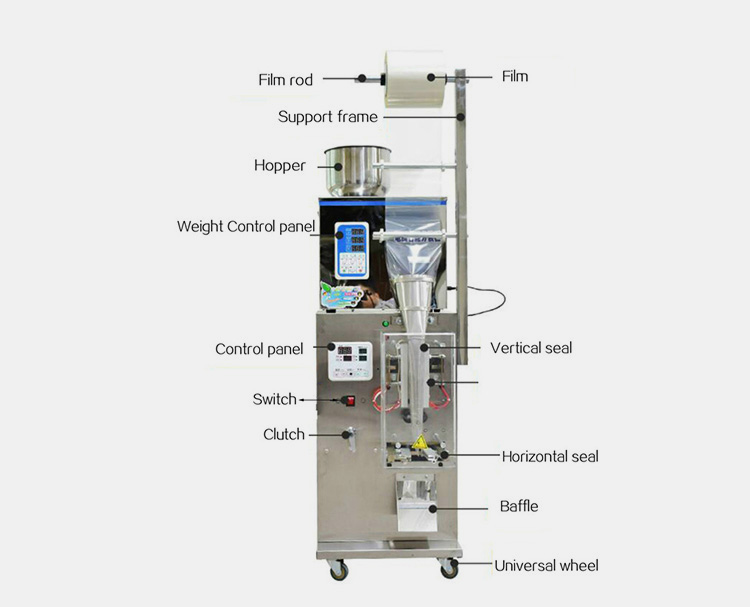

6.Describe The Basic Components Of A Coffee Packaging Machine?

Coffee packaging machine is the assembly of small to large components which collectively enable the machine to perform efficiently. Let's know what are these:

Components of tea/ coffee packaging machine

Hopper

Hopper is the conical shaped circular container that is used to store the coffee for supporting the continuity of machine. It is located at the top of machine having narrow outlet that is attached to weighing mechanism.

Film rod

Film rod is referred to the stand wheel around which film roll is placed for providing film in order to form bags and pouches.

Film

Film is generally used to describe the thin layer of plastic or aluminum. Hence, it is placed into machine in the form of a roll.

Support Frame

Support frame is a stainless steel rod that is attached to the main machine and having at the top of it a film rod for dispensing film.

Weight Control Panel

It is an intelligent control display located at the front of machine which enable user to communicate it the commands regarding scaling of coffee.

Vertical Seal

Vertical seal is simply sealing jaws that stretch from upsidedown and thus frequently create the bag sealing of backside in case of stick packs and pillow bags, while right and left sides in case if sachets.

Switch

Switch is the main power button of coffee packaging machine which when turned on results in energizing the electrical system of machine.

Clutch

Clutch is one of the core components of coffee packaging machine whose function is to issue and activate the length of machine as fixed by operator. For instance, the horizontal sealing of machine seal at the point where desired length of pouch ended.

Horizontal Seal

Horizontal seal consists of a device that stretch from right to left side. It is responsible for closing the bottom and top of pouch through heat sealing.

Baffle

Baffle is a stainless-steel flat device attached to the machine at a point when finished coffee bags are separated from film and ready for discharging. Here, this device work as a conveyor to convey the packages towards collection container.

Universal Wheels

Universal wheels are movable wheels attached to the bottom of machine for convenient mobility. Through these wheels coffee packaging machine can be rotated and moved around 360°.

7.What Is The Classification Of Coffee Packaging Machine?

Coffee packaging machine can be classified into following types:

Coffee Stick Packaging Machine

Automatic multi lane coffee stick packing machine

This multi-lane coffee stick packaging machine is an efficacious equipment tailored with unique features to cope with the complexities of packing instant coffee powder into small stick bags. Through its multiple columns, the machine perfectly form various stick packs and fill precise coffee powder in them.

Structure

The structure of machine is mainly composed of an intelligent PLC and touch screen control system, bag forming columns, vacuum feeder, material silo, coffee measuring system, filling nozzles, bags sealing system, multicolumn cutter, and stainless steel body.

Working Principles

The machine start pulling film from roll and turning it into multiple bags through bag forming columns. Once, the back lower ends of bags get sealed, accurately measured coffee powder or granules are filled into stick packs. Here, the top sealing of bags is carried out and these stick packs get discharged after being separated through cutting.

Pillow Bag Coffee Bean Packing Machine

Pillow bag coffee bean packing machine- Picture Courtesy: fullautopack.com

As the title indicates, this machine is designed to meet the industries need of packaging up to 1kg of coffee beans or granules into various types of pillow-shopped bags, even bags, and gusset bags etc. It is fully automatic in technology due to being integrated with other auxiliary devices to function standalone.

Structure

The machine is made up of a feeding station, z-type feeding machine, multi Head Weigher, supporting platform, bag forming, filling, and sealing device, and finished product conveyor.

Working Principles

The working process begins with z-type conveyor transporting coffee from feeding station towards multihead weigher. Here, coffee is measured through multihead weigher and transported to the pillow bag packaging machine after the bag is formed from plastic film. Hence, precise quantity of coffee is poured into pillow bags which are then sealed and discharged through conveyor.

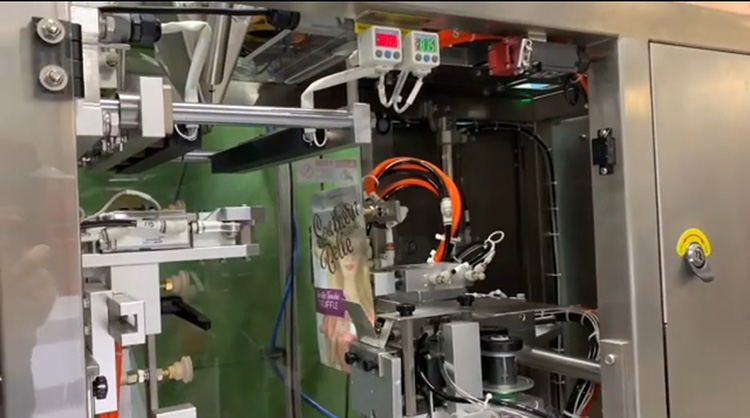

Premade Pouch Packaging Machine

Multihead Weigher Premade Pouch Filling Machine- Allpack

This premade pouch packaging machine can be employed for filling ground coffee and coffee beans into premade pouches. Hence, the machine reduces bother and time that is otherwise spent on making own pouches.

Structure

Several components constitute its structure comprising a feeding station, z-type conveyor, multihead weigher, premade pouch processing rotary plate, control system, bag magazine, and conveyor belt etc.

Working Principles

The machine intelligently control the flow of coffee from feeding station towards multihead weigher. Here, the measuring gets done and coffee is pushed forward where premade pouches are get loaded with accurate coffee dosage and turned into finished coffee bags via sealing.

Drip Coffee Bag Packing Machine

High Speed Drip Coffee Bag Packing Machine- Allpack

This high-speed drip coffee bag packing machine by Allpack is a sophisticated machine introduced to made hanging coffee filter bags along with three side sealed outer bags. So, you can pour your ground coffee, tea, and other particulates into drip bags through this machine.

Structure

The machine can be broadly divided into two components of making inner bag and outer bag. The principal parts include product feeding port, 4 bucket electronic scale, scale control panel, inner bag filter paper, inner bag sealing structure, outer bag sealing instruction, and production date printer etc.

Working Principles

Its processing begins with operator placing group coffee inside the feeder which is then further processed by machine. Firstly, the inner bag is created through unwinding film after which precise dosage of coffee is dropped into it. The inner bag is now sealed, and outer bag start to form by following similar steps. Finally, the inner coffee drip bag is introduced in outer envelope and discharged by the machine.

Coffee Bottle Filling Machine

Automatic coffee bottle filling capping machine

Coffee bottle filling machine is equiped with efficacious tools to fill coffee drink into various types of bottles. The fully automatic machine thus performs the automatic rinsing, unscrambling, filling as well as capping of coffee drink bottles.

Structure

It consists of a rinsing part, filling part, and capping part as a whole. While the main machine is further categorized into intuitive control system, coffee hopper, filling valves, gravity filling mechanism, and conveyor etc.

Working Principles

It works by following automatic principles for accomplishing entire working. The process starts with bottle rinsing after which they are delivered to filling station in a serialized manner. Here, each bottle is concisely filled with coffee drink and then capped tightly before discharging.

8.Write Down The Applications Of A Coffee Packaging Machine?

It is for sure that application of coffee packaging machine is not restricted to coffee packaging only, rather you will find multitude of areas using the machine. Among them some of the most prominent are highlighted below:

Coffee Industry

Various coffee bags- Picture Courtesy: Behance

Indeed, coffee industry is the area where different types of packaging machines are employed to undertake the coffee packaging task. It thus ensures the safe and secure delivery of coffee beans and powders through stick packs, pouches, and sacks etc.

Spice Industry

Various powdered spices

Aside from coffee industry, the need of coffee packaging machine is realized in spice sector as well where minute particles of herbs and condiments need to be precisely packed in dynamic packaging formats like bottles, jars, and bags.

Snack Food Industry

Multiple snack foods- Picture Courtesy: thebakermama.com

Snack food is among the eatables most consumed around the globe every day to beat sudden hunger. In this way, coffee packaging machine is always the suitable equipment to pack your potato chips, candy, gummies, and biscuits in moisture proof packages.

Pharmaceutical Industry

Medicated powder retort pouch and stick pack- Picture Courtesy: liquid.iv.com

Pharmaceutical industry is yet another area with profound eagerness for using effective packaging machine. Here comes the eligibility of coffee packaging machine which pack the medicated powders, granules, and supplements under sterilize and contamination free conditions.

Daily Chemical Industry

Detergent powder pillow bag- Picture Courtesy: Behance

Daily chemical industry involves the manufacturing and packaging of detergent powder, dish washing powder, and other cleaning agents. Similarly, their packaging is carried out quite responsibly to avoid packaging errors especially leakage. Therefore, coffee packaging machine is considered to pack these powders and granules in sachets, pillow bags and gusseted bags etc.

9.Steps To Be Followed For Using And Maintenance Coffee Packaging Machine?

Operators monitoring and maintaining coffee packaging machines- Picture Courtesy: Viking Masek

Although, coffee packaging machine is brilliant enough to provide unstoppable performance regarding coffee packaging, but it must be acknowledged that slight negligence can affect its working quality. Hence, it is significant to follow some precautionary measures before and after using coffee packaging machine. These are as follows:

Before-use Maintenance

While starting coffee packaging machine it is imperative to have checked the machine programmable features.

- Set the volume of coffee to be filled, the length of bag in clutch, and time duration for nitrogen flushing.

- Make sure your hands are dry and clean.

- Wear mask and gloves for safe processing.

- Examine the various components of machine and make sure they are on place.

After-use Maintenance

Once the daily job of machine gets completed you need to make it free from all the debris and prepare it for next operation like before.

- Disassemble the major parts such as hopper, weighing mechanism, and conveyor for cleaning.

- Inspect the screws of machine if they are loose.

- Lubricate the movable parts for smooth running.

- Change the damaged and wear parts for avoiding mishap.

10.Troubleshoot The Common Errors Of A Coffee Packaging Machine?

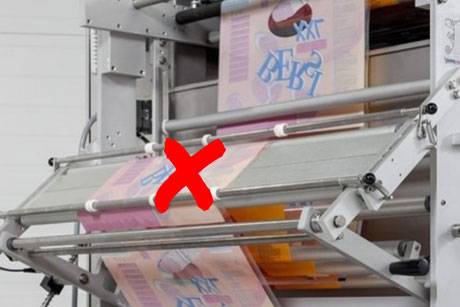

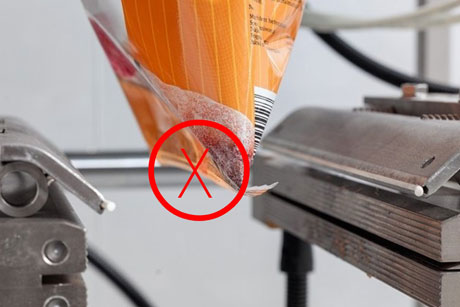

It is quite troublesome to face a spontaneous error thrown by a coffee packaging machine. However, with proper knowledge and advance training you can tackle these conundrums. Let's follow some technical ways for solving them:

| No | Problem | Causes | Solution | Picture |

| 1 | Low air pressure | It occurs when the machine is not reset, and incoming air pressure is below than require | Reset machine for correction and increase the supply airline |

Entrapped coffee powder due to low air pressure- Picture Courtesy: dailycoffeenews.com |

| 2 | Film does not track properly | Several reasons contribute to creation of this problem including unfree carriage, loose film, or poorly centered spindle | Hence, you need to place the spindle at the center, check carriage for free moving, and make the pressure on film roll equal to avoid loosening |

Faulty film tracking- Picture Courtesy: Viking Masek |

| 3 | Bad vertical and horizontal seal | There may be problem in vertical and horizontal sealing jaws which are leading to poor sealing | It can be solved by first examining the seals then setting time, temperature as well as pressure to make an acceptable sealing condition |

Viking Masek |

| 4 | Temperature inconsistencies of sealing jaws | Either the temperature is not settled through PLC or the temperature sensor is faulty | Make sure to check the temperature of sealing jaws twice before starting operation and replace the sensor if damaged |

Encircled sealing jaws- Picture Courtesy: Viking Masek |

| 5 | Coding error | The causes vary from disconnected printer cable to broken or damaged printer ribbon | Check if the printer is switched off. In case of printer ribbon damage, you need to replace it with new one |

Encircled coding over coffee stick pack- Picture Courtesy: Brew Coffee Home |

11.Factors To Consider When Buying A Coffee Packaging Machine?

When intending to add into your production a coffee packaging machine be meticulous as it will play crucial role not only in the packaging of your valuable products but their quality, branding, and stability throughout shelf life. So, follow the below tips to give your coffee packaging machine the attention it deserves!

Coffee Nature

Various forms of coffee in cups

One of the most basic yet significant factors is to have the right knowledge about your coffee. For instance, it will go beyond solid and liquid and will cover the aspects such as free flowing or adhesive coffee powder, because each type of coffee powder has different requirements. So, you can opt for machine which suits your material the most.

Type Of Packaging

Coffee pillow bag and stick pack

Do you want to pack your coffee in stick packs, pillow bags, gusseted bags, or standup pouches? Answering this question will definitely push you to go for right machine because there are enormous types of coffee packaging machines available in market which might perplex you.

Output Ratio

Another important aspect to look for is the output rate of coffee packaging machine which refers to its capacity of packaging the number of bags and pouches per hour. Determining it will assist you to select the machine compatible to your demands.

Convenience Options

Consumer filling cup from spouted coffee doypack

Modern customers are most busy ones who prioritize their time above all. In this way, looking for a coffee packaging machine that supports easy-to-use packaging like zippers, spouts, tin tie or tape down will attract consumers more than labeling.

Conclusion

Coffee packaging machine is becoming an instrumental figure not only in coffee market, but its wide application has raised its value in tea making industry and other food and non-food sectors. It thus implies that to pack your coffee in a safe protected way you must have a quality functional machine. Now, when you have been to this thorough FAQ Guide about Coffee Packaging Machine you may desire to buy it. So, we are here you help you out by recommending topnotch coffee packaging machines offered by Allpack having one year of warranty. Make sure to avail this opportunity by contacting us!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide