High Shear Granulator: The Complete FAQ Guide In 2025

High Shear Granulator is the key instruments in pharmaceutical industry and chemical industry for the mixing of powders and wet granules. This astonishing machine is carrying enough features to tackle the problems of ingredients mixing while minimizing waste and increasing mixing quality.

The highly responsible task of pharmaceutical processing led the modern technology to introduce a machine that will show zero compromise on product hygiene, quality and efficiency. Resultantly, high shear granulator was brought to undertake the mixing of cohesive material. After reading this guide, you will acknowledge the importance of high shear granulator in different industries which is driven by ergonomic structure, unique characteristics and excellent performance. Make sure to not skip any of them!

1.What Is A High Shear Granulator?

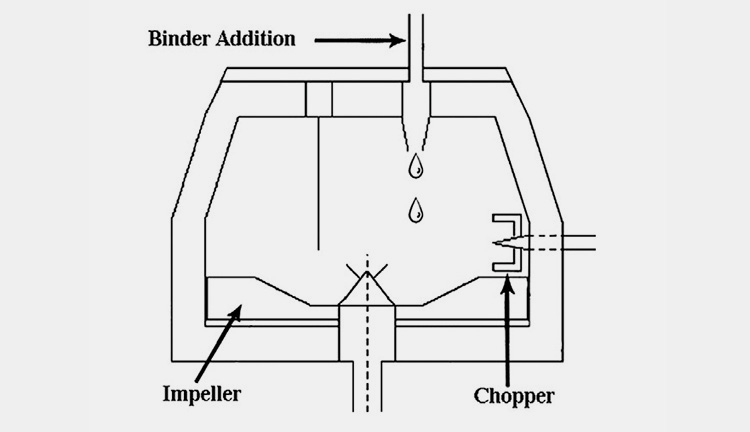

High shear granulator is an innovative machine designed to mix and blend various powders and liquid substances together, which are otherwise difficult to mix. It is also used for forming dense granules and pellets which are useful for pharmaceutical industry. This process of granulation is achieved by the constant rotation of sharp rotating impellers and a chopper. The entire processing is carried in a hygienic environment free from bacterial presence.

This machine has great significance in pharmaceutical industry due to the formation of granules which are used for capsules and tablets. Besides, it can be also used in other manufacturing areas such as pet food industry, cosmetic industry and agrochemical industry.

2.Discuss The Essential Features Of A High Shear Granulator?

High shear granulator is integrated with essential features which together contribute in formulating thick granules. Some of these attributes are discussed below:

Fully Enclosed production

This machine features fully enclosed construction built of GMP's standard stainless steel which is corrosion resistant. The entire process of granulation is safely carried out inside this machine and a glass window is used for observing the mechanism from outside making drug processing free from dust.

High Efficiency

When it comes to performance, the machine exhibits remarkable efficiency. With the help of vacuum pump, material is loaded into the mixing port, and a motor continuously drives a three-bladed impeller along with a side chopper. Together, they quickly come up with a formula.

Reliable

High shear granulator is extremely reliable for the reason of performing blending, mixing and granulating of different solid to liquid substances.

Superior Quality Output

It gives you superior quality output with the help of fast blades and integrated insulated pots. Together, they break the material in a precise form which result in making thick and uniform granulated particles.

High Degree Of Automation

High shear granulator comes with automatic features such as automatic control system, automatic cleaning and running basic specifications including rotation speed and temperature etc.

3.What Is The Working Procedure Of A High Shear Granulator?

High shear granulator functions through proper procedure based on predefined working principles. These working principles can be better understood by the following details:

Material Loading

The process of high shear granulation requires material which has to be processed. This material is in form of powder or granules. For instance, powder can be turned into granules, while as, two or more different types of granules can be well mixed by this machine. Therefore, the material loaded in the mixing bowl via vacuum conveying machine or manually by conical hopper if the machine is semi-automatic.

Mixing

The process of mixing get initiated after the machine is switched on. Material lying inside the pot start rotation, at the same time sharp rotating impellers and a side chopper create stirring effects to make sure all the particles are well mixed.

Binder Addition

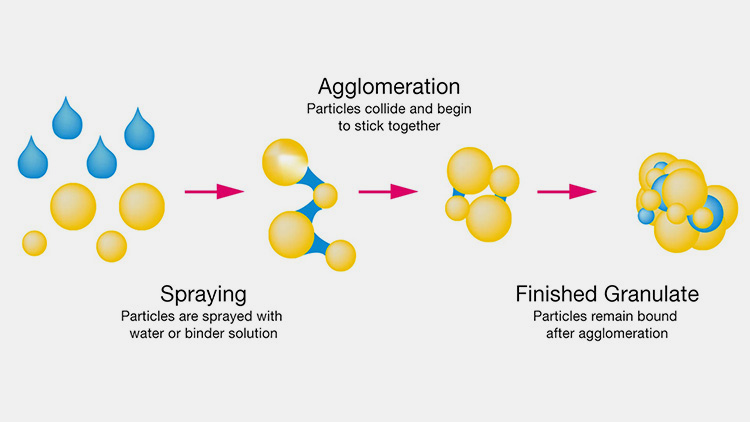

In this step, a liquid agent is added to the sheared particles. This liquid spray work as a binder for the diffused particles and gradually change the properties of material.

Granules Formation

Now comes the core step, where diffused and well moisturized particles are turned into granules. The constant spraying collide particles, and they begin forming a bridge of particles through liquid. This bridge of material is further strengthened by the friction caused by moving blades, and consequently, overturn it into thick and uniform granules.

Product Discharge

The process of high shear granulation come to an end with the final product discharge. Here, the valve of an outlet port is opened and granules are gradually released into the container through pipe.

4.Name The Products Which Can Be Processed By A High Shear Granulator?

High shear granulator can be used for processing various items in form of powders or liquids. The products shown below are some of the examples of material which are processed by this machine.

Food Products

Number of food products are eligible to be processed by a high shear granulator. Some of the prominent examples include sugar, cocoa, milk powder and cassava etc.

Herbal Powders

Herbs have a significant role in the production of pharmaceuticals and therapies. Therefore, herbs powders are processed by this machine for creating any type of granulated or blended formulation for capsules, tablets, or pills.

Chemicals

Chemicals available in form of organic, inorganic or radioactive materials have substantial benefits in their respective spheres. Similarly, they are used for many purposes among which fulfilling human need is an important one. Here example of chemical fertilizers can be taken for which high shear granulator is utilized.

Beauty Products

Among other things, beauty products such as blushing powder, creaming granules, wax powder and vitamin capsules formulation can be easily processed while using a high shear granulator.

5.Explain The Major Components Of A High Shear Granulator?

The beautiful and compact construction of a high shear granulator is the result of various parts perfectly joined together.

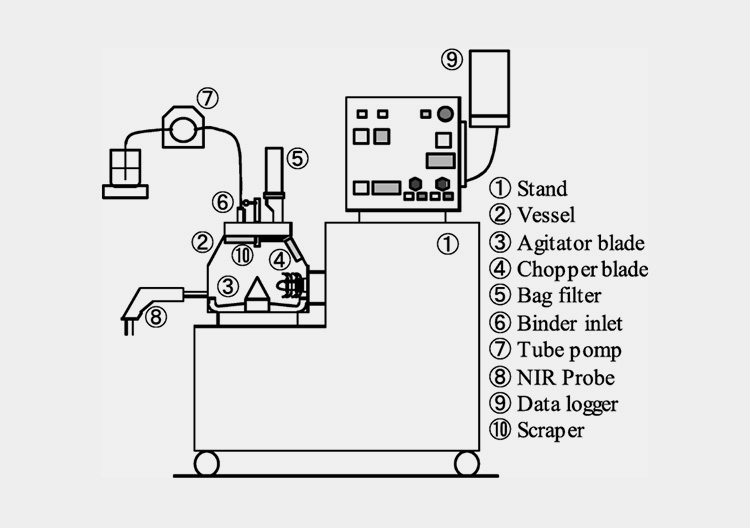

Stand

This part of machine work as a supportive device for the stable function of granulation. It is mainly composed of a rack, motor inside it, chassis, pneumatic control box and a movable door for ensuring safety. The overall structure of machine is made of pure standard steel that is fully resistant to corrosion and can be easily cleaned.

Vessel

Vessel is the main component of high shear granulator. It consists of an observational lid, blades, chopper, funnel, a liquid adding spraying and outlet port. The core task of mixing and granulation occurs inside this pot.

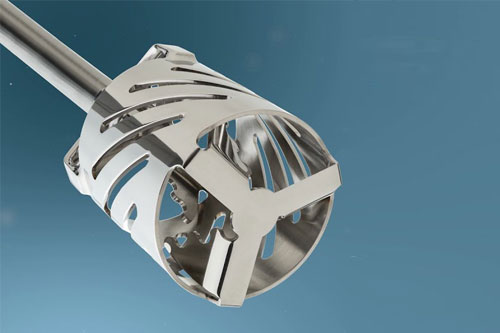

Agitator Blades

As the name indicates, agitator blades are used for urging the material towards upward direction. These agitator blades are located in the bottom of mixing pot and helps in the shearing of material by constant rotation.

Chopper Blade

Chopper blade is located on the side wall of vessel. When material is pushed towards upward direction by stirring peddle, the chopper keeps moving and reduce the size of bounded particles to desired shape granules.

Bag Filter

Bag filter is fixed in the product discharge pipe which is used for filtering granules before getting into container to ensure all the finished particles are free of dust and particles residues.

Binder Inlet

It is also known as liquid adding hopper or spraying device. The main function of binder inlet is to release liquid during powder mixing and make them bind together.

Tube Pump

Tube pump works as a bridge between feeding station and mixing pot. It is the tube pump whose working helps in the automatic transportation of material from feeding station into shearing pot.

Data Logger

Data logger displays a control system through which machine can be executed. It is mainly composed of a touch screen control panel, power button and emergency stop. Basic parameters such as fixing temperature, rotating velocity and liquid amount can be done by using this device.

Discharge Outlet

It is the ejection port attached to the lower part of the vessel, so, the finished granules would easily get discharged at the end.

Scraper

Scraper is a metallic tool located inside the pot to remove processed material from the surface of vessel.

6.What Are The Various Types Of A High Shear Granulator?

High shear granulator can be divided into two types on the basis of automation. They are described below in detail:

Fully Automatic High Shear Granulator

Fully automatic high shear granulator is large sized machine with integrated system of feeding and discharging. It has high capacity of processing bulk material in one run while maintaining the same speedy flow. It is widely used in firms having excessive workload such as pharmaceutical industry, food industry and cosmetic industry etc.

Components

It composed of heavy-duty structure to carry this task. The main components of machine include supporting stand, ladder, mixing pot, control system, feeding station, discharge tube, vacuum pump, glass lid, liquid adding hopper, agitators and blades etc.

Working Principles

It works automatically, where operator set the basic parameters for temperature, speed of rotating impellers and dew points. After that, operator turn the power button on and machine start loading material from feeding station to mixing pot through vacuum pump. The constant rotation of impellers energizes material to move in circular direction and dew drops falling over them gradually turn them into granules. After the process get completed, finished particles are discharged into container through pipe connected with outlet valve.

Semi-Automatic High Shear Granulator

Semi-automatic high shear granulator is another type with effective performance, however, it requires some amount of user's interference in the accomplishment of task. It is more precise and compact in terms of size and occupy less space. Most of the medium to small batch production firms prefer using this machine.

Components

It consists of main frame, control panel, mixing pot, liquid spray, chopper, z-shape blades, funnel and outlet valve.

Working Principles

Operator is required to load the port with desired amount of material. After that, machine get started and well mix the substances together through the rotational force created by blades. The liquid spray strengthen particles to collide together and form granules. At last, the prepared formulation is manually drawn out by the vessel.

7.Differentiate Between High Shear Granulator And Low Shear Granulator?

To better know the differences between high shear granulator and low shear granulator, consider the chart below:

| No | Factors | High Shear Granulator | Low Shear Granulator |

| 1 | Definition | High shear granulator is an effective machine used for processing dry powders or granules | Low shear granulator is also known as wet granulation used to mix the powders with wet formulations |

| 2 | Structure | The structure of machine is different due to impellers with sharp edges and long cutting frame | It consists of a single impeller with only three side edges that does not break the bond of material to very small size |

| 3 | Process | The process of high shear granulation is highly superior with better utilization of ingredients | In contrast, low shear granulation process is steady which resultantly give satisfactory output for limited materials |

| 4 | Speed | The speed of high shear granulator is highly efficient with ending operation in just 5 minutes | On the other hand, low shear granulator require more time for each cycle |

| 5 | Application | It is the best applicable for foodstuff, herbal powders, feeds, cosmetics and pharmaceutical ingredients | While as, it is good for abrasive chemicals, liquid cosmetic formulations and medicines mixture |

| 6 | Picture |  |

|

8.What Are The Uses Of A High Shear Granulator?

The application area of high shear granulator is extensive where you will find the huge number of industries with inevitable need for the machine. Some of them are highlighted below:

Pharmaceutical Industry

When it comes to discuss the application of high shear granulator, pharmaceutical industry can never be ignored. In fact, the entire manufacturing of pharmaceuticals revolve around this equipment. Granulation is important for controlling the drug release. Therefore, capsules, tablets and water dissolving sachets are most of the time composed of granules instead of powder.

Food Industry

High shear granulator is most popularly utilized by number of food processing industries. Products such as milk powder, sugar, coffee and flavoring agents are among the prominent materials which can be perfectly sheared and granulated by this machine.

Feed Industry

Feed manufacturing industry is an area where animal food is prepared in form of granules. Hence, the need for high shear granulator is realized to form small feed granules for animals and pets including chicken, rabbit, fish and cat etc.

Agrochemical Industry

Chemicals which are used to reduce the growth of pests and pathogens in soil are known as agrochemicals. They are counted among special chemicals due to their benefits. Therefore, it becomes another industry which takes help of high shear granulator for formulating agrochemical fertilizers.

Cosmetic Industry

Cosmetic industry has the fastest growing market and this is the contribution of advance technology in developing effective and hygienic formulations. Here, high shear granulator must not be overlooked which can perfectly blend different powders and thickening agents for making beautiful shades.

Pigment Industry

Pigments and dyes are colored substances which can be solved in water and mixed in any other liquid to get desired colors. They are formed by the combination of various ingredients for which high shear granulator is utilized.

9.Enlist The Limitations Of A High Shear Granulator?

Despite having enormous benefits, there are some limitations on high shear granulator which are pointed out here:

Expensive

High shear granulator comes is made up of stainless steel with complex parts. Therefore, it requires high initial investment due to expensive price.

Limitation on Material

Synthetic quality of thermolabile materials might be degraded by this machine due to excessive temperature during granulation process.

Over Wetting

The over wetting and less compression by high shear granulator can cause large lumps.

Large Size

The large size and heavy machinery of high shear granulator make it difficult to mobilize it from one place to another.

10.What Preventive Maintenance Is Required For Smooth Running Of A High Shear Granulator?

It is necessary to take precautionary measures when operating a high shear granulator. Along with that, ensuring the regular maintenance for effective performance of the machine essential. For this, below-mentioned tips can be helpful:

- Keep wearing glasses and gloves when loading and unloading the material from vessel.

- Make sure all the parts of machine are placed on their exact location as improper incorrect parts fixation can cause false granulation.

- Keep all the moving parts of machine well lubricated to avoid noise and ensure smooth functioning.

- Clean the pot after completing each cycle, to fully assure safe and hygienic environment for material.

- It is better to observe the granulation process through window to guarantee even formulation.

11.How To Troubleshoot The Minor And Major Defects When Operating A High Shear Granulator?

Sometimes minor issues can create big problems for you when operating a high shear granulator. To tackle such issues, you can take help from this table:

| No | Defects | Reasons | Troubleshooting | Pictures |

| 1 | The particles processed have lumps | It is due to high amount of liquid addition or low air pressure | Reduce the dew points limit and allow adequate intake of air |  |

| 2 | Shape of granules is not uniform | It occurs due to excessive temperature and long drying time | Make sure the temperature is moderate and drying time is short |  |

| 3 | Finished granules are fragile | This issue is caused by the insufficient adding of liquid | Increase the spray timer to make strong granules |  |

| 4 | Low production at the time of discharge | The sealing and socks of filter are damaged | Replace the sealing and socks of filter |  |

| 5 | Blockage of product flow | It happens if the basic setting is inaccurate | Maintain the speed of blades and select wide shear size to avoided material blockage |  |

12.What Is The Necessary Considerations For Purchasing Effective High Shear Granulator?

Never make decisions too early to regret later. Knowing certain facts about high shear granulator before purchasing can keep you away from great loss. So, let's discover these factors:

Capacity of Bowl

It is one of the essential factors to look when purchasing a high shear granulator. The size of bowl will determine the capacity of material it can process in one run. For instance, you can choose small to large bowls for making the formulations of desired amount.

Nature of Machine

Which type of machine you require? Either fully automatic or semi-automatic? Your current production can better answer this question. For example, large business can take advantage from fully automatic machine. However, it is better for low income small batch industries to use semi-automatic high shear granulator.

Type Of Material

Do you want to process powder substances or mix granules? Is the material foodstuff, medicinal or chemical? The type of material can better help you to choose a machine whose specifications are the best compatible to it.

Warranty Policy

Buying a high shear granulator is a responsible task which require huge amount of money. Therefore, it is obligatory to have some guarantee about the performance of machine, for which the most convenient way is warranty policy.

Quality Certifications

It is important to check the quality certifications of the company you are considering for purchasing this machine. If the company is complying GMP's standards and have similar other quality approved certificates, their machines are turntable.

Conclusion

High shear granulator is the key instrument for forming granules and blending powders in pharmaceutical, food and chemical industries. This superior machine is capable to achieve high quality granulations and ensures hygienic processing. This is the reason why every business wants to make it a part of their production line for gaining profit. You can also take advantage of this innovative machine by simply approaching us via given link.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours