Gummy Maker Machine: The Complete Buying Guide In 2025

The size of gummy market has exceeded the value of 21.40 billion USD and is expected to grow continuously. The reasons are many such as delicious taste, easy swallowing, and appealing looks. However, the core factor for such a rapid increase is the people's preference towards consuming gummies in all its forms including gummy snacks, nutritional gummies, beauty gummies, and CBD medical gummies. It has been an instigating factor for many manufacturers to expand their business spectrum to gummies.

Are you also interested in starting your own business of manufacturing gummy? Sounds good! But do you have sufficient knowledge about how it is made? What ingredients are used? And most importantly, which machine is required for making gummies? You may be puzzled in similar questions. Isn't it? If yes! Let's answer all of them by reading this comprehensive guide which is holding in it every aspect of a gummy maker machine!

1.What Is Gummy?

Various fruit gummies-Picture Courtesy: rosannapansino.com

Gummies are gelatin based chewable sweets often taken as snacks. They are usually made from the mixture of gelatin, starch, sugar, and water etc. Apart from these ingredients, multiple colorants and flavoring agents are added to gummies for creating delicious taste.

Gummies are available in beautiful shapes of bears, vegetables, fruits, and toys etc., to increase their charm and looks. They are light weighted, easy to swallow, and having better taste. This is the reason, that now various types of gummies are available in market which are made with several nutrients and vitamins to enhance beauty, supplement health improvement, and facilitate easy consumption for kids and old people.

2.How Would You Define A Gummy Maker Machine?

Gummy Maker Machine-Aipak

Gummy maker machine is a resilient and specialized equipment designed for making various types of soft and chewy gummies. The machine has a robust construction to undertake the prime function of making gummies. By adopting simple operational procedure with GMP's compliance stainless steel body, gummy maker machine forms a fine mixture of various ingredients.

The same machine is used to deposit the formed mixture into gummy molds and cool them down to make beautiful gummies. Besides that, the gummy maker machine is capable of forming gummies with diverse shapes, sizes and colors, therefore, it is equally important for all the industries including pharmaceutical, cosmetic, and food etc.

3.What Are The Advantages Of Using A Gummy Maker Machine?

Gummy maker machine is designed with substantial features which can greatly advantage your business. Some of the major benefits of a gummy maker machine are as follows:

High Throughput

Bulk gummies-Picture Courtesy:mypurna.com

The key attribute of gummy maker machine is its exceptional performance in terms of production speed and efficiency. It can be understood by the machine's capability of producing gummies of around 600kg just in an hour.

Precision

Gummies display-Picture Courtesy:mypurna.com

One of the greatest advantages of a gummy maker is that it ensures precision of gummy making by depositing fully accurate dosage of gummy mixture into trays. It ultimately results in the formation of uniform and consistent gummies.

Easy Maintenance

Easy maintenance icon-Picture Courtesy: za.biorotar.com

With simple operational procedure, parts changeover, and intuitive control system, gummy maker machine is extremely easy to operate and maintain. Operator can simply execute the machine just after understanding the mechanism.

Adaptability

Various types of gummies-Picture Courtesy: Alphavitaminslaboratoy.com

Gummy maker machine is highly adaptable due to its resilience to make different types of gummies on varying colors, sizes as well as shapes. In addition, the same machine can be employed for making jellies and candies etc.

Cost-effective

As gummy maker machine is automatic in nature, it performs the multiple tasks of gummy mixture making, depositing, cooling, and demolding independently. Hence, it cuts down the production cost by ending errors and irregularities caused by humans and save labor cost.

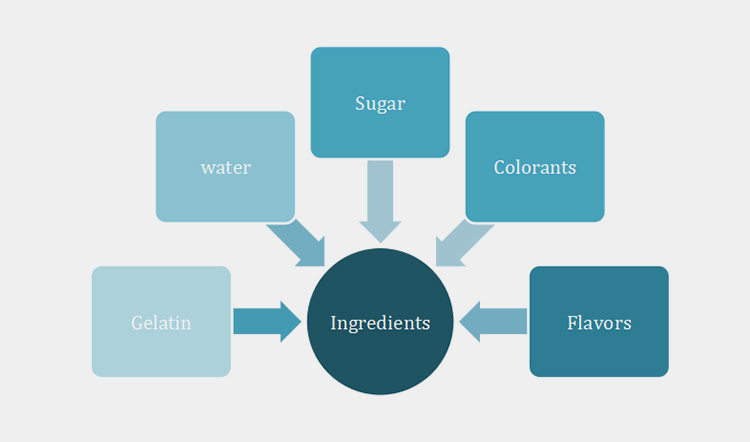

4.List Down The Ingredients Processed By A Gummy Maker Machine To Make Gummies?

There are multitude of ingredients used in gummy making which are processed by a gummy maker machine. Below is the brief description of these ingredients:

Gelatin

Gelatin in various forms-Picture Courtesy: kompass.com

Gelatin is a colorless and flavorless substance derived from collagen which is obtained from animal sources including bones, tendons and ligaments etc. Gelatin works as a thickening agent for making gummies.

Water

Water glass-Picture Courtesy: eatingwell.com

Water is another essential ingredient used for mixing the several components of gummy formula. In essence, water used must be of fixed amount and warm to produce fine solution.

Sugar

Sugar bowl-Picture Courtesy: paleohacks.com

Sugar is one of the main ingredients in making gummy recipe. It gives your gummies sweet and juicy taste. However, the inconsistencies in sugar amount may cause dryness due to low usage and stickiness in case of excess usage.

Colorants

Various food colors-Picture Courtesy: coolmomeats.com

Different types of artificial as well as natural colors are added to gummy mixture to give the gummies beautiful and appealing looks. Common examples of the colors used for gummies include blue#1, beet dye, carmine, and chlorophyll etc.

Flavors

Flavored gummies-Picture Courtesy: buzzfeed.com

Flavors constitute a good portion of gummy mixture to mask the undesirable odor and taste, and create pleasant fragrance. Most of the flavors used in gummies are of fruits and chilli etc.

5.What Are The Common Types Of Gummy A Gummy Maker Machine Can Make?

There are different types of gummies which a gummy maker machine can make. They may be better understood by looking into the underlying categorization:

Gummies on the Basis of Shape

Gummy Bears

Various gummy bears-Picture Courtesy: cathyshop_decoden

Gummy bears are the most common shape given to gummies for the purpose of entertaining both kids and adults.

Gummy Fruits

Heart gummies-Picture Courtesy: parentmap.com

Gummy maker machine is also capable of making various gummies with beautiful fruits shapes like mango, strawberry, and black berry etc.

Gummy Eggs

Gummy eggs-Picture Courtesy: thediscoedit.com

Among other shapes, gummies are frequently found in the shape of eggs with yellow and white color in order to create appealing looks.

Gummy Toys

Gummy fishes-Picture Courtesy: etsy.com

Gummies are also created in form of various toys such as bat, ball, and vehicles etc., for kids.

Gummies on the Basis of Size

Gummy sizes chart-Picture Courtesy: escapeauthority.com

Jumbo Size

The largest size gummy is known as jumbo size which is often used in parties. The weight of such gummies is 26 pounds with length of 2 inches.

Medium Size

Medium size gummy is smaller than jumbo size. It has the length of around 1.25 inches, making it more suitable to be consumed in casual gathering.

Original Size

Original size gummy is the regular size of gummy often delivered in bags and containers as snacks. Their length is 0.75 inches which is why even a kid can swallow the whole gummy without dividing it into chunks.

Gummies on the Basis of Color

Various color gummies-Picture Courtesy: etsy.com

Uni-color

Uni color gummies consists of only one color and one flavor, therefore, they are easily made by a gummy maker machine.

Double Color

Double color gummies are combination of dual color as well as double taste.

Multi Color

Multi color gummies holds various colors and flavors. This gummy maker machine effectively forms precise multi-color gummies.

Center Filled

Gummies with inside gel are known as center filled gummies. So, among other types of gummies processed by a gummy maker machine also include center filled gummies.

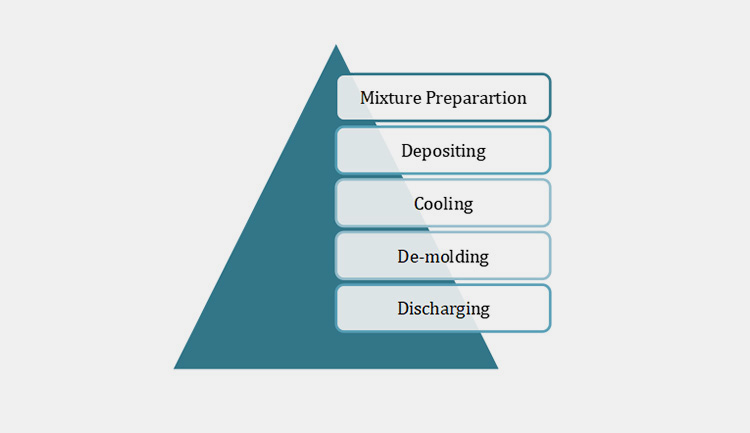

6.Explain The Working Principles Of A Gummy Maker Machine?

Gummy maker follows the underlying steps for making gummies. These include:

Mixture Preparation

Gummy mixture-Aipack

Firstly, mixture for gummy is prepared in a melting pot. For this, various materials used for gummy making including gelatin, water, sugar, citric acid, flavors, and colorants are collectively added into the pot and well-prepared by constant heat produced by the machine.

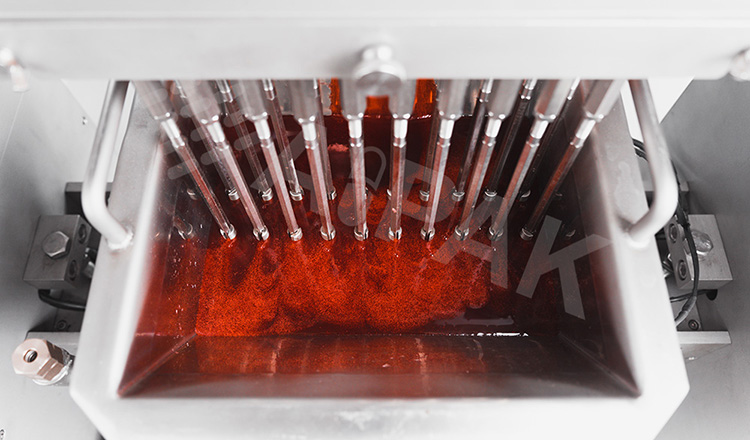

Depositing

Gummy mold filling-Aipak

After the mixture preparation, the formulated gummy formula is transferred into the hopper of gummy depositor. From here start the actual formation of gummy when machine deposit gummy into gummy molds through narrow nozzles.

Cooling

Gummy cooling-Aipak

These gummy filled molds then move forward and pass through the cooling station to get cooled and adopt the shape of mold tray.

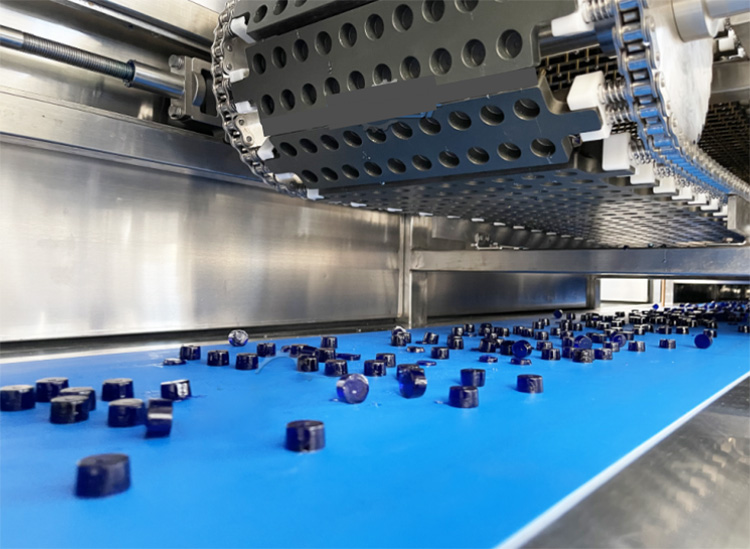

De-molding

Gummy demolding-Aipak

When all the gummies get dry and cool, multiple demolders start demolding the gummies from mold tray resulting in the fall of gummies over conveyor belt.

Discharging

Gummy discharging-Picture Courtesy: mmymachinemaking.com

Finally, the well-formed and soft gummies are discharged into gummy collection tray.

7.Describe The Structure Of A Gummy Maker Machine?

The structure of a gummy maker machine consists of following components:

Structure of gummy maker machine-Aipak

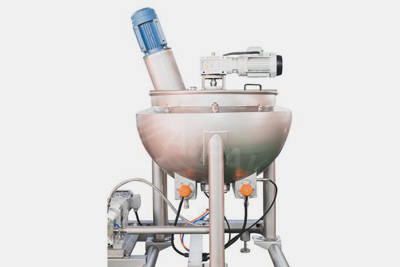

Jacket Heating Kettle

Jacket heating kettle is the mixing pot of machine. It consists of double layer stainless steel sphere body, a motor, pressure gauge, and an agitator for stirring gummy mixture.

Heating Motor

Heating motor is located alongside jacket heating kettle whose function is to produce heat for melting gummy mixture.

Storage Tank

Storage tank is situated after melting pot. When gummy mixture is prepared, it is then exported into storage tank.

Transfer Pump

Transfer pump helps in the convenient and smooth transportation of gummy mixture from one station to another.

Electric Cabinet

Electric cabinet is a storage unit holding all the electrical components of gummy maker machine including wires, knobs, fuses, and circuit breakers.

Gummy Depositor

Gummy depositor is the most crucial device of gummy maker machine. It consists of several other components to undertake the significant task of gummy making. These include:

Hopper

Hopper is located on the top of depositor machine. When gummy mixture get prepared, then it is transported into the hopper.

Nozzles

There are multiple gummy depositing nozzles attached to the hopper. These nozzles dispense the gummy mixture into mold trays.

PLC Control Panel

PLC control panel is a small compact touch screen computer integrated to the gummy maker machine. It provides the operator to communicate with machine and set all essential parameters required for executing machine.

Cooling Station

Cooling tunnel of gummy maker machine produce cool air through blowers to force ambient air to dry and cool down the gummies.

8.What Are The Types Of A Gummy Maker Machine?

A gummy maker machine can be divided into following types such as:

Fully Automatic Gummy Maker Machine

Fully automatic gummy maker machine-Aipak

Fully automatic gummy maker machine is standalone equipment made up of several major devices such as jacket heating kettle, storage tank, gummy depositor, and cooling tunnel etc. The automatic system of machine enables these components to carry out the function of gummy making by formulating gummy mixture, its storage, transfer, depositing and cooling. Finally, the well-formed gummies are automatically discharged via conveyor belt to the gummy holding tray. Therefore, this type of fully automatic gummy maker machine is the best suitable for large scale industries.

Semi-Automatic Gummy Maker Machine

Semi-automatic gummy maker machine-Picture Courtesy: tgmachine.com

Semi-automatic gummy maker machine possess less automation than that of fully automatic machine. It mainly consists of a stainless steel body, depositing channel, hopper, control system, alarm, and filling nozzles. To bring it into operation, the user has to manually feed the hopper of machine with a gummy mixture and set the filling time and amount of liquid gummy to be filled in each mold. After that, the operator will start the machine in turn it will automatically fill mold try. These filled trays would be discharged by the operator manually. Small to medium scale industries can greatly take advantage of this machine.

Manual Gummy Maker Machine

Manual gummy maker machine-Picture Courtesy: cbdfillingfactory.com

Manual gummy maker machine is compact structured small size machine designed to make various types of uni color, multi-color, and center filled gummies. It is composed of a hopper, conveyor belt, servo motor, removable nozzles, and water/oil heating system. It simply requires operator to feed the hopper with liquid gummy and press handle for filling empty mold trays. In addition, hot water or oil can be poured into the jacket of hopper to produce heat for gummy mixture. This machine is good for small level businesses such as restaurants and home based business etc.

9.Highlight The Prominent Industries Where A Gummy Maker Machine Can Be Used?

Gummy maker machine can be used in several industries mentioned below:

Confectionary Industry

Multiple colors gummies-Picture Courtesy: dicasdereceitas.com

Confectionary industry is the prominent area where the use of a gummy maker machine is inevitable. Whether these are gummies or jellies, hard candies or chewable, all of these confections are made by this machine.

Cosmetic Industry

Hair & nails gummies-Picture Courtesy: powergummies.com

Now, various vitamins and proteins are delivered in the form of gummies for beauty purpose. In essence, the use of beauty gummies for enhancing beauty and strengthening hairs and nails are the good examples of cosmetic industry which emphasize that a gummy maker machine is also applicable in this industry.

Pharmaceutical Industry

Sleep gummies-Picture Courtesy: goli.com

Pharmaceutical industry is now more focused on delivering medication in form of gummies due to easy swallowing and good taste. Therefore, the machine has a good demand in this sector.

Nutraceutical Industry

Nutraceutical gummies-Picture Courtesy: teamiblends.com

In order to fulfill the daily nutritional diet and supplement the ongoing medical treatment, nutraceutical gummies can be greatly helpful. Therefore, different types of CBD gummies and gummy vitamins are produced with the help of a gummy maker machine for achieving this aim.

10.Elucidate The Cleaning And Maintenance Of A Gummy Maker Machine?

Cleaning-Picture Courtesy: sights.regencysupply.com

Cleaning and maintenance are the two most significant steps required for a successful and long-running gummy maker machine. To facilitate you in this way, we have provided the details below:

Cleaning

It is important to regularly clean the machine for smooth and pollution free operation.

- To clean the machine, turn it off

- Remove the parts for better cleaning such as hopper and filling nozzles etc.

- Wash all these parts with warm water and repeatedly clean stubborn stains for better cleaning

- Apart from washable parts, use a clean cloth for control panel, electric cabinet and motors etc.

- After thorough cleaning, replace all these parts to accurate place

Maintenance

Regular maintenance of a gummy maker machine involves:

- Adjusting the machine functional parameters including temperature for gummy mixing pot and hopper, amount of liquid gummy to be filled in mold trays, and speed of conveyor belt etc.

- Replacement of worn out parts to avoid product damage, machine jamming, and burns etc.

- Proper lubrication of all movable parts for consistent operation

11.What Are The Troubleshooting Of A Gummy Maker Machine?

The possible problems which you may encounter while using a gummy maker machine can be solved by looking into the solutions given below:

| No | Problems | Causes | Solutions | Pictures |

| 1 | Inconsistent filling | There may be residues left in gummy depositing nozzles | Clean the filling nozzles with warm water to remove out debris |

Gummy mold filling-Aipak |

| 2 | Mixing stirrer does not stir | Either the machine is plugged incorrectly or the mixture is not heated | Make sure the machine is well plugged and wait for gummy mixture to get heated as the stirring takes 7 mints to start after the machine is turned on |

Encircled stirrer-Aipak |

| 3 | Pump is not working | Jammed pumps and overload gummy mixture are the possible causes to this problem | It can be solved by increasing air pressure and cleaning pump with hot water |

Encircled pump-Aipak |

| 4 | Low heating of cooking tank | It occurs due to water seeping and problem in the inlet valves | Check water drainage around the pot and inlet valves |

Gummy cooking tank-Aipak |

12.Which Factors Can Be Considered For Getting The Best Gummy Maker Machine?

To select an effective and reliable gummy maker machine it is crucial to consider several factors. These are highlighted below:

Production Scale

Various gummies-Picture Courtesy: mysweettoddlers.blogspot.com

The most essential factor to look for is how many gummies do you need? Answering this question will lead you to either opt for fully automatic machine and fulfill large volume of gummy production or go for a semi-automatic gummy maker machine to attain the desired volume of gummies.

Quality Standards

Quality standard icon-Picture Courtesy: ibiswebdesign.com

Checking quality standards of the machine you are going to purchase is another aspect to consider. Therefore, to make quality gummies it is important to have a machine which adhere to the quality regulations fixed by FDA and GMP etc.

Budget

Budget presentation idea-Picture Courtesy: livemint.com

How much your budget is allowing you to spend? You must have to think about this question, as it will determine the initial investment of machine cost and associated expenses such as installation, maintenance, and training charges.

Conclusion

To conclude, a gummy maker machine play vital role in the production of precise and quality gummies. Its high production capacity, resilience, and compatibility to various types of gummies enable you to upgrade your business. Besides, Allpack's outstanding line of gummy maker machine can better satisfy your need. Apart from that, you will get one year of warranty with free installation and customer service. So, what are you waiting for. Just click on the given link and approach us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours