Your Best Lab Clarity Tester Supplier

Clarity Tester

Allpack Clarity tester instrument is used to check the clarity of all kinds of bottled liquid injection.The traditional timing dial is removed and replaced with chip integrated control and full touch buttons. The service life of the instrument is increased by 3 times. Users can calibrate the illumination of the instrument by themselves according to the standard illuminance meter, which means the self-correction function is added. Using a digital electronic illuminance meter, the reading is intuitive, the clarity tester is stable and reliable, the detection time can be set arbitrarily, and it has an audible and visual alarm function.

Allpack Clarity Tester

Test Equipment Injection and Bottled Medicine Liquid Clarity Tester

Allpack clarity Tester is our company developed inspection apparatus based on People's Republic of China Pharmacopoeia 2010 edition of Appendix "visible foreign matter test" in light of the provisions of law.Meet the subject "Chinese Pharmacopoeia" requirement, the instrument uses a visual light inspection method for all types of injection, infusion and bottled liquid medicine clarity detect.The operation panel changes into touch buttons, the brand new circuit design, built-in chip and multi-functional, performance operation easier.

Flash eliminated. Illumination is adjustable

Timing and alarming function automatically

Test continuously

The Buyer's Guide

Clarity Tester: The Complete Buying Guide In 2025

Dealing with clear solution may seem horrible when unwanted particles suddenly appear in your liquid filled vials, ampoules, or bottles. It may also lead to significant product as well as time waste. Thus, to end this complication, a Clarity Tester has been developed.

This advanced equipment is designed in such a way that your clear solutions are perfectly tested. Not only this, but it allows you to easily conduct an operation by yourself. You just need to understand its structure, features, working principles, and maintenance steps which are all highlighted in this buying guide. So, take the start and give it a thorough read!

1.What Is A Clarity Tester?

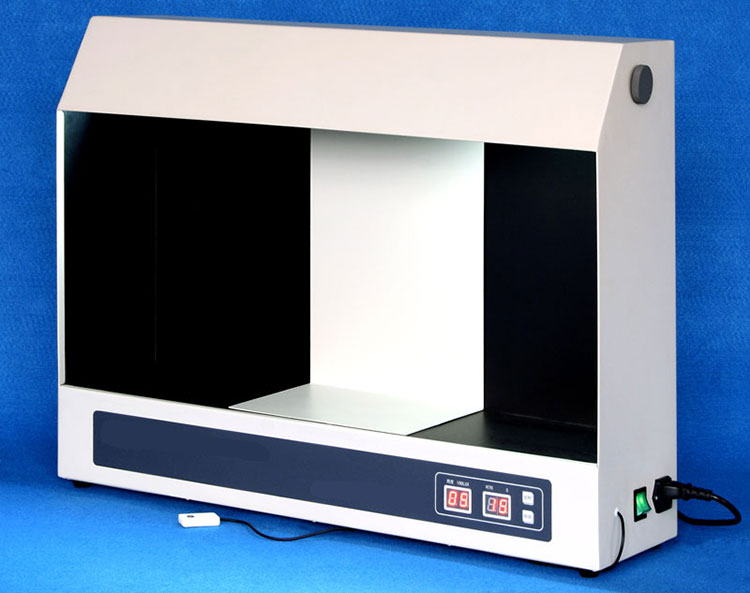

Clarity Tester- Picture Courtesy: medfuture.net

Clarity tester is a simple design equipment used for the purpose of testing clear liquid solutions in ampoules and bottles for unwanted particles. It plays effective role in maintaining the quality of clear medical solutions like injection water, vaccines, and other transparent oral liquids.

The structure of the tester is quite precise which makes it easy-to-use. The bottle is consecutively placed in front of white background and black background to find the different colored substances. A strong illumination is used to make the particles visible and detect them. Thus, in a very short time span, the testing is done.

2.What Is The Purpose Of Clarity Tester?

Liquid filled ampoule in hand- Picture Courtesy: Solution-Pharmacy

The purpose of a clarity tester is straight forward and that is to ensure the safety of drugs being packed and find out the errors caused during their packaging. In medical field, drugs manufacturing and processing is carried out under strict principles, so, as to avoid minor mistake that can lead to serious issues like quality degradation and patient health hazard.

For this reason, two most dominant colors including black and white are used to check the useless matters encompassing glass particles, white particles, and black particles etc. Hence, the application of this visible foreign matter test can enlighten you regarding the inaccuracies and help you take measures in advance.

3.Enumerate The Advantages Of A Clarity Tester?

A clarity tester holds in it various advantages for you both in terms of quality management and building trust in customers for your produced solutions. Below, you will see some of the most important features of a clarity tester.

Precise Structure

Precise structure of a clarity tester- Picture Courtesy: labxyi.com

The foremost attribute of a clarity tester is its compact body and precise structure which make it quite easy to handle the equipment independently. In addition to it, no matter how latest and advance the features a clarity tester possesses, it will always be covering less space. Thus, it is easily movable which is what most of the manufacturers are looking for!

Simple Operation

Clarity tester offers extremely user-friendly operation method where you need to follow few steps without requiring need for any expertise or special training. Once you have understood the basic steps, you can easily operate it by yourself.

Effective Performance

Doctor examining a liquid filled vial- Picture Courtesy:

Although, clarity tester is small in its construction, but it encases range of features to get you done with a perfect testing. For instance, its fluorescent lamp, sensor, timer, illuminance meter, alarm, and brightness system together result in finishing effective inspection and display you even a minor particle that might not by visible otherwise.

Adjustable

Clarity tester is adjustable in a way that you can modify the brightness level in order to regulate it under control. Apart from this, you can fix a stand inside the tester for fixing small containers like ampoules near the flame. It thus allows for a stable operation where container do not shake, and the fear of breakage is also eliminated.

Wide Application

Various types of containers- Picture Courtesy: istockphoto.com

Another most significant advantage of a clarity tester is that it has wide application in many ways. For example, you can test containers of various sizes and shapes like ampoules, vials, and bottles. Similarly, it is not always necessary that a solution must be transparent, but it should be visible and clear whether in multiple colors like blue, pink, or yellow etc.

4.What Type Of Containers Can Be Tested By A Clarity Tester?

As far as the containers supported by a clarity tester are concerned, so, it can test all kinds of ampoules, vials, and bottles which are transparent without any marks and printing. A description of each type has been provided as under:

Ampoules

Clear liquid ampoules- Picture Courtesy: healthcarebusinessclub.com

Ampoules are small size glass containers used for storing injection water, essential oil, plant extract, and other liquids. They are characterized by tube shape body and a narrow tip. The importance of ampoules in pharmaceutical industry can be better understood by their usage as a first preference for preserving single dosage aqueous medication. Thus, a clarity tester is perfectly safe to be used for tiny ampoules.

Bottles

Various sizes bottles

Small to medium size bottles holding clear liquids like oral liquid, mouth wash, glycerin, and spirits etc., can also be tested by using a clarity tester. As bottles are used for holding comparatively large volume of solutions, thus, a clarity tester can be modified to show in depth inspection for examining the particles.

Vials

Liquid filled vial- Picture Courtesy: gerresheimer.com

Vials are small glass vessels frequently used to deliver medication both in solid and liquid form. However, in case of a clarity tester, liquid vials are used for testing which holds aqueous medication like vaccines, injection water, and other liquid formulation.

5.How To Operate A Clarity Tester?

Most of the new manufacturers who aspire to buy a clarity tester, has a misconception about its operation. They find it difficult at first glance, however, the case is totally different when you understand the procedure and undertake it practically. So, be ready to know how a clarity tester can be operated!

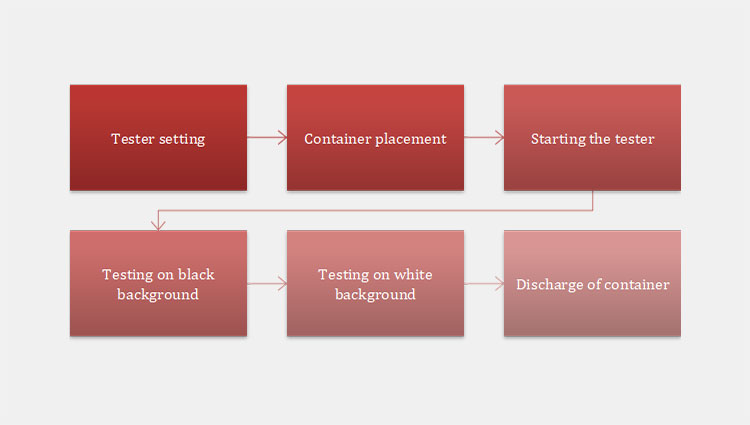

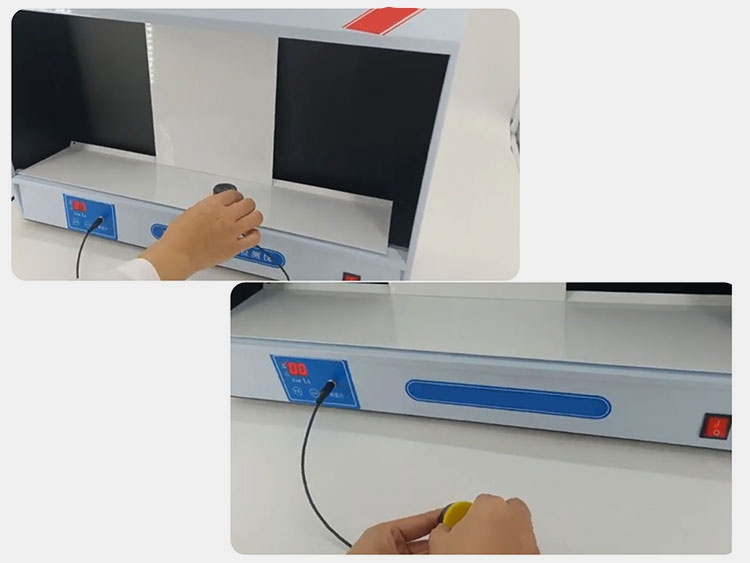

Tester Setting

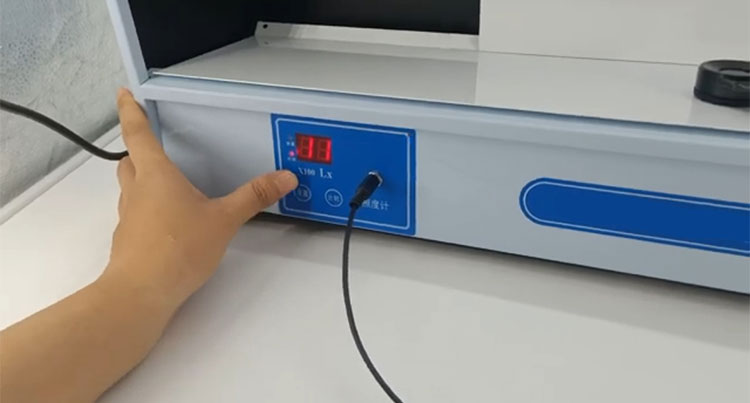

Clarity tester setting- Picture Courtesy: Jiaxinhai Lab

The initial step is to have a look towards the setting of your clarity tester. It simply involves checking the overall body and fitting the necessary parts like fixing container holding frame, infusing the brightness meter, and inserting power circuit into electric board.

Container Placement

Now, place the desired container inside clarity tester. For this, you can either place the bottles as they are or take help of a frame to fit sterile ampoules.

Starting The Tester

Once container is placed, just switch one the tester and adjust the parameters for testing like time and brightness level. Next, press the run button and operation will be started.

Testing On Black Background

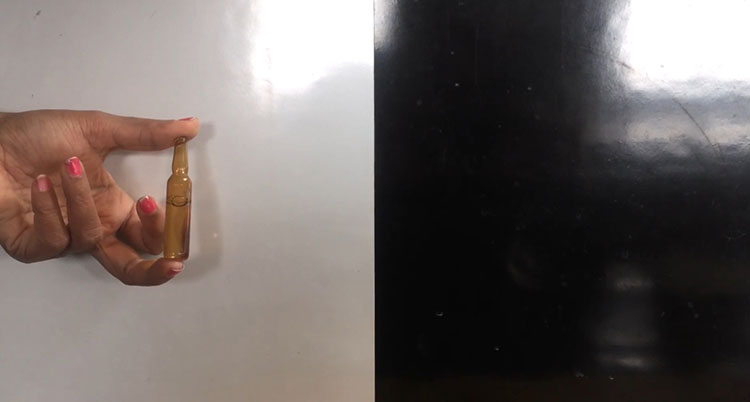

Ampoule clarity testing on black background- Picture Courtesy: Solution-Pharmacy

As the tester has two backgrounds, so, you need to use one side at one time. When on black background, the white particles will start appearing due to the intensity of illumination.

Testing On White Background

Ampoule clarity testing on white background- Picture Courtesy: Solution-Pharmacy

Similarly, black and dark matter will be easily visible when you flip the container on white background. If the solution is free from particles, you will notice that background is clearly shown without any middle obstruction caused by the foreign object. This is what we call a clarity test.

Discharge Of Container

At last, when you are done with the testing, just remove the container from clarity tester base or the fixed frame.

6.Describe The Structure Of A Clarity Tester?

Clarity tester has a precise structure with few small components. Together, they enable the tester to perform its task of conducting a test for clear liquid solutions. So, let's know its structure in detail!

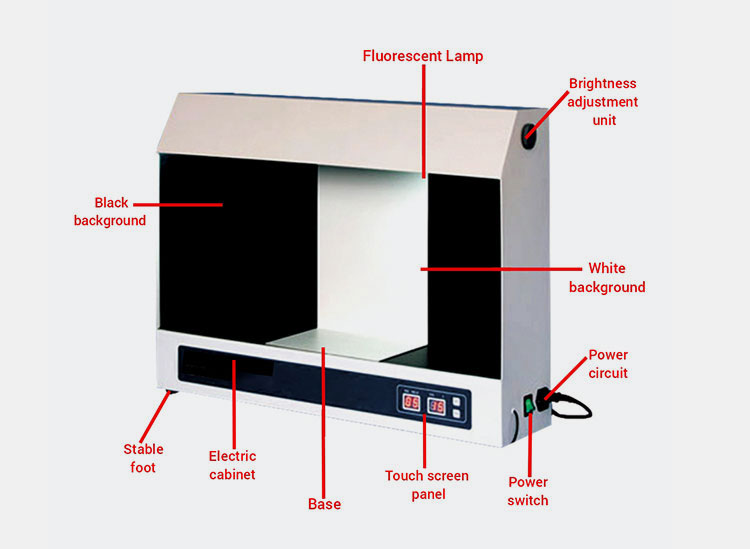

Components of a clarity tester- Picture Courtesy: medfuture.net

Fluorescent Lamp

Fluorescent lamp is the primary part of a clarity tester which is also called three-primary-color lamp. It illuminates the visible light which spread across the background and helps in the testing. The fluorescent lamp is controlled by certain tools including a lightening sensor, shading, and electronic inductor to avoid over lightening that may cause damage.

Brightness Adjustment Unit

It refers to the screwable button which is located on the side of clarity tester. It is used to adjust the brightness level of fluorescent lamp.

Black Background

The tester has a flat horizontal black background attached to its internal front side. It is useful to detect the white foreign particles or constituents present inside the clear solution.

White Background

White background is displayed by a white side that is situated along with black background. At this place, liquid filled ampoules and bottles are placed, so, the colorful or black particles can be detected easily.

Power Circuit

Power circuit is simply represented by a circuit that transfer electricity to the clarity tester by providing a connection between both.

Power Switch

There is a knob located at one side of the clarity tester often with green color. It is known as power switch or power button which is used to power on and off the tester.

Touch Screen Panel

Clarity tester does have a small touch screen panel on the front side. It consists of digital screen which display over them the speed of light and timer running. It also has buttons like preset button.

Base

It refers to the flat area right under the fluorescent lamp where bottles and ampoules are placed for testing.

Electric Cabinet

It is an enclosure located at the bottom side of clarity tester which at the same time holds electrical components of the equipment and provide it structural support against shaking.

Stable Foot

Clarity tester has multiple feet attached to its lower side which strengthen it to lay flat on the surface.

7.What Are The Applications Of A Clarity Tester?

As many as the number of clear liquid solutions we have in our daily life, so, as the fields where a clarity tester is applicable. In upcoming paragraphs, you will be shown some of the prominent areas where the use of a clarity tester is inevitable:

Pharmaceutical Industry

Various liquid pharmaceutical packaging- Picture Courtesy: aphenapharma.com

Well, pharmaceutical industry is on the top of the list when it comes to enumerate the uses of a clarity tester. The reason is hidden from no one! The extensive production, research and development activities to make new drugs and deliver the existing formulas in best possible way simply demand for quality testing. Hence, the help of a clarity tester is taken on different levels.

Biotechnology Industry

Scientist testing liquids in lab- Picture Courtesy: dice.com

As a field intended to advance human health, biotechnology industry take great care of hygiene and environmental safety for things which it processes. Similarly, it adopts every possible testing method to detect the smallest possible particles in order to avoid inconsistencies and maintain quality. Thus, it is a keen user of clarity tester to test the fluids stored in ampoules, vials, and glass tubes.

Dermatology Industry

Dermatologist treating customer- Picture Courtesy: knottstdermatology.com

Dermatology industry is a field that deals with the medication specifically produced for external beauty like the treatment of skin, hair, and nails etc. In this way, various liquids and extract are used through injection which are definitely stored in small to large containers requiring thorough inspection. Thus, a clarity tester is used for testing.

Food Industry

Olive oil presentation idea- Picture Courtesy: refreshyourlife.in

In food industry, we also have clear liquid solutions especially if talking about purified water and edible oil. Similar to the above mentioned nonfood solutions, food liquids are also testable by using a clarity tester. Thus, its presence can also be found in food processing industries.

Chemical Industry

Scientist mixing chemicals in tubes- Picture Courtesy: snexplores.org

Clarity tester is also applicable in chemical industry for the testing of various clear solutions. In this way, it can help in detecting the useless matters which may affect the quality and essence of actual chemicals.

8.What Quality Standards Should A Clarity Tester Comply To?

Quality standards are supposed to be the quality assurance of any equipment especially when they are directly related to public health and safety. Similarly, there are some important standards established on international level whose compliance is necessary for every clarity tester. These quality standards are regulating the rules and principles to ensure the production and processing of safe goods.

Thus, a standard clarity tester must be certified by the underlying certifications:

GMP quality standards- Picture Courtesy: medicalplasticsnews.com

International Organization for Standardization (ISO)

Food and Drugs Administration (FDA)

Good Manufacturing Practices (GMP)

Conformate European (CE)

National Science Foundation (NSF)

9.What Is The Maintenance Requirements Of A Clarity Tester?

In case of a clarity tester, there is no such hard and fast maintenance requirements needed on regular basis, however, you should take care of few things to avoid malfunctioning and keep it on right track. For this, follow the underlying guidelines:

Operator maintaining a clarity tester- Picture Courtesy: Jiaxinhai Lab

Make sure to locate your clarity tester in a safe and clean environment with no exposure to dust and pollution or it may affect the quality of your testing.

Provide adequate voltage and at the same time avoid over voltage as it can lead to the tester breakdown.

Keep the alarm unit, shading, inspection device, and timer on all the time so you will be notified after the cycle ends and the flame will be under control.

Clean the internal area of your clarity tester including black background, white background, and base by using a tidy, soft cloth to remove possible particles. For external main frame, you may use a damp cloth for wiping.

10.Factors To Consider When Choosing A Clarity Tester?

Considering few small but important tips can help you choose the best equipment for you which include:

Container Size

Various sizes of ampoules- Picture Courtesy: carlroth.com

Keeping in view the container size plays instrumental role in buying the most compatible equipment. Now, you can choose between different types of clarity testers made according to the container size. For instance, ampoules and vials can be tested by a standard clarity tester. On the other hand, you may opt for a more complex design tester if dealing with large size bottles that may not fit to small clarity tester.

Production Volume

Ampoules processing on large scale- Picture Courtesy: Pharmec

What is your current production volume? Do you run a large-scale business or small to medium scale? Answering this question will help you choose the clarity tester with relevant capacity, size, and additional tools. For example, you can use a double size frame inside the clarity tester to test two containers at the same time.

Specifications

With new advancements, clarity tester design is also updated with time. Now, operation panel changes into touch buttons and the effectiveness of fluorescence flame can be managed in a much better way. Similarly, when you choose a clarity tester for your business, make sure to check its specifications.

Supplier Reputation

Finding best supplier- Picture Courtesy: golegal.co.za

Last but most important thing to look for is the supplier reputation. You should never overlook the expertise, quality compliance, warranty policy, and customer service if the supplier as these factors can be influential for you in future.

Conclusion

To put in a nutshell, Clarity Tester is the most useful invention of modern technology that has helped manufacturers across the globe to maintain drug quality and essence by convenient method. That's the reason, why its significance has extended to industries beyond pharmacy. So, the bottom line is simply that you should not ignore the presence of a clarity tester in your production line if dealing with any kind of clear liquid solutions. If you are interested in making a purchase or eager to learn more about a clarity tester, then don't forget to contact us!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586