Vacuum Homogenizer Mixer: The Complete Buying Guide In 2025

Are you interested in investing in a vacuum homogenizer mixer? Does your process involve usage of vacuum homogenizer mixer to mix highly viscous and dense products? Do you require a greater range of information regarding the operation of a vacuum homogenizer mixer and its types available globally? This is the right place where you can get all the related information regarding a vacuum homogenizer mixer and its usage. It will support you in selecting the right type of mixer to improve your productivity and quality. Read the complete guide to resolve your queries.

1. What Is A Vacuum Homogenizer Mixer?

High Speed Vacuum Homogenizer Mixer

A vacuum homogenizer mixer is a highly versatile equipment that is used to mix two or more substances that are difficult to be processed naturally. Due to their capability of performing emulsion process, they are widely used in food, pharmaceutical, cosmetics and chemical industry. These mixers are used to produce materials like ointments, creams, gels, lotions and many other with solid liquid formulations.

2.What Are The Industrial Applications Of A Vacuum Homogenizer Mixer?

Due to various abilities and wide range emulsion, a vacuum homogenizer mixer has wide range of applications globally. Some of the industries that uses vacuum homogenizer mixer in their process are

Pharmaceutical Industry

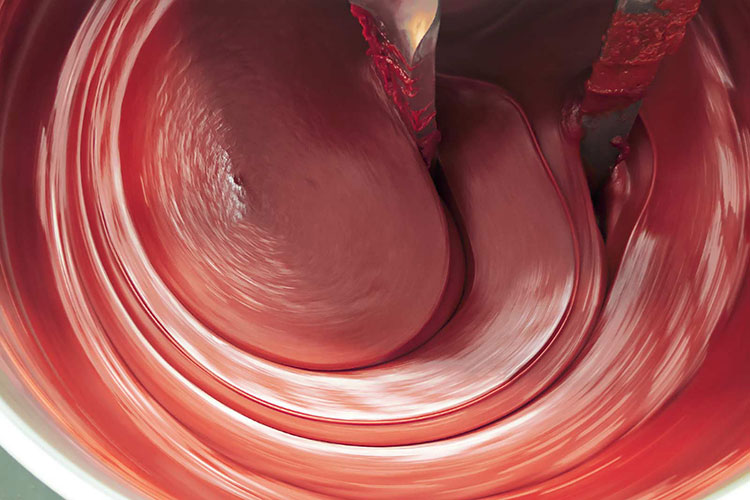

Water And Oil Mixture

Vacuum homogenizer mixers are mostly used in pharmaceutical industry for the preparation of variety of medicines and supplements. It ensures that the mixing is done with accurate and uniform distribution of active ingredients in any product. Variety of ointments, lotions and creams are prepared with suspensions that are not easy to dissolve in other materials. A vacuum homogenizer mixer has this ability to perform mixing with maintaining the efficacy of any system.

Food Industry

Powder Mixture In Food Industry - Picture Courtesy: BAT Group

Most of the sauces and cream products are produced with the help of a vacuum homogenizer mixer. This helps smooth mixing and distribution of material that has high level of density. Products like chocolates, coating, milk and other dairy products are also mixed using a vacuum homogenizer mixer.

Chemical Industry

Mixed Paint Chemistry

Chemical industry also uses vacuum homogenizer mixer for formulation of various types of paints and coatings. These are produced with high level of consistency so that it remained efficient when applied.

Cosmetics Industry

Face Moisturizers For Skin - Picture Courtesy: IT Cosmetics

Most of the cosmetics industry use vacuum homogenizer mixer for production of various health and skin care products. These products are mixed in with a uniform ration so that the performance and texture can be remained as per standard when consumed. Products like moisturizers, creams, serums and others are produced using a vacuum homogenizer mixer.

3.What Benefits You Can From A Vacuum Homogenizer Mixer?

Some of the important benefits that can be taken from a vacuum homogenizer mixer are:

Consistency

High Shear Homogenized Mixing - Picture Courtesy: Hockymeyer

The mixture produced in a vacuum homogenizer mixer is supported by a highly smooth body structure of it which maintains consistency throughout its life. The results are taken with greater speed, consistency and variable parameters to ensure that the product in produced in safer environment.

Product Quality

High Quality Dry Fruit Powder

A vacuum homogenizer mixer gives uniform mixing of materials with greater quality results. The texture, composition and mixing remain consistent throughout the production that helps in performing stable emulsion. Products purchased also make the consumer feel pleasant with its quality and appearance.

Customization

Customized Vacuum Homogenizer Mixer - Picture Courtesy: Jutao Machinery

A vacuum homogenizer mixer not only shows customization with respect to the structure of machine but also supports customization in mixing variety of materials and formulations. The machine can easily be cleaned after a process is carried out and can also be reused at the same time for preparing other formulations.

Precision And Efficiency

Efficient Mixing

A vacuum homogenizer mixer can easily mix variety of materials in a precise and efficient way. The system remains highly active and faster so that the productivity can be increased with efficiency. The process is carried out with wide range of formulations so that the required products can be prepared easily.

4.What Materials Can Be Mixed Using A Vacuum Homogenizer Mixer?

A vacuum homogenizer mixer is used for wide range of materials including:

Active Ingredients

Powerful Active Ingredients - Picture Courtesy: Herbal Dynamics

Pharmaceutical industry uses wide range of active ingredients for preparation of nutritional and therapeutic medications. The bioactive compounds are prepared using variety of excipients like vitamins, minerals, drugs, proteins and etc. For maintaining their chemical composition and viscosity, highly advanced vacuum homogenizer mixers are used that makes the texture and composition unique in each of the product.

Semi-solids

Semi-solids - Picture Courtesy: Contact Pharma

Materials that use mixture of solids and liquids like creams, jellies, and ointments are efficiently mixed using a vacuum homogenizer mixer. These products are thick in nature and are often produced in pharmaceutical and cosmetics industry.

Liquids

Liquid Mixing

Liquid materials that are solutions, emulsions or emulsions are highly applicable in a vacuum homogenizer mixer. The materials are process in a vacuum homogenizer mixer because it is difficult to mix them manually. Mixing of oil with water is a compound that cannot be done easily.

Solids

Solid Mixing In A Vacuum Homogenizer Mixer - Picture Courtesy: Solution Pharmacy

Some of the solid materials that have big sizes or higher density are also mixed using a vacuum homogenizer mixer. These powder, granular or crystal substances are difficult to form suspension and that is why are used to processed using a vacuum homogenizer mixer.

5.What Is The Working Procedure Of A Vacuum Homogenizer Mixer?

Vacuum Homogenizer Mixer - Picture Courtesy: Direct Industry

A vacuum homogenizer mixer has a simple and easy way of working that supports both operator and the environment. The working steps of a vacuum homogenizer mixer are

Feeding Material

In the initial step, the materials are fed into the mixing tank of a vacuum homogenizer mixer. Fixed impellers in the tank help in rotation of blades both in reverse and forward direction so that the material can be mixed with uniformity.

Mixing And Vaccumization

Once the power gets on, highly efficient mixing of materials is carried out with the movement of impeller blades. Up and down movement of materials is ensured with the forward and reverse direction of blades respectively.

Some of the materials are also continuously added throughout the process depending upon their necessity. The centrifugal forces at the center of mixing tank support these materials to get completely in contact with the whole material.

Homogenized mixture is treated with the heat that enters through the walls of tanks in the form of jackets and ensures each particle in mixed properly.

Complete process is carried with vacuum pumping system that controls the removal of air from the mixing tank throughout the process. This vacuum also prevents bubbles and air formation in the tank.

Discharging Of Material

Once the sample from the mixture is checked under quality parameters and gets approved, it is released from the discharge port for further packaging step.

Similarly, vacuum is also removed from the system to maintain the environment of the tank and to clean it so that it can be used for other material mixing with no impurities left.

6.What Are The Different Types Of Vacuum Homogenizer Mixers Available Globally?

Vacuum homogenizer mixers are mostly classified on the basis of their operation working or productivity. Some of the types of vacuum homogenizer mixers available globally are

Types Of vacuum homogenizer mixer depending upon its structure and application

Laboratory Vacuum Homogenizer Mixer

Lab Vacuum Emulsifying Homogenizer Mixer - Picture Courtesy: Yekeey

A laboratory vacuum homogenizer mixer is the simplest type of a vacuum homogenizer mixer used for research and developments purpose in laboratories. The mixture or suspension produced in it is very small in size due to the smaller size of mixing tank. The volume of material is usually mixed with high speed of impellers with consistency and uniformity.

Benchtop Vacuum Homogenizer Mixer

Benchtop Vacuum Homogenizer Mixer

The other type of a vacuum homogenizer mixer is a benchtop vacuum homogenizer mixer. It is also used in small or medium scale industries where limited area is present for mixing and emulsification process. The batch produced in it is also in smaller quantity which can is produced few liters of material.

Fixed Type Vacuum Homogenizer Mixer

Fixed Vacuum Emulsifying Homogenizer Mixer - Picture Courtesy: Jinfeng

Highly accurate and precise mixing results are produced using a fixed type homogenizer mixer. This type of mixer has an internal kinetic energy generation during the movement of impellers that is used along with hydraulic shearing mixed material. Products like oil, paint and etc. can easily get refined in this type of vacuum homogenizer mixer.

Micro Vacuum Homogenizer Mixer

Micro Nano Gel Vacuum Emulsifying Homogenizer Mixer - Picture Courtesy: YODEE

For sorting of material from several types of liquids and solutions can easily be performed by a micro vacuum homogenizer mixer. Pure refining is carried out in it and also all the particles are removed from its surface during the process as well to maintain efficacy and efficiency.

Suppository Vacuum Homogenizer Mixer

Suppository Vacuum Emulsifying Homogenizer Mixer - Picture Courtesy: Ruian Global Machinery

A suppository vacuum homogenizer mixer is used for emulsifying particles that are solid in nature. It is a highly equipped mixer with capability of refining products like stroma and pectic materials. The dust free environment ensures high quality emulsification process.

Bottom Vacuum Homogenizer Mixer

High Shear Bottom Toothpaste Vacuum Emulsifying Homogenizer Mixer

As the name suggests, a bottom vacuum homogenizer mixer has its emulsification process at the bottom base of the mixer where every material can easily get mixed in a uniform manner. This mixer also performs hydraulic shearing mixing that gives continuous mixing effect to the system.

Types Of vacuum homogenizer mixer depending upon its automation level

Planetary Vacuum Homogenizer Mixer

Planetary Vacuum Homogenizer Mixer

A planetary vacuum homogenizer mixer or a manual type of vacuum homogenizer mixer has dual functions impeller blades. These blades not only move on their attached axis but also orbit around mixing vessel in a mixing tank. This motion ensures highly efficient mixture of materials with dispersion of particles in all direction. It is highly applicable for materials with high viscosity levels and can control 5 to 20 liters of mixture at a single time.

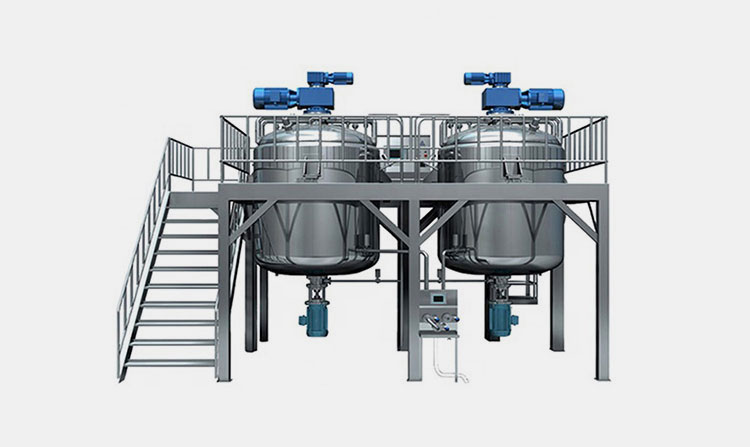

Fully Automatic Vacuum Homogenizer Mixer

Fully Automatic Vacuum Homogenizer Mixer

Finally for continuous mixing of materials in bulk quantity, fully automatic vacuum homogenizer mixers are used to eliminate a single percent of risk in the system. The machine works in a way that all the steps are performed automatically from material loading to offloading. All types of large-scale industries including food, pharmaceutical, cosmetics and chemicals perform mixing using a fully automatic vacuum homogenizer mixer.

7.What Are The Main Components Of A Vacuum Homogenizer Mixer?

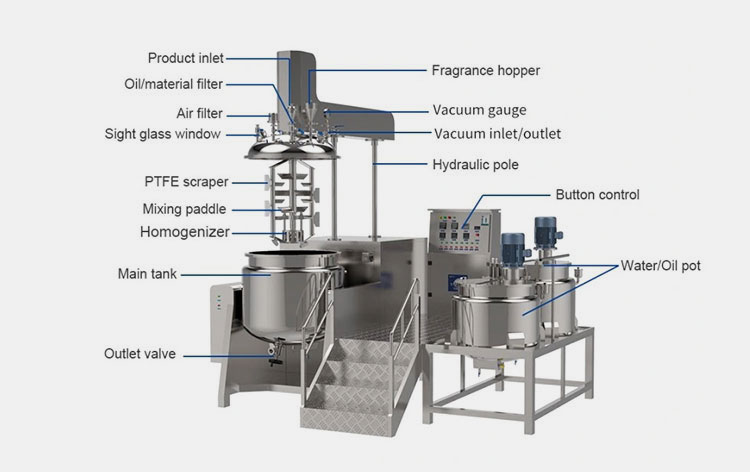

High Quality Vacuum Emulsifier Homogenizer Mixer

The main components of a vacuum homogenizer mixer are

Product Inlet

A product inlet is the place from where the materials are inserted into the main tank of a vacuum homogenizer mixer. It is present mostly at the top of the mixer from where it is easy to insert all sorts of materials.

Fragrance Hopper

In some of the vacuum homogenizer mixer a fragrance hopper is used for mixing and blending of fragrance products. These are added into the material to provide it an extra fragrance nature.

Vacuum Inlet

A vacuum inlet is the most important part of a vacuum homogenizer mixer as it is associated with the vacuum system used to remove air and environmental substances. This inlet gives smooth flow to the vacuum generated from the vacuum pumps.

Oil/Material Filter

An oil/material filter is used for the removal of contaminants from the fluid material. These materials can be oil, air and etc.

Scrapper And Impellers

The main operation of a vacuum homogenizer mixer is performed by these scrappers and impellers present in the main tank. They contain sharp blades that help movement of materials with their efficient mixing.

Main Tank

A main tank usually known as mixing vessel is the place where all the materials are fed and then mixed with the help of moving impellers. It is usually made up of stainless steel that helps prevention from corrosion and ensured durability. Temperature is also inserted in this main tank which helps in proper mixing of solution.

Material Feeding Ports

Some of the vacuum homogenizer mixers also have material feeding ports for entering water or oil into the main tank. The main purpose of this oil and water mixture is to provide lubrication to those materials that are difficult to be mixed in their raw form.

Outlet Valve

This is the place from where the completely mixed material is taken out from the main tank. It is also made up of stainless steel so that corrosion can be avoided. The outlet or discharged valve is mostly present at the bottom side of a vacuum homogenizer mixer from where discharging of materials gets easier.

PLC

Complete control of vacuum homogenizer mixers is present in a PLC that is in its control panels. The working of mixer and its operation is controlled and monitored through different configuration of PLC logic.

8.How Is A Vacuum Homogenizer MixerMore Beneficial Than Other Types Of Mixers?

A vacuum homogenizer mixer is weighted on several parameters when it comes on its efficiency and material mixing capabilities. Some of the important factors that make it more beneficial than other type of mixers are

Deaeration

Benefits Of Vacuum Mixing - Picture Courtesy: VMI Linxis Group

The most important parameter upon which a vacuum homogenizer mixer is considered to be the best among other mixers is it deaeration property. The vacuum system incorporated in it removes all sorts of unwanted gases, air bubbles and dust particles from the main tank which results uneven and defect free mixing of materials. The elimination of agglomerates helps in consistent material mixing.

Flexibility

Fixed Type Vacuum Emulsifying Homogenizer Mixer

Wide range of materials can easily be accommodated in a single vacuum homogenizer mixer that makes it highly feasible for multipurpose usage. The customization features offered by a vacuum homogenizer mixer also integrates it with other systems that cannot easily be done in other type of mixers.

Product Quality

Quality Vacuum Homogenized Powder - Picture Courtesy: Procurenet Limited

A vacuum homogenizer mixer allows uniform mixing of particles of different sizes in its main tank. This not only maintains the consistency of materials but also give high quality results that are recommended for further process as per the standards. A vacuum homogenizer mixer not only acts as a simple mixer but has variety of applications due to its customization and process efficiency features.

Conclusion

Different types of materials with separate material properties can easily be mixed using a vacuum homogenizer mixer. Its ability to cope up with several materials makes it highly beneficial and economical. But it is always important to select the right type of mixer for any production setup by knowing all its relevant information. Hopefully, this guide solves your queries regarding a vacuum homogenizer and its operation. If you still have any ambiguity Allpack is here to answer those and provide you assistance. Feel free to contact out customer care team that is available 24/7 to provide you guidance.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours