Coffee Bagging Machine: The Complete Buying Guide in 2025

Do you know that coffee is actually a fruit and was first discovered by a goat? Today, coffee is one of the most consumed beverages across the globe and it is because the coffee bagging machine creates sturdy coffee packaging which plays an integral role in the import and export of coffee.

The coffee bagging machine packs both coffee beans and coffee ground in different types of bags. It is an automated solution that processes versatile bag styles in a short time, consequently increasing production and lowering operational expenses.

In the market, a variety of coffee bagging machines exist and buying the right equipment requires a certain knack. So, here is a specialty blog in which you will find tips and tricks about buying and operating a coffee bagging machine.

1.What is Meant by a Coffee Bagging Machine?

Allpack Drip Coffee Bagging Machine

A coffee bagging machine is employed in the food industry for enclosing, covering, and containing coffee beans, liquid coffee and coffee powders in bags, for example, pouches, sachets, and sticks. It has a prime value in coffee packaging because of its automation, efficiency, and speed.

The coffee pouches are \ tough and durable containers that store single-serve and multi-serve coffee. A coffee bagging machine forms, packs, and seals coffee bags with the aid of packaging film that is plastic, laminate, aluminum foil, nylon, bio mesh, kraft paper, and filter paper.

A coffee bagging machine has a dominant place in the coffee packaging sector because it efficiently processes and hygienically handles coffee.

2.Why Select the Coffee Bagging Machine?

The utility of a coffee bagging machine is rapidly increasing day by day in coffee packaging because of the high consumer demand for coffee. This machine is renowned for its productivity and accuracy. Some important reasons for selecting a coffee bagging machine for use are:

Cost-Effectivity

Cost-Effectivity of Coffee Bagging Machine

A coffee bagging machine is a cost-effective solution because it decreases the need for manual labor which in turn saves labor wages. This machine aids manufacturers in relocating resources that are otherwise spent on expensive labor.

Ease of Handling

Ease of Handling Coffee Bagging Machine

This machine is controlled using computerized HMI technology and motion control technology. These technologies make it convenient for operators to handle machines. Moreover, with remote connectivity, operators can monitor the machine operation in their homes and offices without needing to stand and view the progress of the coffee bagging machine.

High Productivity

High Productivity with Coffee Bagging Machine- Picture Courtesy: Jochamp

The coffee bagging machine with its automated systems works at a much faster rate than simple hand-filling and constructs more coffee bags in less time. High productivity translates into more coffee products in the retail stores, which in turn boosts profit margins.

All-Rounder in Processing

Versatility of Coffee Bagging Machine- Picture Courtesy: Dieline

The coffee bagging machine is a versatile and adaptable unit that has a knack for processing multiple bag styles with simple and fast changes of parts. This feature is especially useful for manufacturers that package different coffee bags. Whether you process different bag styles, shapes, sizes, and pack coffee types, this machine is capable of handling it all.

Consistent Performance

Consistent Performance of Coffee Bagging Machine- Picture Courtesy: Viking Masek

Consistency is key when it comes to packaging because variations could result in product recall and profit loss. With accurate forming, filling, and sealing devices, the coffee packaging machine achieves seamless consistency in every batch. Furthermore, with its automation, there is less chance of human error in coffee bagging.

Less Wastage

Less Wastage by Coffee Bagging Machine- Picture Courtesy: Mentpack

With its computerized control systems, the coffee bagging machine uses a precise amount of packaging materials that prevent film wastage by decreasing the amount of scraps and it also prevents manufacturers from ordering more packaging films So, brands will get maximum return on investment.

3.Where is the Coffee Bagging Machine Utilized?

Coffee bagging machine comes with a wide range of advantages and manufacturers will get the highest possible bang for their buck by adding this machine to their productions. Because of its high profit rates, it is present in every industry, for instance:

Coffee and Tea Industry

Use of Coffee Bagging Machine in Coffee Industry- Picture Courtesy: Dribble

These industries are the biggest users of the coffee bagging machine. Because of its flexibility and adaptability, it can pack various volumes of coffee and tea in numerous bag styles. It can precisely load different coffee beans, ground coffee, black tea, Earl Grey, herbal tea, matcha, and Assam in single and multi-serve bags.

Food Industry

Use of Coffee Bagging Machine in the Food Industry- Picture Courtesy: Dieline

It is equipped with automated systems that lower downtimes in the packaging of foods which could occur by hand-packaging. A coffee bagging machine is in high demand in the food industry for the filling of miscellaneous food products like sugar, salt, spices, pepper, grains, pulses, nuts, pastes, snacks, dressings, dried fruits, soups, and herbs in striking bags.

Cosmetic Industry

Use of Coffee Bagging Machine in Cosmetic Industry- Picture Courtesy: Dieline

In the cosmetic industry, this machine is used for fabricating stylish and sophisticated pouches for the protection of cosmetic products, for instance, face masks, dyes, moisturizers, body mist, and many more. A coffee bagging machine is a part of the cosmetic industry, mainly because of its versatile bagging.

Pharmaceutical and Nutraceutical Industry

Use of Coffee Bagging Machine in Pharmaceutical and Nutraceutical Industry- Picture Courtesy: Dieline

The coffee bagging machine has prominence in the pharmaceutical and nutraceutical industry because of its extreme protection. This machine extends the shelf-life of capsules, tablets, pharmaceutical powders, health supplements, probiotics, protein blends, energy drinks, and others by packing them in airtight pouches.

Personal Care Industry

Use of Coffee Bagging Machine in Personal Care Industry- Picture Courtesy: V Magazine

This machine is integral in the packaging of shampoos, conditioners, liquid soaps, sanitisers, lotions, creams, and gel in sturdy and eye-catching bags for attracting and captivating customers.

Household Industry

Use of Coffee Bagging Machine in Household Industry

In the household industry, the coffee bagging machine is commonly seen because of its speed, minimal bottlenecks, and exceptional packaging. This industry utilizes this equipment for filling and sealing detergents, bleaches, dishwashers, glues, sealants, etc in robust bags.

Agriculture Industry

Use of Coffee Bagging Machine in the Agriculture Industry- Picture Courtesy: Dieline

This machine is also found in the agriculture industry for loading and storing fertilizer, pesticides, herbicides, bug control chemicals, soils, seeds and many more in elegant bags. This machine is popular in the agriculture industry because of its meticulous quality packaging and streamlined operation.

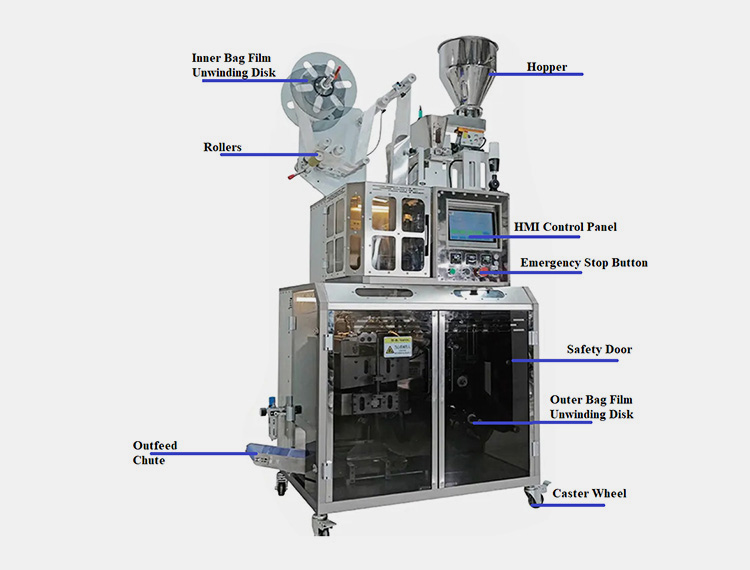

4.What Parts are Present in Coffee Bagging Machine?

In the coffee bagging machine, various electronic and mechanical components are present that act in harmony to acquire precision in the coffee bagging machine. These parts of the coffee bagging machine are detailed below:

Parts of Coffee Bagging Machine

| Inner Bag Film Unwinding disk | This unwinding disk is located at the upper part of the coffee bagging machine. It rotates to unwind the packaging film that is used for forming an inner coffee bag. |

| Hopper | It is a conical or square component, typically found at the upper part of most coffee bagging machines. It stores bulk quantities of coffee beans and powders for packaging operations. |

| HMI Control Panel | HMI is the intelligent and user-friendly control panel with which operators interact with this machine. It lets operators monitor and troubleshoot the machine. |

| Emergency Stop Button | It is a kill switch that instantly stops the machine in case of an accident to prevent injury to the operator. This button has a prominent place on the control panel for easy access in case of fire or electric hazards. |

| Safety Door | It is clear or opaque glass doors that prevent direct machine access during its packaging operation. |

| Outer Bag Fim Unwinding Disk | This unwinding disk is present at the bottom of the machine and holds the packaging film that forms the outer bag. |

| Caster Wheel | It is a support and portability mechanism that rotates for the mobility of the coffee bagging machine. |

| Outfeed Chute | Packed coffee bags after complete processing drop down into outfeed chute for collection. |

5.What Kinds of Coffee Bagging Machines Exist in the Market?

There are a variety of coffee bagging machines in the market that are classified into different types depending on packaging operations and filling devices. These types of coffee bagging machines are:

According to the Filling Type

Aguer Coffee Bagging Machine

Auger Coffee Bagging Machine

It is one of the most common coffee bagging machines. It is a closed device used for clean and hygienic filling of coffee powders. The auger screws rotate with the magnetic clutch. This rotation moves the coffee materials from hoppers to auger plates and finally loads them into the coffee bag.

Vibratory Plate Coffee Bagging Machine

Vibratory Plate Coffee Bagging Machine

This machine is equipped with vibratory plates for the gradual and precise filling of coffee into the coffee bag. It is frequently employed for filling fragile powders that may break down when processed with other devices. With the vibrations of the perforated plates, the coffee beans or powders move from the hopper to the filling nozzles, after passing through the holes of plates. From filling nozzles, these materials are fed into coffee bags.

Piston Coffee Bagging Machine

Piston Coffee Bagging Machine

It is an extremely precise and accurate type of coffee bagging machine. The piston cylinder is the main device in the coffee bagging machine that aids in the fluidity of coffee granules and powder particles into a coffee bag. The piston in the cylinder moves forward and draws the coffee materials into the cylinder and the backward movement of a piston in the cylinder forces the materials into filling nozzles.

Volumetric Cup Coffee Bagging Machine

Volumetric Cup Coffee Bagging Machine

It is popular in the coffee industry because of its simple work and cost-effectivity. However, it has higher filling errors than other types of coffee bagging machines. First, the exact quantity of coffee powders for filling is measured and loaded inside the cup, from where they get dispensed inside the bag by the rotation of the disk.

According to to Packaging Style

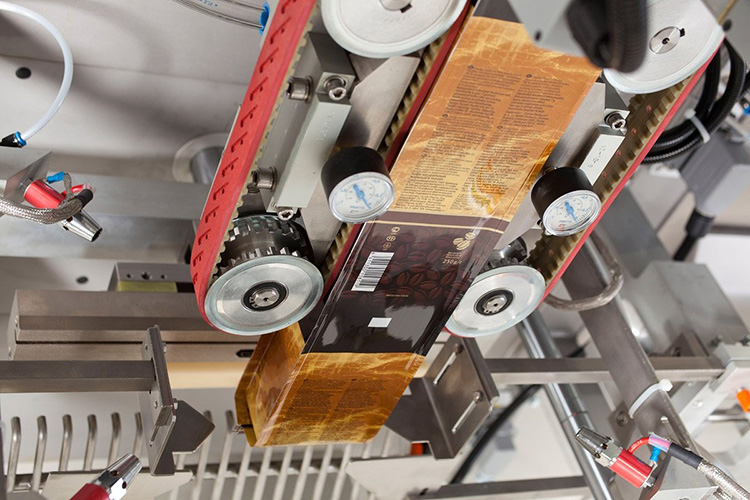

Vertical Form, Fill, and Seal Machine

Vertical Form, Fill, and Seal Machine

It is routinely found in the coffee bagging lines because of its reasonable price, simple operation, versatility, and smaller footprint. Servo-driven motors in this equipment move different components like unwinding disks, rollers, and sealing jaws. The packaging film travels over the roller and reaches the forming station. It then doubles, wraps around forming a collar and is fashioned into a pouch. Afterwards, filling and sealing take place.

Doypack Bagging Machine

Allpak Doypack Bagging Machine

This machine outputs exceptional-quality coffee bags because of its high-precision metering. Furthermore, it has flexible components that allow convenience in handling, cleaning, and maintaining the machine. The bag is formed by a film roll with the action of cutters and sealing jaws. After forming, the filling of coffee powders takes place by different filling devices, and finally, sealing jaws seal the top edges.

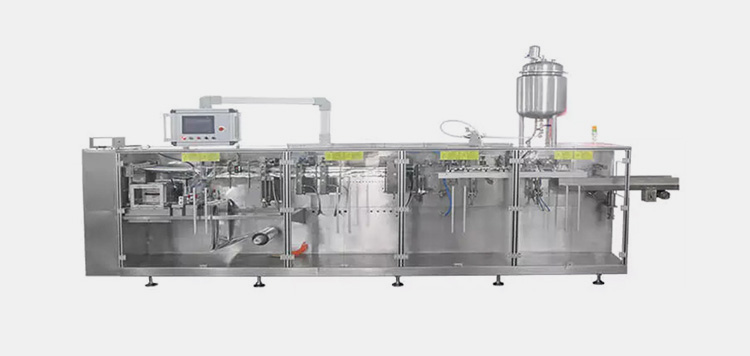

Premade Pouch Bagging Machine

Allpak Premade Pouch Bagging Machine

It is an adaptable coffee packaging machine and is considered a highly productive unit due to its filling and sealing of already-made coffee bags. It easily fills both granular and powdery coffee in the zipper pouch, standup, quad seal, flat bottom, and pillow pouch.

It has straightforward working with the loading of premade bags, their opening, and their inflation occurring in sequence. Coffee materials are dispensed into the coffee bags and in the end, the top side of these bags is sealed by heated sealers.

Coffee Stick Pack Bagging Machine

Allpak Coffee Stick Pack Machine

It is more efficient than a coffee sachet bagging machine because of its numerous lanes. It can have up to twenty lanes, thus producing twenty stick packs in one go. Servo motors draw film from unwinding disks and accurately position it over rollers. This packaging film is cut into smaller strips and transformed into individual sticks by forming a tube. Filling and sealing occur after the formation of coffee stick packs in this machine.

Coffee Sachet Bagging Machine

Coffee Sachet Bagging Machine

It is a compact small-sized machine, that is popular because it packs a one-time serve of coffee in portable sachets. It has an innovative stainless-steel design that provides utmost corrosion protection. Packaging film in these machines is used for creating sachet. This formation of sachets occurs by vertical sealers and forming stations. Upon sachet formation, the exact quantity of coffee powders is dosed into the sachet and finally, sachets bags are hermetically sealed by sealer.

Drip Coffee Bagging Machine

Drip Coffee Bagging Machine

This machine packs an innovative coffee bag style known as a drip coffee bag. The drip coffee bag machine is easy to use and provides extreme protection to coffee by packaging it twice; it packs coffee in an inner bag made from filter paper and an outer bag created using laminated film.

First, the inner packaging film travels to the forming station where it is cut and sealed by heated sealer. After that coffee is loaded into the drip coffee bag and its top side is closed by sealers. After that, the outer film is shaped into the bag, filled with an inner bag, and ultimately, airtightly secured by sealers.

6.What are the Bag Types Formed by Coffee Bagging Machine?

In the market, you see a variety of coffee bag styles and this is all due to the multipurpose packaging of a coffee bagging machine. The details of all these bag styles are discussed below:

Multi-Serve Coffee Bags

| Standup Coffee Pouch

Standup Coffee Pouch- Picture Courtesy: BeanPak |

These bags are one of the most popular packaging styles of coffee bags. Due to its flat lower gussets, it has a prominent presence on the display shelves that attract coffee lovers. |

| Side Gusset Coffee Pouch

Side Gusset Coffee Pouch- Picture Courtesy: xwpak |

As the name suggests, these bags feature side folding that expands on coffee filling. It usually packs bulk volumes of coffee. |

| Quad Seal Coffee Pouch

Quad Seal Coffee Pouch- Picture Courtesy: Quma |

These coffee bags have unique structures featuring distinct vertical panels and side foldings. Their rectangular appearance and crisp cut convey a sense of sophistication. |

| Flat Bottom Coffee Pouch

Flat Bottom Coffee Pouch- Picture Courtesy: PBFY |

It has a flat bottom and a box-like look; hence also called a box pouch and block bottom pouch. It has excellent stability and seal strength. Due to its expansion on filling coffee, it is often used in coffee bagging for holding bulk quantities of coffee. |

| Gable Top Coffee Pouch

Gable Top Coffee Pouch- Picture Courtesy: Packagingblue.com |

It has a slope-like seal on the top of the pouch and has vertical panels that form a flat bottom at its rear end. This feature allows it to stand upright; however, it has limited room for printing. |

| Spout Coffee Pouch

Spout Coffee Pouch |

It has a spout usually at its top corner, which offers convenience in pouring out liquid coffee. |

| Valve Coffee Pouch

Valve Coffee Pouch- Picture Courtesy: Brand My Café Blog |

This coffee bag has a small perforation at its upper side that acts as a one-way valve. Valve coffee pouch is mostly used for packaging roasted coffee beans because they release carbon dioxide into the environment. The valve prevents the entry of gases inside. |

| Pillow Coffee Pouch

Pillow Coffee Pouch- Picture Courtesy: Moka Mama |

This pouch is also known as a T-seal coffee pouch because of its central seal that goes along its entire length. The upper and bottom seals give it a pillow-like appearance. |

| Vacuum Coffee Pouch

Vacuum Coffee Pouch- Picture Courtesy: eco-brothers |

This coffee bag offers the highest protection and upholds coffee freshness by vacuum sealing it. |

| Shaped Coffee Pouch

Shaped Coffee Pouch- Picture Courtesy: MTPak Coffee |

It is styled in different shapes like cups, fruits, cones, etc to mesmerize customers. |

Single-Serve Coffee Bags

| Coffee Stick Pack

Coffee Stick Pack- Picture Courtesy: Aranow |

It is a narrow tubular coffee bag that has a one-time serving of coffee powders. This stick pack is rectangular ideal for an on-the-go lifestyle and has three to four seals. |

| Coffee Bags

Coffee Bags |

These are small compact coffee bags that are used in instant coffee preparation. They may come in rectangular, square, pyramid, and circular shapes. |

| Drip Coffee Bags

Drip Coffee Bags- Picture Courtesy: Koffie Snack |

It is a new style of coffee bag consisting of small handles with which they are suspended over coffee mugs. It is a mess-free way of preparing coffee by simply pouring boiling water over drip coffee bags. |

7.What Films are Processed by the Coffee Bagging Machine?

There are distinct coffee bag formats that are created by diverse film styles. A few of these films processed by coffee bagging machines are discussed below:

Plastic Film

Plastic Film Coffee Bag- Picture Courtesy: FAFF Coffee

Flexible coffee pouches are made with plastic films such as polyethylene (PE), polypropylene (PP), and Polyethylene Terephthalate films. These films work best with both ground coffee and coffee beans and provide excellent protection to inside products.

Laminated Films

Laminated Coffee Bag- Picture Courtesy: Hibags

A coffee bagging machine is designed to process laminated coffee films. These films are multi-layered and created from plastics, such as polyester, PE and aluminum foil. They are used for fashioning extreme barrier coffee pouches.

Metalized Films

Metallised Film Coffee Bag- Picture Courtesy: Template.net

The coffee bagging machine handles metalized film to make premium quality high-end coffee bags. These films are formed by placing a thin layer of aluminum over plastics, such as nylon, PET, or PE. Metalized films offer coffee bags a shiny look.

Kraft Paper Film

Kraft Paper Film Coffee Bag- Picture Courtesy: The Bag Broker

These films are utilized to give coffee bags an earthy look and feel. These films are made with brown kraft paper and are biodegradable.

Nylon Films

Nylon Film Coffee Bag- Picture Courtesy: Packing Material.com

These are the synthetic fibers often used for making drip coffee bags. These films are composed of multi-layered fibers and have high durability.

8.Does Nitrogen Flushing Exist in Coffee Bagging Machine?

Nitrogen Flushing in Coffee Bagging Machine- Picture Courtesy: PAC Machinery

In short answer yes, nitrogen flushing is a convenient feature present in most advanced coffee bagging machines. Gas flushing stations introduce nitrogen in the coffee bags before sealing. This inert gas replaces oxygen inside coffee bags, which could otherwise cause oxidation of coffee components.

This handy feature extends the shelf life of the coffee products and minimizes their staling. Nitrogen in coffee bags controls the emission of carbon dioxide and prevents moisture absorbance by coffee beans.

Nitrogen protects aromatic coffee oils, thereby preserving coffee crispiness, fragrant smell, tantalizing flavor, and smooth texture.

9.How Coffee Bagging Machine is Sustainable?

Sustainability of Coffee Bagging Machine- Picture Courtesy: MTPak Coffee

Due to environmental concerns, manufacturers are making conscious efforts to ensure the sustainability and eco-friendliness of their coffee bagging machines. Now, more and more brands are using biodegradable and compostable films, such as bio mesh, and kraft paper with their equipment. These films are decomposed easily, consequently resulting in a lower landfill.

Moreover, the modern coffee bagging machine with its high-performance filling system consumes less energy in turn, resulting in lower carbon emissions. This machine also generates less packaging waste and produces lightweight coffee bags that are easily transported. This lightweight transportation consumes less fuel, making shipment more carbon neutral.

10.What are Cleaning Suggestions for a Coffee Bagging Machine?

Cleaning of Coffee Bagging Machine

Routine cleaning goes a long way in the healthy performance of a coffee bagging machine, so there are a few useful cleaning suggestions:

- First, turn off the coffee bagging machine and disconnect all the cables and wires before starting the cleaning process.

- Use a brush or dry cloth to shake off any loose coffee powder and debris. With a dry cloth, gently clean the exterior surface and frame of the coffee bagging machine.

- Use food-grade mild cleaning solution or detergent to remove hard sticky powders or other accumulated products from the coffee bagging machine. Wipe its interior, hopper, filling nozzles, and other filling devices with a wet cloth to thoroughly clean every surface.

- Sanitize and de-contaminate all the food contact points to avoid contamination risk.

- Lubricate every mobile joint, nuts, screws, and other bearings.

- Use air blowers or other dryers to completely dry the coffee bagging machine before use.

11.What are the Kinds of Technical Faults in the Coffee Bagging Machine? How to Remedy Them?

Unexpected problems with the coffee bagging machine are troubling and lead to the wastage of productive time. However, there is no need to worry and numerous problems in this machine are easily remedied, for example

| Causes | Remedy | Image |

| Wrinkling or Creasing of Film | ||

| Inadequate film tension.

Incorrect leveling of film rollers. Inappropriate placement of packaging film. |

Fix the film tension.

Realign the film rollers. Correctly place the packaging film. |

Wrinkling or Creasing of Film- Picture Courtesy: Nobelus University |

| Poor Sealing of the Coffee Bags | ||

| Extreme sealing temperature.

Inadequate sealing pressure. The dirty or uneven exterior of sealing bars. The bag is not properly positioned in the sealers. |

Lower the sealing temperature.

Adjust the sealing pressure. Thoroughly wipe the surface of the sealing jaws. Adjust the position of the bag in the sealers. |

Poor Sealing of the Coffee Bags- Picture Courtesy: Batch Coffee Club |

| Failure in Pouch Opening | ||

| Out-of-order vacuum pad.

Incorrect bag loading. Defect in the air valve Worn-out air filter. Incorrect bag opening settings. |

Repair vacuum pad.

Reload the bag so that it is correctly positioned in the grippers. Replace air valve Change the air filter. Adjust machine settings on the machine interface. |

Failure in Pouch Opening- Picture Courtesy: Justdial |

| Variation in Coffee Fill | ||

| Poor calibration of fill devices.

Blockage in the coffee flow passageway. Incorrect fill settings Unevenness in sizes of coffee particles. |

Re-calibrate the filling device.

Clear the blockage in the coffee flow pathway. Reset the fill settings. Regrind the coffee mixture to acquire uniformity in coffee particles. |

Variation in Coffee Fill |

| Abnormal Machine Vibrations | ||

| Unaligned machine components that are not properly leveled.

Poor lubrication of machine components Imbalanced rotating components. |

Properly level machine parts and tighten them.

Oil every mobile component. Balance the rotating parts.

|

Abnormal Machine Vibrations |

12.What are the Buying Tips for Coffee Bagging Machine?

Selection of the right coffee bagging machine translates into higher profit rates. Here are some buying tips especially for you:

Production Rate

Production Rate of Coffee Bagging Machine- Picture Courtesy: Single O

First, determine how many coffee bags will you package per hour. Knowing this will give an estimate of the production capacity of the coffee bagging machine. Compatibility of production goals and coffee bagging machine brings you more fruitful results.

Nature of Coffee

Coffee Types- Picture Courtesy: Abbots Mitre

Brands pack roasted coffee, ground coffee, coffee beans and liquid coffee in coffee bags. Plan about your particular type as every coffee type has its requirements. The nature of coffee will determine the type of filling device in the coffee bagging machines.

Bag Type

Coffee Bags- Picture Courtesy: ocean property

Will you process large multi-serve coffee bags like standup or flat bottom or will you package small single-serve bags like drip coffee bags? The selection of a particular coffee bag type will decide your potential coffee bagging machine. This is because different coffee bagging machines have their bag processing specialties.

Sealing Options

Sealing Options- Picture Courtesy: Recreo Coffee

Different coffee bagging machine features different sealing options, for instance, cold sealing, heat sealing, and ultrasonic sealing. These sealing options depend upon bag manufacturing film and the desired shelf life of coffee. Ponder these two points before going to the market to buy a coffee bagging machine.

Ease in Integration

Easy Integration of Coffee Bagging Machine- Picture Courtesy: Spack Machine

When buying a coffee bagging machine, ask yourself a question will this machine be easily added to your production? Is it well-matched with existing equipment in production lines? Smooth incorporation means synchronized packaging operation.

Conclusion

The coffee bagging machine is exceptional equipment that automates production and with its consistent performance, you can get high-quality state-of-the-art coffee bags. Hopefully, by reading this guide, you have learned about different elements that make coffee bagging machines, a piece of handy equipment for production lines. If you have more queries about this machine, you are more than welcome to contact our sales representatives. Allpack is a hub for displaying a huge series of coffee bagging machines. Please contact us for more information & equipment Purchase.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide